JP2010142845A - Release agent composition for die casting, and release agent for emulsion type die casting using the same - Google Patents

Release agent composition for die casting, and release agent for emulsion type die casting using the same Download PDFInfo

- Publication number

- JP2010142845A JP2010142845A JP2008323837A JP2008323837A JP2010142845A JP 2010142845 A JP2010142845 A JP 2010142845A JP 2008323837 A JP2008323837 A JP 2008323837A JP 2008323837 A JP2008323837 A JP 2008323837A JP 2010142845 A JP2010142845 A JP 2010142845A

- Authority

- JP

- Japan

- Prior art keywords

- group

- carbon atoms

- die casting

- release agent

- containing organopolysiloxane

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Mold Materials And Core Materials (AREA)

- Lubricants (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Abstract

【課題】優れた離型性、耐熱性、金型付着性、ペインタブル性を有し、高温で連続的にダイカストを行ったときの堆積性が低いダイカスト用離型剤組成物及びそれを用いるエマルジョン型ダイカスト用離型剤を提供する。

【解決手段】(A)(A1)特定のアラルキル基含有オルガノポリシロキサン、特定のアリール基含有オルガノポリシロキサン又はその組み合わせ及び(A2)該アラルキル基含有オルガノポリシロキサンと25℃での粘度が10〜500mPa・sのジメチルポリシロキサンとの組み合わせ、の何れか1種90〜99.7質量%、並びに(B)特定の芳香族アミノ基含有オルガノポリシロキサン0.3〜10質量%、からなるオルガノポリシロキサン混合物(但し、(A)及び(B)成分の合計が100質量%)を含むダイカスト用離型剤組成物;該ダイカスト用離型剤組成物、界面活性剤及び水を含むエマルジョンからなるエマルジョン型ダイカスト用離型剤。

【選択図】図2Disclosed is a die casting mold release agent composition having excellent mold release properties, heat resistance, mold adhesion, and paintability, and having low depositability when die casting is continuously performed at a high temperature, and an emulsion using the same. A mold release agent for die casting is provided.

SOLUTION: (A) (A1) A specific aralkyl group-containing organopolysiloxane, a specific aryl group-containing organopolysiloxane or a combination thereof and (A2) the aralkyl group-containing organopolysiloxane and a viscosity at 25 ° C. of 10 to 10. Any one of 90 to 99.7% by mass of a combination with 500 mPa · s dimethylpolysiloxane, and (B) a specific aromatic amino group-containing organopolysiloxane of 0.3 to 10% by mass. Die casting mold release composition comprising a siloxane mixture (provided that the total of components (A) and (B) is 100% by mass); an emulsion comprising the mold casting release composition, a surfactant and an emulsion containing water Mold release agent for die casting.

[Selection] Figure 2

Description

本発明は、アルミニウム合金、マグネシウム合金、亜鉛合金等からなるダイカスト成形物(ダイカスト製品)を製造するためのダイカスト用金型に塗布して使用するダイカスト用離型剤組成物およびそれを用いるエマルジョン型ダイカスト用離型剤に関し、特に高温での潤滑性、離型性、金型付着性に優れるダイカスト用離型剤組成物およびそれを用いるエマルジョン型ダイカスト用離型剤に関する。 The present invention relates to a release agent composition for die casting used by applying to a die casting die for producing a die casting product (die casting product) made of an aluminum alloy, a magnesium alloy, a zinc alloy or the like, and an emulsion type using the same. The present invention relates to a mold release agent for die casting, and more particularly to a mold release agent composition for die casting that is excellent in lubricity at high temperatures, mold release properties, and mold adhesion, and a mold release agent for emulsion type die casting using the same.

ダイカスト(Diecasting)とは、特殊鋼で精度の高い金型を作り、その金型をダイカストマシンに取り付け、これに溶融したアルミニウム合金、マグネシウム合金、亜鉛合金などを高圧で注入し、迅速に凝固させてダイカスト製品を作製し、こうして作製したダイカスト製品を取り出す工程を有する高生産性の鋳造方式である。ダイカスト製品は、寸法精度が高く強度に優れ、外観が美しく、必要な機械加工が少ないという優れた特長を有する。 Die-casting is a high-precision mold made of special steel, and the mold is attached to a die-casting machine, and molten aluminum alloy, magnesium alloy, zinc alloy, etc. are injected into it at high pressure and rapidly solidified. This is a high-productivity casting system that includes a step of producing a die-cast product and taking out the die-cast product thus produced. Die-cast products have excellent features such as high dimensional accuracy, excellent strength, beautiful appearance, and less machining required.

水性ダイカスト用離型剤として、従来、ジメチルシリコーンオイル等のアルキル変性シリコーンオイル、またはメチルフェニルシリコーンオイルの乳化物が使用されている。更に最近では、大型の成形物や複雑形状の成形物の製造に用いられる水性ダイカスト用離型剤として、高温でのシリコーン分の残存性を活かした耐熱性のアラルキル変性シリコーンオイルの乳化物も汎用されている。アルキル基やアラルキル基により潤滑性を付与されたこれらの離型剤は、金型上で加熱されて固着化し、強固な離型皮膜を形成することにより、高い離型性を示す。しかし、より高温になると離型性が不足して成形物の外観が悪くなり、更には金型に成形物が付着してしまうといった不具合が発生する。 Conventionally, as a mold release agent for aqueous die casting, an alkyl-modified silicone oil such as dimethyl silicone oil or an emulsion of methylphenyl silicone oil has been used. More recently, emulsions of heat-resistant aralkyl-modified silicone oils that take advantage of the residual silicone content at high temperatures are also widely used as mold release agents for water-based die castings used in the manufacture of large-sized molded products and molded products with complex shapes. Has been. These release agents imparted with lubricity by alkyl groups or aralkyl groups are heated and fixed on the mold to form a strong release film, thereby exhibiting high release properties. However, when the temperature is higher, the mold releasability is insufficient, the appearance of the molded product is deteriorated, and further, the molded product adheres to the mold.

そこで、上記の不具合を改善する目的で、ジメチルシリコーンオイルとアルキル変性シリコーンオイルの混合物で耐熱性を改良した離型剤(特許文献1)、アルキル基とアラルキル基の双方を含有するジオルガノポリシロキサンにより耐熱性を向上させた離型剤(特許文献2)、アルキル変性シリコーンオイルに微量のトリアルコキシシリルアルキル基を導入して金型との接着性を高めた離型剤(特許文献3)が提案されている。 Therefore, for the purpose of improving the above problems, a release agent (Patent Document 1) having improved heat resistance with a mixture of dimethyl silicone oil and alkyl-modified silicone oil, and diorganopolysiloxane containing both alkyl groups and aralkyl groups. A release agent (Patent Document 2) with improved heat resistance by introducing a trace amount of trialkoxysilylalkyl group into the alkyl-modified silicone oil to improve the adhesion to the mold (Patent Document 3) Proposed.

しかし、上記離型剤は、耐熱性が高まったとはいえ、十分とはいえず、より高温では垂直な金型での流れ落ち現象が見られ、大型成形物の上部では外観異常が発生するといった問題がある。また、特許文献2で提案されている離型剤は、炭素原子数の大きい有機基で変性されたシリコーン(例えば、炭素原子数20以上の長鎖アルキル基で変性されたシリコーン)を含む高融点の固形状の離型剤であるため、一般的な乳化機で乳化するのは困難であり、特殊な乳化機を必要とするなど、工業的にも不利である。 However, although the above-mentioned mold release agent has improved heat resistance, it is not sufficient, and there is a problem that a flow-off phenomenon is observed in a vertical mold at a higher temperature, and an appearance abnormality occurs at the upper part of a large molded product. There is. The mold release agent proposed in Patent Document 2 has a high melting point containing silicone modified with an organic group having a large number of carbon atoms (for example, silicone modified with a long-chain alkyl group having 20 or more carbon atoms). Therefore, it is difficult to emulsify with a general emulsifier, and it is industrially disadvantageous because a special emulsifier is required.

