JP2008307364A - Pachinko ball supply device - Google Patents

Pachinko ball supply device Download PDFInfo

- Publication number

- JP2008307364A JP2008307364A JP2007324932A JP2007324932A JP2008307364A JP 2008307364 A JP2008307364 A JP 2008307364A JP 2007324932 A JP2007324932 A JP 2007324932A JP 2007324932 A JP2007324932 A JP 2007324932A JP 2008307364 A JP2008307364 A JP 2008307364A

- Authority

- JP

- Japan

- Prior art keywords

- pachinko ball

- pachinko

- supply

- conveyor belt

- gaming machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Pinball Game Machines (AREA)

Abstract

Description

本発明は、パチンコ遊技場の遊技機島に設けられ、その遊技機島を構成する各遊技機へパチンコ玉を供給するための供給装置に関するものである。 The present invention relates to a supply device for supplying a pachinko ball to each gaming machine which is provided on a gaming machine island of a pachinko gaming machine and which forms the gaming machine island.

パチンコ遊技場においては、左右に背合わせ状に配列された複数の遊技機によって遊技機島が構成され、この遊技機島の上部には、各遊技機にパチンコ玉を供給するための供給装置が設けられている。 In the pachinko game hall, a gaming machine island is configured by a plurality of gaming machines arranged back and forth on the left and right, and a supply device for supplying pachinko balls to each gaming machine is formed above the gaming machine island. Is provided.

従来、パチンコ玉の供給装置としては、樋状の搬送路を、揚送装置から遊技機島の前後長手方向に傾斜させて設け、パチンコ玉をその自重によって転がし、各遊技機に供給するものがある(例えば、特許文献1参照)。また、前後長手方向に水平に設けた無端状の搬送ベルトを駆動装置によって周回させ、その搬送ベルトの上にパチンコ玉を載せて供給する装置もある(例えば、特許文献2参照)。 Conventionally, as a pachinko ball supply device, a bowl-shaped conveyance path is provided to be inclined in the longitudinal direction of the gaming machine island from the lifting device, and the pachinko ball is rolled by its own weight and supplied to each gaming machine. Yes (see, for example, Patent Document 1). There is also an apparatus in which an endless transport belt provided horizontally in the longitudinal direction is rotated by a driving device and a pachinko ball is placed on the transport belt and supplied (for example, see Patent Document 2).

さらには、駆動装置で周回する搬送ベルトと、その直下に設けた平板状の補給樋との間でパチンコ玉を挟持して搬送し、各パチンコ機へ供給する装置もある(例えば、特許文献3参照)。この装置は、搬送ベルトをウレタン製とし、また、補給樋をその中央から左右の両方向へ下向傾斜させ、パチンコ玉をその自重で転がし、遊技機島の左右両側の各パチンコ機に供給するようにしている。 Furthermore, there is also a device that sandwiches and conveys pachinko balls between a conveyor belt that circulates by a driving device and a flat plate-shaped replenisher provided immediately below the belt (for example, Patent Document 3). reference). In this device, the conveyor belt is made of urethane, and the replenishment basket is inclined downward from the center in both the left and right directions, and the pachinko balls are rolled by their own weight to be supplied to the respective pachinko machines on the left and right sides of the gaming machine island. I have to.

しかし、上記した従来技術には、それぞれ以下に述べる問題がある。特許文献1に記載の傾斜を利用した供給装置は、パチンコ機の搬送にパチンコ玉の自重を利用しているため、当該パチンコ玉の搬送状態を適切に制御するのが困難であり、その結果、いわゆる玉詰まり等の搬送不良が発生し易い。また、搬送路の傾斜が必要であることから、高さ方向に大きな設置スペースを占有し、それだけパチンコ遊技場が狭くなったり、照明が遮られて暗くなるなど、好ましくない。 However, each of the above conventional techniques has the following problems. Since the supply device using the inclination described in Patent Document 1 uses the weight of the pachinko ball for the conveyance of the pachinko machine, it is difficult to appropriately control the conveyance state of the pachinko ball, and as a result, A conveyance failure such as so-called clogging is likely to occur. In addition, since the transport path needs to be inclined, a large installation space is occupied in the height direction, and the pachinko game hall becomes so narrow that the lighting is blocked and it becomes dark.

