JP2009192049A - Nonseparable angular contact ball bearing - Google Patents

Nonseparable angular contact ball bearing Download PDFInfo

- Publication number

- JP2009192049A JP2009192049A JP2008036072A JP2008036072A JP2009192049A JP 2009192049 A JP2009192049 A JP 2009192049A JP 2008036072 A JP2008036072 A JP 2008036072A JP 2008036072 A JP2008036072 A JP 2008036072A JP 2009192049 A JP2009192049 A JP 2009192049A

- Authority

- JP

- Japan

- Prior art keywords

- outer ring

- angular contact

- radius

- balls

- inner ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/14—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load

- F16C19/16—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with a single row of balls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/583—Details of specific parts of races

- F16C33/585—Details of specific parts of races of raceways, e.g. ribs to guide the rollers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/30—Angles, e.g. inclinations

- F16C2240/34—Contact angles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/40—Linear dimensions, e.g. length, radius, thickness, gap

- F16C2240/46—Gap sizes or clearances

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/40—Linear dimensions, e.g. length, radius, thickness, gap

- F16C2240/70—Diameters; Radii

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mounting Of Bearings Or Others (AREA)

- Rolling Contact Bearings (AREA)

Abstract

Description

本発明は、外輪を加熱することによって内輪と外輪の間に玉を組み込んで組み立てる非分離型アンギュラ玉軸受に関し、特にかかり代を特定した非分離型アンギュラ玉軸受に関する。 The present invention relates to a non-separable angular contact ball bearing that is assembled by assembling a ball between an inner ring and an outer ring by heating an outer ring, and more particularly to a non-separable angular contact ball bearing with a specified allowance.

アンギュラ玉軸受は、転動体に玉を用いたアンギュラ接触型のラジアル軸受であり、それを構成する内輪または外輪の少なくとも一方において、軌道面に隣接する肩部の軸方向の片側が削られてカウンターボアが形成されている(例えば、特許文献1を参照)。

そして、非分離型アンギュラ玉軸受では、かかり代(以下、半径分の値を示す)の寸法が設定されている。具体的には、外輪にカウンターボアが形成された非分離型アンギュラ玉軸受の場合では、玉を内輪に寄せたときに玉の配列する外接円の半径と外輪のカウンターボアの最小半径との差を、内輪にカウンターボアが形成された非分離型アンギュラ玉軸受の場合では、内輪のカウンターボアの最大半径と玉を外輪に寄せたときに玉の配列する内接円の半径との差を、かかり代と呼ぶ。組立の際、非分離型アンギュラ玉軸受では、外輪が加熱されて熱膨張して玉がかかり代を乗り越えることによって、内外輪の軌道面間に玉が組み込まれる。そして、組立後の取扱時において、かかり代の存在によって、外輪あるいは内輪が外れにくくなって、非分離型アンギュラ玉軸受が実現される。

従来、外輪にカウンターボアを形成した非分離型アンギュラ玉軸受において、かかり代:W(mm)を、0.005Dw≦W≦0.030Dw、とすることが提案されている(特許文献2を参照)。ここで、Dwは玉の直径である。また、組立時の外輪の加熱温度として、100℃程度の温度が推奨されている。

In the non-separable angular contact ball bearing, the dimension of the allowance (hereinafter, a value corresponding to the radius) is set. Specifically, in the case of a non-separable angular contact ball bearing with a counter bore formed on the outer ring, the difference between the radius of the circumscribed circle where the balls are arranged and the minimum radius of the counter bore of the outer ring when the ball is brought close to the inner ring In the case of a non-separable angular contact ball bearing with a counter bore formed in the inner ring, the difference between the maximum radius of the counter bore of the inner ring and the radius of the inscribed circle where the balls are arranged when the ball is brought to the outer ring, This is called a bill. At the time of assembly, in the non-separable angular ball bearing, the outer ring is heated and thermally expanded to hit the ball, and the ball is assembled between the raceway surfaces of the inner and outer rings. When handling after assembly, the presence of the allowance makes it difficult for the outer ring or the inner ring to come off, thereby realizing a non-separable angular ball bearing.

Conventionally, in a non-separable angular contact ball bearing in which a counter bore is formed on an outer ring, it has been proposed that the allowance: W (mm) is 0.005 Dw ≦ W ≦ 0.030 Dw (see Patent Document 2). ). Here, Dw is the diameter of the ball. Further, a temperature of about 100 ° C. is recommended as the heating temperature of the outer ring during assembly.

一般に、非分離型アンギュラ玉軸受において、かかり代が小さい場合、組立時の外輪の加熱温度を低くできるために、軸受の組立は容易であるが、取扱時に外輪あるいは内輪が外れ易いとい問題がある。反対に、かかり代が大きい場合、組立時の外輪の加熱温度を高くする必要があるために、軸受の組立が困難であり、加熱温度が不足した際には、玉に傷が入るという問題がある。

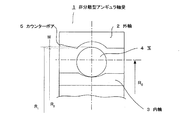

そして、従来技術(特開2005−009643)の問題点を、呼び番号7906Aの外輪にカウンターボアを形成したアンギュラ玉軸受の場合で、図1を用いて説明する。図では、内輪の中心軸と外輪の中心軸を重ねている。図1において、1は軸受、2は外輪、3は内輪、4は玉である。なお、保持器は省略した。

7906Aの外形寸法は、内径×外径×幅=30mm×47mm×9mm、玉の直径:Dw=4.763mm、接触角30度に対応するラジアル内部隙間:Δr=0.0574mmである。玉の直径から、かかり代Wの推奨値は、0.024mm≦W≦0.143mmと計算される。

Generally, in a non-separable angular contact ball bearing, when the allowance is small, the heating temperature of the outer ring during assembly can be lowered, so that the assembly of the bearing is easy, but there is a problem that the outer ring or the inner ring is easily detached during handling. . On the other hand, when the cost is large, it is necessary to increase the heating temperature of the outer ring at the time of assembly, so that it is difficult to assemble the bearing, and when the heating temperature is insufficient, the ball may be damaged. is there.

The problem of the prior art (Japanese Patent Laid-Open No. 2005-009643) will be described with reference to FIG. 1 in the case of an angular ball bearing in which a counter bore is formed on the outer ring of the reference number 7906A. In the figure, the central axis of the inner ring and the central axis of the outer ring are overlapped. In FIG. 1, 1 is a bearing, 2 is an outer ring, 3 is an inner ring, and 4 is a ball. The cage was omitted.

The external dimensions of 7906A are inner diameter × outer diameter × width = 30 mm × 47 mm × 9 mm, ball diameter: Dw = 4.763 mm, and radial internal gap corresponding to a contact angle of 30 degrees: Δr = 0.0574 mm. From the diameter of the ball, the recommended value of the allowance W is calculated as 0.024 mm ≦ W ≦ 0.143 mm.

ここで、推奨されるかかり代の最大値であるW=0.143mmの場合において、外輪を100℃に加熱した際のかかり代Hを計算する。軸受の材料は軸受鋼(SUJ2)とする。加熱前の諸寸法は次のとおりである。

・軸受の外周と内周の中央半径:R0=(30+47)/4=19.250mm

・玉を内輪に寄せたときに玉の配列する外接円の半径

:R1=R0+Dw/2−Δr/4=21.617mm

・外輪のカウンターボアの最小半径:R2=R1−W=21.474mm

室温を20℃、軸受の材料(SUJ2)の線膨張係数:α=12.5×10−6(℃−1)とすると、

・100℃における外輪のカウンターボアの最小半径

:R3=R2×(1+α×(100−20))=21.495mm

従って、

100℃に加熱した際のかかり代:H=R1−R3=0.122mm

となる。0.122mmのかかり代(H)は大きな値であり、100℃の加熱温度では、軸受の組立は容易ではなく、無理に組み立てると玉の傷の発生は避けられないとい問題がある。仮に、かかり代W0.143mmの外輪において、加熱時のかかり代Hを0mmとするためには、約550℃に加熱する必要があり、現実的には組立は不可能であるという問題もある。

Here, in the case of W = 0.143 mm which is the maximum value of the recommended allowance, the allowance H when the outer ring is heated to 100 ° C. is calculated. The bearing material is bearing steel (SUJ2). Various dimensions before heating are as follows.