従来、有機物の耐熱性向上剤として、各種のヒンダードアミンやヒンダードフェノールが市販されているが、オルガノポリシロキサンとの相溶性に乏しいため、シリコーンオイルを含む水性ダイカスト用離型剤に添加しても沈殿してしまい、耐熱性向上作用を発揮できない。 Conventionally, various hindered amines and hindered phenols have been commercially available as organic heat resistance improvers, but they are poorly compatible with organopolysiloxanes, so they can be added to aqueous die casting release agents containing silicone oil. It precipitates and cannot exert an effect of improving heat resistance.

なお、特許文献4および5には、芳香族アミノ基含有オルガノポリシロキサンが開示されているが、この芳香族アミノ基含有オルガノポリシロキサンを含むダイカスト用離型剤組成物は記載されておらず、このダイカスト用離型剤組成物が優れた離型性、耐熱性、金型付着性、ペインタブル性を有し、高温で連続的にダイカストを行ったときの堆積性が低いことも記載されていない。

本発明は、上記事情に鑑みなされたもので、優れた離型性、耐熱性、金型付着性、ペインタブル性を有し、高温で連続的にダイカストを行ったときの堆積性が低いダイカスト用離型剤組成物およびそれを用いるエマルジョン型ダイカスト用離型剤を提供することを目的とする。 The present invention has been made in view of the above circumstances, and has excellent releasability, heat resistance, mold adhesion, and paintability, and has low depositability when continuously die-casting at a high temperature. It is an object of the present invention to provide a release agent composition and an emulsion type die casting release agent using the same.

本発明者らは、鋭意検討を行った結果、アラルキル基含有オルガノポリシロキサン等の、従来、離型性付与成分として用いられているオルガノポリシロキサンに、耐熱性付与成分として特定の芳香族アミノ基含有オルガノポリシロキサンを添加することにより上記目的を達成することができることを知見し、本発明をなすに至った。 As a result of intensive studies, the inventors of the present invention have developed a specific aromatic amino group as a heat resistance-imparting component into an organopolysiloxane conventionally used as a releasability-imparting component, such as an aralkyl group-containing organopolysiloxane. It has been found that the above object can be achieved by adding the organopolysiloxane, and the present invention has been made.

従って、本発明は第一に、

(A)(A1)下記一般式(1)で示されるアラルキル基含有オルガノポリシロキサン、下記一般式(2)で示されるアリール基含有オルガノポリシロキサン、又はその組み合わせ、および

(A2)下記一般式(1)で示されるアラルキル基含有オルガノポリシロキサンと25℃における粘度が10〜500mPa・sのジメチルポリシロキサンとの組み合わせ

のいずれか1種 90〜99.7質量%、ならびに

(B)下記一般式(3)で示される芳香族アミノ基含有オルガノポリシロキサン、下記一般式(4)で示される芳香族アミノ基含有オルガノポリシロキサン、又はその組み合わせ 0.3〜10質量%

からなるオルガノポリシロキサン混合物(ただし、(A)および(B)成分の合計が100質量%である。)

を含むダイカスト用離型剤組成物を提供する。

Therefore, the present invention firstly

(A) (A1) Aralkyl group-containing organopolysiloxane represented by the following general formula (1), aryl group-containing organopolysiloxane represented by the following general formula (2), or a combination thereof; and (A2) the following general formula ( 90% to 99.7% by mass of any one of a combination of an aralkyl group-containing organopolysiloxane represented by 1) and a dimethylpolysiloxane having a viscosity of 10 to 500 mPa · s at 25 ° C., and (B) the following general formula ( 3) Aromatic amino group-containing organopolysiloxane represented by the following general formula (4), or a combination thereof: 0.3 to 10% by mass

(However, the total of the components (A) and (B) is 100% by mass.)

A mold release agent composition for die casting is provided.

(式中、Rは独立に炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、又は炭素原子数1〜5のアルコキシ基を表し、

R1は炭素原子数7〜17のアラルキル基を表し、

mおよびnはおのおの0〜1,000の整数であり、かつ、m+nは10〜1,000の整数であり、

R2は独立に炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、炭素原子数1〜5のアルコキシ基、又は炭素原子数7〜17のアラルキル基を表し、

但し、n=0のとき、R2は炭素原子数7〜17のアラルキル基である。)

(In the formula, R independently represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, or an alkoxy group having 1 to 5 carbon atoms,

R 1 represents an aralkyl group having 7 to 17 carbon atoms,

m and n are each an integer of 0 to 1,000, and m + n is an integer of 10 to 1,000.

R 2 independently represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, an alkoxy group having 1 to 5 carbon atoms, or an aralkyl group having 7 to 17 carbon atoms. ,

However, when n = 0, R 2 is an aralkyl group having from 7 to 17 carbon atoms. )

(式中、Rは前記のとおりであり、

R3は炭素原子数6〜12のアリール基を表し、

R4は炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、炭素原子数1〜5のアルコキシ基、又は炭素原子数6〜12のアリール基を表し、複数存在する場合には互いに同一又は異なり、

sは0〜999の整数であり、tは1〜1,000の整数であり、かつ、s+tは10〜1,000の整数である。)

(Wherein R is as defined above,

R 3 represents an aryl group having 6 to 12 carbon atoms,

R 4 represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, an alkoxy group having 1 to 5 carbon atoms, or an aryl group having 6 to 12 carbon atoms. If present, they are the same or different from each other,

s is an integer of 0 to 999, t is an integer of 1 to 1,000, and s + t is an integer of 10 to 1,000. )

(式中、R5は独立に

(Wherein R 5 is independently

を表し、

R6は独立に炭素原子数1〜14の直鎖状アルキル基、又はフェニル基を表し、

pは1〜50の整数である。)

Represents

R 6 independently represents a linear alkyl group having 1 to 14 carbon atoms or a phenyl group,

p is an integer of 1-50. )

(式中、R5およびR6は前記のとおりであり、

qは0〜47の整数であり、rは1〜10の整数であり、かつ、q+rは1〜48の整数である。)

Wherein R 5 and R 6 are as described above,

q is an integer of 0 to 47, r is an integer of 1 to 10, and q + r is an integer of 1 to 48. )

本発明は第二に、上記ダイカスト用離型剤組成物、界面活性剤、および水を含むエマルジョンからなるエマルジョン型ダイカスト用離型剤を提供する。 Secondly, the present invention provides an emulsion type die casting mold release agent comprising the above die casting mold release composition, a surfactant, and an emulsion containing water.

本発明のダイカスト用離型剤組成物は、アルミニウム合金、マグネシウム合金、亜鉛合金等を成形するためのダイカスト用金型に塗布して用いられて良好な離型性およびペインタブル性を示し、200℃程度の低温から300℃以上の高温までの幅広い温度範囲において優れた金型付着性を示す。本発明のダイカスト用離型剤組成物は、高温で連続的にダイカストを行っても堆積性が低く、作業性を著しく向上させ、ダイカスト用金型からの離型の効率を大幅に改善するものである。本発明のダイカスト用離型剤組成物は耐熱性に優れているので大型成形物の作製にも適用することができる。 The mold release agent composition for die casting of the present invention is used by being applied to a die casting mold for forming an aluminum alloy, a magnesium alloy, a zinc alloy, etc., and exhibits a good mold release property and paintability. Excellent mold adhesion is exhibited in a wide temperature range from a low temperature to a high temperature of 300 ° C. or higher. The release agent composition for die casting of the present invention has low depositability even when die casting is continuously performed at a high temperature, remarkably improves workability, and greatly improves the efficiency of release from a die casting die. It is. Since the release agent composition for die casting of the present invention is excellent in heat resistance, it can also be applied to the production of a large molded product.