また、特許文献2に記載の搬送ベルトを利用した装置は、搬送不良や設置スペースの問題は解消できるものの、パチンコ玉を搬送ベルトに載せて搬送するため、その搬送ベルト上にパチンコ玉が存在している状態では、例えば、ベルトを緩めることもできないので、簡単な保守点検をも行うことができないといった問題がある。従って、この供給装置に軽微な不具合が発生しても、その稼働を停止しなければ修理することができないので、パチンコ遊技場の稼働率を低下させてしまう結果となる。

Moreover, although the apparatus using the conveyance belt described in

さらに、特許文献3に記載の搬送ベルトと補給樋とでパチンコ玉を挟持して搬送する装置は、例えば、当該搬送ベルトと補給樋との間隙にバラツキが発生し、その間隙が所定より大きいと、パチンコ玉を円滑に搬送することができないといった問題がある。また、補給樋をその中央から左右の両方向へ下向傾斜させ、左右側両方のパチンコ機にパチンコ玉を供給するので、補給樋の傾斜のバラツキ等により、パチンコ玉を、左側または右側のパチンコ機へ均等に供給することができないといった問題が発生する。

Furthermore, in the apparatus for holding and transporting the pachinko ball between the transport belt and the replenishment rod described in

本発明は、こうした問題に鑑み創案されたもので、パチンコ玉を円滑に搬送でき、高さ方向に大きな設置スペースを必要とせず、パチンコ玉を搬送中にも保守点検ができ、常に、確実に左右両側の遊技機に均等にパチンコ玉を供給することのできるパチンコ玉搬送装置を提供することを課題とする。 The present invention was devised in view of these problems, and can smoothly transport pachinko balls, does not require a large installation space in the height direction, and can be maintained and inspected while transporting pachinko balls. It is an object of the present invention to provide a pachinko ball conveying device capable of evenly supplying pachinko balls to left and right game machines.

図1乃至図6を参照して説明する。請求項1に記載のパチンコ玉供給装置1は、左右に背合わせ状にパチンコ機3を配列して形成される遊技機島2の上部に設けられ、各パチンコ機3にパチンコ玉4を供給する装置であって、前記遊技機島2の前後長手方向にほぼ水平に配置され、上流側と下流側に設けた二つのローラー11に懸架され、当該ローラー11と共に、左右短尺方向の一方側に所定角度αで傾斜させた無端状の搬送ベルト10と、 前記搬送ベルト10の直下に、前記パチンコ玉4の直径とほぼ等しい間隔Cを開け、前記搬送ベルト10と同一の傾斜角度で設けられた、上面を前記パチンコ玉4が移動する補給樋20と、前記補給樋20の低所側Lである左右短尺方向の一方側に、前後長手方向に沿って設けられ、前記補給樋20の上面のパチンコ玉4を、その自重で、前記低所側Lに位置するパチンコ機3に供給する第一補給シュート60aと、前記低所側Lに、前後長手方向に沿って設けられ、前記補給樋20の上面のパチンコ玉4を、その自重で、前記補給樋20の高所側Hに位置するパチンコ機3に供給する第二補給シュート60bと、を備えたことを特徴とする。

This will be described with reference to FIGS. The pachinko ball supply device 1 according to claim 1 is provided on an upper part of a

請求項2に記載のパチンコ玉供給装置1は、請求項1に記載の発明において、搬送ベルト10が、その外周面に、パチンコ玉4に移動方向への速度を付与する速度付与部材として、前記パチンコ玉4に当接する突出部10aを複数有するものであることを特徴とする。

The pachinko ball supply device 1 according to

請求項3に記載のパチンコ玉供給装置1は、請求項1に記載の発明において、搬送ベルト10が、パチンコ玉4に移動方向への速度を付与するために、磁気性材料で形成されたものであることを特徴とする。

The pachinko ball supply device 1 according to

請求項4に記載のパチンコ玉供給装置1は、請求項3に記載の発明において、搬送ベルト10が、ゴム材に砂鉄を混在させて形成され、前記砂鉄が磁化された磁気性材料であることを特徴とする。

