GB2558231A - Method and apparatus for deploying a supporting net when replacing overhead conductors - Google Patents

Method and apparatus for deploying a supporting net when replacing overhead conductors Download PDFInfo

- Publication number

- GB2558231A GB2558231A GB1622026.1A GB201622026A GB2558231A GB 2558231 A GB2558231 A GB 2558231A GB 201622026 A GB201622026 A GB 201622026A GB 2558231 A GB2558231 A GB 2558231A

- Authority

- GB

- United Kingdom

- Prior art keywords

- netting

- hauling

- supporting

- equipment

- conductor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G1/00—Methods or apparatus specially adapted for installing, maintaining, repairing or dismantling electric cables or lines

- H02G1/02—Methods or apparatus specially adapted for installing, maintaining, repairing or dismantling electric cables or lines for overhead lines or cables

- H02G1/04—Methods or apparatus specially adapted for installing, maintaining, repairing or dismantling electric cables or lines for overhead lines or cables for mounting or stretching

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G7/00—Overhead installations of electric lines or cables

- H02G7/18—Devices affording mechanical protection in the event of breakage of a line or cable, e.g. net for catching broken lines

Landscapes

- Devices Affording Protection Of Roads Or Walls For Sound Insulation (AREA)

Abstract

A method, and the associated equipment, for installing protective netting 62 between overhead conductor towers comprising: erecting a supporting structure 50, 52 containing two uprights 56a, 56b with bases 54a, 54b, a crossbeam 58 and a stabilising weight arrangement 60a, 60b; passing hauling lines over the crossbeams 58 using an endless rope; coupling the hauling line to a netting structure on a roll 72 at one support structure and pulling the hauling line from the other support structure; and, fixing the netting structure to the other support structure. The support structures 50, 52 can be erected at ground level. The length of the uprights 56a, 56b, which may have a hopper at their top, can be adjusted, but may have a maximum height of 8-12m. The bases 54a, 54b may be provided with a levelling arrangement. There may be a ground level cross piece 66 or netting roller 72 extending between two base portions 60a, 60b of a supporting structure. The protective netting 62 may be used in conjunction with a method of replacing overhead conductors, which may use a catenary support system.

Description

(54) Title of the Invention: Method and apparatus for deploying a supporting net when replacing overhead conductors

Abstract Title: Method and equipment for deploying a supporting net when replacing overhead conductors (57) A method, and the associated equipment, for installing protective netting 62 between overhead conductor towers comprising: erecting a supporting structure 50, 52 containing two uprights 56a, 56b with bases 54a, 54b, a crossbeam 58 and a stabilising weight arrangement 60a, 60b; passing hauling lines over the crossbeams 58 using an endless rope; coupling the hauling line to a netting structure on a roll 72 at one support structure and pulling the hauling line from the other support structure; and, fixing the netting structure to the other support structure. The support structures 50, 52 can be erected at ground level. The length of the uprights 56a, 56b, which may have a hopper at their top, can be adjusted, but may have a maximum height of 8-12m. The bases 54a, 54b may be provided with a levelling arrangement. There may be a ground level cross piece 66 or netting roller 72 extending between two base portions 60a, 60b of a supporting structure. The protective netting 62 may be used in conjunction with a method of replacing overhead conductors, which may use a catenary support system.

54b) “G:

-s it- -- q* -«4^ j .-..8-........' Bi

54b

66' ί ;O6a 64 1,866 52 54a

FIG. 5

:) , ? GJL 54a z \

J

FIG. 7 *7

60a·

1/8

FIG. 1

ΟΥ s

\vS 3 •x-SS*

X fy] s ΛI . *«X\<· < $

2/8

FIG. 2 x<\ I >

,^d

M

Xsvy s A^X •\· *

Ά'ί >

id

As \\ s \s

L\

W, \\

3/8 •'<sXx» $' ·$··.

: -x . Α'.χί &

- <

\ Ax* %$ >,\A, XXsXsS»S'-v'> jX

........ \ |\ I

.....

sx

Ν'χ'ύ ' i\ x\

AL

ΓΛ y 7 h4sχ·> X x s •xx x

VT »AJ Ά, | ,' | > < ........

jf s ' ^'«.«ss''··^· ^s. a $ ; ΑΆ^' -4''' '·»»-' \\AW------—.

\ χ \XX.

A \^ \A

A* s ?: M χχ

A \

X X

A>1 <

V. \ S \ S § \Λ

Π . sX·co

O

4/8

518

618

7/8 t 4390 i 4292

FIG. 8

1«S MAX.