以下、本発明につき更に詳しく説明する。なお、本明細書において、粘度は、ブルックフィールド・エンジニアリング・ラボラトリーズ社(BROOKFIELD ENGINEERING LABORATORIES,INC.)製の粘弾性測定装置(Viscometer)により測定した25℃における値である。 Hereinafter, the present invention will be described in more detail. In addition, in this specification, a viscosity is the value in 25 degreeC measured with the viscoelasticity measuring apparatus (Viscometer) by the Brookfield Engineering Laboratories (BROOKFIELD ENGINEERING LABORATORIES, INC.).

[ダイカスト用離型剤組成物]

本発明のダイカスト用離型剤組成物は、上記のとおり、(A)成分および(B)成分からなるオルガノポリシロキサン混合物を含むものである。

[Die Casting Release Agent Composition]

The mold release agent composition for die casting of the present invention includes an organopolysiloxane mixture composed of the component (A) and the component (B) as described above.

<オルガノポリシロキサン混合物>

・(A)成分

(A)成分は、本発明のダイカスト用離型剤組成物に高温での離型性を与える離型性付与成分であり、上記(A1)および(A2)成分のいずれか1種である。

<Organopolysiloxane mixture>

-Component (A) Component (A) is a releasability-imparting component that imparts releasability at a high temperature to the release agent composition for die casting of the present invention, and is any one of the above components (A1) and (A2) One type.

・・(A1)成分

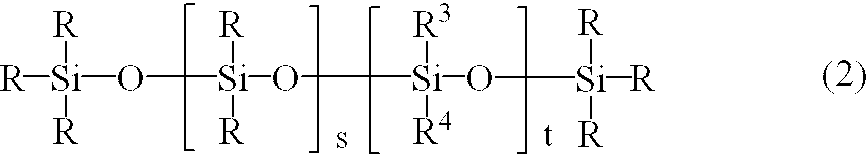

(A1)成分は、下記一般式(1)で示されるアラルキル基含有オルガノポリシロキサン、下記一般式(2)で示されるアリール基含有オルガノポリシロキサン、又はその組み合わせであるが、典型的には下記一般式(1)で示されるアラルキル基含有オルガノポリシロキサン又は下記一般式(2)で示されるアリール基含有オルガノポリシロキサンである。

.. (A1) component Although the component (A1) is an aralkyl group-containing organopolysiloxane represented by the following general formula (1), an aryl group-containing organopolysiloxane represented by the following general formula (2), or a combination thereof: These are typically aralkyl group-containing organopolysiloxanes represented by the following general formula (1) or aryl group-containing organopolysiloxanes represented by the following general formula (2).

(式中、Rは独立に炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、又は炭素原子数1〜5のアルコキシ基を表し、

R1は炭素原子数7〜17のアラルキル基を表し、

R2は独立に炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、炭素原子数1〜5のアルコキシ基、又は炭素原子数7〜17のアラルキル基を表し、

mおよびnはおのおの0〜1,000の整数であり、かつ、m+nは10〜1,000の整数であり、

但し、n=0のとき、R2は炭素原子数7〜17のアラルキル基である。)

(In the formula, R independently represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, or an alkoxy group having 1 to 5 carbon atoms,

R 1 represents an aralkyl group having from 7 to 17 carbon atoms,

R 2 independently represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, an alkoxy group having 1 to 5 carbon atoms, or an aralkyl group having 7 to 17 carbon atoms. ,

m and n are each an integer of 0 to 1,000, and m + n is an integer of 10 to 1,000.

However, when n = 0, R 2 is an aralkyl group having 7 to 17 carbon atoms. )

(式中、Rは前記のとおりであり、

R3は炭素原子数6〜12のアリール基を表し、

R4は炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、炭素原子数1〜5のアルコキシ基、又は炭素原子数6〜12のアリール基を表し、複数存在する場合には互いに同一又は異なり、

sは0〜999の整数であり、tは1〜1,000の整数であり、かつ、s+tは10〜1,000の整数である。)

(Wherein R is as defined above,

R 3 represents an aryl group having 6 to 12 carbon atoms,

R 4 represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, an alkoxy group having 1 to 5 carbon atoms, or an aryl group having 6 to 12 carbon atoms. If present, they are the same or different from each other,

s is an integer of 0 to 999, t is an integer of 1 to 1,000, and s + t is an integer of 10 to 1,000. )

炭素原子数1〜14の直鎖状アルキル基である上記Rとしては、例えば、メチル基、エチル基、プロピル基、ブチル基、ヘキシル基、デシル基、ドデシル基、テトラデシル基等が挙げられる。炭素原子数2〜5のアルケニル基である上記Rとしては、例えば、ビニル基等が挙げられる。炭素原子数1〜5のアルコキシ基である上記Rとしては、例えば、メトキシ基、エトキシ基等が挙げられる。得られる離型剤組成物にペインタブル性を付与する上では、上記一般式(1)において、全R中の適度な割合、例えば、全R中の20〜50モル%が炭素原子数8〜14の直鎖状アルキル基であることが好ましい。上記一般式(1)において、上記Rは、メチル基、メチル基とデシル基との組み合わせ、又はメチル基とドデシル基との組み合わせであることが特に好ましい。上記一般式(2)において、上記Rは、特にメチル基であることが工業的に好ましい。 As said R which is a C1-C14 linear alkyl group, a methyl group, an ethyl group, a propyl group, a butyl group, a hexyl group, a decyl group, a dodecyl group, a tetradecyl group etc. are mentioned, for example. As said R which is a C2-C5 alkenyl group, a vinyl group etc. are mentioned, for example. As said R which is a C1-C5 alkoxy group, a methoxy group, an ethoxy group, etc. are mentioned, for example. In imparting paintability to the resulting release agent composition, in the above general formula (1), an appropriate ratio in the total R, for example, 20 to 50 mol% in the total R is 8 to 14 carbon atoms. The linear alkyl group is preferable. In the general formula (1), R is particularly preferably a methyl group, a combination of a methyl group and a decyl group, or a combination of a methyl group and a dodecyl group. In the general formula (2), it is industrially preferable that R is a methyl group.

上記R1は炭素原子数7〜17のアラルキル基である。R1の炭素原子数が7未満では得られる組成物の高温での付着性が乏しくなる場合がある。R1の炭素原子数が17を超えると、上記一般式(1)で示されるオルガノポリシロキサンを製造するためのオレフィン原料が固体となるので工業的に取り扱いにくくなる。上記R1としては、例えば、ベンジル基、2−フェニルエチル基、2−フェニルプロピル基等が挙げられるが、特に2−フェニルプロピル基が好ましい。 R 1 is an aralkyl group having 7 to 17 carbon atoms. If the number of carbon atoms in R 1 is less than 7, the resulting composition may have poor adhesion at high temperatures. When the number of carbon atoms in R 1 exceeds 17, the olefin raw material for producing the organopolysiloxane represented by the general formula (1) becomes a solid, which makes it difficult to handle industrially. Examples of R 1 include a benzyl group, a 2-phenylethyl group, and a 2-phenylpropyl group, and a 2-phenylpropyl group is particularly preferable.

上記R2としては、例えば、上記RおよびR1のおのおのについて具体的に例示した有機基が挙げられる。 Examples of R 2 include organic groups specifically exemplified for the above R and R 1 .

上記R3としては、例えば、フェニル基、ナフチル基等が挙げられ、特にフェニル基であることが工業的に好ましい。 Examples of R 3 include a phenyl group and a naphthyl group. Particularly, a phenyl group is industrially preferable.

上記R4としては、例えば、上記RおよびR3のおのおのについて具体的に例示した有機基が挙げられる。 Examples of R 4 include organic groups specifically exemplified for each of R and R 3 above.

