JP2010051607A - Lower runner of umbrella - Google Patents

Lower runner of umbrella Download PDFInfo

- Publication number

- JP2010051607A JP2010051607A JP2008220644A JP2008220644A JP2010051607A JP 2010051607 A JP2010051607 A JP 2010051607A JP 2008220644 A JP2008220644 A JP 2008220644A JP 2008220644 A JP2008220644 A JP 2008220644A JP 2010051607 A JP2010051607 A JP 2010051607A

- Authority

- JP

- Japan

- Prior art keywords

- slit

- umbrella

- main body

- repelling

- tube wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Abstract

Description

本発明は、手を傷めることなく傘を安全に閉じることができるようにした傘の下ろくろに関する。 The present invention relates to an umbrella handle that can be safely closed without damaging the hand.

従来、傘を安全に開閉できるようにした種々の下ろくろが開発されている(例えば特許文献1,2参照)。

これらの従来技術は、いずれも上はじきを直接指の腹で押して、下ろくろに対するロックを解除するものである。しかるに、上はじきは薄い鉄片により構成され、ばね圧によって下ろくろとのロックを解除しにくくなっているため、これを強く指の腹で押すと手を傷めてしまうという問題点がある。

また本願出願人は、はじきに相当する金属製の係止片を把手を介して押す構成とした下ろくろを開発したが(特願2006−332926号)、係止片を下ろくろ側に配設する構造をとるため、下ろくろの構造が複雑になってしまうという問題点がある。

本発明は上記問題点を解決することを目的とするものである。

In each of these prior arts, the upper flip is pushed directly with the belly of the finger to release the lock on the bottom rail. However, the upper pallet is made of a thin iron piece, and it is difficult to release the lock on the bottom with the spring pressure, so that there is a problem that the hand is hurt if it is strongly pressed with the belly of the finger.

In addition, the applicant of the present application has developed a bottom roller configured to push a metal locking piece corresponding to a flip through a handle (Japanese Patent Application No. 2006-332926), but the locking piece is disposed on the bottom side. Therefore, there is a problem that the bottom structure becomes complicated.

The present invention aims to solve the above problems.

上記目的を達成するため本発明は、筒状の本体18に形成された連結部16が傘の骨部分12に連結し、該筒状の本体18を傘のシャフト部分に沿ってスライドさせて、傘の開閉を行うための下ろくろであって、前記シャフト部分に設けられた上はじき14を前記本体18の管璧28から突出する方向に開放するための前記本体18の管璧28に形成されたスリット30と、前記スリット30から突出する上はじき14の外側突出部14aの石突側の端面を係止するための前記本体の管璧28に形成された係止面8aと、前記スリット30の傘柄側の端部に隣接して前記本体18の管璧28に設けられた鍔部24と、前記スリット30に所定の間隔を存して略平行に対面するように前記鍔部24に揺動自在に形成された細長状の上はじき用操作片26とを備え、前記操作片26を前記本体18の内側方向に屈曲させて前記スリット30から突出する上はじき14の上側突出部14aを前記係止面8aから外れる方向に押し込むことができるようにしたものである。

また本発明は、前記上はじき用操作片26を可撓弾力性を有する部材により構成したものである。

また本発明は、前記スリット30の他に、前記本体18の管璧28に、下はじき用のスリットを設け、該スリットの傘柄側の端部に位置して、前記本体18の管璧28に前記シャフト部分に設けた下はじきと係合するための係止面を設けたものである。

また本発明は、筒状の本体18に形成された連結部16が傘の骨部分12に連結し、該筒状の本体18を傘のシャフト部分に沿ってスライドさせて、傘の開閉を行うための下ろくろであって、前記シャフト部分に設けられた上はじき14を前記本体18の管璧28から突出する方向に開放するための前記本体18の管璧28に形成されたスリット30と、前記スリット30から突出する上はじき14の外側突出部14aの石突側の端面を係止するための前記本体の管璧28に形成された係止面8aと、前記スリット30の傘柄側の端部に隣接して前記本体18の管璧28に設けられた鍔部24と、前記スリット30に所定の間隔を存して略平行に対面するように前記鍔部24に揺動自在に形成された細長状の上はじき用操作片26とを備え、前記操作片26を前記本体18の内側方向に屈曲させて前記スリット30から突出する上はじき14の上側突出部14aを前記係止面8aから外れる方向に押し込むことができるようにし、前記スリット30の傘柄側の端部に位置して、前記本体18の管璧28に前記シャフト部分に設けた下はじきと係合するための係止面40を設け、前記上はじき用操作片26にU字状にスリットを設けてU字状の下はじき用操作片38を揺動自在に形成し、該下はじき用操作片38を前記本体18の内側方向に屈曲させて前記スリット30から突出する下はじき34の外側突出部34aを前記下はじき用係止面40から外れる方向に押し込むことができるようにしたものである。