・ Center radius of the outer periphery and inner periphery of the bearing: R 0 = (30 + 47) /4=19.250 mm

The radius of the circumscribed circle in which the balls are arranged when the balls are brought to the inner ring: R 1 = R 0 + Dw / 2−Δr / 4 = 21.617 mm

・ Minimum radius of counter bore of outer ring: R 2 = R 1 −W = 21.474 mm

Assuming that the room temperature is 20 ° C. and the linear expansion coefficient of the bearing material (SUJ2) is α = 12.5 × 10 −6 (° C. −1 ),

・ Minimum radius of counter bore of outer ring at 100 ° C .: R 3 = R 2 × (1 + α × (100−20)) = 21.495 mm

Therefore,

Cost for heating to 100 ° C .: H = R 1 −R 3 = 0.122 mm

It becomes. The allowance (H) of 0.122 mm is a large value, and at a heating temperature of 100 ° C., the assembly of the bearing is not easy, and there is a problem that the occurrence of ball scratches is inevitable when forcibly assembled. Temporarily, in an outer ring with a allowance W of 0.143 mm, in order to set the allowance H at the time of heating to 0 mm, it is necessary to heat to about 550 ° C., and there is a problem that assembly is impossible in practice.

また、100℃加熱時のかかり代(H)を0mmとするためには、かかり代Wは0.021mmとする必要があるが、この値は、従来技術(特開2005−009643)が示すかかり代Wの最小値0.024mmを下回ることとなって、かかり代が実現しないという問題もある。

更に、従来技術(特開2005−009643)におけるかかり代Wの最小値0.024mmを検討する。組立後における軸受の状態は図1のとおりである。図示しない軸受の下半分にも、ラジアル内部隙間の半分の値である0.0287mmが存在する。そのため、軸受を実際に取り扱う際には、図1において、軸受の内輪は、0.0287mm下に下がり、玉の配列する外接円も0.0287mm下に移動する。そのため、玉の配列する外接円の位置は、外輪におけるカウンターボアの最小半径の位置より、下側に位置することとなり、外輪が外れ易いという問題もある。

Further, in order to set the cost (H) during heating at 100 ° C. to 0 mm, the cost W needs to be 0.021 mm. This value is indicated by the prior art (Japanese Patent Laid-Open No. 2005-009643). There is also a problem that the allowance is not realized because the allowance W is below the minimum value 0.024 mm.

Furthermore, the minimum value 0.024 mm of the starting allowance W in the prior art (Japanese Patent Laid-Open No. 2005-009643) is examined. The state of the bearing after assembly is as shown in FIG. The lower half of the bearing (not shown) also has a value of 0.0287 mm, which is half the radial internal clearance. Therefore, when the bearing is actually handled, in FIG. 1, the inner ring of the bearing is lowered by 0.0287 mm, and the circumscribed circle in which the balls are arranged is also moved by 0.0287 mm. Therefore, the position of the circumscribed circle where the balls are arranged is located below the position of the minimum radius of the counterbore in the outer ring, and there is a problem that the outer ring is easily detached.

このように、従来技術の非分離型アンギュラ玉軸受では、加熱温度が低くて作業が容易であること、組立時に玉に傷が発生しないこと、取扱時に分離しないことを完全に満足できないという問題がある。

そして、玉に固体潤滑膜が形成された非分離型アンギュラ玉軸受においては、組立時に固体潤滑膜が損傷し、使用時の軸受寿命が短くなるという問題がある。また、固体潤滑膜が玉に形成されておらず、内輪および外輪の軌道面に形成された非分離型アンギュラ玉軸受においても、組立時に玉が損傷した場合は、玉の傷が内輪および外輪の軌道面に形成された固体潤滑膜を損傷させ、使用時の軸受寿命が短くなるという問題がある。更に、組立時の外輪の加熱温度が高くなるほど、加熱時に固体潤滑膜が酸化劣化して、使用時の軸受寿命が短くなるという問題がある。このため、玉の表面、内輪の軌道面、外輪の軌道面のいずれか一カ所以上に固体潤滑膜を形成した従来の非分離型アンギュラ玉軸受においては、組立時に固体潤滑膜が損傷したり、酸化劣化したりすることによって、固体潤滑膜の寿命が低下して使用時の軸受寿命が短くなるという問題がある。

このように、従来の非分離型アンギュラ玉軸受は、かかり代が適切に設計されていないため、組立時の加熱温度が高くて作業が困難である、組立時に玉に傷が入る、取扱時に外輪または内輪が分離する、そして、使用時の軸受寿命が短い、という問題があった。

As described above, in the conventional non-separable angular contact ball bearing, there are problems that the heating temperature is low and the operation is easy, the ball is not damaged during assembly, and it is not completely satisfied that the ball is not separated during handling. is there.

And in the non-separable angular contact ball bearing in which the solid lubricating film is formed on the ball, there is a problem that the solid lubricating film is damaged at the time of assembly and the bearing life in use is shortened. Also, in non-separable angular contact ball bearings formed on the raceway surfaces of the inner ring and outer ring, where the solid lubricating film is not formed on the balls, if the balls are damaged during assembly, the balls will be scratched on the inner and outer rings. There is a problem that the solid lubricating film formed on the raceway surface is damaged and the bearing life in use is shortened. Furthermore, as the heating temperature of the outer ring at the time of assembly increases, there is a problem that the solid lubricating film deteriorates by oxidation during heating and the bearing life in use is shortened. For this reason, in conventional non-separable angular contact ball bearings in which a solid lubricating film is formed on one or more of the ball surface, the inner ring raceway surface, and the outer ring raceway surface, the solid lubricating film is damaged during assembly, Due to oxidative deterioration, there is a problem that the life of the solid lubricating film is reduced and the life of the bearing in use is shortened.

As described above, the conventional non-separable angular contact ball bearings are not designed with appropriate margins, so the heating temperature during assembly is high and the work is difficult, the balls are damaged during assembly, and the outer ring is handled during handling. Or there was a problem that the inner ring was separated and the bearing life in use was short.

本発明はこのような問題点に鑑みてなされたものであり、かかり代を適切に設計することによって、組立時の加熱温度が低くて作業が容易である、組立時に玉に傷が入らない、取扱時に外輪または内輪が分離しない、そして、使用時の軸受寿命が長い、という非分離型アンギュラ玉軸受を提供することを目的とする。 The present invention has been made in view of such problems, and by appropriately designing the allowance, the heating temperature at the time of assembly is low and the operation is easy, the ball is not damaged during assembly, It is an object of the present invention to provide a non-separable angular contact ball bearing in which an outer ring or an inner ring is not separated during handling and a bearing life in use is long.