8/8

F\G.9

METHOD AND APPARATUS FOR DEPLOYING A SUPPORTING NET WHEN REPLACING OVERHEAD CONDUCTORS

Field of the invention

This invention relates to supporting nets used within overhead power transmission systems. In such power transmission systems, electrical conductors are supported along their length by towers, masts or other structures (hereinafter referred to simply as towers).

Background of the invention

Power transmission systems typically operate at a voltage for example from 10 kV to 400 kV. Each conductive path between towers is typically provided by multiple conductors, electrically in parallel. The use of multiple conductors in parallel increases the power carrying capabilities of the overhead system.

Such systems are normally divided into a number of sections each of which corresponds to a single length of conductor or conductor set. At each end of a section, a tension tower both supports the conductor(s) and applies the correct tension to the lengths of conductor, while between the tension towers one or more suspension towers may be present whose purpose is simply to support the conductors with adequate ground clearance.

In such systems, it may be necessary, from time to time, to replace one or more of the electrical conductors, for example because the original conductor has become damaged due to lightning, corrosion or for other reasons.

It is known to achieve this by reducing the tension in the conductor, attaching a running out block at each tower and supporting the conductor by the running out blocks, connecting a new conductor to the old conductor, and pulling the old conductor in along the length of the section so that, once the old conductor has been pulled in, the new conductor extends along the length of the section. The new conductor can then be tensioned correctly (sagged) by applying the correct tension to the conductor at one or each section end, and supported at each tower by the insulators.

While such a procedure may be employed along most of the path of the transmission system, it cannot be employed where the conductor spans buildings, roads or other rights of way or lower voltage overhead lines, without additional safety procedures being adopted.

For a long time, the practice had been to build scaffolding across such areas in order to prevent any interference to traffic, people, or other overhead systems caused by the conductor as the tension is reduced and the conductor height falls below the minimum required ground clearance. However, the cost of erecting scaffolding is extremely high.

GB 2 311 899 discloses a method of replacing an old conductor with a new conductor between a pair of towers, in which a supporting cable is first extended between the towers, and is suspended beneath the conductor to be replaced. When the tension in the conductor is lowered, the supporting cable supports the conductor and limits the sagging of the conductor. An end of the new conductor is then attached to an end of the old conductor, and the old conductor is pulled in. This method does not require the erection of scaffolding in order to provide protection to traffic or other personnel below the span of the conductors, and provides a relatively simple procedure for replacing a conductor. This method is termed the “catenary support system”.

There is still however a potential danger when the span extends over a highway or other public right of way. It is known to install safety netting which is used to prevent conductors sagging below a minimum amount, or even catching conductors should they fall.

The installation of the netting is time consuming and expensive. Typically, it involves building scaffolds at the side of the road or crossing to be protected, so that the use of the netting gives rise to the same problems as the traditional method of conductor replacement A series of bonds are deployed between the opposing structures and the net is then attached to the bonds to provide protection.

For this scaffold-based system, the installation of the catenary bonds usually requires a road closure. The nets are then hauled over the scaffolding by having a climber working at height in each position on the scaffold and pulling a series of ropes until the nets cover the crossing.

There is a general desire to minimise the amount of work that needs to be carried out at height, to reduce the risk of accident and to reduce the cost of the method being used. There is therefore a need for an improved method and apparatus for deploying the safety nets.

Summary of the invention

According to the invention, there is provided a method of installing protective netting along a span between towers of an overhead conductor arrangement, the method comprising:

erecting a supporting structure at each side of the span, the supporting structure comprising a base, a pair of uprights, an elevated cross beam, and a stabilising weight arrangement for the base;

providing a set of hauling lines;

from ground level, passing each hauling line over the cross beams using an endless rope, which endless rope is positioned around the cross beam;

at one support structure, coupling a same end of each hauling line to a free end of a netting structure which is on a roll;

at the other support structure, pulling the free end of the netting structure over the two supporting structures by pulling the hauling lines; and fixing the free end of the netting structure to the other support structure.

This method can all be performed from ground level without requiring any scaffolding. The supporting structures can then be erected by locating uprights on the base and the cross beam on the uprights. During this time, no additional weight is being supported, so it can be performed from ground level.

Once the hauling lines are in place and have been tensioned when initially pulling the hauling lines, the span is safe. The netting structure is installed by unrolling it while pulling it over the two supporting structures.

The method preferably comprises adjusting the length of the uprights when erecting the supporting structures. This enables use of a modular design for different heights and lengths of spans.