In order to achieve the above object, according to the present invention, the connecting

In the present invention, the upper

Further, in the present invention, in addition to the

Further, according to the present invention, the connecting

本発明は上述の如く構成したので、指を傷めることなく安全に傘を閉じることができる。 Since the present invention is configured as described above, the umbrella can be safely closed without damaging the finger.

以下に本発明の実施の形態を添付した図面を参照して詳細に説明する。

図4は、折り畳み式洋傘のシャフト部分と、骨組み部分の一部を示す説明図であり、傘を開いた状態を示している。シャフト部分2は、3本のシャフトからなり、傘柄が取り付けられた一番太い下部シャフト(図示省略)には、中間スライドシャフト4がスライド自在に嵌挿配置され、該スライドシャフト4に上部スライドシャフト6がスライド自在に嵌挿配置されている。

Embodiments of the present invention will be described below in detail with reference to the accompanying drawings.

FIG. 4 is an explanatory view showing a shaft portion of a foldable western umbrella and a part of a skeleton portion, and shows a state in which the umbrella is opened. The

前記シャフト部分2には、下ろくろ8がスライド可能に嵌挿配置されている。前記上部スライドシャフト6の上端には、石突が固設された上ろくろ10が固設されている。前記上部スライドシャフト6の上部の所定の位置には上はじき14が内蔵され、該上はじき14は、その上側突出部14aが、前記スライドシャフト6の管璧に形成されたスリットから外部に弾発的に突出している。

On the

前記上はじき14は、金属板により構成され、外側突出部14aにシャフト6に対して直角方向に延びるストッパー部14bが形成されている。上はじき14は、その外側突出部14aを押圧することにより、シャフト6から引っ込む方向に揺動させることができるように構成されている。この上はじき14の構成は、従来公知であるためその詳細な説明を省略する。

The

前記下部シャフトと、スライドシャフト4,6から成るシャフト部分2は全体として伸縮自在な入れ子式のいわゆる中棒を構成している。前記シャフト部分2は、3本のシャフトが互いに相対回転しないように、互いに回転防止機構(図示省略)を介して嵌合し、3本のシャフトは軸方向にのみ互いにスライド自在に嵌合している。

The lower shaft and the

前記上ろくろ10と下ろくろ8には、折り畳み自在な骨部分12が結合している。シャフト部分2を伸ばし、下ろくろ8を、シャフト部分2に沿って先端(石突)方向に移動させると、図4に示すように、骨部分12が、下ろくろ8の移動に伴って開く。下ろくろ8は、シャフト部分2に設けられたストッパー15(図2参照)に係止される位置まで移動すると、連結部16の下側に位置して、前記下ろくろ8に形成された係止面8aが上はじき14によって解除可能に係止されるように構成されている。

A

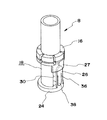

図1乃至図3は、本発明の第1の実施形態の下ろくろ8の構造を示している。下ろくろ8の本体18は、合成樹脂の筒体により構成され、中空部20がシャフト部分2にスライド自在に遊嵌している。本体18の中間部には、フランジ状に連結部16が形成され、該連結部16の外周面に形成された凹溝部22には、骨部分12の受骨12aの各一端が枢支され、下ろくろ8は、受骨12aとの結合によって、シャフト部分2に対して、回転方向の移動が規制されている。