上記問題を解決するため、本発明は次のように構成したものである。

なお、以下に記載の半径、直径、かかり代、隙間などの寸法の単位はmmである。

請求項1に記載の発明は、軸受鋼からなる外輪の内側の軌道面に隣接する肩部の軸方向の片側が削られてカウンターボアが形成され、前記外輪を加熱することによって内輪と外輪の間に玉を組み込んで組み立てられる非分離型アンギュラ玉軸受において、

前記玉を前記内輪に寄せたときに玉の配列する外接円の半径R1と前記外輪のカウンターボアの最小半径との差であるかかり代を0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.25×10−5×R1×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたものである。

請求項2に記載の発明は、軸受鋼からなる外輪と対向する内輪の外側の軌道面に隣接する肩部の軸方向の片側が削られてカウンターボアが形成され、前記外輪を加熱することによって前記内輪と外輪の間に玉を組み込んで組み立てられる非分離型アンギュラ玉軸受において、前記外輪の軌道面の最大半径をR7とするときに、前記内輪のカウンターボアの最大半径と前記玉を外輪に寄せたときに玉の配列する内接円の半径との差であるかかり代を、0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.25×10−5×R7×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたものである。

請求項3に記載の発明は、マルテンサイトステンレス鋼からなる外輪の内側の軌道面に隣接する肩部の軸方向の片側が削られてカウンターボアが形成され、前記外輪を加熱することによって前記内輪と外輪の間に玉を組み込んで組み立てられる非分離型アンギュラ玉軸受において、前記玉を前記内輪に寄せたときに玉の配列する外接円の半径R1と前記外輪のカウンターボアの最小半径との差であるかかり代を、0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.01×10−5×R1×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたものである。

請求項4に記載の発明は、マルテンサイトステンレス鋼からなる外輪と対向する内輪の外側の軌道面に隣接する肩部の軸方向の片側が削られてカウンターボアが形成され、前記外輪を加熱することによって前記内輪と外輪の間に玉を組み込んで組み立てられる非分離型アンギュラ玉軸受において、前記外輪の軌道面の最大半径をR7とするときに、前記内輪のカウンターボアの最大半径と前記玉を外輪に寄せたときに玉の配列する内接円の半径との差であるかかり代を、0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.01×10−5×R7×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたものである。

請求項5に記載の発明は、外輪の加熱温度と組立時の室温との差を、150℃以下としたものである。

請求項6に記載の発明は、前記玉の表面、前記内輪および外輪の軌道面のいずれか一カ所以上に固体潤滑膜を形成したものである。

In order to solve the above problems, the present invention is configured as follows.

In addition, the unit of dimensions, such as a radius, a diameter, a margin, a clearance gap, described below is mm.

According to the first aspect of the present invention, one side in the axial direction of the shoulder adjacent to the inner raceway surface of the outer ring made of bearing steel is scraped to form a counterbore, and the inner ring and the outer ring are heated by heating the outer ring. In non-separable angular contact ball bearings assembled with balls in between,

0.0125mm barbs margin is the difference between the minimum radius of counterbore radius R 1 and the outer ring of the circumscribed circle of the sequence of balls when asked the balls to the inner ring, or half the value of the radial clearance From the larger numerical value of 1.25 × 10 −5 × R 1 × (heating temperature of the outer ring−room temperature during assembly) +0.010 mm.

According to the second aspect of the present invention, a counter bore is formed by cutting one side in the axial direction of the shoulder adjacent to the outer raceway surface of the inner ring facing the outer ring made of bearing steel, and heating the outer ring in non-separable angular contact ball bearing assembled by incorporating a ball between the inner ring and the outer ring, the maximum radius of the raceway surface of the outer ring when the R 7, the outer ring of the ball and the maximum radius of the inner ring of the counterbore From the larger value of 0.0125 mm, or half of the radial internal gap, the difference between the radius of the inscribed circle where the balls are arranged when the ball is moved to 1.25 × 10 −5 × R 7 × (outer ring heating temperature−room temperature during assembly) +0.010 mm.

According to a third aspect of the present invention, there is provided a counterbore formed by shaving one axial side of the shoulder adjacent to the inner raceway surface of the outer ring made of martensitic stainless steel, and the inner ring is heated by heating the outer ring. In the non-separable angular contact ball bearing assembled by incorporating balls between the outer ring and the outer ring, a radius R 1 of a circumscribed circle in which the balls are arranged when the balls are brought close to the inner ring and a minimum radius of the counter bore of the outer ring The difference, which is the difference, is 0.0125 mm or half of the radial internal gap, whichever is larger, 1.01 × 10 −5 × R 1 × (heating temperature of outer ring−room temperature during assembly) +0 The range is .010 mm.

According to a fourth aspect of the present invention, one side in the axial direction of the shoulder adjacent to the outer raceway surface of the inner ring facing the outer ring made of martensite stainless steel is scraped to form a counterbore, and the outer ring is heated. wherein the inner ring and the non-separable angular contact ball bearing assembled by incorporating a ball between the outer ring, the maximum radius of the raceway surface of the outer ring when the R 7, wherein the maximum radius of the inner ring counterbore ball by From the larger value of 0.0125 mm or half of the radial internal clearance, 1.01 × 10 6 is calculated as the difference between the radius of the inscribed circle in which the balls are arranged when the ball is moved to the outer ring. -5 × R 7 × (outer ring heating temperature−room temperature during assembly) +0.010 mm.

In the fifth aspect of the present invention, the difference between the heating temperature of the outer ring and the room temperature during assembly is set to 150 ° C. or less.

According to a sixth aspect of the present invention, a solid lubricating film is formed on any one or more of the surface of the ball, the raceway surface of the inner ring and the outer ring.

まず、かかり代の上限値に関する効果を説明する。玉に固体潤滑膜を形成したアンギュラ玉軸受の実験から、かかり代が0.010mm以下であれば、固体潤滑膜に傷が発生することがないことを見出した。これに基づくと、

請求項1および3に記載の発明おいては、外輪を加熱した際にかかり代の熱膨張変化を生じせしめる「外輪のカウンターボアの最小半径」の寸法に近しい寸法である「玉を内輪に寄せたときに玉の配列する外接円の半径」に着目し、(外輪の加熱温度−組立時の室温)および外輪の材料の線膨張係数に応じたかかり代を設定したので、加熱時のかかり代が0.010mm以下となり、組立の際に、玉に傷が発生することはない。

また、請求項2および4に記載の発明おいては、外輪を加熱した際にかかり代の熱膨張変化を生じせしめる「外輪の軌道溝の最大半径」の寸法に着目し、(外輪の加熱温度−組立時の室温)および外輪の材料の線膨張係数に応じたかかり代を設定したので、加熱時のかかり代が0.010mm以下となり、組立の際に、玉に傷が発生することはない。

次に、かかり代の下限値に関する効果を説明する。まず、玉に固体潤滑膜を形成したアンギュラ玉軸受の実験から、かかり代が0.0125mm以上であれば、軸受が分離しにくいことを見出した。しかし、かかり代が0.0125mm以上であっても、ラジアル内部隙間の半分の値が0.0125mmより大きい場合は、軸受が分離し易いことも見出した。

この結果から、請求項1から4に記載の発明おいては、かかり代を、0.0125mm、もしくは、ラジアル内部隙間の半分の値、のいずれか大きい数値以上に設定したので、組立後の取扱の際に、軸受が分離しにくくなる。

請求項5に記載の発明おいては、外輪の加熱温度と組立時の室温との差を150℃以下としたことによって、前記の効果に加えて、加熱温度が低くなって更に組立作業が容易となる。

請求項6に記載の発明おいては、玉の表面、内輪の軌道面、外輪の軌道面のいずれか一カ所以上に固体潤滑膜を形成した非分離型アンギュラ軸受において、組立時の加熱の際に、固体潤滑膜の傷の発生が避けられると共に、固体潤滑膜の酸化劣化が軽減されるために、使用時の軸受寿命が長くなる。

First, the effect relating to the upper limit of the allowance will be described. From an experiment of an angular ball bearing in which a solid lubricating film is formed on a ball, it has been found that if the cost is 0.010 mm or less, the solid lubricating film will not be damaged. Based on this,

According to the first and third aspects of the present invention, when the outer ring is heated, the ball is brought close to the “minimum radius of the counterbore of the outer ring” which causes a change in thermal expansion of the allowance. Paying attention to the "radius of the circumscribed circle where the balls are arranged", and the allowance according to the linear expansion coefficient of the outer ring material (heating temperature of the outer ring-room temperature during assembly) and the allowance for heating Is 0.010 mm or less, and the ball is not damaged during assembly.