The pachinko ball feeder 1 according to

請求項5に記載のパチンコ玉供給装置1は、左右に背合わせ状にパチンコ機3を配列して形成される遊技機島2の上部に設けられ、各パチンコ機3にパチンコ玉4を供給する装置であって、前記遊技機島2の前後長手方向にほぼ水平に配置され、上流側と下流側に設けられた駆動ローラー11aと従動ローラー11bとに懸架され、当該駆動ローラー11aおよび従動ローラー11bと共に、左右短尺方向の一方側に所定角度αで傾斜させた無端状の搬送ベルト10と、前記搬送ベルト10の直下に、前記パチンコ玉4の直径とほぼ等しい間隔Cを開けて設けられた平板状で、前記搬送ベルト10と同一の傾斜角度で固定され、上面を前記パチンコ玉4が移動するステンレス製の補給樋20と、前記補給樋20の低所側Lである左右短尺方向の一方側に、前後長手方向に沿ってほぼ等間隔で設けられ、前記補給樋20の上面のパチンコ玉4を、その自重で、前記低所側Lに位置するパチンコ機3に供給する複数の第一補給シュート60aと、前記第一補給シュート60aに隣接して、前記低所側Lに、前後長手方向に沿ってほぼ等間隔で設けられ、前記補給樋20の上面のパチンコ玉4を、その自重で、前記補給樋20の高所側Hに位置するパチンコ機3に供給する複数の第二補給シュート60bと、を備える。そして、前記搬送ベルト10が、ゴム材に砂鉄を混在させて形成され、前記砂鉄が磁化された磁気性材料で形成されたものであることを特徴とする。

The pachinko ball supply device 1 according to claim 5 is provided on an upper part of the

請求項6に記載のパチンコ玉供給装置1は、左右に背合わせ状にパチンコ機3を配列して形成される遊技機島2の上部に設けられ、各パチンコ機3にパチンコ玉4を供給する装置であって、前記遊技機島2の前後長手方向に水平に配置され、上流側と下流側に設けた二つのローラー11に懸架され、当該ローラー11と共に、左右短尺方向の一方側に所定角度αで傾斜させた無端状の搬送ベルト10と、前記搬送ベルト10の直下に、前記パチンコ玉4の直径とほぼ等しい間隔Cを開けて設けられた平板状で、前記搬送ベルト10と同一の傾斜角度で固定され、上面を前記パチンコ玉4が移動する補給樋20と、前記補給樋20の低所側Lである左右短尺方向の一方側に、前後長手方向に沿ってほぼ等間隔で設けられ、前記補給樋20の上面のパチンコ玉4を、その自重で、前記低所側Lに位置するパチンコ機3に供給する複数の第一補給シュート60aと、前記第一補給シュート60aに隣接して、前記低所側Lに、前後長手方向に沿ってほぼ等間隔で設けられ、前記補給樋20の上面のパチンコ玉4を、その自重で、前記補給樋20の高所側Hに位置するパチンコ機3に供給する複数の第二補給シュート60bと、を備える。そして、前記搬送ベルト10が、その外周面に、パチンコ玉4に移動方向への速度を付与する速度付与部材として、前記パチンコ玉4に当接する突出部10aを複数有するものであることを特徴とする。

The pachinko ball supply device 1 according to claim 6 is provided on an upper part of the

請求項1に記載のパチンコ玉供給装置1は、搬送ベルト10を前後長手方向にほぼ水平に配置しているので、従来技術の傾斜させた場合と比較して、高さ方向に大きな設置スペースを必要としない。また、照明を遮らない。従って、遊技場を広く開放感があり、明るい雰囲気の場所とすることができる。

The pachinko ball supply apparatus 1 according to claim 1 has a large installation space in the height direction as compared with the case where the

また、搬送ベルト10の直下に補給樋20を設け、両者の間でパチンコ玉4を搬送するので、パチンコ玉4を搬送中でも、当該搬送ベルト10およびそれを周回させるローラー11や駆動装置の保守点検を行うことができる。

In addition, since the

さらに、搬送ベルト10および補給樋20を、左右短尺方向の一方側に所定角度αで傾斜させ、低所側Lに第一補給シュート60aと第二補給シュート60bを設けているので、左右両側のパチンコ機3に均等にパチンコ玉4を供給することができる。