The method may also comprising adjusting the base to perform levelling when erecting the supporting structure. This provides a stable supporting structure for the netting.

The invention also provides a method of replacing overhead conductors, comprising:

installing protective netting over one or more spans along the path of the overhead conductors to be replaced using the method described above; and replacing the overhead conductors.

Replacing the overhead conductors may comprise using a catenary support system.

In this way, the need for climbing and scaffolding is minimized for both the conductor replacement and the netting installation.

The invention also provides installing equipment for installing protective netting along a span between towers of an overhead conductor arrangement, the equipment comprising:

a pair of supporting structures, each comprising a base, a pair of uprights, a cross beam, and a stabilising weight arrangement;

a set of hauling lines;

an endless rope at each supporting structure for the hauling lines, which endless rope is positioned around the cross beam to enable a hauling line to be lifted over the cross beam from ground level;

a netting structure on a roll; and a coupling arrangement for fixing a free end of the netting structure to a same end of each hauling line.

The endless rope enables the hauling lines to be lifted in place over the cross beams from ground level. The netting structure can then be pulled over the cross beams, again from ground level.

The supporting structures preferably each comprise:

a first base portion, a first extendable upright and a first stabilising weight for mounting on the first base portion;

a second base portion, a second extendable upright and a second stabilising weight for mounting on the second base portion; and a ground level cross piece connecting the first and second base portions.

The use of two base portions enables the structure to be adjusted more easily for uneven ground. There may more more than two base portions for wider netting arrangements, and a modular arrangement may be used.

Each base portion may comprise a levelling arrangement. In this way, each base portion can be made locally level, and the extendable uprights can be adjusted to ensure the cross beam is then horizontal.

The supporting structures may each comprise a netting roller extending between the first and second base portions. The netting structure thus extends between two rollers - one at each supporting structure.

The extending uprights for example have a maximum height of between 8m and 12m. Each upright has a hopper at its top for receiving a connection portion of the cross beam. In this way, the cross beam may be held in place simply by coupling with the hopper under gravity.

Brief description of the drawings

Examples of the invention will now be described in detail with reference to the accompanying drawings, in which:

Figure 1 is a schematic view of a span of an overhead power transmission system as a supporting cable is being passed out along the old conductor using a known method;

Figure 2 is a schematic view of the span once the supporting cable has been installed;

Figure 3 is a schematic view of the span as the new conductor is being pulled in; Figure 4 shows a known netting system;

Figure 5 shows an installed netting system in accordance with the invention;