Further, in the inventions of claims 2 and 4, paying attention to the dimension of the “maximum radius of the race groove of the outer ring” that causes a change in thermal expansion when the outer ring is heated, -Room temperature at the time of assembly) and the allowance according to the linear expansion coefficient of the material of the outer ring are set, so the allowance during heating is 0.010 mm or less, and the ball is not damaged during assembly. .

Next, effects related to the lower limit of the allowance will be described. First, from an experiment of an angular ball bearing in which a solid lubricating film is formed on a ball, it was found that the bearing is difficult to separate if the cost is 0.0125 mm or more. However, it has also been found that even if the cost is 0.0125 mm or more, if the half value of the radial internal gap is larger than 0.0125 mm, the bearings are easily separated.

From this result, in the invention according to claims 1 to 4, the cost is set to 0.0125 mm or half of the radial internal gap, whichever is larger. In this case, the bearing is difficult to separate.

In the invention according to claim 5, by setting the difference between the heating temperature of the outer ring and the room temperature at the time of assembly to 150 ° C. or less, in addition to the above effect, the heating temperature is lowered and the assembly work is further facilitated. It becomes.

In the invention according to claim 6, in the non-separable angular bearing in which the solid lubricating film is formed on any one or more of the ball surface, the inner raceway surface, and the outer raceway surface, In addition, the occurrence of scratches on the solid lubricating film is avoided, and the oxidation deterioration of the solid lubricating film is reduced, so that the bearing life in use is extended.

以下、本発明の方法の具体的実施例について、図、表に基づいて説明する。 Hereinafter, specific examples of the method of the present invention will be described with reference to the drawings and tables.

本発明の非分離型アンギュラ玉軸受の中から、外輪の内側の軌道面に隣接する肩部の軸方向の片側が削られてカウンターボアが形成された第1の実施例について、その断面図を図1に示す。図において、1は非分離型アンギュラ玉軸受、2は外輪、3は内輪、4は玉、5は外輪2のカウンターボアである。

外輪2の回転中心軸と内輪3の回転中心軸を重なっており、保持器の図示は省略してある。R0は、軸受1の外周と内周の中央半径、R1は、玉4を内輪3に寄せたときに玉4の配列する外接円の半径、R2は、外輪2のカウンターボア5の最小半径である。また、ラジアル内部隙間をΔrとすると、玉4と外輪2との間には、Δr/2の隙間が存在し、玉4の中心は、ピッチ円半径R0からΔr/4だけ下がった所に位置する。そして、Wは、玉4を内輪3に寄せたときに玉4の配列する外接円の半径R1と外輪2のカウンターボア5の最小半径R2との差であるかかり代である。

軸受1の組立は次のように行う。内輪3に玉4を寄せた状態において、高周波誘導加熱装置等によって所定温度に加熱した外輪2を、カウンターボア5から挿入して組み立てる。外輪2を加熱することによって、外輪2のカウンターボア5の最小半径はR3に膨張し、R1とR3との差が、加熱時のかかり代Hとなる。なお、R3とHは図示しない。加熱時のかかり代Hは、マイナスの値も存在する。

通常、加熱時のかかり代Hは、0mm以下であれば、組立時に玉に傷が入ることはないと考えられ。しかし、加熱時のかかり代Hを不必要にマイナス側の大きな数値にすることは、加熱温度が高くなり組立が困難になること、または、組立後のかかり代Wが小さくなって、軸受が分離し易くなるという恐れがある。

A cross-sectional view of the first embodiment in which the counter bore is formed by cutting one axial side of the shoulder adjacent to the inner raceway surface of the outer ring from the non-separable angular contact ball bearing of the present invention. As shown in FIG. In the figure, 1 is a non-separable angular ball bearing, 2 is an outer ring, 3 is an inner ring, 4 is a ball, and 5 is a counter bore of the outer ring 2.

The rotation center axis of the outer ring 2 and the rotation center axis of the inner ring 3 are overlapped, and the illustration of the cage is omitted. R 0 is the center radius of the outer periphery and inner periphery of the bearing 1, R 1 is the radius of the circumscribed circle in which the balls 4 are arranged when the balls 4 are brought close to the inner ring 3, and R 2 is the counter bore 5 of the outer ring 2. The minimum radius. When the radial internal clearance is Δr, there is a clearance of Δr / 2 between the ball 4 and the outer ring 2, and the center of the ball 4 is lowered by Δr / 4 from the pitch circle radius R 0. To position. W is a cost that is the difference between the radius R 1 of the circumscribed circle in which the balls 4 are arranged when the ball 4 is brought close to the inner ring 3 and the minimum radius R 2 of the counter bore 5 of the outer ring 2.

The assembly of the bearing 1 is performed as follows. In a state where the balls 4 are brought close to the inner ring 3, the outer ring 2 heated to a predetermined temperature by a high frequency induction heating device or the like is inserted from the counter bore 5 and assembled. By heating the outer ring 2, the minimum radius of the counterbore 5 of the outer ring 2 expands in R 3, the difference between R 1 and R 3, the heating time of the take cash H. R 3 and H are not shown. There is also a negative value for the allowance H during heating.

Usually, if the cost H during heating is 0 mm or less, it is considered that the ball is not damaged during assembly. However, if the cost H during heating is unnecessarily set to a large negative value, the heating temperature becomes high and assembly becomes difficult, or the cost W after assembly becomes small and the bearing is separated. There is a fear that it becomes easy to do.

ここで、玉に固体潤滑膜を形成したアンギュラ玉軸受を用いて非加熱での組立実験を行った。その結果、非加熱時のかかり代Wが、0.010mm以下であれば、玉に形成した固体潤滑膜に傷が入らないことを見出した。Wが若干のプラス側の数値まで許容される理由は、実際の組立時に内輪あるいは外輪が傾いて、図1の状態からずれることによって生じると考えられる。この結果から、加熱時のかかり代Hが、0.010mm以下であれば、玉に形成した固体潤滑膜に傷が入らないと推測される。

そこで、請求項1および3に記載の発明おいては、外輪を加熱した際にかかり代の熱膨張変化を生じせしめる「外輪のカウンターボアの最小半径」の寸法に近しい寸法である「玉を内輪に寄せたときに玉の配列する外接円の半径:R1」に着目し、外輪の材料別に、(外輪の加熱温度−組立時の室温):ΔT(℃)とR1に対して、かかり代の最大値を次式で示す値とした。

Here, a non-heating assembly experiment was performed using an angular ball bearing in which a solid lubricating film was formed on the ball. As a result, it was found that the solid lubricating film formed on the ball would not be damaged if the cost W during non-heating is 0.010 mm or less. The reason why W is allowed up to a slightly positive value is considered to be caused by the inner ring or the outer ring being inclined during actual assembly and deviating from the state shown in FIG. From this result, it is inferred that the solid lubricant film formed on the ball is not damaged if the cost H during heating is 0.010 mm or less.

Therefore, in the inventions according to claims 1 and 3, “balls that are close to the dimension of the“ minimum radius of the counterbore of the outer ring ”, which causes a change in thermal expansion when the outer ring is heated, are produced. Focusing on the radius of the circumscribed circle in which the balls are arranged at the time of the movement: R 1 ”, depending on the material of the outer ring (heating temperature of the outer ring−room temperature at the time of assembly): ΔT (° C.) and R 1 The maximum value of the allowance was set to the value represented by the following formula.