Furthermore, since the

すなわち、補給樋20を左右の一方側に傾斜させているため、全てのパチンコ玉4は搬送されながら補給樋20の低所側Lに集まる。そして、低所側Lに集まったパチンコ玉4は、第一補給シュート60aによって低所側Lのパチンコ機3に供給され、第二補給シュート60bによって高所側Hのパチンコ機3に供給される。従って、左右両側のパチンコ機3に均等にパチンコ玉4を供給することができる。

That is, since the

請求項2に記載のパチンコ玉供給装置1は、請求項1に記載の発明と同様の効果を発揮する。また、搬送ベルト10が、その外周面に、パチンコ玉4に移動方向への速度を付与する速度付与部材として、前記パチンコ玉4に当接する突出部10aを複数有するので、この突出部10aがパチンコ玉4を移動方向へ押す。従って、パチンコ玉4を効率的に搬送することができる。

The pachinko ball supply device 1 according to

請求項3に記載のパチンコ玉供給装置1は、請求項1に記載の発明と同様の効果を発揮する。また、搬送ベルト10が磁気性材料で形成されているので、磁力によって鉄製であるパチンコ玉4を吸着することができる。従って、当該パチンコ玉4を、効率的に搬送することができる。

The pachinko ball supply device 1 according to

なお、搬送ベルト10と補給樋20の間隔Cを、パチンコ玉4の直径とほぼ等しく設定しているので、当該搬送ベルト10をパチンコ玉4に確実に接触させることができる。これにより、パチンコ玉4を、より効率的に搬送することができる。

In addition, since the distance C between the

請求項4に記載のパチンコ玉供給装置1は、請求項3に記載の発明と同様の効果を発揮する。また、搬送ベルト10が、ゴム材に砂鉄を混在させて形成され、その砂鉄が磁化された磁気性材料で構成されているので、当該搬送ベルト10に効果的かつ廉価なコストで磁力を与えることができる。

The pachinko ball supply device 1 according to claim 4 exhibits the same effects as the invention according to

請求項5に記載のパチンコ玉供給装置1は、搬送ベルト10を前後長手方向にほぼ水平に配置しているので、従来技術の傾斜させた場合と比較して、高さ方向に大きな設置スペースを必要としない。

The pachinko ball supply device 1 according to claim 5 has a large installation space in the height direction as compared with the case where the

また、搬送ベルト10の直下に補給樋20を設け、両者の間でパチンコ玉4を搬送するので、パチンコ玉4を搬送中でも、当該搬送ベルト10およびそれを周回させるローラー11や駆動装置の保守点検を行うことができる。

In addition, since the replenishing

さらに、搬送ベルト10および補給樋20を、左右短尺方向の一方側に所定角度αで傾斜させ、低所側Lに第一補給シュート60aと第二補給シュート60bを設けているので、左右両側のパチンコ機3に均等にパチンコ玉4を供給することができる。

Furthermore, since the

また、搬送ベルト10が磁気性材料で形成されているので、磁力によって鉄製であるパチンコ玉4を吸着することができる。従って、当該パチンコ玉4を効率的に搬送することができる。

Moreover, since the

また、搬送ベルト10と補給樋20の間隔Cを、パチンコ玉4の直径とほぼ等しく設定しているので、当該搬送ベルト10をパチンコ玉4に確実に接触させることができる。これにより、パチンコ玉4を、より効率的に搬送することができる。

Further, since the distance C between the

なお、この搬送ベルト10は、ゴム材に砂鉄を混在させて形成され、その砂鉄が磁化された磁気性材料で構成されているので、当該搬送ベルト10に効果的かつ廉価なコストで磁力を与えることができる。

The

なお、補給樋20はステンレス製であるので、表面が滑らかで剛性も高い。従って、パチンコ玉4は補給樋20の上面を長期にわたって円滑に移動することができる。

Since the replenishing

請求項6に記載のパチンコ玉供給装置1は、請求項1および2に記載の発明と同様の効果を発揮する。すなわち、遊技場を広く開放感があり、明るい雰囲気の場所とすることができる。また、パチンコ玉4の搬送中でも保守点検を行うことができる。また、左右両側のパチンコ機3に均等にパチンコ玉4を供給することができる。さらに、複数の突出部10aによって、パチンコ玉4を効率的に搬送することができる。

The pachinko ball supply device 1 according to claim 6 exhibits the same effects as the inventions according to

