JP2007152360A - Spot welding electrode elevating in vertical attitude - Google Patents

Spot welding electrode elevating in vertical attitude Download PDFInfo

- Publication number

- JP2007152360A JP2007152360A JP2005347132A JP2005347132A JP2007152360A JP 2007152360 A JP2007152360 A JP 2007152360A JP 2005347132 A JP2005347132 A JP 2005347132A JP 2005347132 A JP2005347132 A JP 2005347132A JP 2007152360 A JP2007152360 A JP 2007152360A

- Authority

- JP

- Japan

- Prior art keywords

- welding

- electrode

- spot

- tip

- vertical

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Resistance Welding (AREA)

Abstract

Description

本発明は縦向き姿勢によるスポット溶接用電極に係り、詳しくは、縦向き姿勢で昇降する電極により金属材などから成る被溶接物を局部的にはさみ加圧通電して溶接する溶接電極であって、溶接打点が被溶接物の内部にあっても縦向き姿勢で昇降させて溶接できる溶接電極である。 The present invention relates to an electrode for spot welding in a vertical orientation, and more specifically, a welding electrode for welding a workpiece made of a metal material or the like by locally sandwiching an object to be moved up and down in a vertical orientation and applying pressure. This is a welding electrode that can be welded by moving it up and down in a vertical orientation even when the welding spot is inside the workpiece.

従来から、各種金属板、例えば圧延鋼板、アルミニウムおよびその合金材、およびZnめっき鋼板などの被溶接材を溶接する場合に、少なくとも2枚またはそれ以上の被溶接材を重ねて、これを上下電極で挾み、加圧、通電して溶接し、ナゲットを形成して溶接するスポット溶接が用いられ、現在、電気エネルギ−を利用する電気溶接のうちで最も普及されている溶接法の一つであって、自動車産業のほか広く金属加工、板金加工といわれる分野で広く用いられている。 Conventionally, when welding materials to be welded such as various metal plates, such as rolled steel plates, aluminum and their alloy materials, and Zn-plated steel plates, at least two or more materials to be welded are stacked on top and bottom electrodes. Spot welding is used in which welding is performed by squeezing, pressurizing and energizing, forming a nugget and welding, and is currently one of the most popular welding methods using electric energy. In addition to the automobile industry, it is widely used in fields called metal processing and sheet metal processing.

一般的に云って、スポット溶接では数秒で一つのスポット溶接ができ、溶接は被溶接材の間で行なわれるため、他にシ−ルドガスなどを必要としない。一度溶接条件を設定すると全く素人の人やロボットでも容易に溶接ができる。安定した溶接ナゲットや継手強度が得られる利点がある。それ故に、自動車等の量生産方式における接合手段としては勿論のほか、広く金属加工一般で用いられている。 Generally speaking, in spot welding, one spot welding can be performed in a few seconds, and welding is performed between workpieces, so that no other shield gas or the like is required. Once the welding conditions are set, welding can be easily performed even by completely amateur people or robots. There is an advantage that a stable weld nugget and joint strength can be obtained. Therefore, it is widely used in general metal processing as well as a joining means in a mass production system of automobiles and the like.

しかし、スポット溶接は高い加圧力を求めるために、縦向き姿勢で昇降する溶接ガンを用いて溶接することから、被溶接材やそれによる構造物の内部に溶接打点があるときには、被溶接物の一部が昇降時の障害になって溶接できない欠点がある。 However, spot welding is performed using a welding gun that moves up and down in a vertical orientation to obtain a high applied pressure. Therefore, when there is a welding point inside the work piece and the resulting structure, There is a drawback that some of them can not be welded because they become obstacles when moving up and down.

すなわち、スポット溶接機において、縦向き姿勢で昇降する溶接電極は、

(1)溶接すべき溶接打点に大きな溶接電流を供給すること、

(2)溶接すべき溶接打点に高い加圧力を与えること、

(3)溶接すべき溶接打点の表面を冷却すること、

などの目的をもっている。

That is, in a spot welder, the welding electrode that moves up and down in a vertical orientation is

(1) supplying a large welding current to the welding spot to be welded;

(2) Giving high welding pressure to the welding spot to be welded;

(3) cooling the surface of the welding spot to be welded;

It has a purpose such as.