・軸受鋼の場合:1.25×10−5×R1×ΔT+0.010

・マルテンサイトステンレス鋼の場合:1.01×10−5×R1×ΔT+0.010

従来技術の説明の際に使用した#7906の場合で、かかり代の数値を検討する。軸受の材料が軸受鋼(SUJ2)で、組立室の室温を20℃、加熱温度を200℃として、前述したR1の数値:21.617mmを用いると、かかり代:Wは、

1.25×10−5×21.617×180+0.010=0.0586mmとなる。

そして、外輪のカウンターボアの最小半径:R2=R1−W=21.558mmとなる。室温を20℃、軸受鋼(SUJ2)の線膨張係数:α=12.5×10−6(℃−1)とすると、200℃における外輪のカウンターボアの最小半径:R3は、

R2×(1+α×(200−20))=21.607mm

となり、200℃に加熱した際のかかり代:H=R1−R3=0.010mm

となる。従って、組立時に玉に傷が入ることがない。更に、加熱温度を150℃に下げる場合は、かかり代を0.0452mmに設定すればよく、加熱温度が下がることで組立作業が容易となる。

・ For bearing steel: 1.25 × 10 −5 × R 1 × ΔT + 0.010

In the case of martensitic stainless steel: 1.01 × 10 −5 × R 1 × ΔT + 0.010

In the case of # 7906 used in the description of the prior art, a numerical value of the allowance is examined. When the bearing material is bearing steel (SUJ2), the room temperature of the assembly chamber is 20 ° C., the heating temperature is 200 ° C., and the above-mentioned numerical value of R 1 : 21.617 mm is used, the cost: W

It becomes 1.25 × 10 −5 × 21.617 × 180 + 0.010 = 0.0586 mm.

The minimum radius of the counter bore of the outer ring is R 2 = R 1 −W = 21.558 mm. When the room temperature is 20 ° C. and the linear expansion coefficient of the bearing steel (SUJ2) is α = 12.5 × 10 −6 (° C. −1 ), the minimum radius of the counter bore of the outer ring at 200 ° C .: R 3 is

R 2 × (1 + α × (200−20)) = 21.707 mm

And cost when heated to 200 ° C .: H = R 1 −R 3 = 0.010 mm

It becomes. Therefore, the ball is not damaged during assembly. Furthermore, when the heating temperature is lowered to 150 ° C., the cost is set to 0.0452 mm, and the assembly operation is facilitated by lowering the heating temperature.

次に、かかり代の下限値の設定について説明する。我々は、玉に固体潤滑膜を形成したアンギュラ玉軸受を用いて非加熱での組立実験を行った。その結果、非加熱時のかかり代Wが、0.0125mm以上であれば、軸受が分離しにくいことを見出した。同時に、かかり代が0.0125mm以上であっても、ラジアル内部隙間の半分の値より大きい場合は、軸受が分離し易いことも見出した。組立後における軸受の状態は図1のとおりである。図示しない軸受の下半分にも、ラジアル内部隙間の半分の値が存在する。そのため、軸受を実際に取り扱う際に、図1において、軸受の内輪は、ラジアル内部隙間の半分の値だけ下に下がり、玉の配列する外接円も同じ寸法だけ移動する。そのため、かかり代が0.0125mm以上の場合であっても、ラジアル内部隙間の半分の値が0.0125mmより大きい場合は、軸受が分離し易いことになる。

従って、かかり代の下限値を、0.0125mm、もしくは、ラジアル内部隙間の半分の値、のいずれか大きい数値に設定したので、組立後の取扱の際に、軸受が分離しにくくなる。

Next, the setting of the lower limit value of the allowance will be described. We conducted an unheated assembly experiment using angular contact ball bearings with a solid lubricant film on the balls. As a result, it was found that the bearing is difficult to separate if the unloading allowance W is 0.0125 mm or more. At the same time, it has also been found that even if the allowance is 0.0125 mm or more, the bearing is easily separated if it is larger than half the radial internal clearance. The state of the bearing after assembly is as shown in FIG. The lower half of the bearing, not shown, also has a value that is half the radial internal clearance. Therefore, when the bearing is actually handled, in FIG. 1, the inner ring of the bearing is lowered by half the value of the radial internal gap, and the circumscribed circle in which the balls are arranged moves by the same dimension. Therefore, even if the cost is 0.0125 mm or more, if the half value of the radial internal gap is larger than 0.0125 mm, the bearings are easily separated.

Accordingly, since the lower limit value of the allowance is set to 0.0125 mm or half the radial internal gap, whichever is larger, the bearings are difficult to separate during handling after assembly.

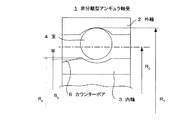

図2は、本発明の第2の実施例を示す断面図である。

本実施例は、非分離型アンギュラ玉軸受の中から、内輪の外側の軌道面に隣接する肩部の軸方向の片側が削られてカウンターボアが形成された例である。図において、1は非分離型アンギュラ玉軸受、2は外輪、3は内輪、4は玉、6は内輪3のカウンターボアである。図において、外輪2の回転中心軸と内輪3の回転中心軸を重なっており、保持器の図示は省略してある。R0は、軸受1の外周と内周の中央半径、R4は、内輪3のカウンターボア6の最大半径、R5は、玉4を外輪2に寄せたときに玉4の配列する内接円の半径、R7は、外輪2の軌道溝の最大半径である。また、ラジアル内部隙間をΔrとすると、玉4と内輪3との間には、Δr/2の隙間が存在し、玉4の中心は、ピッチ円半径R0からΔr/4上がった所に位置する。そして、Wは、玉4を外輪2に寄せたときに玉4の配列する内接円の半径R4と内輪3のカウンターボア6の最大半径R5との差であるかかり代である。

軸受1の組立は次のように行う。外輪2に玉4を寄せた状態において、高周波誘導加熱装置等によって所定温度に外輪2を加熱し、そこに内輪3をカウンターボア6側から挿入して組み立てる。外輪2を加熱することによって、外輪2の軌道溝の最大半径R7が膨張し、その結果、玉4が図の上側に移動して、玉4を外輪2に寄せたときに玉4の配列する内接円の半径がR6に大きくなる。そして、内輪3のカウンターボア6の最大半径R4とR6との差が、加熱時のかかり代Hとなる。なお、R6とHは図示しない。加熱時のかかり代Hは、マイナスの値も存在する。

FIG. 2 is a sectional view showing a second embodiment of the present invention.

This embodiment is an example in which one side in the axial direction of the shoulder adjacent to the outer raceway surface of the inner ring is cut out from the non-separable angular contact ball bearing to form a counterbore. In the figure, 1 is a non-separable angular contact ball bearing, 2 is an outer ring, 3 is an inner ring, 4 is a ball, and 6 is a counter bore of the inner ring 3. In the figure, the rotation center axis of the outer ring 2 and the rotation center axis of the inner ring 3 are overlapped, and the illustration of the cage is omitted. R 0 is the central radius of the outer periphery and inner periphery of the bearing 1, R 4 is the maximum radius of the counterbore 6 of the inner ring 3, and R 5 is the inscribed arrangement of the balls 4 when the balls 4 are brought close to the outer ring 2. The radius of the circle, R 7, is the maximum radius of the raceway groove of the outer ring 2. When the radial internal clearance is Δr, there is a clearance of Δr / 2 between the ball 4 and the inner ring 3, and the center of the ball 4 is located at a position that is Δr / 4 higher than the pitch circle radius R0. To do. W is a margin that is the difference between the radius R 4 of the inscribed circle in which the balls 4 are arranged when the balls 4 are brought close to the outer ring 2 and the maximum radius R 5 of the counter bore 6 of the inner ring 3.

The assembly of the bearing 1 is performed as follows. In a state where the balls 4 are brought close to the outer ring 2, the outer ring 2 is heated to a predetermined temperature by a high frequency induction heating device or the like, and the inner ring 3 is inserted into the outer ring 2 from the counter bore 6 side and assembled. By heating the outer ring 2, the maximum radius R 7 of the raceway groove of the outer ring 2 expands, and as a result, the balls 4 move upward in the figure and the balls 4 are arranged when the balls 4 are brought close to the outer ring 2. radius of an inscribed circle becomes larger in R 6 to. Then, the difference between the maximum radii R 4 and R 6 of the counter bore 6 of the inner ring 3 is a cost H during heating. R 6 and H are not shown. There is also a negative value for the allowance H during heating.