上記mおよびnはおのおの0〜1,000、好ましくは5〜200の整数であり、かつ、m+nは10〜1,000、好ましくは20〜800の整数である。m+nが10未満では得られる組成物は高温での優れた離型性を有さない場合がある。m+nが1,000を超えると、得られるオルガノポリシロキサンは粘度が高くなりやすく乳化が困難になる場合がある。 M and n are each an integer of 0 to 1,000, preferably 5 to 200, and m + n is an integer of 10 to 1,000, preferably 20 to 800. If m + n is less than 10, the resulting composition may not have excellent releasability at high temperatures. When m + n exceeds 1,000, the resulting organopolysiloxane tends to have a high viscosity and may be difficult to emulsify.

上記sは0〜999の整数であり、アリール基含有シロキサン単位の個数を表す上記tは1〜1,000の整数であり、かつ、s+tは10〜1,000、好ましくは10〜800の整数である。s+tが10未満では得られる組成物は高温での優れた離型性を有さない場合がある。s+tが1,000を超えると、得られるオルガノポリシロキサンは高粘度になりやすく乳化が困難になる場合がある。 The s is an integer of 0 to 999, the t representing the number of aryl group-containing siloxane units is an integer of 1 to 1,000, and s + t is an integer of 10 to 1,000, preferably 10 to 800. It is. If s + t is less than 10, the resulting composition may not have excellent releasability at high temperatures. When s + t exceeds 1,000, the resulting organopolysiloxane tends to have a high viscosity and may be difficult to emulsify.

・・(A2)成分

(A2)成分は、上記一般式(1)で示されるアラルキル基含有オルガノポリシロキサンと25℃における粘度が10〜500mPa・sのジメチルポリシロキサンとの組み合わせである。このジメチルポリシロキサンを上記一般式(1)で示されるアラルキル基含有オルガノポリシロキサンと併用することで、得られる組成物のペインタブル性を更に向上させることがしにくくなる場合はあるものの、該組成物の低温部(250℃程度以下の範囲)での離型性をより向上させることができる。

-(A2) component (A2) component is a combination of the aralkyl group containing organopolysiloxane shown by the said General formula (1), and the dimethylpolysiloxane whose viscosity in 25 degreeC is 10-500 mPa * s. Although this dimethylpolysiloxane is used in combination with the aralkyl group-containing organopolysiloxane represented by the above general formula (1), it may be difficult to further improve the paintability of the resulting composition. The releasability in the low temperature part (range of about 250 ° C. or less) can be further improved.

前記ジメチルポリシロキサンの25℃における粘度は10〜500mPa・sであるが、好ましくは20〜350mPa・sである。該粘度が10mPa・s未満では、得られる組成物は離型性に乏しくなる場合がある。また、該粘度が500mPa・sを超えると、ジメチルポリシロキサンは離型性付与成分である(A1)成分との相溶性に乏しくなる場合があり、また、得られる組成物はペインタブル性に乏しくなる場合がある。 The dimethylpolysiloxane has a viscosity at 25 ° C. of 10 to 500 mPa · s, preferably 20 to 350 mPa · s. When the viscosity is less than 10 mPa · s, the resulting composition may be poor in releasability. On the other hand, when the viscosity exceeds 500 mPa · s, dimethylpolysiloxane may have poor compatibility with the component (A1), which is a releasability-imparting component, and the resulting composition will have poor paintability. There is a case.

上記一般式(1)で示されるアラルキル基含有オルガノポリシロキサンの(A2)成分中の配合量は、(A)成分と(B)成分とからなるオルガノポリシロキサン混合物中での該オルガノポリシロキサンの量が70〜99質量%となる量とすることが好ましい。一方、前記ジメチルポリシロキサンの(A2)成分中の配合量は、(A)成分と(B)成分とからなるオルガノポリシロキサン混合物中での該ジメチルポリシロキサンの量が0.7〜29.7質量%となる量とすることが好ましい。これらの配合量を上記の範囲とすることにより、良好なペインタブル性を維持したままで、得られる組成物の前記低温部での離型性を更に向上させることが容易となる。 The blending amount of the aralkyl group-containing organopolysiloxane represented by the general formula (1) in the component (A2) is such that the organopolysiloxane in the organopolysiloxane mixture composed of the component (A) and the component (B). The amount is preferably 70 to 99% by mass. On the other hand, the blending amount of the dimethylpolysiloxane in the component (A2) is such that the amount of the dimethylpolysiloxane in the organopolysiloxane mixture comprising the component (A) and the component (B) is 0.7 to 29.7. It is preferable to set the amount to be mass%. By making these compounding quantities into the above ranges, it becomes easy to further improve the releasability in the low temperature part of the resulting composition while maintaining good paintability.

・(B)成分

(B)成分は、本発明のダイカスト用離型剤組成物に耐熱性を与える耐熱性付与成分であり、下記一般式(3)で示される芳香族アミノ基含有オルガノポリシロキサン、下記一般式(4)で示される芳香族アミノ基含有オルガノポリシロキサン、又はその組み合わせであるが、典型的には下記一般式(3)で示される芳香族アミノ基含有オルガノポリシロキサン又は下記一般式(4)で示される芳香族アミノ基含有オルガノポリシロキサンである。(B)成分は、従来の耐熱性向上剤である各種のヒンダードアミンやヒンダードフェノールと異なり、(A)成分の離型性付与性のオルガノポリシロキサンに均一に溶解するので、本発明のダイカスト用離型剤組成物に著しい耐熱性を付与することができる。

-Component (B) The component (B) is a heat resistance-imparting component that imparts heat resistance to the release agent composition for die casting of the present invention. The aromatic amino group-containing organopolysiloxane represented by the following general formula (3) An aromatic amino group-containing organopolysiloxane represented by the following general formula (4), or a combination thereof, typically an aromatic amino group-containing organopolysiloxane represented by the following general formula (3) or An aromatic amino group-containing organopolysiloxane represented by the formula (4). Unlike the various hindered amines and hindered phenols that are conventional heat resistance improvers, the component (B) is uniformly dissolved in the releasability-providing organopolysiloxane of the component (A). Significant heat resistance can be imparted to the release agent composition.

(式中、R5は独立に

(Wherein R 5 is independently

(即ち、N−フェニルアミノフェニル基、N−(p−アニリノフェニル)アミノフェニル基、N−(α−ナフチル)アミノフェニル基、またはN−(β−ナフチル)アミノフェニル基)

を表し、

R6は独立に炭素原子数1〜14の直鎖状アルキル基、又はフェニル基を表し、

pは1〜50の整数である。)

(That is, N-phenylaminophenyl group, N- (p-anilinophenyl) aminophenyl group, N- (α-naphthyl) aminophenyl group, or N- (β-naphthyl) aminophenyl group)

Represents

R 6 independently represents a linear alkyl group having 1 to 14 carbon atoms or a phenyl group,

p is an integer of 1-50. )

(式中、R5およびR6は前記のとおりであり、

qは0〜47の整数であり、rは1〜10の整数であり、かつ、q+rは1〜48の整数である。)

Wherein R 5 and R 6 are as described above,

q is an integer of 0 to 47, r is an integer of 1 to 10, and q + r is an integer of 1 to 48. )

炭素原子数1〜14の直鎖状アルキル基である上記R6としては、例えば、メチル基、エチル基、プロピル基、ブチル基、ヘキシル基、デシル基、ドデシル基、テトラデシル基等が挙げられる。上記一般式(3)および(4)において、上記R6は、メチル基またはフェニル基であることが好ましい。 As the R 6 is a straight chain alkyl group having 1 to 14 carbon atoms, e.g., methyl group, ethyl group, propyl group, butyl group, hexyl group, decyl group, dodecyl group, etc. tetradecyl group. In the general formulas (3) and (4), R 6 is preferably a methyl group or a phenyl group.