このため、溶接中、電極の電流密度は100〜500A/mm2というような高い値になり、圧力も5〜12kgf/mm2に及んでいる。このように高い圧力を得るにはどうしても縦向き姿勢で電極を全く障害物なく昇降させることが必要になって、例えば函や容器などの被溶接物の内部に溶接打点があるときには、スポット溶接では溶接できないといわれている。 For this reason, during welding, the current density of the electrode is as high as 100 to 500 A / mm 2 , and the pressure ranges from 5 to 12 kgf / mm 2 . In order to obtain such a high pressure, it is absolutely necessary to raise and lower the electrode in an upright position without any obstacles.For example, when there is a welding spot inside the work piece such as a box or a container, It is said that it cannot be welded.

そこで、本発明者らは、先に、特許第3445636号明細書に記載されるように、被溶接材を上下からはさむ上部および下部の溶接電極のうちで、棒状に構成される上部の溶接電極に対し、下部の溶接電極をその表面に平坦で導電性をもつテ−ブル状のものとして構成し、このテ−ブル状電極上に被溶接材をセットしたままで溶接できるスポット溶接機を提案した。 Therefore, as described above in the specification of Japanese Patent No. 3445636, the present inventors have made an upper welding electrode configured in a rod shape among upper and lower welding electrodes that sandwich a material to be welded from above and below. On the other hand, a spot welding machine is proposed in which the lower welding electrode is formed as a flat and conductive table on the surface, and welding can be performed with the work piece set on the table-like electrode. did.

このテ−ブル式スポット溶接機は、上部電極の溶接ガンを横向き姿勢で利用するものであって、この棒状電極をてことして利用するものであるため、被溶接物の内部に溶接打点があっても、横向き姿勢の溶接ガンを侵入させることができる。しかし、このテ−ブル式スポット溶接機はてこ機構という倍力機構を利用して下向きの加圧力を与えられるのは好ましいが、横向き姿勢の溶接ガンをてことして利用するため、かける力をあまり高くすることは構造上の支障があり、それほど高い加圧力が得られない欠点がある。 This table type spot welding machine uses the welding gun of the upper electrode in a horizontal orientation, and uses it by levering this rod-like electrode, so there is a welding spot inside the work piece. Also, it is possible to infiltrate a welding gun in a lateral orientation. However, it is preferable that this table type spot welder can apply a downward pressure using a lever mechanism called a lever mechanism. However, there is a drawback in that the structure is hindered and a high pressure cannot be obtained.

また、縦向き姿勢で昇降する溶接ガンの先端、つまり溶接チップには高温度下に高い加圧力が加えられ、溶接点数の進行にともなってだんだん圧潰し変形し、電極チップの接触面は合金化し汚れ(ピック・アップ)を生ずる。このため、スポットの溶接点数が溶接品質や作業能率に影響するところに達すると、平たくいうと、電極の寿命に達すると、新しい溶接チップや溶接電極にとり換えることが必要となる。 Also, a high pressure is applied to the tip of the welding gun that moves up and down in a vertical orientation, that is, the welding tip, and it gradually crushes and deforms as the number of welding points progresses, and the contact surface of the electrode tip is alloyed. Causes dirt (pick up). For this reason, when the number of spot welds reaches a point where the welding quality or work efficiency is affected, it is necessary to replace it with a new welding tip or welding electrode when the life of the electrode is reached.

しかし、この溶接チップの交換、取替えなどの作業には多大の手間がかかる。すなわち、溶接チップや溶接電極は高温下での加圧という悪条件にさらされ、このため、取替えるべき溶接チップや溶接電極が変形して焼き付いており、その溶接チップを取外すことに多大の手間がかかるという欠点がある。 However, it takes a lot of work to replace and replace the welding tip. That is, the welding tip and the welding electrode are exposed to an adverse condition of pressurization at a high temperature. Therefore, the welding tip and the welding electrode to be replaced are deformed and seized, and it takes a lot of trouble to remove the welding tip. There is a disadvantage that it takes.