本発明に係るパチンコ玉供給装置1の実施形態を、図1乃至図6に示す。これは、パチンコ玉を用いる遊技機の一例としてパチンコ機3を、左右に背合わせ状に配列して形成される遊技機島2の上部に設けられ、各パチンコ機3にパチンコ玉4を供給する装置であり、搬送ベルト10、補給樋20、第一補給シュート60a、および第二補給シュート60bを備える。

An embodiment of a pachinko ball supply apparatus 1 according to the present invention is shown in FIGS. This is provided in the upper part of the

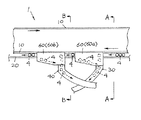

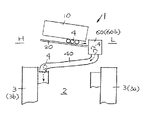

搬送ベルト10は、無端状のいわゆる無端ベルトで構成し、遊技機島2の前後長手方向に水平に配置されている。また、上流側(または下流側)に設けられモーターで回転する駆動ローラー11aと、下流側(または上流側)に設けられた従動ローラー11bとに懸架され、これら駆動ローラー11aおよび従動ローラー11bと共に、左右短尺方向の一方側(右側)に所定角度αで傾斜させている(図3参照)。なお、図3において、符号Eは水平ラインを示し、符号Dは搬送ベルトの傾斜ラインを示す。

The

補給樋20は、搬送ベルト10の直下に、パチンコ玉4の直径とほぼ等しい間隔Cを開けて設けられており、本実施形態では、非磁性体のSUS304のステンレス製で平板状である。また、搬送ベルト10と同一の傾斜角度で設けられ、上面を搬送ベルト10で搬送されるパチンコ玉4が移動する。

The replenishing

第一補給シュート60aは、複数が、補給樋20の低所側Lである左右短尺方向の一方側(右側)に、前後長手方向に沿って、低所側Lの各パチンコ機3aに対応して設けられ、補給樋20の上面のパチンコ玉4を、その自重で、低所側(右側)Lに位置するパチンコ機3aに、下流端部に設けられたジャバラ30を経由して供給する。なお、本実施形態では、各第一捕球シュート60aは、ほぼ等間隔で設けられている。

A plurality of

第二補給シュート60bは、複数が、捕球樋20の低所側Lである左右短尺方向の一定側(右側)に、前後長手方向に沿って、高所側Hの各パチンコ機3bに対応して設けられ、補給樋20の上面のパチンコ玉4を、その自重で、高所側(左側)Hに位置するパチンコ機3bに、下流端部に設けられたジャバラ40を経由して供給する。

なお、本実施形態では、各第二補給シュート60bは、ほぼ等間隔で設けられている。また、第一補給シュート60aと第二補給シュート60bは交互に設けられている。

A plurality of

In the present embodiment, the

そして、補給シュートの間には、図示が省略する側壁が設けられている。(特開平08−164263号公報参照)

また、遊技機島2に玉貸機が設けられる場合には、玉貸機用の補給シュートが設けられる。(図示省略)

A side wall (not shown) is provided between the replenishing chutes. (See JP 08-164263 A)

When a ball lending machine is provided on the

そして、搬送ベルト10は、ゴム材に砂鉄を混在させて形成し、その後、砂鉄を磁化した磁気性材料で構成している。

The

このパチンコ玉供給装置1は、次のように作動する。まず、モーターを稼動させて駆動ローラー11aを回転させ、搬送ベルト10を、駆動ローラー11aと従動ローラー11bとの間で周回させる。これにより、揚送機構50によって補給樋20の上流側に供給されたパチンコ玉4を、搬送ベルト10の磁力によって吸着し補給樋20の上面に沿って下流側へ搬送する。

This pachinko ball supply device 1 operates as follows. First, the motor is operated to rotate the driving roller 11a, and the

搬送ベルト10によって搬送されるパチンコ玉4は、補給樋20の上面を下流側に移動しながら、随時、補給樋20の傾斜の作用により、低所側Lに自重で転がる。そして、低所側Lおよび高所側Hの各パチンコ機3a,3bに対応して設けられ、補給樋20上のパチンコ玉を分配して各パチンコ機3に供給するか分離器としての第一補給シュート60a,第二補給シュート60bに入り、そこからジャバラ30およびジャバラ40を通過して、ジャバラの下流端部に設けられた

100切可変式や連続補給式などの補給カウンター(図示省略)を経由して、それぞれ低所側Lのパチンコ機3aおよび高所側Hのパチンコ機3b の上部に設けられた貯留タンクに供給される。これにより、低所側Lおよび高所側Hの全てのパチンコ機3に、パチンコ玉4が均等に供給される(図4,5,6参照)。

なお、補給カウンターについては、特許庁作成の標準技術集(遊技機及びその関連技術)に記載されているため説明を省略する。

The

The replenishment counter is described in the standard technology collection (amusement machines and related technologies) prepared by the JPO, so the explanation is omitted.