通常、加熱時のかかり代Hは、0mm以下であれば、組立時に玉に傷が入ることはないと考えられ。しかし、加熱時のかかり代Hを不必要にマイナス側の大きな数値にすることは、加熱温度が高くなり組立が困難になること、または、組立後のかかり代Wが小さくなって、軸受が分離し易くなるという恐れがある。

ここで、玉に固体潤滑膜を形成したアンギュラ玉軸受を用いて非加熱での組立実験を行った結果、非加熱時のかかり代Wが、0.010mm以下であれば、玉に形成した固体潤滑膜に傷が入らないことを見出した。Wが若干のプラス側の数値まで許容される理由は、実際の組立時に内輪あるいは外輪が傾いて、図1の状態からずれることによって生じると考えられる。この結果から、加熱時のかかり代Hが、0.010mm以下であれば、玉に形成した固体潤滑膜に傷が入らないと推測される。

そこで、請求項2および4に記載の発明おいては、外輪を加熱した際にかかり代の熱膨張変化を生じせしめる「外輪の軌道溝の最大半径R7」に着目し、外輪の材料別に、(外輪の加熱温度−組立時の室温):ΔT(単位℃)とR7に対して、かかり代の最大値を次式で示す値とした。

Usually, if the cost H during heating is 0 mm or less, it is considered that the ball is not damaged during assembly. However, if the cost H during heating is unnecessarily set to a large negative value, the heating temperature becomes high and assembly becomes difficult, or the cost W after assembly becomes small and the bearing is separated. There is a fear that it becomes easy to do.

Here, as a result of performing an unheated assembly experiment using an angular ball bearing in which a solid lubricating film is formed on the ball, the solid formed on the ball is less than 0.010 mm when the unloading allowance W is 0.010 mm or less. It was found that the lubricating film was not damaged. The reason why W is allowed up to a slightly positive value is considered to be caused by the inner ring or the outer ring being inclined during actual assembly and deviating from the state shown in FIG. From this result, it is inferred that the solid lubricant film formed on the ball is not damaged if the cost H during heating is 0.010 mm or less.

Therefore, in the inventions according to claims 2 and 4, paying attention to the “maximum radius R 7 of the race groove of the outer ring” that causes a change in thermal expansion when the outer ring is heated, (Heating temperature of outer ring—room temperature during assembly): For ΔT (unit ° C.) and R 7 , the maximum value of the allowance was set to a value represented by the following equation.

・軸受鋼の場合:1.25×10−5×R7×ΔT+0.010

・マルテンサイトステンレス鋼の場合:1.01×10−5×R7×ΔT+0.010

従来技術の説明の際に使用した#7906の場合で、かかり代の数値を検討する。軸受の材料が軸受鋼(SUJ2)で、組立室の室温を20℃、加熱温度を200℃とした。玉の直径をDw、ラジアル内部隙間をΔrとすると加熱前の諸寸法は次のとおりである。

・軸受の外周と内周の中央半径:R0=(30+47)/4=19.250mm

・玉を外輪に寄せたときに玉の配列する内接円の半径

:R5=R0−Dw/2+Δr/4=16.883mm

・外輪の軌道溝の最大半径

:R7=R0+Dw/2+Δr/4=21.646mm

これより、かかり代:Wは、

1.25×10−5×21.646×180+0.010=0.0587mmとなる。

そして、内輪のカウンターボアの最大半径:R4=R5+W=16.942mmとなる。室温を20℃、軸受鋼(SUJ2)の線膨張係数:α=12.5×10−6(℃−1)とすると、200℃における玉を外輪に寄せたときに玉の配列する内接円の半径R6は、

R5+(R7×α×(200−20))=16.932mm

となり、200℃に加熱した際のかかり代:H=R4−R6=0.010mm

となる。従って、組立時に玉に傷が入ることがない。更に、加熱温度を150℃に下げる場合は、かかり代を0.0452mmに設定すればよく、加熱温度がさがることで組立作業が容易となる。

・ For bearing steel: 1.25 × 10−5 × R 7 × ΔT + 0.010

In the case of martensitic stainless steel: 1.01 × 10 −5 × R 7 × ΔT + 0.010

In the case of # 7906 used in the description of the prior art, a numerical value of the allowance is examined. The material of the bearing was bearing steel (SUJ2), the room temperature of the assembly chamber was 20 ° C, and the heating temperature was 200 ° C. If the diameter of the ball is Dw and the radial internal gap is Δr, the dimensions before heating are as follows.

・ Center radius of the outer periphery and inner periphery of the bearing: R 0 = (30 + 47) /4=19.250 mm

The radius of the inscribed circle where the balls are arranged when the balls are brought close to the outer ring: R 5 = R 0 −Dw / 2 + Δr / 4 = 16.883 mm

・ Maximum radius of outer raceway groove: R 7 = R 0 + Dw / 2 + Δr / 4 = 21.646 mm

From this, cost: W is

It becomes 1.25 × 10 −5 × 21.646 × 180 + 0.010 = 0.0587 mm.

The maximum radius of the counter bore of the inner ring is R 4 = R 5 + W = 16.942 mm. When the room temperature is 20 ° C. and the linear expansion coefficient of the bearing steel (SUJ2) is α = 12.5 × 10 −6 (° C. −1 ), an inscribed circle in which the balls are arranged when the balls at 200 ° C. are brought close to the outer ring. The radius R 6 of

R 5 + (R 7 × α × (200−20)) = 16.932 mm

And cost when heated to 200 ° C .: H = R 4 −R 6 = 0.010 mm

It becomes. Therefore, the ball is not damaged during assembly. Furthermore, when the heating temperature is lowered to 150 ° C., the cost is set to 0.0452 mm, and the assembly operation is facilitated by reducing the heating temperature.

次に、かかり代の下限値の設定について説明する。我々は、玉に固体潤滑膜を形成したアンギュラ玉軸受を用いて非加熱での組立実験を行った。その結果、非加熱時のかかり代Wが、0.0125mm以上であれば、軸受が分離しにくいことを見出した。同時に、かかり代が0.0125mm以上であっても、ラジアル内部隙間の半分の値より大きい場合は、軸受が分離し易いことも見出した。組立後における軸受の状態は図1のとおりである。図示しない軸受の下半分にも、ラジアル内部隙間の半分の値が存在する。そのため、軸受を実際に取り扱う際に、図1において、軸受の内輪は、ラジアル内部隙間の半分の値だけ下に下がり、玉の配列する外接円も同じ寸法だけ移動する。そのため、かかり代が0.0125mm以上の場合であっても、ラジアル内部隙間の半分の値が0.0125mmより大きい場合は、軸受が分離し易いことになる。

従って、かかり代の下限値を、0.0125mm、もしくは、ラジアル内部隙間(単位mm)の半分の値、のいずれか大きい数値に設定したので、組立後の取扱の際に、軸受が分離しにくくなる。

そして、玉の表面、内輪の軌道面、外輪の軌道面のいずれか一カ所以上に固体潤滑膜を形成した非分離型アンギュラ軸受においては、組立時の加熱の際に、固体潤滑膜の傷の発生が避けられると共に、固体潤滑膜の酸化劣化が軽減されるために、使用時の軸受寿命が長くなる。

Next, the setting of the lower limit value of the allowance will be described. We conducted an unheated assembly experiment using angular contact ball bearings with a solid lubricant film on the balls. As a result, it was found that the bearing is difficult to separate if the unloading allowance W is 0.0125 mm or more. At the same time, it has also been found that even if the allowance is 0.0125 mm or more, the bearing is easily separated if it is larger than half the radial internal clearance. The state of the bearing after assembly is as shown in FIG. The lower half of the bearing, not shown, also has a value that is half the radial internal clearance. Therefore, when the bearing is actually handled, in FIG. 1, the inner ring of the bearing is lowered by half the value of the radial internal gap, and the circumscribed circle in which the balls are arranged moves by the same dimension. Therefore, even if the cost is 0.0125 mm or more, if the half value of the radial internal gap is larger than 0.0125 mm, the bearings are easily separated.