上記一般式(3)又は(4)で示される芳香族アミノ基含有オルガノポリシロキサンにおいて、ケイ素原子数(即ち、シロキサン単位の重合度)が50より大きくなると、相対的に芳香族アミノ基の含有量が小さくなり過ぎて、得られる組成物は所望の耐熱性を発揮しにくくなるため、上記pは1〜50の整数であり、上記q+rは1〜48の整数である。また、上記一般式(4)で示される芳香族アミノ基含有オルガノポリシロキサンは、rが10より大きいと、離型性付与成分である(A)成分への溶解性に乏しくなるので、上記一般式(4)において、qは0〜47の整数であり、rは1〜10の整数である。 In the aromatic amino group-containing organopolysiloxane represented by the above general formula (3) or (4), when the number of silicon atoms (that is, the degree of polymerization of the siloxane unit) is greater than 50, the aromatic amino group is relatively contained. Since the amount becomes too small and the resulting composition hardly exhibits desired heat resistance, p is an integer of 1 to 50, and q + r is an integer of 1 to 48. In addition, the aromatic amino group-containing organopolysiloxane represented by the general formula (4) has poor solubility in the component (A), which is a releasability-imparting component, when r is greater than 10, In Formula (4), q is an integer of 0 to 47, and r is an integer of 1 to 10.

上記一般式(3)又は(4)で示される芳香族アミノ基含有オルガノポリシロキサンとしては、例えば、下記式A)〜G)で示されるものが挙げられる。 Examples of the aromatic amino group-containing organopolysiloxane represented by the general formula (3) or (4) include those represented by the following formulas A) to G).

(A)成分および(B)成分からなるオルガノポリシロキサン混合物において、(A)成分の添加量は90〜99.7質量%であり、(B)成分の添加量は0.3〜10質量%であり、ただし、(A)および(B)成分の合計が100質量%である。(B)成分の添加量が0.3質量%未満(即ち、(A)成分の添加量が99.7質量%超)では、得られる組成物は耐熱性が向上しにくい。(B)成分の添加量が10質量%を超えると(即ち、(A)成分の添加量が90質量%未満であると)、(A)成分と(B)成分との溶解性が乏しくなりやすく、更に、(B)成分の添加量を増やしても、得られる組成物の耐熱性が向上しにくくなるので、経済的にも不利である。 In the organopolysiloxane mixture comprising the component (A) and the component (B), the addition amount of the component (A) is 90 to 99.7% by mass, and the addition amount of the component (B) is 0.3 to 10% by mass. However, the sum total of (A) and (B) component is 100 mass%. When the addition amount of the component (B) is less than 0.3% by mass (that is, the addition amount of the component (A) exceeds 99.7% by mass), the resulting composition is difficult to improve the heat resistance. When the addition amount of the component (B) exceeds 10% by mass (that is, the addition amount of the component (A) is less than 90% by mass), the solubility of the component (A) and the component (B) becomes poor. Further, even if the amount of component (B) is increased, the heat resistance of the resulting composition is difficult to improve, which is economically disadvantageous.

[その他の任意成分]

本発明のダイカスト用離型剤組成物には、本発明の効果を損なわない範囲で、オルガノポリシロキサン混合物以外に、その他の任意成分、例えば、防腐剤、防黴剤、防錆剤、増粘剤等の一般的にシリコーンエマルジョンに使用される添加剤や、離型性を調整する目的で、エステル油、鉱油、油脂類、各種合成ワックス類、アルミニウム粉、黒鉛などの(A)成分以外の離型性付与成分を更に配合することができる。これらその他の任意成分の配合量は、離型剤組成物中、0.1〜10質量%とすることが好ましく、特に0.5〜5質量%とすることが好ましい。

[Other optional ingredients]

In the mold release agent composition for die casting of the present invention, in addition to the organopolysiloxane mixture, other optional components such as preservatives, antifungal agents, rust preventives, thickeners are included within the range not impairing the effects of the present invention. Additives generally used in silicone emulsions such as agents, and other than component (A) such as ester oil, mineral oil, fats and oils, various synthetic waxes, aluminum powder, graphite, etc., for the purpose of adjusting releasability A releasability-imparting component can be further blended. The blending amount of these other optional components is preferably 0.1 to 10% by mass, particularly preferably 0.5 to 5% by mass in the release agent composition.

[エマルジョン型ダイカスト用離型剤]

本発明のダイカスト用離型剤組成物は、有機溶剤で希釈して金型に塗布することもできるが、一般工業的には乳化して用いる。そこで、本発明のダイカスト用離型剤は、本発明のダイカスト用離型剤組成物、界面活性剤、および水を含むエマルジョンからなるエマルジョン型ダイカスト用離型剤である。

[Emulsion type die casting release agent]

The mold release agent composition for die casting of the present invention can be diluted with an organic solvent and applied to a mold, but is generally emulsified for industrial use. Accordingly, the mold release agent for die casting of the present invention is an emulsion type mold release agent for die casting comprising an emulsion containing the mold release agent composition of the present invention, a surfactant, and water.

使用される界面活性剤は、特に限定されず、例えば、アニオン系界面活性剤、ノニオン系界面活性剤、カチオン系界面活性剤などが挙げられるが、特にノニオン系界面活性剤が安定性面で好ましい。ノニオン系界面活性剤としては、例えば、ポリオキシエチレンデシルエーテル、ポリオキシエチレンドデシルエーテル(ポリオキシエチレンラウリルエーテル)、ポリオキシエチレントリデシルエーテル、ポリオキシエチレン・ノニルフェニルエーテル、ポリオキシエチレン・オクチルフェニルエーテル等が挙げられる。 The surfactant to be used is not particularly limited, and examples thereof include anionic surfactants, nonionic surfactants, and cationic surfactants. Nonionic surfactants are particularly preferable in terms of stability. . Nonionic surfactants include, for example, polyoxyethylene decyl ether, polyoxyethylene dodecyl ether (polyoxyethylene lauryl ether), polyoxyethylene tridecyl ether, polyoxyethylene nonylphenyl ether, polyoxyethylene octylphenyl Examples include ether.

前記エマルジョンの製造方法は特に限定されないが、本発明のダイカスト用離型剤組成物に界面活性剤および水を加え、せん断応力を加えて乳化することにより、水中油型のエマルジョンとして前記エマルジョンを得ることができる。乳化は、ホモミキサー、コロイドミル、ラインミル、ホモジナイザー、プラネタリーミキサー、トリミックスミキサー等の乳化機又は混合機を用いて行うことができる。 The method for producing the emulsion is not particularly limited, and the emulsion is obtained as an oil-in-water emulsion by adding a surfactant and water to the release agent composition for die casting of the present invention and emulsifying by applying shear stress. be able to. Emulsification can be performed using an emulsifier or a mixer such as a homomixer, a colloid mill, a line mill, a homogenizer, a planetary mixer, or a trimix mixer.

本発明の効果を損なわない限り、前記エマルジョン中の各成分の配合量は特に制限されない。しかし、前記エマルジョン中の本発明のダイカスト用離型剤組成物の配合量は1〜50質量%であることが好ましく、5〜30質量%であることがより好ましい。また、前記エマルジョン中の界面活性剤の配合量は、0.1〜10質量%であることが好ましく、0.5〜5質量%であることがより好ましい。更に、残部を水とすることが好ましい。前記ダイカスト用離型剤組成物の配合量が1〜50質量%であると、得られるエマルジョンからなるエマルジョン型ダイカスト用離型剤は、高粘度となりにくいので塗布しやすく、また、より良好な離型性を発現する。前記界面活性剤の配合量が0.1〜10質量%であると、該界面活性剤の乳化力は十分なものとなりやすく、かつ、得られるエマルジョンからなるエマルジョン型ダイカスト用離型剤は離型性が悪化しにくい。 As long as the effects of the present invention are not impaired, the amount of each component in the emulsion is not particularly limited. However, the blending amount of the release agent composition for die casting of the present invention in the emulsion is preferably 1 to 50% by mass, and more preferably 5 to 30% by mass. Moreover, it is preferable that the compounding quantity of surfactant in the said emulsion is 0.1-10 mass%, and it is more preferable that it is 0.5-5 mass%. Furthermore, the balance is preferably water. When the blending amount of the mold release agent composition for die casting is 1 to 50% by mass, the emulsion type mold release agent for emulsion die casting made of the resulting emulsion is less likely to have high viscosity, and thus it is easy to apply. Expresses type. When the blending amount of the surfactant is 0.1 to 10% by mass, the emulsifying power of the surfactant tends to be sufficient, and the release agent for emulsion type die casting comprising the resulting emulsion is a release agent. Sex is difficult to deteriorate.