なお、搬送ベルト10を磁気性材料で形成する手段としては、上記の他に、ゴム等の弾性材製のベルト本体の外周面に、ベルトの長手方向にS極とN極を交互に着磁して磁性帯を形成することが考えられる。(特開平3−46942号公報参照)

In addition to the above, as a means for forming the

本実施形態に係るパチンコ玉供給装置1は、搬送ベルト10を前後長手方向に水平に配置しているので、高さ方向に大きな設置スペースを必要とせず、従って、遊技場を広く開放感があり、雰囲気の明るい場所とすることができる。

In the pachinko ball supply apparatus 1 according to the present embodiment, the

また、搬送ベルト10の直下に補給樋20を設け、両者の間でパチンコ玉4を搬送するので、パチンコ玉4を搬送中でも、当該搬送ベルト10およびそれを周回させるローラー11や駆動装置の保守点検を行うことができる。

In addition, since the replenishing

また、搬送ベルト10および補給樋20を、左右短尺方向の一方側に所定角度αで傾斜させて、低所側Lに第一補給シュート60aと第二補給シュート60bの両方を設けているので、左右両側(低所側Lと高所側H)のパチンコ機3に均等にパチンコ玉4を供給することができる。

In addition, since the

また、搬送ベルト10を磁気性材料で形成しているので、磁力によって鉄製であるパチンコ玉4を吸着することができ、当該パチンコ玉4を効率的に搬送することができる。

Moreover, since the

なお、搬送ベルト10と補給樋20の間隔Cを、パチンコ玉4の直径とほぼ等しく設定しているので、当該搬送ベルト10をパチンコ玉4に確実に接触させることができる。これにより、パチンコ玉4を、より効率的に搬送することができる。

In addition, since the distance C between the

この搬送ベルト10はその上流側と下流側に設けた二つのローラー11に懸架させているので、その中央部分が自重によって垂下し易いが、この垂下によってパチンコ玉4により強く接触するので、当該パチンコ玉4を効率的に搬送することができる。

Since the

また、搬送ベルト10を、ゴム材に砂鉄を混在させて形成し、その砂鉄を磁化して形成しているので、当該搬送ベルト10に効果的かつ廉価なコストで磁力を与えることができる。

Further, since the

なお、補給樋20はSUS304のステンレス製であるので、搬送ベルト10の磁力が作用せず、また、表面が滑らかで剛性も高い。従って、パチンコ玉4は補給樋20の上面を、長期にわたって円滑に移動することができる。

Since the replenishing

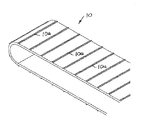

なお、上記実施形態における搬送ベルト10は磁気性材料で形成しているが、本発明はこうした構成に限定されるものではなく、例えば、図7に示すように、非磁気性材料(または磁気性材料)で形成し、その外周面に多数の突出部10aを形成して構成することができる。この突出部10aは、左右短尺方向に形成した壁状であり(高さ約2mm)、前後長手方向に所定間隔(パチンコ玉の複数個分)を空けて設けている。

In addition, although the

この突出部10aは、搬送ベルト10の移動によって補給樋20上面のパチンコ玉4の上部に当接し、当該パチンコ玉4に移動方向への速度を付与する速度付与部材として作用する。

The

また、この搬送ベルト10は、図8および図9に示すように、その外周面に例えば半径約2mmの半球状の突出部10aを左右短尺方向に等間隔(パチンコ玉1〜2個分)で設けて半球体列10Lを形成し、その半球体列10Lを前後長手方向に等間隔(パチンコ玉複数個分)で多数配列して構成したものである。なお、各半球体列10Lの突出部10aを、それに対応する前後半球体列10Lの突出部10aから左右斜め方向にずらして設け、いわゆる千鳥状に配置している。この突出部10aも、搬送ベルト10の移動によって補給樋20上面のパチンコ玉4の上部に当接し、当該パチンコ玉4に移動方向への速度を付与する速度付与部材として作用する。