更に説明すると、溶接部表面の冷却には溶接チップが直接関与し、溶接チップの変形により冷却水がもれ、溶接ガン先端、なかでも溶接チップの取付構造にはこのようなところの改善が行なわれていることが望まれている。

本発明は上記欠点の解決を目的とし、具体的には、鋼板その他の金属板をはさんで加圧通電するために用いられる縦向き姿勢の溶接電極において、その一部に凸状のにげ部を設けて、このにげ部によって被溶接物の構造による障害を除去し、被溶接物の内部にある溶接打点であっても、溶接電極の縦向き姿勢での昇降により溶接できる縦向き溶接電極を提案する。 An object of the present invention is to solve the above-mentioned drawbacks. Specifically, in a welding electrode in a vertical orientation used for energizing and pressing a steel plate or other metal plate, a convex bow is formed on a part thereof. Vertical welding that removes obstacles due to the structure of the work piece by this bald part and can be welded by raising and lowering the welding electrode in a vertical position even at the welding spot inside the work piece Propose electrodes.

すなわち、本発明は被溶接材をはさんで抵抗溶接する一対の電極のうちで一方の電極の縦向き棒状溶接ガンの少なくとも一部に凸状にげ部を設け、このにげ部の少なくとも一部を取付け面としてホルダ部材を取付け、このホルダ部材により縦向き棒状溶接ガン先端の溶接部を縦向き棒状溶接ガンと共通の縦向き直線上に位置するよう保持して成ることを特徴とする。 That is, according to the present invention, among the pair of electrodes that are resistance-welded across the material to be welded, at least a part of the vertically-oriented bar-shaped welding gun of one electrode is provided with a convex ridge, and at least one of the ridges is provided. A holder member is attached with the portion as an attachment surface, and the welded portion at the tip of the vertical bar-shaped welding gun is held by this holder member so as to be positioned on a common vertical straight line with the vertical bar-shaped welding gun.

このように、本発明に係る溶接電極、つまり溶接ガンの一部ににげ部として凸状部を具えるため、溶接のときに被溶接物の一部が障害になっても、その障害部分はにげ部に吸収されるため、支障なく溶接できる。また、突出するにげ凸部にはそれを利用してホルダ部材を着脱自在に取付けることができるとともに、このホルダ部材を溶接チップなどを取付けることができるため、溶接チップの交換はホルダ部材を取外すのみで達成でき、支障なく溶接の交換が達成できる。 As described above, since the welding electrode according to the present invention, that is, a part of the welding gun is provided with a convex portion as a bow portion, even if a part of the work piece becomes an obstacle during welding, the obstacle part Since it is absorbed by the bald part, it can be welded without any problem. In addition, a holder member can be detachably attached to the protruding convex protrusion using this, and a welding tip or the like can be attached to the holder member. It is possible to achieve the replacement of welding without any trouble.

そこで、本発明の好適な実施例について添付図面を通じてつぎのとおり、説明する。 Therefore, a preferred embodiment of the present invention will be described as follows through the accompanying drawings.

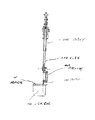

なお、図1は本発明の一つの実施例に係る溶接電極の一部を断面で示す正面図である。 In addition, FIG. 1 is a front view which shows a part of welding electrode which concerns on one Example of this invention in a cross section.

図2は図1の一部の拡大断面図である。 FIG. 2 is an enlarged cross-sectional view of a part of FIG.

図3は図1に示す溶接電極に設けられる溶接チップなどの保持装置の一例の組立図である。 FIG. 3 is an assembly diagram of an example of a holding device such as a welding tip provided on the welding electrode shown in FIG.

図4は図2の一部を拡大して示す説明図である。 FIG. 4 is an explanatory view showing a part of FIG. 2 in an enlarged manner.