1 to 3 show the structure of the

前記連結部16の、傘柄側の端部には、下ろくろ8の軸方向に対して垂直な係止面8aが形成されている。前記本体18の、傘柄側の端部には、前記連結部16との間に、前記上はじき14の外側突出部14aの全長と略同一の長さの間隔を存して、鍔部24が一体的に形成され、該鍔部24の外径部に、前記連結部16側に延びる、弾力性と可撓性を有する、操作片26が一体的に、本体18の軸方向に沿って、形成されている。

At the end of the connecting

前記操作片26の上部開放端側は、連結部16に一体的に形成された薄板状のカバー片27とこれに対して内側に位置して平行に対向している。このカバー片27は、操作片26が外方に跳ね上がるのを防止している。前記本体18の、前記連結部16と鍔部24との間の筒状部の管璧28には、上はじき14の外側突出部14aを管璧28から開放する所定の幅のスリット30が形成されている。

The upper open end side of the

前記スリット30の横幅は、本実施形態では、管璧28を円周方向に略90度切欠した範囲に設定されている。前記スリット30の上端面は、前記連結部16の下面と同一面上に形成され、該下面とともに、係止面8aを構成している。前記操作片26の先端は、前記連結部16の係止面8aを有する下部端面と所定の間隔を存して対向し、該操作片26は、前記鍔部24から、前記スリット30に対して所定の間隔を存して、平行に延びている。

In this embodiment, the lateral width of the

前記操作片26の横幅は、前記上はじき14の外側突出部14aの厚みよりも広く設定され、且つ、前記スリット30の横幅よりも狭く設定されている。前記操作片26は、下ろくろ8の係止面8aが、図2に示すように、上はじき14によって下方向の移動が係止された状態において、上はじき14の外側突出部14aに対向している。

The lateral width of the

上記した構成において、傘が閉じた状態では、下ろくろ8は、上はじき14の下方に位置している。傘を開くときは、シャフト部分2を伸ばし、下ろくろ8をシャフト部分2に沿って先端の石突方向に、手操作により、骨部分12からの弾発力に抗して、移動させる。この移動中、下ろくろ8が上はじき14を通過するときは、上はじき14は、下ろくろ8の中空部20の内周面により、シャフト部分2の内側方向に押圧され、外側突出部14aが、ばね力に抗してシャフト部分2の内側方向に引っ込む。

In the above-described configuration, when the umbrella is closed, the

更に下ろくろ8がストッパー15に衝突する位置まで移動すると、下ろくろ8のスリット30が上はじき14の外側突出部14aの直上に移動する。スリット30が上はじき14の外側突出部14aに移動すると、図2に示すように、上はじき14は、下ろくろ8からの押圧力から開放され、外側突出部14aが、シャフト部分2の内部から、ばね力により外側に突出し、外側突出部14aのストッパー部14bが、下ろくろ8の係止面8aと対面する。

When the

これにより、下ろくろ8は、上はじき14により、シャフト部分2に沿った下方向の移動が阻止され、下ろくろ8は、上部スライドシャフト6の先端側の所定位置に係止される。下ろくろ8が上はじき14に係止された状態において、図4に示すように、傘が開いた状態となる。傘を閉じたいときは、操作片26を指の腹で押し、これを屈曲させて上はじき14を図3に示すように、シャフト部分2の内側方向に押し込む。

As a result, the

これにより、上はじき14の下ろくろ8に対する係止が外れ、下ろくろ8は自由にシャフト部分2に沿って傘柄方向にスライド自在となる。該状態において、下ろくろ8をシャフト部分2に沿って、傘柄側にスライドさせ、傘を閉じ、且つシャフト部分2を短縮させる。

As a result, the

尚、本実施形態では、伸縮型のシャフト部分2に下はじきを設けていないが、下はじきを上はじき14に対して円周方向にずらして設けても良い。この場合には、この下はじき用のスリットを図1に示すスリット30に隣接して、本体18の管璧28に設ける。この場合、管璧28には下はじき用スリットによって、下はじきの下端と係合する係止面(図示省略)が形成される。この下はじき用のスリットの構造は一般的な構成であるためその図示及び説明を省略する。