Further, as shown in FIGS. 8 and 9, the

なお、突出部10aを半球状とし、パチンコ玉より大きい間隔で配置しているので、パチンコ玉4はこれら突出部10a間を容易に通過することができる。従って、パチンコ玉4が詰まるといった事態を未然に回避することができる。また、突出部10aを千鳥状に配置しているので、突出部10a間を通過してそこに留まっているパチンコ玉4に、後続の突出部10aが当接する。従って、全てのパチンコ玉4を円滑に搬送することができる。

In addition, since the

なお、上記実施形態における補給シュートは、パチンコ機1台に対応して1つ設けられているが、本発明はこうした構成に限定されるものではなく、特開平7−163741号公報に記載のように、複数の補給シュートを一体化して設けても良い。 One replenishment chute in the above embodiment is provided corresponding to one pachinko machine, but the present invention is not limited to such a configuration, as described in JP-A-7-163741 In addition, a plurality of supply chutes may be provided integrally.

例えば、補給シュートの一方のジャバラから低所側Lのパチンコ機3aに、他方のジャバラから高所側Hのパチンコ機3bに供給されるように、つまり、第一補給シュート60aと第二補給シュート60bを一体化してもよい。

For example, the

また、補給シュートの一方のジャバラから低所側Lのパチンコ機3aに、他方のジャバラから低所側Lの他パチンコ機3aに供給されるように、つまり、第一補給シュート60aと第一補給シュート60aを一体化してもよい。

Further, the supply chute is supplied from one bellows to the low-side

また、同様に、第二補給シュート60bと第二補給シュート60bを一体化してもよい。

また、同様に、玉貸機用の補給シュートを設ける場合に、玉貸機用の補給シュートを、第一補給シュート60aまたは、第二補給シュート60bと一体化してもよい。

Similarly, the

Similarly, when a supply chute for a ball lending machine is provided, the replenishment chute for the ball lending machine may be integrated with the

また、上記実施形態における補給樋20は、SUS304のステンレス製の平板であるが、本発明はこうした構成に限定されるものではなく、例えば、補給樋20をアルミ製の押出し材としてもよい。また、アルミ製の押出し材の上にステンレス製の平板を貼付したり載置しても良い。またSUS304以外のステンレス製でもよい。

Further, the replenishing

1 パチンコ玉供給装置

2 遊技機島

3 パチンコ機

3a パチンコ機(低所側)

3b パチンコ機(高所側)

4 パチンコ玉

10 搬送ベルト

10a 突出部

10L 半球体列

11 ローラー

11a 駆動ローラー

11b 従動ローラー

20 補給樋

30 ジャバラ

40 ジャバラ

50 揚送機構

60 補給シュート

60a 第一補給シュート(低所側)

60b 第二補給シュート(高所側)

C 間隔

D 搬送ベルト(およびローラー)の傾斜ライン

E 水平ライン

H 高所側

L 低所側

α 所定角度

1 Pachinko

3b Pachinko machine (high side)

4

60b Second supply chute (high side)

C Spacing D Conveyor belt (and roller) tilt line E Horizontal line H High side L Low side α Predetermined angle

Claims (6)

前記搬送ベルトが、その外周面に、パチンコ玉に移動方向への速度を付与する速度付与部材として、前記パチンコ玉に当接する突出部を複数有するものであることを特徴とするパチンコ玉供給装置。 A device for supplying pachinko balls to each gaming machine, which is provided by arranging gaming machines in a back-to-back arrangement on the left and right, and is horizontally arranged in the longitudinal direction of the gaming machine island. An endless conveyor belt suspended by two rollers provided on the upstream side and the downstream side, and inclined at a predetermined angle to one side in the lateral direction of the left and right sides, and the pachinko belt just below the conveyor belt. A flat plate provided with an interval substantially equal to the diameter of the ball, fixed at the same inclination angle as the conveyor belt, and a lower surface side of the supply rod on which the pachinko ball moves on the upper surface Provided on one side of the left and right short direction at substantially equal intervals along the longitudinal direction, and a plurality of first pachinko balls on the top surface of the replenishing bowl are supplied to the gaming machine located on the low side by its own weight. One supply chute and the first supply A game that is provided on the lower side, adjacent to the mute, at substantially equal intervals along the longitudinal direction, and that the pachinko balls on the upper surface of the replenishing basket are located on the higher side of the replenishing bowl with their own weight. A plurality of second supply chutes for supplying to the machine,