まず、図1、図2、図3および図4において、符号200は、本発明に一つの実施例に係る溶接電極、つまり、溶接ガンを示し、符号100はこの溶接ガン200の一部に設けられる溶接チップなどの保持装置を示し、符号300は下部電極の一例として働くテ−ブル状電極を示し、符号Wは被溶接材を示す。この保持装置100において符号110はホルダ部材、120はリング体、130は止めねじをそれぞれ示す。

First, in FIG. 1, FIG. 2, FIG. 3 and FIG. 4,

図1において符号200で示され、図2においてその一部が示される溶接ガン200は、縦向き姿勢で使用され昇降自在に構成され、例えばエア−シリンダ(図示せず)の付勢によって被溶接材Wに高い加圧力が加えられる。溶接ガン200はそれに対応するテ−ブル状電極300との間で上下から被溶接材Wをはさみ、加圧通電して抵抗溶接する。

A

なお、この被溶接材Wは、図2に示すとおり、例えば金属容器や金属函のように鋼板が組合わされて構成されている。このため、その内部に溶接打点が存在する。それ故に、従来例の溶接ガンのように直線状に構成されているものであると、それの昇降の時に被溶接材Wの一部が障害となり、溶接できないといわれている。 In addition, as shown in FIG. 2, this to-be-welded material W is comprised with the steel plate combined like a metal container or a metal box, for example. For this reason, a welding spot exists in the inside. Therefore, it is said that if the welding gun is configured in a straight line like the conventional welding gun, a part of the workpiece W is obstructed when it is raised and lowered, and welding cannot be performed.

溶接ガン200は溶接電源(図示せず)の一方の極に接続されて上部電極として働くのに対し、下部電極として溶接電源の他方の極に接続されるテ−ブル状電極300はその上に被溶接材Wをのせられ、溶接打点の進行に応じて動かすことなくそのままにして順次に溶接打点を変更して上部電極として働く溶接ガン200によって連続的に順次に溶接点を打ってスポット溶接することができる。

The

図4に示す実施例は下部電極としてテ−ブル状電極300を用いているが、必ずしもテ−ブル状電極として構成する必要がない。従来例の定置型溶接機のように棒状の溶接電極として構成することができる。しかし、図4に示す如く、テ−ブル状電極300であると、溶接のときに被溶接材又は被溶接物Wをその上に置いたままで順次に被溶接材Wのコ−ナ部を溶接できる。 Although the embodiment shown in FIG. 4 uses the table-like electrode 300 as the lower electrode, it is not always necessary to configure it as a table-like electrode. It can be configured as a rod-shaped welding electrode as in the conventional stationary welding machine. However, as shown in FIG. 4, in the case of the table-like electrode 300, the corner portions of the workpiece W are sequentially welded while the workpiece or workpiece W is placed on the welding electrode. it can.

すなわち、テ−ブル状電極300の表面の何れのところも通電されており、溶接ガン200で打ったところはスポット電極として働くことができるため、所定の打点を打ったのちでも被溶接材Wを移動させることなく溶接できる。

That is, any part of the surface of the table-like electrode 300 is energized, and when it is struck with the

一方、このように上部電極を成す棒状の溶接ガン200は先端に溶接チップ210を具えるものであれば何れにも構成できるが、この溶接チップ210を所望のシャンク部材220に嵌合させても構成できる。

On the other hand, the rod-

すなわち、図1およびその一部が図2に示す溶接ガン200は溶接ガン本体230と中間部材240とから成って、これらは互いにはめ合わされて接合されている。このため、所望に応じて溶接部の位置や被溶接材Wの形状に応じて中間部材240を交換して溶接できる。

That is, the

このようにガン本体230に接合する中間部材240の先端には溶接チップ210が設けられるが、溶接チップ210はシャンク部材220を介して取付けられる。しかし、場合によっては溶接チップ210そのものを直接中間部材240に取付けることが構成できる。しかし、溶接ガン200の先端にシャンク部材220を介在させると、例えば、図2に示すように、シャンク部材220を僅かにオフセットさせて構成することもでき、そのオフセット分だけ溶接チップ210の位置をづらすことができる。