Therefore, since the lower limit of the allowance is set to 0.0125 mm or half the radial internal clearance (unit: mm), whichever is larger, the bearing is difficult to separate during handling after assembly. Become.

In a non-separable angular bearing in which a solid lubricating film is formed on one or more of the ball surface, the inner ring raceway surface, or the outer ring raceway surface, the solid lubricating film is damaged during heating during assembly. Since generation | occurrence | production is avoided and the oxidative degradation of a solid lubricating film is reduced, the bearing life at the time of use becomes long.

以上に述べたように、外輪を加熱することによって内輪と外輪の間に玉を組み込んで組み立てる非分離型アンギュラ玉軸受において、玉を内輪に寄せたときに玉の配列する外接円の半径、または、外輪の軌道面の最大半径、(外輪の加熱温度−組立時の室温)、外輪の材料の熱膨張係数、それから、ラジアル内部隙間に応じて、かかり代を適切に設計することによって、組立時の加熱温度が低くて作業が容易である、組立時に玉に傷が入らない、そして、取扱時に外輪または内輪が分離しない、という非分離型アンギュラ玉軸受を提供することができる。

特に、玉の表面、内輪の軌道面、外輪の軌道面のいずれか一カ所以上に固体潤滑膜を形成した非分離型アンギュラ玉軸受においては、上記の方策によって、組立時の加熱温度が低くて作業が容易である、組立時に玉に傷が入らない、取扱時に外輪または内輪が分離しない、そして、使用時の軸受寿命が長い、という非分離型アンギュラ玉軸受を提供することができる。

As described above, in a non-separable angular contact ball bearing that is assembled by assembling a ball between the inner ring and the outer ring by heating the outer ring, the radius of the circumscribed circle in which the balls are arranged when the ball is brought to the inner ring, or , The maximum radius of the raceway surface of the outer ring, (heating temperature of the outer ring-room temperature during assembly), the coefficient of thermal expansion of the material of the outer ring, and then by appropriately designing the allowance according to the radial internal clearance, during assembly Therefore, it is possible to provide a non-separable angular contact ball bearing in which the heating temperature is low, the work is easy, the ball is not damaged during assembly, and the outer ring or the inner ring is not separated during handling.

In particular, in the non-separable angular contact ball bearings in which a solid lubricating film is formed on one or more of the ball surface, the inner ring raceway surface, and the outer ring raceway surface, the heating temperature during assembly is reduced by the above measures. It is possible to provide a non-separable angular contact ball bearing that is easy to work, does not damage the ball during assembly, does not separate the outer ring or the inner ring during handling, and has a long bearing life in use.

今回の実施例は、潤滑油や潤滑用グリースで潤滑される非分離型アンギュラ玉軸受に適している。そして、固体潤滑膜で潤滑される非分離型アンギュラ玉軸受に対して、さらに有効である。 This embodiment is suitable for non-separable angular contact ball bearings lubricated with lubricating oil or lubricating grease. This is more effective for non-separable angular contact ball bearings lubricated with a solid lubricating film.

1 非分離型アンギュラ玉軸受

2 外輪

3 内輪

4 玉

5 外輪のカウンターボア

6 内輪のカウンターボア

R0 軸受の外周と内周の中央半径

R1 玉を内輪に寄せたときに玉の配列する外接円の半径

R2 外輪のカウンターボアの最小半径

R4 内輪のカウンターボアの最大半径

R5 玉を外輪に寄せたときに玉の配列する内接円の半径

R7 外輪の軌道面の最大半径

W かかり代

DESCRIPTION OF SYMBOLS 1 Non-separable angular contact ball bearing 2 Outer ring 3 Inner ring 4 Ball 5 Outer ring counter bore 6 Inner ring counter bore R 0 Center radius R of the outer circumference and inner circumference R 1 Radius R 2 Minimum radius R of outer ring counter bore R 4 Maximum radius of counter bore R of inner ring R 5 Radius of inscribed circle in which balls are arranged when they are brought close to outer ring R 7 Maximum radius W of outer ring raceway surface Generation

Claims (6)

前記玉を前記内輪に寄せたときに玉の配列する外接円の半径R1と前記外輪のカウンターボアの最小半径との差であるかかり代を0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.25×10−5×R1×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたことを特徴とする非分離型アンギュラ玉軸受。 One side in the axial direction of the shoulder adjacent to the inner raceway surface of the outer ring made of bearing steel is scraped to form a counterbore, and the outer ring is heated to assemble a ball between the inner ring and the outer ring. In the separated angular contact ball bearing,

0.0125mm barbs margin is the difference between the minimum radius of counterbore radius R 1 and the outer ring of the circumscribed circle of the sequence of balls when asked the balls to the inner ring, or half the value of the radial clearance A non-separable angular contact ball bearing characterized by a range of 1.25 × 10 −5 × R 1 × (heating temperature of outer ring−room temperature during assembly) +0.010 mm.

前記外輪の軌道面の最大半径をR7とするときに、前記内輪のカウンターボアの最大半径と前記玉を外輪に寄せたときに玉の配列する内接円の半径との差であるかかり代を、0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.25×10−5×R7×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたことを特徴とする非分離型アンギュラ玉軸受。 One side in the axial direction of the shoulder adjacent to the outer raceway surface of the inner ring facing the outer ring made of bearing steel is scraped to form a counterbore, and by heating the outer ring, a ball is inserted between the inner ring and the outer ring. In non-separable angular contact ball bearings assembled and assembled,

When the maximum radius of the raceway surface of the outer ring is R 7 , the margin is the difference between the maximum radius of the counter bore of the inner ring and the radius of the inscribed circle in which the balls are arranged when the balls are brought close to the outer ring. From the larger value of 0.0125 mm or half of the radial internal clearance, 1.25 × 10 −5 × R 7 × (outer ring heating temperature−room temperature during assembly) +0.010 mm Non-separable angular contact ball bearings.

前記玉を前記内輪に寄せたときに玉の配列する外接円の半径R1と前記外輪のカウンターボアの最小半径との差であるかかり代を、0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.01×10−5×R1×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたことを特徴とする非分離型アンギュラ玉軸受。 A counterbore is formed by shaving the axial side of the shoulder adjacent to the inner raceway surface of the outer ring made of martensitic stainless steel, and a ball is incorporated between the inner ring and the outer ring by heating the outer ring. In non-separable angular contact ball bearings to be assembled,

The engagement allowance is the difference between the minimum radius of counterbore radius R 1 and the outer ring of the circumscribed circle of arrangement of the ball when asked the balls into inner ring, 0.0125 mm, or half of the radial clearance A non-separable angular contact ball bearing characterized in that the larger value is 1.01 × 10 −5 × R 1 × (heating temperature of outer ring−room temperature during assembly) +0.010 mm.