In the present embodiment, the

下はじきを指の腹で押し、下はじきによる下ろくろ8に対する係止を解除する動作は比較的弱い押圧力で行うことができるので、下ろくろ8に下はじき用の操作片を特に設けなくても良い。勿論、下ろくろ8に下はじき用の操作片を設けても良く、その場合の実施形態については後述する。シャフト部分2に下はじきを設け、下ろくろ8に下はじき用のスリットを設けた場合、傘を閉じると、下ろくろ8側の、下はじき用のスリット(図示省略)の係止面(図示省略)に、下はじきの上側突出部が係合し、下ろくろ8は下はじきに係止される。この係止は、下はじきを指の腹で軽く押すことで解除することができる。

Since the operation of releasing the repelling with the belly of the finger and releasing the locking of the

次に図5乃至図8を参照して、通常の長傘に使用する下ろくろの実施形態について説明する。この実施形態の下ろくろは、通常の長傘以外に、シャフト部分が伸縮する下はじきを備えた折り畳み式洋傘にも適用することができる。

図7において、符号32は、長傘のシャフト部分であり、これに上はじき(図示省略)と下はじき34が設けられている。

Next, with reference to FIG. 5 thru | or FIG. 8, embodiment of the ironing board used for a normal long umbrella is demonstrated. The armor of this embodiment can be applied not only to a normal long umbrella but also to a foldable western umbrella having a lower repellency in which a shaft portion expands and contracts.

In FIG. 7,

このシャフト部分32に下ろくろ8がスライド自在に嵌挿配置されている。前記上はじきと下はじき34は、下ろくろ8のスリット30の、シャフト部分32に沿った、移動線上に配置されている。下ろくろ8の下はじき用操作片26には、U字状に切り込み線36が形成され、この切り込み線36によって前記上はじき用操作片26に、弾力性と可撓性を備えたU字状の下はじき用操作片38が形成されている。下ろくろ8の他の構成は、図1乃至図3に示す第1の実施形態の下ろくろ8の構成と同一であり、互いの同一の部分には同一の符号を付して対応関係を明らかにしている。

The

上記した構成において、下ろくろ8をシャフト部分32に、上はじきによって係止する作用は、第1の実施形態と同一であるのでその説明を省略する。

長傘を閉じるとき、シャフト部分32に沿って、下ろくろ8を傘柄側に、鍔部24の内周面が、下はじき34を越えるまでスライドさせる。下ろくろ8のこのスライドにより、下はじき34が下ろくろ8のスリット30内に位置すると、下はじき34の外側突出部34aはばね力によって、シャフト部分32から突出し、下はじき用操作片38に当接して、これを若干外方に押し上げる。

In the above-described configuration, the action of locking the

When closing the long umbrella, slide the

このとき下ろくろ8の鍔部24の、下ろくろ8の軸方向に対して垂直な係止面40と、下はじき34のストッパー部は対面し、このストッパー部と係止面40とによって、下ろくろ8の、シャフト部分32に沿った石突方向の移動が係止される。この下ろくろ8が、下はじき34によって係止された状態において、傘は閉じた状態となる。

At this time, the locking

この係止状態を解除したいときは、下はじき用操作片38を図8に示すように、指で押し、操作片38を本体18の内側方向に屈曲させて、下はじき34をシャフト部分32の内側方向に引っ込める。これにより、下はじき34の、下ろくろ8に対する係止が外れ、下ろくろ8は自由にシャフト部分32に沿って、石突方向にスライド自在となる。

When it is desired to release this locked state, as shown in FIG. 8, the lower

2 シャフト部分

4 スライドシャフト

6 上部スライドシャフト

8 下ろくろ

8a 係止面

10 上ろくろ

12 骨部分

12a 受骨

14 上はじき

14a 外側突出部

14b ストッパー部

15 ストッパー

16 連結部

18 本体

20 中空部

22 凹溝部

24 鍔部

26 操作片

27 カバー片

28 管璧

30 スリット

32 シャフト部分

34 下はじき

34a 外側突出部

36 切り込み線

38 操作片

40 係止面

2 Shaft portion 4

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008220644A JP5270262B2 (en) | 2008-08-29 | 2008-08-29 | Under the umbrella |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008220644A JP5270262B2 (en) | 2008-08-29 | 2008-08-29 | Under the umbrella |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010051607A true JP2010051607A (en) | 2010-03-11 |