Thus, the

以上のとおり、被溶接材Wを上下からはさんで抵抗溶接する上部電極として働く溶接ガン200において、少なくとも一部として凸状にげ部400を設ける。このにげ部400は、図2に拡大して示す通り、溶接ガン200の一部、なかでもその中間部材240の一部が突出したものであって、図2に示すとおり、コ字状に形成されている。このにげ部400を設けることに伴って、溶接ガン200の一部が変形凸状となるが、全体として中間部材240の先端に設けられる溶接チップ210と溶接ガン200、なかでもガン本体230とが共通の縦向き直線上に位置するよう構成する。

As described above, in the

縦向き姿勢で働く溶接ガンは一般に全体にわたって一つの直線状を成すのが好ましい。この理由はその縦軸を通じて加圧力が加えられるために溶接ガンで力の作用点が横にふれると、その分だけ曲げ、捩りなどの応力がかかり、先端の溶接チップ210が被溶接材Wの表面に平均して接触することができない。形成される溶接部の強度が劣化する。

It is generally preferred that the welding gun working in a vertical orientation is generally straight. The reason for this is that pressure is applied through the vertical axis, so that if the point of action of the welding gun is moved sideways, stress such as bending or twisting is applied to that extent, and the tip of the

これに対し、本発明者らは検討したところ、途中の一部ににげ部を設けても、全体として、なかでも、垂直荷重の作用する力点のガン本体230と荷重点の溶接チップ210とが同一軸線上にあるときには、平均して加圧力がかかり、強度の一定の溶接部が得られることがわかった。

On the other hand, when the present inventors examined, even if it provided a bow part in the middle part, as a whole, especially the gun body 230 of the power point to which a vertical load acts, and the

要するに、にげ部400を設けてもその部分の強度が圧さく破壊されない程度の強度であってオフセットの割合があまり大きくない場合は、溶接チップ210の接触面全体に平均して垂直な力を加えることができ、溶接性も損なうことがない。

In short, even if the

また、スポット溶接で縦向き姿勢で使用される電極においては凸状のにげ部400は図1および図2に示すコ字状に構成する代りに、図示を省略するが、多角形状に折曲げて構成することもできる。

Further, in an electrode used in a vertical orientation in spot welding, the

また、凸状にげ部400はコ字状に折曲げて構成するが、凸状にげ部400において、その中に形成される冷却水流路の折曲げ部の少なくとも一部を円弧状に構成することもできる。すなわち、にげ部400の形成にともなって内部の冷却水流路に折曲げ部が形成され、この折曲げ部によって冷却水の流れの内側と外側で流速が大巾に変わる。この変化は冷却能力の均一性を欠くことになり、このところが円弧部を形成することにより緩和できて好ましい。

Further, the convex

また、凸状のにげ部400を設けることによってその外面の少なくとも一部に平面状の取付面を設けることができる。この取付面を介して後記のホルダ部材から成る溶接チップなどのホルダ装置100を着脱自在に取付けることができる。ホルダ部材によると、溶接ガン200の先端部分を周囲から押えて保持でき、溶接チップなどの交換や焼付きのときには、ホルダ部材を取り外すのみで溶接チップなどは取外すことができる。また、ホルダ部材は凸状にげ部400の取付面にねじ止めでき、ねじを取外すのみで着脱自在に構成できる。

Further, by providing the

以上のとおり構成される溶接ガン200において、その一部、なかでも、中間部材240そのものを図2に示すとおり、凸状にげ部400を具えるものとして構成すると、このにげ部400の取付面を介して保持装置100を着脱自在に取付けることができ、さらに、溶接チップ210をオフセットして溶接する場合にのみにげ部400を具える中間部材240を取替えて溶接できる。