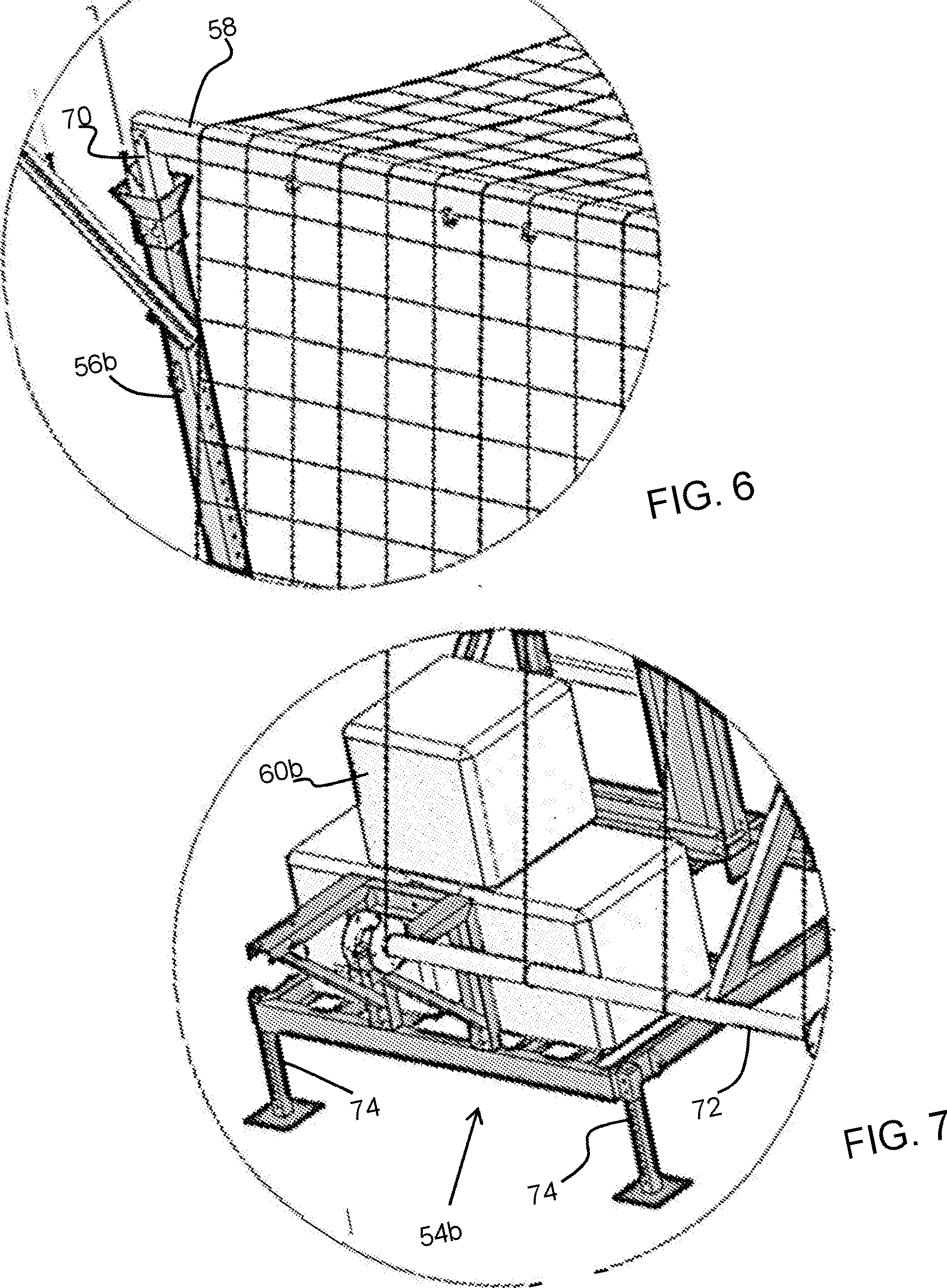

Figure 6 shows an enlarged view of the top of one upright;

Figure 7 shows an enlarged view of one base portion;

Figure 8 shows example dimensions for the support structure; and

Figure 9 shows that the system may be modular and may thus be extended to different sizes.

Detailed description

The invention provides a method and apparatus for installing protective netting along a span between towers of an overhead conductor arrangement. A supporting structure is provided at each side of the span. Hauling lines are passed over cross beams of the supporting structures from ground level. A netting structure on a roll is coupled to the hauling lines and pulled over the two supporting structures by pulling the hauling lines.

The netting structure is then fixed in place. The installation can all be performed from ground level without requiring any scaffolding.

The invention is typically used as part of a method of replacing overhead conductors. For completeness, a known method of replacing an overhead conductor will first be described with reference to Figures 1 to 3. Further details can be found in GB 2 311 899.

As shown in Figure 1, a section of conductor 1 includes a span that extends between two towers A and B and which passes over a right of way (not shown) that requires protection from any restringing operation. After securing insulator units 2, fixing line ladders 4 and installing running-out blocks 6 at the tower, a supporting cable 8 is fed out from a rope drum 10 located in the region of Tower A.

The supporting cable 8 is passed through the running-out block 6 and along the span of the old conductor 1. A tug unit 12 is located on the old conductor at tower A, and the supporting cable 8 is attached to it. The supporting cable 8 is provided with a number of catenary-blocks 14 attached thereto at intervals of about 5 to 25 metres along its length according to a pre-prepared schedule. These are hooked onto the conductor 1 as soon as the supporting cable passes through the running-out block 6. As the tug unit 12 travels along the conductor span between the towers, the supporting cable 8 is paid out from the drum 10, and additional catenary-blocks 14 are hooked onto the conductor.

When the tug unit 12 has arrived at tower B, the supporting cable 8 is unhooked from the tug unit 12 and attached to the end of the insulator unit 2 by means of a temporary sheathed rope catch-off device, and the tug unit is removed by means of a lifting rig. As shown in Figure 2, the supporting cable 8 is then passed through an Ansel-Jones block 20, is passed down to ground, and is anchored to the ground by means of an anchor sledge 22 via a tirfor 24. The Ansel-Jones block 20 is held out from the insulator unit by means of a sling attached to the tower so that the block is separated from the conductor both laterally and vertically by at least 0.5 metres in order to allow the catenary-blocks to rotate. The anchor sledge is positioned in line with the conductor 1 and at a position located from tower B by a distance of at least twice the height of the tower.