本発明のエマルジョン型ダイカスト用離型剤をダイカスト用金型にスプレー塗布、浸漬等の公知の方法により塗布し、該離型剤が塗布された該金型に溶融したアルミニウム合金、マグネシウム合金、亜鉛合金などの合金を注入し、該合金を凝固させ、凝固した該合金を該金型から取り出すことにより、ダイカスト成形物を製造することができる。 The emulsion type die casting release agent of the present invention is applied to a die casting mold by a known method such as spray coating or dipping, and the molten aluminum alloy, magnesium alloy, zinc is applied to the mold coated with the release agent. A die-cast product can be produced by injecting an alloy such as an alloy, solidifying the alloy, and taking out the solidified alloy from the mold.

以下、実施例及び比較例を示し、本発明を具体的に説明するが、本発明は下記の実施例に制限されるものではない。なお、下記の例において、部及び%はそれぞれ質量部及び質量%を示し、Meはメチル基を、Phはフェニル基を示す。 EXAMPLES Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated concretely, this invention is not restrict | limited to the following Example. In the following examples, parts and% represent parts by mass and% by mass, Me represents a methyl group, and Ph represents a phenyl group, respectively.

[エマルジョンの調製方法]

下記の実施例1〜5の各々で調製したオルガノポリシロキサン混合物または下記の比較例1に記載のオルガノポリシロキサン50部、ポリオキシエチレンドデシルエーテル(HLB=10.5)3部、及びポリオキシエチレンドデシルエーテル(HLB=16.3)2部を均一に分散混合した後、水4部を加えて攪拌した。攪拌後の試料をコロイドミルに通して乳化し、得られた乳化物に更に水95部を添加して試料が均一になるまで攪拌して、水性エマルジョンを得た。得られた水性エマルジョンについて、下記のとおりにして、離型性、付着性、堆積性を調べた。結果を表1に示す。

[Method for preparing emulsion]

50 parts of the organopolysiloxane mixture prepared in each of the following Examples 1 to 5 or 3 parts of polyoxyethylene dodecyl ether (HLB = 10.5) described in Comparative Example 1 below, and polyoxyethylene After 2 parts of dodecyl ether (HLB = 16.3) was uniformly dispersed and mixed, 4 parts of water was added and stirred. The sample after stirring was emulsified through a colloid mill, and 95 parts of water was further added to the obtained emulsion and stirred until the sample was uniform to obtain an aqueous emulsion. About the obtained aqueous | water-based emulsion, the mold release property, adhesiveness, and deposition property were investigated as follows. The results are shown in Table 1.

[実施例1]

下記式(5)で示されるアラルキル基含有オルガノポリシロキサン49.5部、及び下記式A)で示される芳香族アミノ基含有オルガノポリシロキサン0.5部を均一に混合してオルガノポリシロキサン混合物を調製した。

[Example 1]

An organopolysiloxane mixture is prepared by uniformly mixing 49.5 parts of an aralkyl group-containing organopolysiloxane represented by the following formula (5) and 0.5 part of an aromatic amino group-containing organopolysiloxane represented by the following formula A). Prepared.

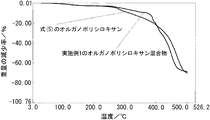

上記式(5)で示されるアラルキル基含有オルガノポリシロキサン単独及び上記オルガノポリシロキサン混合物について空気中で熱重量分析を行った(測定機器:株式会社リガク製 Thermo plus TG8120、測定条件:昇温速度10.0℃/分)。結果を図1に示す。図1では、測定開始時の温度(25℃)での重量に対する各温度での重量の減少率を温度に対してプロットした。図1に示すとおり、上記オルガノポリシロキサン混合物は、上記式(5)で示されるアラルキル基含有オルガノポリシロキサン単独と比較して、約220〜約400℃の範囲において重量の減少率が小さく、より高い耐熱性を有していた。 The aralkyl group-containing organopolysiloxane represented by the above formula (5) alone and the organopolysiloxane mixture were subjected to thermogravimetric analysis in the air (measuring instrument: Thermo plus TG8120 manufactured by Rigaku Corporation, measurement condition: heating rate 10) .0 ° C./min). The results are shown in FIG. In FIG. 1, the weight reduction rate at each temperature against the weight at the temperature at the start of measurement (25 ° C.) is plotted against the temperature. As shown in FIG. 1, the organopolysiloxane mixture has a smaller weight reduction rate in the range of about 220 to about 400 ° C. than the aralkyl group-containing organopolysiloxane alone represented by the above formula (5). It had high heat resistance.

[実施例2]

上記式(5)で示されるアラルキル基含有オルガノポリシロキサン48部、及び上記式A)で示される芳香族アミノ基含有オルガノポリシロキサン2部を均一に混合してオルガノポリシロキサン混合物を調製した。

[Example 2]

An organopolysiloxane mixture was prepared by uniformly mixing 48 parts of an aralkyl group-containing organopolysiloxane represented by the above formula (5) and 2 parts of an aromatic amino group-containing organopolysiloxane represented by the above formula A).

[実施例3]

下記式(6)で示されるアラルキル基含有オルガノポリシロキサン49部、及び下記式G)で示される芳香族アミノ基含有オルガノポリシロキサン1部を均一に混合してオルガノポリシロキサン混合物を調製した。

[Example 3]

An organopolysiloxane mixture was prepared by uniformly mixing 49 parts of an aralkyl group-containing organopolysiloxane represented by the following formula (6) and 1 part of an aromatic amino group-containing organopolysiloxane represented by the following formula G).

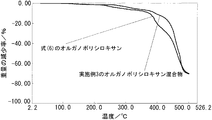

実施例1と同様に、上記式(6)で示されるアラルキル基含有オルガノポリシロキサン単独及び上記オルガノポリシロキサン混合物について空気中で熱重量分析を行った。結果を図2に示す。図2では、測定開始時の温度(25℃)での重量に対する各温度での重量の減少率を温度に対してプロットした。図2に示すとおり、上記オルガノポリシロキサン混合物は、上記式(6)で示されるアラルキル基含有オルガノポリシロキサン単独と比較して、約220〜約480℃の範囲において重量の減少率が小さく、より高い耐熱性を有していた。 As in Example 1, thermogravimetric analysis was performed in air on the aralkyl group-containing organopolysiloxane alone and the organopolysiloxane mixture represented by the above formula (6). The results are shown in FIG. In FIG. 2, the weight reduction rate at each temperature against the weight at the temperature at the start of measurement (25 ° C.) is plotted against the temperature. As shown in FIG. 2, the organopolysiloxane mixture has a smaller weight reduction rate in the range of about 220 to about 480 ° C. than the aralkyl group-containing organopolysiloxane alone represented by the above formula (6). It had high heat resistance.

[実施例4]

上記式(5)で示されるアラルキル基含有オルガノポリシロキサン40部、25℃における粘度が100mPa・sのジメチルポリシロキサン9部、及び上記式A)で示される芳香族アミノ基含有オルガノポリシロキサン1部を均一に混合してオルガノポリシロキサン混合物を調製した。

[Example 4]

40 parts of an aralkyl group-containing organopolysiloxane represented by the above formula (5), 9 parts of dimethylpolysiloxane having a viscosity of 100 mPa · s at 25 ° C., and 1 part of an aromatic amino group-containing organopolysiloxane represented by the above formula A) Were mixed uniformly to prepare an organopolysiloxane mixture.