In the

保持装置100は、溶接キャップ210を保持するためのものであって、保持装置100にはホルダ部材110を設け、このホルダ部材110を板状材から構成すると共に、このホルダ部材110の一部に嵌合孔120を形成し、この嵌合孔120に溶接チップ210又はそれに介在させるシャンク部材220を嵌合させ抜差自在に構成させる。

The holding

このように溶接キャップ210を保持装置100を介して溶接ガン200の先端に取付けると、溶接キャップ210の取付けに関与するのは保持装置100であって、保持装置100、なかでもホルダ部材110を取外すのみで溶接チップ210を交換できるため、きわめて交換が容易となる。しかしながら、このように交換機構を構成すると、交換機構の保持装置100から冷却水などがもれを防止する必要がある。このところから、板状材から成るホルダ部材110の嵌合孔120の周囲にリング溝121を設け、このリング溝121にリング体130を着座させ、このリング体130によって嵌合孔120に嵌合させるシャンク部材220を締め付けるように構成するのが好ましい。

When the

また、溶接キャップの保持装置100においてそのホルダ部材110を着脱自在に構成するのと併って、溶接ガン200の先端にはその一部に取付面を構成し、その取外面にホルダ部材110をねじ止めすることもできる。

In addition, the

また、溶接ガン200を溶接ガン本体230とホルダ部240とを分割して構成し、そのホルダ部240の一部に取付面を設けるのに伴って、この取付面に関連させてホルダ部240内に冷却水通路241が形成できる。このように分割されたホルダ部240内に冷却水通路241を形成すると、この部分を閉塞する栓部材242を開放することにより、冷却水通路241内のつまりを防止できる。

Further, the

以上のとおり、本発明は被溶接材をはさんで抵抗溶接する際に縦向き姿勢で一方の電極として働く縦向き棒状溶接ガンの少なくとも一部に凸状にげ部が設けられており、このにげ部を利用してホルダ部材を着脱自在に取付けてこのホルダ部材により溶接ガン先端の溶接部を保持するものであって、このような縦向き電極はスポット溶接一般に用いられ、なかでも、金属函、配電板そのほか所謂板金加工と称せられる分野に用いることができる。 As described above, the present invention is provided with a convex bald portion on at least a part of a vertical rod-shaped welding gun that works as one electrode in a vertical posture when resistance welding is performed across a material to be welded. A holder member is detachably attached using a barb portion, and the welded portion at the tip of the welding gun is held by this holder member. Such a vertical electrode is generally used for spot welding, and in particular, metal It can be used in a field called box processing, distribution board and so-called sheet metal processing.

100 保持装置

200 溶接ガン

230 ガン本体

300 シ−ト状電極

400 凸状にげ部

W 被溶接材

DESCRIPTION OF

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005347132A JP2007152360A (en) | 2005-11-30 | 2005-11-30 | Spot welding electrode elevating in vertical attitude |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005347132A JP2007152360A (en) | 2005-11-30 | 2005-11-30 | Spot welding electrode elevating in vertical attitude |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007152360A true JP2007152360A (en) | 2007-06-21 |

| JP2007152360A5 JP2007152360A5 (en) | 2010-04-30 |

Family

ID=38237371

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005347132A Pending JP2007152360A (en) | 2005-11-30 | 2005-11-30 | Spot welding electrode elevating in vertical attitude |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2007152360A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011110585A (en) * | 2009-11-27 | 2011-06-09 | Koyo Giken:Kk | Power supply system of spot welding machine |

| JP2023048881A (en) * | 2021-09-28 | 2023-04-07 | Obara株式会社 | Exchange holding device of electrode tip |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58122186A (en) * | 1982-01-12 | 1983-07-20 | Tokyu Car Corp | Spot welding machine |

| JPS6037172Y2 (en) * | 1982-01-12 | 1985-11-05 | 東急車輌製造株式会社 | Irregular electrode rotation mechanism of spot welding machine |

| JPH06170553A (en) * | 1992-12-03 | 1994-06-21 | Daihatsu Motor Co Ltd | Automatic exchanging device for spot welding electrode |

| JPH0938779A (en) * | 1995-07-28 | 1997-02-10 | Amada Metrecs Co Ltd | Spot welding device |

| JP2003311431A (en) * | 2002-04-24 | 2003-11-05 | Honda Motor Co Ltd | Structure of electrode attaching and detaching section of welding gun |

| JP2005238317A (en) * | 2004-02-27 | 2005-09-08 | Koyo Giken:Kk | Spot welding machine |