The pachinko ball supply device according to claim 1, wherein the conveyor belt has a plurality of protrusions that contact the pachinko ball as a speed imparting member that imparts a speed in the moving direction to the pachinko ball on an outer peripheral surface thereof.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007324932A JP2008307364A (en) | 2007-05-15 | 2007-12-17 | Pachinko ball supply device |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007128963 | 2007-05-15 | ||

| JP2007324932A JP2008307364A (en) | 2007-05-15 | 2007-12-17 | Pachinko ball supply device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008307364A true JP2008307364A (en) | 2008-12-25 |

| JP2008307364A5 JP2008307364A5 (en) | 2011-01-27 |

Family

ID=40235500

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007324932A Pending JP2008307364A (en) | 2007-05-15 | 2007-12-17 | Pachinko ball supply device |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2008307364A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20150094483A (en) * | 2014-02-10 | 2015-08-19 | 삼성전자주식회사 | Electro device configured to display three dimensional virtual space and method for controlling thereof |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04266780A (en) * | 1991-02-21 | 1992-09-22 | Ikyo Kk | Horizontal carriage device for pachinko ball |

| JPH09299583A (en) * | 1996-05-17 | 1997-11-25 | Sankyo Kk | Device for game |

| JP2004160022A (en) * | 2002-11-14 | 2004-06-10 | Heiwa Corp | Device for collecting falling ball |

-

2007

- 2007-12-17 JP JP2007324932A patent/JP2008307364A/en active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04266780A (en) * | 1991-02-21 | 1992-09-22 | Ikyo Kk | Horizontal carriage device for pachinko ball |

| JPH09299583A (en) * | 1996-05-17 | 1997-11-25 | Sankyo Kk | Device for game |

| JP2004160022A (en) * | 2002-11-14 | 2004-06-10 | Heiwa Corp | Device for collecting falling ball |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20150094483A (en) * | 2014-02-10 | 2015-08-19 | 삼성전자주식회사 | Electro device configured to display three dimensional virtual space and method for controlling thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2008307364A (en) | Pachinko ball supply device | |

| JP2008307364A5 (en) | ||

| KR101039714B1 (en) | Conveyor system with meandering mechanism | |

| JP2009102106A (en) | Component supply apparatus and component supply method | |

| JP2010012139A (en) | Game ball feeder | |

| JP5042747B2 (en) | Pachinko ball feeder | |

| JP5339228B2 (en) | Pachinko ball feeder | |

| JP5123620B2 (en) | Pachinko ball feeder | |

| JP5280048B2 (en) | Game ball supply device | |

| JPH07148334A (en) | Method and device for supplying balls to pachinko island unit | |

| JP2008006093A (en) | Game ball lifting device | |

| JP2008302104A5 (en) | ||

| JP2009050628A5 (en) | ||

| JP5374066B2 (en) | Game ball supply device | |

| JP6037231B2 (en) | Game ball transport device | |

| JP2016204147A (en) | Feed repeating device for small-sized formed article | |

| JP2009066102A5 (en) | ||

| JP2006341028A (en) | Mini lift for pachinko ball | |

| JP4012231B2 (en) | Pachinko Island | |

| JP4912066B2 (en) | Game media transport device | |

| JP5280049B2 (en) | Game ball supply device | |

| JP2008000518A (en) | Game ball lifting device | |

| JP2002186768A (en) | Inclined mini lift for pachinko ball | |

| JP5185674B2 (en) | Game ball supply device | |

| JP5185675B2 (en) | Game ball supply device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101207 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101207 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20120607 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20120607 |

|

| RD04 | Notification of resignation of power of attorney |

Effective date: 20120628 Free format text: JAPANESE INTERMEDIATE CODE: A7424 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120928 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20121002 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130402 |