前記外輪の軌道面の最大半径をR7とするときに、前記内輪のカウンターボアの最大半径と前記玉を外輪に寄せたときに玉の配列する内接円の半径との差であるかかり代を、0.0125mm、もしくは、ラジアル内部隙間の半分の値のいずれか大きい数値から、1.01×10−5×R7×(外輪の加熱温度−組立時の室温)+0.010mmの範囲にしたことを特徴とする非分離型アンギュラ玉軸受。 One side in the axial direction of the shoulder adjacent to the outer raceway surface of the inner ring facing the outer ring made of martensitic stainless steel is scraped to form a counterbore, and the outer ring is heated between the inner ring and the outer ring. In non-separable angular contact ball bearings assembled with balls,

When the maximum radius of the raceway surface of the outer ring is R 7 , the margin is the difference between the maximum radius of the counter bore of the inner ring and the radius of the inscribed circle in which the balls are arranged when the balls are brought close to the outer ring. From the larger value of 0.0125 mm or half of the radial internal clearance to 1.01 × 10 −5 × R 7 × (heating temperature of outer ring−room temperature during assembly) +0.010 mm Non-separable angular contact ball bearings.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008036072A JP2009192049A (en) | 2008-02-18 | 2008-02-18 | Nonseparable angular contact ball bearing |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008036072A JP2009192049A (en) | 2008-02-18 | 2008-02-18 | Nonseparable angular contact ball bearing |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009192049A true JP2009192049A (en) | 2009-08-27 |

| JP2009192049A5 JP2009192049A5 (en) | 2011-11-17 |

Family

ID=41074238

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008036072A Pending JP2009192049A (en) | 2008-02-18 | 2008-02-18 | Nonseparable angular contact ball bearing |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2009192049A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014035033A (en) * | 2012-08-09 | 2014-02-24 | Nsk Ltd | Tandem type multi row angular contact ball bearing |

| JP2014040870A (en) * | 2012-08-23 | 2014-03-06 | Nsk Ltd | Tandem type double row angular ball bearing |

| JP2014062574A (en) * | 2012-09-20 | 2014-04-10 | Nsk Ltd | Tandem type double-row angular contact ball bearing |

| CN103727141A (en) * | 2013-12-10 | 2014-04-16 | 洛阳轴研科技股份有限公司 | Method for fitting angular contact ball bearing |

| CN106351967A (en) * | 2016-08-31 | 2017-01-25 | 洛阳轴研科技股份有限公司 | Angular contact ball bearing assembling and sleeving method |

| WO2020192818A1 (en) * | 2019-03-25 | 2020-10-01 | Schaeffler Technologies AG & Co. KG | Ball bearing and method for assembling same |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58162319U (en) * | 1982-04-26 | 1983-10-28 | 株式会社不二越 | Non-separable angular contact ball bearing |

| JPS62187581A (en) * | 1986-02-12 | 1987-08-15 | Mitsubishi Heavy Ind Ltd | Production of multiple cylindrical member |

| JPS63158306A (en) * | 1986-12-19 | 1988-07-01 | 株式会社リケン | Coupling structure of cylindrical member made of aluminum alloy and shaft made of steel |

| JPH0632501Y2 (en) * | 1987-02-12 | 1994-08-24 | 日本精工株式会社 | Non-separable angular contact ball bearing |

| JPH0861374A (en) * | 1994-08-24 | 1996-03-08 | Yaskawa Electric Corp | Angular ball bearing |

| JPH11270563A (en) * | 1998-03-25 | 1999-10-05 | Ntn Corp | Angular ball bearing |

| JP2005009643A (en) * | 2003-06-20 | 2005-01-13 | Nsk Ltd | Nonseparable angular contact ball bearing |

| JP2005214262A (en) * | 2004-01-28 | 2005-08-11 | Koyo Seiko Co Ltd | Obliquely contact ball bearing |

| JP2005331026A (en) * | 2004-05-19 | 2005-12-02 | Ntn Corp | Angular ball bearing |

| JP2006307894A (en) * | 2005-04-26 | 2006-11-09 | Ntn Corp | Angular contact ball bearing |

| JP2006336780A (en) * | 2005-06-02 | 2006-12-14 | Nsk Ltd | Motor device with worm gear |

-

2008

- 2008-02-18 JP JP2008036072A patent/JP2009192049A/en active Pending

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58162319U (en) * | 1982-04-26 | 1983-10-28 | 株式会社不二越 | Non-separable angular contact ball bearing |

| JPS62187581A (en) * | 1986-02-12 | 1987-08-15 | Mitsubishi Heavy Ind Ltd | Production of multiple cylindrical member |

| JPS63158306A (en) * | 1986-12-19 | 1988-07-01 | 株式会社リケン | Coupling structure of cylindrical member made of aluminum alloy and shaft made of steel |

| JPH0632501Y2 (en) * | 1987-02-12 | 1994-08-24 | 日本精工株式会社 | Non-separable angular contact ball bearing |

| JPH0861374A (en) * | 1994-08-24 | 1996-03-08 | Yaskawa Electric Corp | Angular ball bearing |

| JPH11270563A (en) * | 1998-03-25 | 1999-10-05 | Ntn Corp | Angular ball bearing |

| JP2005009643A (en) * | 2003-06-20 | 2005-01-13 | Nsk Ltd | Nonseparable angular contact ball bearing |

| JP2005214262A (en) * | 2004-01-28 | 2005-08-11 | Koyo Seiko Co Ltd | Obliquely contact ball bearing |

| JP2005331026A (en) * | 2004-05-19 | 2005-12-02 | Ntn Corp | Angular ball bearing |

| JP2006307894A (en) * | 2005-04-26 | 2006-11-09 | Ntn Corp | Angular contact ball bearing |

| JP2006336780A (en) * | 2005-06-02 | 2006-12-14 | Nsk Ltd | Motor device with worm gear |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014035033A (en) * | 2012-08-09 | 2014-02-24 | Nsk Ltd | Tandem type multi row angular contact ball bearing |

| JP2014040870A (en) * | 2012-08-23 | 2014-03-06 | Nsk Ltd | Tandem type double row angular ball bearing |

| JP2014062574A (en) * | 2012-09-20 | 2014-04-10 | Nsk Ltd | Tandem type double-row angular contact ball bearing |

| CN103727141A (en) * | 2013-12-10 | 2014-04-16 | 洛阳轴研科技股份有限公司 | Method for fitting angular contact ball bearing |

| CN106351967A (en) * | 2016-08-31 | 2017-01-25 | 洛阳轴研科技股份有限公司 | Angular contact ball bearing assembling and sleeving method |

| WO2020192818A1 (en) * | 2019-03-25 | 2020-10-01 | Schaeffler Technologies AG & Co. KG | Ball bearing and method for assembling same |

| CN113272565A (en) * | 2019-03-25 | 2021-08-17 | 舍弗勒技术股份两合公司 | Ball bearing and method of assembling the same |

| CN113272565B (en) * | 2019-03-25 | 2023-04-07 | 舍弗勒技术股份两合公司 | Ball bearing and method of assembling the same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2009192049A (en) | Nonseparable angular contact ball bearing | |

| JP6512264B2 (en) | Cylindrical roller bearing | |

| JP2008180246A (en) | Tapered roller bearing | |

| JP2010138933A (en) | Ball bearing, and bearing for alternator using the same | |

| JP2006300079A (en) | Roller bearing | |

| JP2009203846A (en) | Ball bearing arrangement for turbocharger | |

| JP2014159840A (en) | Roller bearing | |

| JP2005214330A (en) | Four-point contact ball bearing and manufacturing method thereof | |

| JP2008121820A (en) | Seal device for rolling bearing | |

| JP2007155021A (en) | Roller bearing | |

| JP2005106214A (en) | Rolling bearing device | |

| JP2008121767A (en) | Conical bearing | |

| JP2011127645A (en) | Roller bearing and cage for roller bearing | |

| JP2005076674A (en) | Tapered roller bearing for transmission of automobile | |

| JP2010196726A (en) | Shell-shaped needle bearing | |

| JP2007040427A (en) | Rolling bearing | |

| JP2007239929A (en) | Roller bearing | |

| JP6051725B2 (en) | Tandem double-row angular contact ball bearings for automotive differentials | |

| JP2006177511A (en) | Bearing device | |

| JP6106830B2 (en) | Rolling bearing and method of using the same | |

| JP2013167346A (en) | Rolling bearing | |

| JP4494128B2 (en) | Vehicle bearing device | |

| JP2005265094A (en) | Double row obliquely contacting ball bearing and pinion shaft support bearing device | |

| JP2009203845A (en) | Bearing device for turbocharger | |

| JP2007298184A (en) | Angular ball-bearing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101117 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110930 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20111220 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111222 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120507 |