[実施例5]

下記式(7)で示されるフェニル基含有オルガノポリシロキサン49部、及び上記式G)で示される芳香族アミノ基含有オルガノポリシロキサン1部を均一に混合してオルガノポリシロキサン混合物を調製した。

[Example 5]

An organopolysiloxane mixture was prepared by uniformly mixing 49 parts of a phenyl group-containing organopolysiloxane represented by the following formula (7) and 1 part of an aromatic amino group-containing organopolysiloxane represented by the above formula G).

[比較例1]

下記式(8)で示されるオルガノポリシロキサンをエマルジョンの調製に用いた。

[Comparative Example 1]

An organopolysiloxane represented by the following formula (8) was used for the preparation of the emulsion.

<離型性の評価>

長さ5cm×幅5cm×深さ5mmであり、底面に断面が半径2mmの半円状をした溝を長さ方向および幅方向に沿って1cm毎に方眼状に掘った金型に、オルガノポリシロキサンの合計の濃度が1%になるように水で希釈した水性エマルジョンを吹き付け、350℃に予熱した。この金型に電気炉により750℃で溶融させたアルミニウムを注ぎ込み、冷却後、金型からアルミニウムを剥し、はがれやすさの程度を下記の基準で評価した。

○:容易に脱型、 △:脱型がやや困難、 ×:脱型が非常に困難

<Evaluation of releasability>

A mold having a length of 5 cm, a width of 5 cm, and a depth of 5 mm, and a semi-circular groove having a radius of 2 mm in cross section on the bottom surface and dug in a square shape every 1 cm along the length and width directions, An aqueous emulsion diluted with water so as to have a total concentration of siloxane of 1% was sprayed and preheated to 350 ° C. Aluminum melted at 750 ° C. by an electric furnace was poured into this mold, and after cooling, the aluminum was peeled off from the mold, and the degree of ease of peeling was evaluated according to the following criteria.

○: easy demolding, △: demolding is somewhat difficult, ×: demolding is very difficult

<付着性の評価>

10cm×10cm×1cmの鉄板を200℃、300℃、又は400℃に加熱し、オルガノポリシロキサンの合計の濃度が1%になるように水で希釈した水性エマルジョン40mlを4kgf/cm2のスプレー圧で、この加熱した鉄板の表面に吹き付け、付着の度合いを観察し、下記の基準で評価した。

○:厚く均一に付着、 △:薄く均一に付着、 ×:薄く斑に付着

<Evaluation of adhesion>

A 10 cm × 10 cm × 1 cm iron plate is heated to 200 ° C., 300 ° C., or 400 ° C., and 40 ml of an aqueous emulsion diluted with water so that the total concentration of organopolysiloxane is 1% is spray pressure of 4 kgf / cm 2 . Then, it sprayed on the surface of this heated iron plate, the degree of adhesion was observed, and the following reference | standard evaluated.

○: Thick and uniform adhesion, △: Thin and uniform adhesion, ×: Thin and uniform adhesion

<堆積性の評価>

10cm×10cm×1cmの鉄板を200℃に加熱し、オルガノポリシロキサンの合計の濃度が2%になるように水で希釈した水性エマルジョンを、この加熱した鉄板の表面に50回スプレーした後、水を染み込ませたガーゼで鉄板上の堆積物をふき取り、堆積物の除去のしやすさを調べ、下記の基準で評価した。

○:容易に除去、 △:膜が若干残存、 ×:除去困難

<Evaluation of sedimentation>

A 10 cm × 10 cm × 1 cm iron plate was heated to 200 ° C., and an aqueous emulsion diluted with water so that the total concentration of the organopolysiloxane was 2% was sprayed on the surface of the heated iron plate 50 times. The deposits on the iron plate were wiped off with gauze soaked in to determine the ease of removing the deposits, and evaluated according to the following criteria.

○: Easily removed, △: Some film remained, ×: Difficult to remove

Claims (4)

(A2)下記一般式(1)で示されるアラルキル基含有オルガノポリシロキサンと25℃における粘度が10〜500mPa・sのジメチルポリシロキサンとの組み合わせ

のいずれか1種 90〜99.7質量%、ならびに

(B)下記一般式(3)で示される芳香族アミノ基含有オルガノポリシロキサン、下記一般式(4)で示される芳香族アミノ基含有オルガノポリシロキサン、又はその組み合わせ 0.3〜10質量%

からなるオルガノポリシロキサン混合物(ただし、(A)および(B)成分の合計が100質量%である。)

を含むダイカスト用離型剤組成物。

(式中、Rは独立に炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、又は炭素原子数1〜5のアルコキシ基を表し、

R1は炭素原子数7〜17のアラルキル基を表し、

R2は独立に炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、炭素原子数1〜5のアルコキシ基、又は炭素原子数7〜17のアラルキル基を表し、

mおよびnはおのおの0〜1,000の整数であり、かつ、m+nは10〜1,000の整数であり、

但し、n=0のとき、R2は炭素原子数7〜17のアラルキル基である。)

(式中、Rは前記のとおりであり、

R3は炭素原子数6〜12のアリール基を表し、

R4は炭素原子数1〜14の直鎖状アルキル基、炭素原子数2〜5のアルケニル基、炭素原子数1〜5のアルコキシ基、又は炭素原子数6〜12のアリール基を表し、複数存在する場合には互いに同一又は異なり、

sは0〜999の整数であり、tは1〜1,000の整数であり、かつ、s+tは10〜1,000の整数である。)

(式中、R5は独立に

を表し、

R6は独立に炭素原子数1〜14の直鎖状アルキル基、又はフェニル基を表し、

pは1〜50の整数である。)

(式中、R5およびR6は前記のとおりであり、

qは0〜47の整数であり、rは1〜10の整数であり、かつ、q+rは1〜48の整数である。) (A) (A1) Aralkyl group-containing organopolysiloxane represented by the following general formula (1), aryl group-containing organopolysiloxane represented by the following general formula (2), or a combination thereof; and (A2) the following general formula ( 90% to 99.7% by mass of any one of a combination of an aralkyl group-containing organopolysiloxane represented by 1) and a dimethylpolysiloxane having a viscosity of 10 to 500 mPa · s at 25 ° C., and (B) the following general formula ( 3) Aromatic amino group-containing organopolysiloxane represented by the following general formula (4), or a combination thereof: 0.3 to 10% by mass

(However, the total of the components (A) and (B) is 100% by mass.)

A mold release agent composition for die casting.

(In the formula, R independently represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, or an alkoxy group having 1 to 5 carbon atoms,

R 1 represents an aralkyl group having 7 to 17 carbon atoms,

R 2 is independently a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, an alkoxy group having 1 to 5 carbon atoms, or an aralkyl group having a carbon number of 7 to 17 ,

m and n are each an integer of 0 to 1,000, and m + n is an integer of 10 to 1,000.

However, when n = 0, R 2 is an aralkyl group having 7 to 17 carbon atoms. )

(Wherein R is as defined above,

R 3 represents an aryl group having 6 to 12 carbon atoms,

R 4 represents a linear alkyl group having 1 to 14 carbon atoms, an alkenyl group having 2 to 5 carbon atoms, an alkoxy group having 1 to 5 carbon atoms, or an aryl group having 6 to 12 carbon atoms. If present, they are the same or different from each other,

s is an integer of 0 to 999, t is an integer of 1 to 1,000, and s + t is an integer of 10 to 1,000. )

(Wherein R 5 is independently

Represents

R 6 independently represents a linear alkyl group having 1 to 14 carbon atoms or a phenyl group,

p is an integer of 1-50. )

Wherein R 5 and R 6 are as described above,

q is an integer of 0 to 47, r is an integer of 1 to 10, and q + r is an integer of 1 to 48. )

(B)成分が上記一般式(3)で示される芳香族アミノ基含有オルガノポリシロキサン又は上記一般式(4)で示される芳香族アミノ基含有オルガノポリシロキサンである

請求項1に係るダイカスト用離型剤組成物。 The component (A1) is an aralkyl group-containing organopolysiloxane represented by the general formula (1) or an aryl group-containing organopolysiloxane represented by the general formula (2).