At tower A, the supporting cable 8 is also anchored to the ground by means of another ground anchor sledge 25. The supporting cable 8 is then tensioned by means of the tirfor 24 so that it becomes self-supporting, and the catenary-blocks 14 rotate by part of a revolution.

Once the section has been prepared for re-stringing, including attaching one end of a new conductor 26 to the end of the old conductor 1 by means of joint 28 at one end of the section, the tension in the conductor 1 is reduced, thereby allowing the conductor to sag between the other towers in the section. Between towers A and B, the conductor 1 is supported by the supporting cable 8 and the catenary-blocks 14, causing the catenaryblocks to rotate further until they have rotated by 180 degrees, as shown in Figure 3. The old conductor 1 is then hauled in at the other end of the section causing the new conductor 26 to travel along the length of the section, and to pass through the catenary-blocks 14 between towers A and B.

When the new conductor 26 has reached the tension tower at the beginning of the section, the old conductor is removed and the new conductor is terminated in accordance with conventional procedure. The new conductor is then hung on the insulator units of the towers, and is tensioned until the correct tension has been achieved. During this operation, the catenary-blocks 14 will rotate back part of a revolution as the new conductor 26 becomes self-supporting.

When the new conductor 26 has been correctly tensioned, the tension in the supporting cable may be reduced, thereby causing the catenary-blocks 14 to rotate back under their weight and the weight of the rope 8 until the rope 8 hangs underneath the new conductor. A brake unit is then placed on the conductor 26 and attached to the end of the supporting cable 8. The rope 8 is winched back onto the rope drum 10 while the brake unit ensures that the correct tension is applied to the rope 8 during this operation. Finally, when the rope 8 has been hauled in, the brake unit and the other items of installation equipment such as the running out blocks 6 and the ladders are removed, and the tension in the new conductor is checked and adjusted if necessary using the normal method.

Figure 4 shows a way to ensure conductors cannot sag below a particular height during the replacement operation. As shown, a net 40 is supported by the support cables 42. The net is has a fabric or other sheet construction so that it can concertina into a small space, and then be extended out as shown. The net 40 is supported by bars 44 which are fixed on the support cables 42. The installation of the net takes place at the towers, and thus requires work on ladders or scaffolding.

The invention provides an improved netting design and installation method.

The installed netting structure is shown in Figure 5.

The netting system is independent of the system and method used for replacing the overhead conductors, and provides an independent safety structure over a span to be protected. The span to be protected has a length which is independent of the spacing between towers. The netting structure only needs to be sized to provide protection for the particular span.

The netting structure and its associated installation equipment comprises a pair of supporting structures 50, 52. Each one comprises a base 54a,54b, a pair of uprights 56a,56b, a cross beam 58, and a stabilising weight arrangement 60a,60b.

The netting structure 62 extends between the cross beams 58 and then down to the bottom of each support structure 50, 52.

The netting structure comprises a mesh part, for example with a mesh size between 10cm and 50cm. The mesh part is for example formed of 5mm nylon twine. There are reinforcing metal cables 64 formed as part of the netting structure. These are for example spaced with lm to 5m spacing and they run along the length direction of the netting structure (i.e. across the span).

By way of example, Figure 5 shows a netting structure with aim spacing between 12mm diameter reinforcing cables 64. Ten cables 64 give rise to an overall 9m width. The nylon netting mesh is sewn onto the cables 64.

The supporting structures each comprise a first base portion 54a, a first extendable upright 56a and a first stabilising weight 60a for mounting on the first base portion 54a, and a second base portion 54b, a second extendable upright 56b and a second stabilising weight 60b for mounting on the second base portion 54b.

The weights 60a, 60b are chosen to provide the required support for the uprights to hold the netting structure and also any conductors which have fallen down to be supported by the netting structure. They may each comprise a set of concrete blocks.

A ground level cross piece 66 connects the first and second base portions 54a, 54b.

The use of two base portions enables the structure to be adjusted more easily for uneven ground.

Figure 6 shows an enlarged part of one upright 56b. It shows that a downwardly projecting connection part 70 of the cross beam 58 is simply a push fit into the top of the upright, and is held in place by gravity. The top of the upright 56b thus functions as a hopper.

Figure 7 shows an enlarged part of one base portion 54b. It shows that a netting roller 72 extends between the first and second base portions. The reinforcing cables are fixed to and wound on the roller to provide the desired tension of the netting structure. The netting structure thus extends between two rollers 72 - one at each supporting structure. Figure 7 also shows that each base portion has a levelling arrangement 74. There may be four legs to each base portion, and some or all of the legs are adjustable. In this way, each base portion can be made locally level, and the uprights may also be adjustable to ensure the cross beam is then horizontal.

The installation equipment is modular. For this purpose, the uprights are extendable in height for example to a maximum height of 10m. The space between base portions is also adjustable, by having adjustable cross pieces 66 and rollers 72 or by having a set of different length cross pieces and rollers. By way of example, there may be standard widths of 6m or 9m and greater widths can be achieved by having three or more base portions.

Figure 8 shows an example set of dimensions for the supporting structure. The uprights have a maximum height of 10848mm in this example and a minimum height of 6556mm. They can be adjusted continuously between to ensure the cross beam 58 is horizontal. The cross beam has a 9m length. The weights 60a, 60b comprise three 1.4 tonne concrete blocks.

Figure 9 shows that this modular design may be expanded by adding base portions. This example shows four base portions 54a to 54d with three netting spans side by side. The netting spans are joined together in the width direction and are provided on a single roller.

The cross beams may be in multiple sections, and where two cross beams are adjacent, the upright may comprise a double hopper design for securing both adjacent cross beams.

In order to install the protective netting structure, the supporting structure 50, 52 at each side of the span is first erected.

This involves placing a set of endless ropes around the cross beam 58. The uprights are then lifted and secured to the base portions. This is achieved using a loader crane (e.g. a Hiab). The cross beams are then raised and positioned on the uprights, again using a loader crane. Lifting eyes and hooks are used for this purpose, which are removed once the cross beams are in place. The endless ropes (i.e. loops) reach down to near ground level, and there is for example a number of endless ropes corresponding to the number of reinforcing metal cables 64.

The length of the uprights may be adjusted to account for uneven ground levels, and also the base portions are adjusted to perform levelling.

A set of hauling lines is then laid along across the span. Each hauling line comprises a rope. The hauling lines are passed over the cross beams using the endless ropes so that the set of hauling lines extend across the span and over the cross beams. To save time, the hauling lines are put in place in parallel hence it is preferred to provide an endless rope for each hauling line. The hauling lines are for example walked from one side of the span to the other, passing over the cross beam at one side then the cross beam at the the other side.

Of course, one endless rope could be used in turn for each hauling line.

The end result is a set of hauling lines laid over both cross beams, and down the outer sides to ground level.

At one supporting structure, the netting structure is provided on a roll. The free ends of the reinforcing metal cables 64 of the netting structure are then attached to the ends of the hauling lines for example simply with a knot.

At the opposite supporting structure, the hauling lines are then rolled onto the roller 72. A manually operated winch and roller is used for this purpose. Once the lines are under tension, this tension can be maintained by control of the two rollers 72 so that the span may re-opened for traffic or rail or pedestrians.

The hauling lines are rolled further to pull the free end of the netting structure over the two supporting structures. Once the netting structure is in place, the free end of the netting structure (now at the opposite structure to the location of the netting roll) is fixed to the support structure.

The ends of the reinforcing metal cables 64 are for example each formed into a loop using crosbie clips, and those loops are coupled to the supporting structures, for example using a fibre sling.

At the opposite structure (where the netting is/was on the roll), the other ends of the reinforcing metal cables 64 may also each formed into a loop using crosbie clips, and those loops are also coupled to the supporting structures. However, there may be spare netting, which remains on the roll. The reinforcing metal cables 64 are still connected to the support structure, and this may then be at a location within the mesh area rather than beyond the mesh area. Loops may again be formed for this purpose by pulling out some netting from the roll.

Fencing protection may then be installed around the base areas to prevent vandalism.

The erection of the supporting structures as well as the positioning of the hauling lines may all be performed from ground level, avoiding the need for scaffolding or climbing equipment, and improving safety as well as the speed of deployment.

This system may thus be built at the side of the road or railway as a self-contained base for each upright, with two bases and a cross beam forming an H-shaped beam structure. The concrete blocks are selected based on the length of crossing (the netted span) and the conductor configuration to be protected.

If a bundle of conductors were to fall to the ground, the system is designed to provide protection for the under lying service (road, railway, river, low voltage line, footpath, farm track etc...) and traffic for instance can continue.

Various other modifications will be apparent to those skilled in the art.

Claims (13)

1. A method of installing protective netting along a span between towers of an overhead conductor arrangement, the method comprising:

erecting a supporting structure at each side of the span, the supporting structure comprising a base, a pair of uprights, an elevated cross beam, and a stabilising weight arrangement for the base;

providing a set of hauling lines;

from ground level, passing each hauling line over the cross beams using an endless rope, which endless rope is positioned around the cross beam;

at one support structure, coupling a same end of each hauling line to a free end of a netting structure which is on a roll;

at the other support structure, pulling the free end of the netting structure over the two supporting structures by pulling the hauling lines; and fixing the free end of the netting structure to the other support structure.

2. A method as claimed in claim 1, wherein erecting the supporting structures is performed from ground level.

3. A method as claimed in claim 1 or 2, comprising adjusting the length of the uprights when erecting the supporting structures.

4. A method as claimed in any preceding claim, comprising adjusting the base to perform levelling when erecting the supporting structure.

5. A method of replacing overhead conductors, comprising:

installing protective netting over one or more spans along the path of the overhead conductors to be replaced using a method as claimed in any preceding claim; and replacing the overhead conductors.

6. A method as claimed in claim 5, wherein replacing the overhead conductors comprises using a catenary support system.

7. Installing equipment for installing protective netting along a span between towers of an overhead conductor arrangement, the equipment comprising:

a pair of supporting structures, each comprising a base, a pair of uprights, a cross beam, and a stabilising weight arrangement;

a set of hauling lines;

an endless rope at each supporting structure for the hauling lines, which endless rope is positioned around the cross beam to enable a hauling line to be lifted over the cross beam from ground level;

a netting structure on a roll; and a coupling arrangement for fixing a free end of the netting structure to a same end of each hauling line.

8. Equipment as claimed in claim 7, comprising an endless rope for each hauling line at each support structure.

9. Equipment as claimed in claim 7 or 8, wherein the supporting structures each comprise:

a first base portion, a first extendable upright and a first stabilising weight for mounting on the first base portion;

a second base portion, a second extendable upright and a second stabilising weight for mounting on the second base portion; and a ground level cross piece connecting the first and second base portions.

10. Equipment as claimed in claim 9, wherein each base portion comprises a levelling arrangement.

11. Equipment as claimed in claim 9 or 10, wherein the supporting structures each comprise a netting roller extending between the first and second base portions.

12. Equipment as claimed in claim 9, 10 or 11, wherein the extending uprights have a maximum height of between 8m and 12m.

13. Equipment as claimed in any one of claims 9 to 12, wherein each upright has a hopper at its top for receiving a connection portion of the cross beam.

Intellectual

Property

Office

Application No: GB 1622026.1

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB1622026.1A GB2558231B (en) | 2016-12-22 | 2016-12-22 | Method and apparatus for deploying a supporting net when replacing overhead conductors |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB1622026.1A GB2558231B (en) | 2016-12-22 | 2016-12-22 | Method and apparatus for deploying a supporting net when replacing overhead conductors |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| GB201622026D0 GB201622026D0 (en) | 2017-02-08 |

| GB2558231A true GB2558231A (en) | 2018-07-11 |

| GB2558231B GB2558231B (en) | 2021-12-08 |

Family

ID=58360465

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| GB1622026.1A Active GB2558231B (en) | 2016-12-22 | 2016-12-22 | Method and apparatus for deploying a supporting net when replacing overhead conductors |

Country Status (1)

| Country | Link |

|---|---|

| GB (1) | GB2558231B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110518492A (en) * | 2019-09-11 | 2019-11-29 | 国网山东省电力公司济南市长清区供电公司 | A kind of power grid construction highway crossing support frame |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110492391B (en) * | 2019-09-16 | 2024-05-14 | 杨平 | Jacking type full-protection crossing frame and building method thereof |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2428074A1 (en) * | 1974-06-11 | 1975-12-18 | Egon Dipl Ing Dennig | Cable support system for protective net - has several lines attached at one end to cable and by their other ends to net |

| DE2813610A1 (en) * | 1978-03-30 | 1979-10-04 | Bbc Brown Boveri & Cie | Overhead protective suspension net erection - uses slider mechanism mounted between masts in first row of support uprights to pull net up into required position |

| EP0598629A1 (en) * | 1992-11-19 | 1994-05-25 | POWER LINES, PIPES & CABLES LIMITED | Trailer-mounted netting support system |

| GB2274473A (en) * | 1993-01-20 | 1994-07-27 | Pressed Drums Ltd | Portable portal frame structure |

| GB2311899A (en) * | 1996-04-03 | 1997-10-08 | Bicc Plc | Method of replacing an overhead conductor |

| GB2343061A (en) * | 1998-08-06 | 2000-04-26 | Amec Power Limited | Protective device for use in replacement of overhead cables |

| US20050158137A1 (en) * | 2004-01-16 | 2005-07-21 | Gregory Lynch | Sheet member dispensing apparatus for use with articles stacked on a bed of a trailer |

| CN202285309U (en) * | 2011-10-28 | 2012-06-27 | 湖北省输变电工程公司 | Lifting energized spanning frame |

| EP3081524A1 (en) * | 2015-04-13 | 2016-10-19 | Eric Salvi | Mesh track protection |

-

2016

- 2016-12-22 GB GB1622026.1A patent/GB2558231B/en active Active

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2428074A1 (en) * | 1974-06-11 | 1975-12-18 | Egon Dipl Ing Dennig | Cable support system for protective net - has several lines attached at one end to cable and by their other ends to net |

| DE2813610A1 (en) * | 1978-03-30 | 1979-10-04 | Bbc Brown Boveri & Cie | Overhead protective suspension net erection - uses slider mechanism mounted between masts in first row of support uprights to pull net up into required position |

| EP0598629A1 (en) * | 1992-11-19 | 1994-05-25 | POWER LINES, PIPES & CABLES LIMITED | Trailer-mounted netting support system |

| GB2274473A (en) * | 1993-01-20 | 1994-07-27 | Pressed Drums Ltd | Portable portal frame structure |

| GB2311899A (en) * | 1996-04-03 | 1997-10-08 | Bicc Plc | Method of replacing an overhead conductor |

| GB2343061A (en) * | 1998-08-06 | 2000-04-26 | Amec Power Limited | Protective device for use in replacement of overhead cables |

| US20050158137A1 (en) * | 2004-01-16 | 2005-07-21 | Gregory Lynch | Sheet member dispensing apparatus for use with articles stacked on a bed of a trailer |

| CN202285309U (en) * | 2011-10-28 | 2012-06-27 | 湖北省输变电工程公司 | Lifting energized spanning frame |

| EP3081524A1 (en) * | 2015-04-13 | 2016-10-19 | Eric Salvi | Mesh track protection |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110518492A (en) * | 2019-09-11 | 2019-11-29 | 国网山东省电力公司济南市长清区供电公司 | A kind of power grid construction highway crossing support frame |

Also Published As

| Publication number | Publication date |

|---|---|

| GB2558231B (en) | 2021-12-08 |

| GB201622026D0 (en) | 2017-02-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108736377B (en) | Live crossing system for paying-off construction crossing power line and application method thereof | |

| CN109488038B (en) | Method for installing beam string flexible inhaul cable spanning existing building | |

| GB2558231A (en) | Method and apparatus for deploying a supporting net when replacing overhead conductors | |

| CN101958519B (en) | Method for transforming tangent tower of double-circuit double-bundle transmission lines by lifting in electrified mode in another place | |

| US11686055B2 (en) | Sheath for a structural cable of a construction work, methods of installation and maintenance | |

| EP0680540B1 (en) | Scaffolding system | |

| CN105586832A (en) | Suspension type catwalk surface net mounting system | |

| JP7325838B2 (en) | Movable modules for lifting telescopic towers and methods for lifting telescopic towers | |

| GB2311899A (en) | Method of replacing an overhead conductor | |

| CN105275251A (en) | Railway existing line overhead line system hard crossbeam erection method | |

| CN117977437A (en) | Follow-up protection suspension cable type crossing frame for power transmission line | |

| CN110983978B (en) | Method for installing tie bar of arch bridge | |

| CN109267500A (en) | Bridge maintaining lift truss work platform | |

| JP2013113007A (en) | Method and device for temporarily constructing net for steel tower and method and system for repairing steel tower | |

| CN107217912B (en) | A kind of superelevation physical isolation construction method for neighbouring high-speed rail Business Line construction | |

| CN205955164U (en) | Portable steel truss operation platform | |

| CN210628940U (en) | Jacking type full-protection crossing frame | |

| GB2430016A (en) | Four-to-three connector for replacing overhead cables | |

| JP2012249437A (en) | Power line extending method | |

| GB2343061A (en) | Protective device for use in replacement of overhead cables | |

| GB2533691A (en) | An overhead line crossing guard system, a method of assembling an overhead line crossing guard system and a method of disassembling an overhead line | |

| EP3125381B1 (en) | Transmission line replacement system & method | |

| EP0598629B1 (en) | Trailer-mounted netting support system | |

| CN114673088B (en) | Construction method applied to catwalk of space main cable suspension bridge | |

| CN215164791U (en) | High-altitude assembly welding device |