-

2005

- 2005-11-30 JP JP2005347132A patent/JP2007152360A/en active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58122186A (en) * | 1982-01-12 | 1983-07-20 | Tokyu Car Corp | Spot welding machine |

| JPS6037172Y2 (en) * | 1982-01-12 | 1985-11-05 | 東急車輌製造株式会社 | Irregular electrode rotation mechanism of spot welding machine |

| JPH06170553A (en) * | 1992-12-03 | 1994-06-21 | Daihatsu Motor Co Ltd | Automatic exchanging device for spot welding electrode |

| JPH0938779A (en) * | 1995-07-28 | 1997-02-10 | Amada Metrecs Co Ltd | Spot welding device |

| JP2003311431A (en) * | 2002-04-24 | 2003-11-05 | Honda Motor Co Ltd | Structure of electrode attaching and detaching section of welding gun |

| JP2005238317A (en) * | 2004-02-27 | 2005-09-08 | Koyo Giken:Kk | Spot welding machine |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011110585A (en) * | 2009-11-27 | 2011-06-09 | Koyo Giken:Kk | Power supply system of spot welding machine |

| JP2023048881A (en) * | 2021-09-28 | 2023-04-07 | Obara株式会社 | Exchange holding device of electrode tip |

| JP7320032B2 (en) | 2021-09-28 | 2023-08-02 | Obara株式会社 | Replacement holding device for electrode tips |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101149733B1 (en) | Clamping jig for spot welding | |

| US9089924B2 (en) | Indirect spot welding method | |

| US20190193190A1 (en) | Resistance-Welding Equipment | |

| JP4836515B2 (en) | Resistance welding method | |

| JP2007152360A (en) | Spot welding electrode elevating in vertical attitude | |

| CA2211617A1 (en) | Consumable electrode type arc welding method and device | |

| JPWO2008053639A1 (en) | Sheet metal repair jig, sheet metal repair apparatus using the same, and sheet metal repair method | |

| JP5162185B2 (en) | Spot resistance welding machine | |

| US20150174694A1 (en) | Sacrificial resistance weld electrode | |

| CN2865977Y (en) | Electric resistance spot welding electrode capable of preventing fusing pit from splashing | |

| CN110948098B (en) | Indirect spot welding device and welding method | |

| JP2007152359A (en) | Welding cap holding device in spot welding machine | |

| CN211387393U (en) | Nuclear fuel assembly framework automatic spot welding machine, electrode and welding gun assembly | |

| JP3700746B2 (en) | Spot welding gun | |

| JP2005238316A5 (en) | ||

| JP2007152360A5 (en) | ||

| JP4419174B2 (en) | Spot welder | |

| US7253374B2 (en) | Sheet-to-tube welded structure and method | |

| CN114555272A (en) | Resistance spot welding method for aluminum material, resistance spot welding control device for aluminum material, and resistance spot welding machine | |

| JP2005186140A (en) | Spot welding machine | |

| JP2005186140A5 (en) | ||

| JP2007125559A (en) | Spot welding machine | |

| CN109202315A (en) | The method of two kinds of metal material superposition welding | |

| JPH0596378A (en) | Resistance welding method, electrode tip and rotating device thereof | |

| JP2005238317A (en) | Spot welding machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081201 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081201 |

|

| RD05 | Notification of revocation of power of attorney |

Effective date: 20090220 Free format text: JAPANESE INTERMEDIATE CODE: A7425 |

|

| A521 | Written amendment |

Effective date: 20100312 Free format text: JAPANESE INTERMEDIATE CODE: A523 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20100312 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100423 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20100526 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20100622 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100708 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20101026 |