2. The die casting separation according to claim 1, wherein the component (B) is an aromatic amino group-containing organopolysiloxane represented by the general formula (3) or an aromatic amino group-containing organopolysiloxane represented by the general formula (4). Mold composition.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008323837A JP5532600B2 (en) | 2008-12-19 | 2008-12-19 | Die-cast mold release agent composition and emulsion-type die-cast mold release agent using the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008323837A JP5532600B2 (en) | 2008-12-19 | 2008-12-19 | Die-cast mold release agent composition and emulsion-type die-cast mold release agent using the same |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010142845A true JP2010142845A (en) | 2010-07-01 |

| JP5532600B2 JP5532600B2 (en) | 2014-06-25 |

Family

ID=42563818

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008323837A Active JP5532600B2 (en) | 2008-12-19 | 2008-12-19 | Die-cast mold release agent composition and emulsion-type die-cast mold release agent using the same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5532600B2 (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013121851A1 (en) * | 2012-02-16 | 2013-08-22 | 東レ・ダウコーニング株式会社 | Mold release emulsion composition for die casting |

| WO2013122238A1 (en) | 2012-02-16 | 2013-08-22 | Dow Corning Toray Co., Ltd. | Mold release agent for die casting |

| JP2016175086A (en) * | 2015-03-18 | 2016-10-06 | ユシロ化学工業株式会社 | Die-casting method, die-cast product manufacturing method, and aqueous mold release agent for die-casting |

| CN107474931A (en) * | 2017-07-21 | 2017-12-15 | 南京信息工程大学 | A kind of water-based recessed soil matrix casting mold-releasing agent and preparation method thereof |

| EP4310157A4 (en) * | 2021-03-31 | 2025-12-03 | Nissan Chemical Corp | LAMINATE, RELEASE AGENT COMPOSITION AND METHOD FOR PRODUCING A PRODUCED SEMICONDUCER SUBSTRATE |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59189167A (en) * | 1983-04-12 | 1984-10-26 | Shin Etsu Chem Co Ltd | Heat-resistant silicone oil composition |

| JPH02283765A (en) * | 1989-04-25 | 1990-11-21 | Shin Etsu Chem Co Ltd | silicone composition |

| JPH0912886A (en) * | 1995-06-30 | 1997-01-14 | Toray Dow Corning Silicone Co Ltd | Silicone aqueous emulsion mold release agent and preparation thereof |

| JP2001114895A (en) * | 1999-10-21 | 2001-04-24 | Dow Corning Corp | HIGH-MOLECULAR WEIGHT ALKYLMETYL-ALKYLARYLSILOXANE TERPOLYMER HAVING LOW SiH CONTENT AND METHOD FOR PRODUCING THE SAME |

| JP2001259787A (en) * | 2000-03-17 | 2001-09-25 | Nicca Chemical Co Ltd | Parting agent for die casting |

-

2008

- 2008-12-19 JP JP2008323837A patent/JP5532600B2/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59189167A (en) * | 1983-04-12 | 1984-10-26 | Shin Etsu Chem Co Ltd | Heat-resistant silicone oil composition |

| JPH02283765A (en) * | 1989-04-25 | 1990-11-21 | Shin Etsu Chem Co Ltd | silicone composition |

| JPH0912886A (en) * | 1995-06-30 | 1997-01-14 | Toray Dow Corning Silicone Co Ltd | Silicone aqueous emulsion mold release agent and preparation thereof |

| JP2001114895A (en) * | 1999-10-21 | 2001-04-24 | Dow Corning Corp | HIGH-MOLECULAR WEIGHT ALKYLMETYL-ALKYLARYLSILOXANE TERPOLYMER HAVING LOW SiH CONTENT AND METHOD FOR PRODUCING THE SAME |

| JP2001259787A (en) * | 2000-03-17 | 2001-09-25 | Nicca Chemical Co Ltd | Parting agent for die casting |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013121851A1 (en) * | 2012-02-16 | 2013-08-22 | 東レ・ダウコーニング株式会社 | Mold release emulsion composition for die casting |

| WO2013122238A1 (en) | 2012-02-16 | 2013-08-22 | Dow Corning Toray Co., Ltd. | Mold release agent for die casting |

| JP2016175086A (en) * | 2015-03-18 | 2016-10-06 | ユシロ化学工業株式会社 | Die-casting method, die-cast product manufacturing method, and aqueous mold release agent for die-casting |

| CN107474931A (en) * | 2017-07-21 | 2017-12-15 | 南京信息工程大学 | A kind of water-based recessed soil matrix casting mold-releasing agent and preparation method thereof |

| CN107474931B (en) * | 2017-07-21 | 2020-09-01 | 南京信息工程大学 | A kind of water-based attapulgite-based die-casting release agent and preparation method thereof |

| EP4310157A4 (en) * | 2021-03-31 | 2025-12-03 | Nissan Chemical Corp | LAMINATE, RELEASE AGENT COMPOSITION AND METHOD FOR PRODUCING A PRODUCED SEMICONDUCER SUBSTRATE |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5532600B2 (en) | 2014-06-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5532600B2 (en) | Die-cast mold release agent composition and emulsion-type die-cast mold release agent using the same | |

| JP5819606B2 (en) | Organo-modified silicone, mold release agent containing the same, and production method thereof | |

| JP3524635B2 (en) | Silicone aqueous emulsion release agent and method for producing the same | |

| CN108339930A (en) | A kind of water based mold release agent and preparation method thereof applied to aluminum alloy die casting | |

| JP5930172B2 (en) | Release agent for die casting | |

| CN105218826A (en) | A kind of modified silicon oil and water base casting mold-releasing agent therefrom | |

| KR100740064B1 (en) | Release agents for die casting | |

| JPH05177294A (en) | Release agent composition for aluminum die casting | |

| WO2013121851A1 (en) | Mold release emulsion composition for die casting | |

| JP3318344B2 (en) | Silicone emulsion composition | |

| CN107614150B (en) | Release agent composition for casting | |

| JP2010082650A (en) | Die casting release agent composition | |

| JP4722542B2 (en) | Silicone emulsion composition | |

| FR2780065A1 (en) | AQUEOUS SILICONE RESIN EMULSION FOR WATERPROOFING CONSTRUCTION MATERIALS | |

| CN108856643A (en) | The ultra-thin magnesium alloy die casting release agent of plate in a kind of 3C electronic product casing frame | |

| JPH082475B2 (en) | Aluminum die cast release emulsion composition | |

| WO1992007673A1 (en) | Parting agent for die casting | |

| JP4717435B2 (en) | Silicone emulsion composition and mold release agent | |

| JPH0940866A (en) | Silicone aqueous emulsion and its production | |

| JP4058620B2 (en) | Aqueous release agent composition for die casting | |

| KR20170041497A (en) | Release agent or lubricant for using in mold or plunger of di-casting machine | |

| JP2019118925A (en) | Die release agent composition for die casting | |

| KR100566156B1 (en) | Aqueous release agent composition for die casting with excellent paintability | |

| JP3524157B2 (en) | Aqueous release agent for die-casting and method for imparting releasability to a die-cast molded article using the aqueous release agent | |

| JP2008069215A (en) | Branched organically modified silicone oil, method for producing the same, and mold release agent using the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101224 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20120808 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20120822 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130625 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130823 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140401 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5532600 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140414 |