| JP2010051607A5 JP2010051607A5 (en) | 2011-09-15 |

| JP5270262B2 JP5270262B2 (en) | 2013-08-21 |

Family

ID=42068151

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008220644A Expired - Fee Related JP5270262B2 (en) | 2008-08-29 | 2008-08-29 | Under the umbrella |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5270262B2 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20120174953A1 (en) * | 2011-01-06 | 2012-07-12 | Hsia-Hui Chen | Runner fastening device for an umbrella |

| JP2013085949A (en) * | 2011-10-20 | 2013-05-13 | Jui-Chieh Chen | Umbrella |

| JP2014133129A (en) * | 2013-01-10 | 2014-07-24 | Chuanyang Chen | Opening/closing device of folding umbrella |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5413764U (en) * | 1977-06-30 | 1979-01-29 | ||

| JPH04110515U (en) * | 1991-03-06 | 1992-09-25 | 福太洋傘工廠股ふん有限公司 | potter's wheel under a western umbrella |

| JPH09154610A (en) * | 1995-12-01 | 1997-06-17 | Mikawa Shiyousuke | Ring of umbrella |

| JP2000050928A (en) * | 1998-08-14 | 2000-02-22 | Zoei Go | Lower runner for manually operating umbrella |

-

2008

- 2008-08-29 JP JP2008220644A patent/JP5270262B2/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5413764U (en) * | 1977-06-30 | 1979-01-29 | ||

| JPH04110515U (en) * | 1991-03-06 | 1992-09-25 | 福太洋傘工廠股ふん有限公司 | potter's wheel under a western umbrella |

| JPH09154610A (en) * | 1995-12-01 | 1997-06-17 | Mikawa Shiyousuke | Ring of umbrella |

| JP2000050928A (en) * | 1998-08-14 | 2000-02-22 | Zoei Go | Lower runner for manually operating umbrella |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20120174953A1 (en) * | 2011-01-06 | 2012-07-12 | Hsia-Hui Chen | Runner fastening device for an umbrella |

| JP2012143532A (en) * | 2011-01-06 | 2012-08-02 | Hsia-Hui Chen | Runner fastening device for umbrella |

| US8459281B2 (en) * | 2011-01-06 | 2013-06-11 | Hsia-Hui Chen | Runner fastening device for an umbrella |

| JP2013085949A (en) * | 2011-10-20 | 2013-05-13 | Jui-Chieh Chen | Umbrella |

| JP2014133129A (en) * | 2013-01-10 | 2014-07-24 | Chuanyang Chen | Opening/closing device of folding umbrella |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5270262B2 (en) | 2013-08-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5398782B2 (en) | Runner fixing device for umbrella | |

| US3467116A (en) | Pick-up walking stick | |

| JP5270262B2 (en) | Under the umbrella | |

| JP2008142310A (en) | Runner engagement mechanism | |

| JP6966576B2 (en) | Needle automatic retractable blood collection needle | |

| BR0116050A (en) | Medical needle safety guard | |

| JP6169794B2 (en) | Safety blood collection needle | |

| JP5481533B2 (en) | umbrella | |

| KR101707129B1 (en) | Length adjustable walking assistance device | |

| WO2009125612A1 (en) | Telescopic shaft mechanism for use in folding umbrella | |

| CN109963479B (en) | Umbrella | |

| US2515493A (en) | Folding umbrella | |

| KR101053902B1 (en) | Safety umbrella | |

| JP2008188325A (en) | Self-sustaining stick body | |

| JP2010051607A5 (en) | ||

| JP2019030632A (en) | Quick and laborsaving device for opening/closing umbrella | |

| JP5575296B1 (en) | Telescopic shaft for foldable umbrella | |

| KR101517536B1 (en) | Door knob | |

| CN208463127U (en) | Multi-fold umbrella opens the fastening structure that closes one's umbrella | |

| JP3170930U (en) | umbrella | |

| JP5759050B1 (en) | umbrella | |

| JP3156397U (en) | Umbrella with a retractable center rod | |

| JP2008188185A (en) | Contractible one-touch folding fan | |

| JP5916699B2 (en) | Folding umbrella opening and closing device | |

| US3003511A (en) | Collapsible umbrellas |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110802 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110805 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130329 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130404 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130412 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130502 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130509 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |