ES2703220A1 - Method for the preparation of a new ERI molecular sieve (Machine-translation by Google Translate, not legally binding) - Google Patents

Method for the preparation of a new ERI molecular sieve (Machine-translation by Google Translate, not legally binding) Download PDFInfo

- Publication number

- ES2703220A1 ES2703220A1 ES201731089A ES201731089A ES2703220A1 ES 2703220 A1 ES2703220 A1 ES 2703220A1 ES 201731089 A ES201731089 A ES 201731089A ES 201731089 A ES201731089 A ES 201731089A ES 2703220 A1 ES2703220 A1 ES 2703220A1

- Authority

- ES

- Spain

- Prior art keywords

- molecular sieve

- bis

- eri

- cyclohexane

- silica

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- URGAHOPLAPQHLN-UHFFFAOYSA-N sodium aluminosilicate Chemical compound [Na+].[Al+3].[O-][Si]([O-])=O.[O-][Si]([O-])=O URGAHOPLAPQHLN-UHFFFAOYSA-N 0.000 title claims abstract description 121

- 239000002808 molecular sieve Substances 0.000 title claims abstract description 119

- 238000000034 method Methods 0.000 title claims abstract description 34

- 238000002360 preparation method Methods 0.000 title claims abstract description 15

- 125000005208 trialkylammonium group Chemical group 0.000 claims abstract description 8

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 62

- 239000000203 mixture Substances 0.000 claims description 33

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims description 31

- 239000000377 silicon dioxide Substances 0.000 claims description 30

- 230000015572 biosynthetic process Effects 0.000 claims description 23

- 238000003786 synthesis reaction Methods 0.000 claims description 22

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 15

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 14

- 229910052751 metal Inorganic materials 0.000 claims description 13

- 239000002184 metal Substances 0.000 claims description 13

- 239000010949 copper Substances 0.000 claims description 11

- 150000002739 metals Chemical class 0.000 claims description 9

- 229910052742 iron Inorganic materials 0.000 claims description 8

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 7

- 229910052802 copper Inorganic materials 0.000 claims description 7

- GETQZCLCWQTVFV-UHFFFAOYSA-N trimethylamine Chemical compound CN(C)C GETQZCLCWQTVFV-UHFFFAOYSA-N 0.000 claims description 6

- 229910052783 alkali metal Inorganic materials 0.000 claims description 5

- 150000001340 alkali metals Chemical class 0.000 claims description 5

- 229910052784 alkaline earth metal Inorganic materials 0.000 claims description 5

- 150000001342 alkaline earth metals Chemical class 0.000 claims description 5

- 229910052782 aluminium Inorganic materials 0.000 claims description 5

- 229910052719 titanium Inorganic materials 0.000 claims description 5

- 239000010936 titanium Substances 0.000 claims description 5

- 238000002441 X-ray diffraction Methods 0.000 claims description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 4

- 150000001768 cations Chemical group 0.000 claims description 4

- 230000005855 radiation Effects 0.000 claims description 4

- 229910052718 tin Inorganic materials 0.000 claims description 4

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 3

- GYHNNYVSQQEPJS-UHFFFAOYSA-N Gallium Chemical compound [Ga] GYHNNYVSQQEPJS-UHFFFAOYSA-N 0.000 claims description 3

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims description 3

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 3

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 claims description 3

- 229910052796 boron Inorganic materials 0.000 claims description 3

- 238000001354 calcination Methods 0.000 claims description 3

- 239000000428 dust Substances 0.000 claims description 3

- 229910052733 gallium Inorganic materials 0.000 claims description 3

- 229910052732 germanium Inorganic materials 0.000 claims description 3

- GNPVGFCGXDBREM-UHFFFAOYSA-N germanium atom Chemical compound [Ge] GNPVGFCGXDBREM-UHFFFAOYSA-N 0.000 claims description 3

- 229910052735 hafnium Inorganic materials 0.000 claims description 3

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 claims description 3

- 229910052738 indium Inorganic materials 0.000 claims description 3

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 claims description 3

- 229910052710 silicon Inorganic materials 0.000 claims description 3

- 229910052726 zirconium Inorganic materials 0.000 claims description 3

- DAZXVJBJRMWXJP-UHFFFAOYSA-N n,n-dimethylethylamine Chemical compound CCN(C)C DAZXVJBJRMWXJP-UHFFFAOYSA-N 0.000 claims description 2

- GNVRJGIVDSQCOP-UHFFFAOYSA-N n-ethyl-n-methylethanamine Chemical compound CCN(C)CC GNVRJGIVDSQCOP-UHFFFAOYSA-N 0.000 claims description 2

- 239000010703 silicon Substances 0.000 claims description 2

- ZMANZCXQSJIPKH-UHFFFAOYSA-O triethylammonium ion Chemical compound CC[NH+](CC)CC ZMANZCXQSJIPKH-UHFFFAOYSA-O 0.000 claims description 2

- 239000003795 chemical substances by application Substances 0.000 abstract description 5

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical group N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 45

- 229910052675 erionite Inorganic materials 0.000 description 45

- 239000003054 catalyst Substances 0.000 description 31

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 23

- 229910021529 ammonia Inorganic materials 0.000 description 21

- 239000007789 gas Substances 0.000 description 21

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 18

- 239000000047 product Substances 0.000 description 18

- 239000000463 material Substances 0.000 description 17

- 230000003647 oxidation Effects 0.000 description 16

- 238000007254 oxidation reaction Methods 0.000 description 16

- 230000003197 catalytic effect Effects 0.000 description 15

- 235000012239 silicon dioxide Nutrition 0.000 description 14

- 229910052681 coesite Inorganic materials 0.000 description 13

- 229910052593 corundum Inorganic materials 0.000 description 13

- 229910052906 cristobalite Inorganic materials 0.000 description 13

- 229910052682 stishovite Inorganic materials 0.000 description 13

- 239000000758 substrate Substances 0.000 description 13

- 229910052905 tridymite Inorganic materials 0.000 description 13

- 229910001845 yogo sapphire Inorganic materials 0.000 description 13

- 239000007864 aqueous solution Substances 0.000 description 11

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 10

- GQPLMRYTRLFLPF-UHFFFAOYSA-N Nitrous Oxide Chemical compound [O-][N+]#N GQPLMRYTRLFLPF-UHFFFAOYSA-N 0.000 description 9

- 239000010457 zeolite Substances 0.000 description 9

- 238000006243 chemical reaction Methods 0.000 description 8

- 239000013078 crystal Substances 0.000 description 8

- 229930195733 hydrocarbon Natural products 0.000 description 8

- 150000002430 hydrocarbons Chemical class 0.000 description 8

- 238000000634 powder X-ray diffraction Methods 0.000 description 8

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 7

- 229910021536 Zeolite Inorganic materials 0.000 description 6

- 238000004458 analytical method Methods 0.000 description 6

- 239000011230 binding agent Substances 0.000 description 6

- 238000002425 crystallisation Methods 0.000 description 6

- 230000008025 crystallization Effects 0.000 description 6

- 239000012071 phase Substances 0.000 description 6

- 239000012265 solid product Substances 0.000 description 6

- 239000000126 substance Substances 0.000 description 6

- 238000011282 treatment Methods 0.000 description 6

- -1 N, N-dimethylpiperidinium cations Chemical class 0.000 description 5

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 5

- 238000010438 heat treatment Methods 0.000 description 5

- 229910021645 metal ion Inorganic materials 0.000 description 5

- 239000001301 oxygen Substances 0.000 description 5

- 229910052760 oxygen Inorganic materials 0.000 description 5

- BJAARRARQJZURR-UHFFFAOYSA-N trimethylazanium;hydroxide Chemical compound O.CN(C)C BJAARRARQJZURR-UHFFFAOYSA-N 0.000 description 5

- 238000005406 washing Methods 0.000 description 5

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 4

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 4

- LCGLNKUTAGEVQW-UHFFFAOYSA-N Dimethyl ether Chemical compound COC LCGLNKUTAGEVQW-UHFFFAOYSA-N 0.000 description 4

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 4

- 239000004809 Teflon Substances 0.000 description 4

- 229920006362 Teflon® Polymers 0.000 description 4

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 4

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 4

- 239000003638 chemical reducing agent Substances 0.000 description 4

- 239000008367 deionised water Substances 0.000 description 4

- 229910021641 deionized water Inorganic materials 0.000 description 4

- 239000012153 distilled water Substances 0.000 description 4

- 238000005342 ion exchange Methods 0.000 description 4

- 239000001272 nitrous oxide Substances 0.000 description 4

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 4

- 239000011148 porous material Substances 0.000 description 4

- 238000000926 separation method Methods 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 description 3

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 3

- ZMANZCXQSJIPKH-UHFFFAOYSA-N Triethylamine Chemical compound CCN(CC)CC ZMANZCXQSJIPKH-UHFFFAOYSA-N 0.000 description 3

- 150000001298 alcohols Chemical class 0.000 description 3

- 229910000323 aluminium silicate Inorganic materials 0.000 description 3

- 239000011959 amorphous silica alumina Substances 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 150000002500 ions Chemical class 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 229910052763 palladium Inorganic materials 0.000 description 3

- 229910052697 platinum Inorganic materials 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- 239000010970 precious metal Substances 0.000 description 3

- 238000011084 recovery Methods 0.000 description 3

- 238000006722 reduction reaction Methods 0.000 description 3

- 238000004626 scanning electron microscopy Methods 0.000 description 3

- 229910052723 transition metal Inorganic materials 0.000 description 3

- 150000003624 transition metals Chemical class 0.000 description 3

- IMNIMPAHZVJRPE-UHFFFAOYSA-N triethylenediamine Chemical compound C1CN2CCN1CC2 IMNIMPAHZVJRPE-UHFFFAOYSA-N 0.000 description 3

- 238000011144 upstream manufacturing Methods 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- ROSDSFDQCJNGOL-UHFFFAOYSA-N Dimethylamine Chemical compound CNC ROSDSFDQCJNGOL-UHFFFAOYSA-N 0.000 description 2

- BAVYZALUXZFZLV-UHFFFAOYSA-N Methylamine Chemical compound NC BAVYZALUXZFZLV-UHFFFAOYSA-N 0.000 description 2

- UIIMBOGNXHQVGW-UHFFFAOYSA-M Sodium bicarbonate Chemical compound [Na+].OC([O-])=O UIIMBOGNXHQVGW-UHFFFAOYSA-M 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 150000001336 alkenes Chemical class 0.000 description 2

- 150000001412 amines Chemical class 0.000 description 2

- 229910002092 carbon dioxide Inorganic materials 0.000 description 2

- 238000010531 catalytic reduction reaction Methods 0.000 description 2

- CETPSERCERDGAM-UHFFFAOYSA-N ceric oxide Chemical compound O=[Ce]=O CETPSERCERDGAM-UHFFFAOYSA-N 0.000 description 2

- 229910000422 cerium(IV) oxide Inorganic materials 0.000 description 2

- 238000002485 combustion reaction Methods 0.000 description 2

- 239000012973 diazabicyclooctane Substances 0.000 description 2

- 150000002170 ethers Chemical class 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- 238000001914 filtration Methods 0.000 description 2

- 238000002354 inductively-coupled plasma atomic emission spectroscopy Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 description 2

- 239000002105 nanoparticle Substances 0.000 description 2

- 229910000069 nitrogen hydride Inorganic materials 0.000 description 2

- 230000001590 oxidative effect Effects 0.000 description 2

- 239000008188 pellet Substances 0.000 description 2

- 229920000768 polyamine Polymers 0.000 description 2

- 239000002243 precursor Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 150000003839 salts Chemical class 0.000 description 2

- 238000001878 scanning electron micrograph Methods 0.000 description 2

- 239000003381 stabilizer Substances 0.000 description 2

- 229910001428 transition metal ion Inorganic materials 0.000 description 2

- NWUYHJFMYQTDRP-UHFFFAOYSA-N 1,2-bis(ethenyl)benzene;1-ethenyl-2-ethylbenzene;styrene Chemical compound C=CC1=CC=CC=C1.CCC1=CC=CC=C1C=C.C=CC1=CC=CC=C1C=C NWUYHJFMYQTDRP-UHFFFAOYSA-N 0.000 description 1

- XEZNGIUYQVAUSS-UHFFFAOYSA-N 18-crown-6 Chemical compound C1COCCOCCOCCOCCOCCO1 XEZNGIUYQVAUSS-UHFFFAOYSA-N 0.000 description 1

- OSWFIVFLDKOXQC-UHFFFAOYSA-N 4-(3-methoxyphenyl)aniline Chemical compound COC1=CC=CC(C=2C=CC(N)=CC=2)=C1 OSWFIVFLDKOXQC-UHFFFAOYSA-N 0.000 description 1

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 1

- 239000005995 Aluminium silicate Substances 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- CPELXLSAUQHCOX-UHFFFAOYSA-M Bromide Chemical compound [Br-] CPELXLSAUQHCOX-UHFFFAOYSA-M 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- 229910052684 Cerium Inorganic materials 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- KCXVZYZYPLLWCC-UHFFFAOYSA-N EDTA Chemical compound OC(=O)CN(CC(O)=O)CCN(CC(O)=O)CC(O)=O KCXVZYZYPLLWCC-UHFFFAOYSA-N 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229910010413 TiO 2 Inorganic materials 0.000 description 1

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 1

- 239000006096 absorbing agent Substances 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 150000001299 aldehydes Chemical class 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- 125000000217 alkyl group Chemical group 0.000 description 1

- 150000004645 aluminates Chemical class 0.000 description 1

- 235000012211 aluminium silicate Nutrition 0.000 description 1

- 150000001450 anions Chemical class 0.000 description 1

- 150000001491 aromatic compounds Chemical class 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- YOUGRGFIHBUKRS-UHFFFAOYSA-N benzyl(trimethyl)azanium Chemical compound C[N+](C)(C)CC1=CC=CC=C1 YOUGRGFIHBUKRS-UHFFFAOYSA-N 0.000 description 1

- 230000001588 bifunctional effect Effects 0.000 description 1

- 229910001593 boehmite Inorganic materials 0.000 description 1

- 239000004202 carbamide Substances 0.000 description 1

- 125000004432 carbon atom Chemical group C* 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002091 carbon monoxide Inorganic materials 0.000 description 1

- 150000001728 carbonyl compounds Chemical class 0.000 description 1

- 150000001735 carboxylic acids Chemical class 0.000 description 1

- 238000004517 catalytic hydrocracking Methods 0.000 description 1

- 238000006555 catalytic reaction Methods 0.000 description 1

- 239000003518 caustics Substances 0.000 description 1

- 238000005119 centrifugation Methods 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 235000013339 cereals Nutrition 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 239000008119 colloidal silica Substances 0.000 description 1

- 239000008139 complexing agent Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 238000010908 decantation Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000007324 demetalation reaction Methods 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 238000001493 electron microscopy Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 235000019253 formic acid Nutrition 0.000 description 1

- 238000004108 freeze drying Methods 0.000 description 1

- 229910021485 fumed silica Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- XMBWDFGMSWQBCA-UHFFFAOYSA-N hydrogen iodide Chemical compound I XMBWDFGMSWQBCA-UHFFFAOYSA-N 0.000 description 1

- 238000005216 hydrothermal crystallization Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-M hydroxide Chemical compound [OH-] XLYOFNOQVPJJNP-UHFFFAOYSA-M 0.000 description 1

- FAHBNUUHRFUEAI-UHFFFAOYSA-M hydroxidooxidoaluminium Chemical compound O[Al]=O FAHBNUUHRFUEAI-UHFFFAOYSA-M 0.000 description 1

- 238000005470 impregnation Methods 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- INQOMBQAUSQDDS-UHFFFAOYSA-N iodomethane Chemical compound IC INQOMBQAUSQDDS-UHFFFAOYSA-N 0.000 description 1

- 239000003456 ion exchange resin Substances 0.000 description 1

- 229920003303 ion-exchange polymer Polymers 0.000 description 1

- 229910052741 iridium Inorganic materials 0.000 description 1

- 238000006317 isomerization reaction Methods 0.000 description 1

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 1

- 150000002576 ketones Chemical class 0.000 description 1

- 238000002386 leaching Methods 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 239000013335 mesoporous material Substances 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 239000012229 microporous material Substances 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 235000010755 mineral Nutrition 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000002707 nanocrystalline material Substances 0.000 description 1

- 239000003345 natural gas Substances 0.000 description 1

- 229910052605 nesosilicate Inorganic materials 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- 229910000510 noble metal Inorganic materials 0.000 description 1

- TVMXDCGIABBOFY-UHFFFAOYSA-N octane Chemical compound CCCCCCCC TVMXDCGIABBOFY-UHFFFAOYSA-N 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 239000006259 organic additive Substances 0.000 description 1

- 239000011368 organic material Substances 0.000 description 1

- 150000004762 orthosilicates Chemical class 0.000 description 1

- 125000004430 oxygen atom Chemical group O* 0.000 description 1

- 229910052698 phosphorus Inorganic materials 0.000 description 1

- 238000006303 photolysis reaction Methods 0.000 description 1

- 230000015843 photosynthesis, light reaction Effects 0.000 description 1

- 238000004375 physisorption Methods 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 230000008929 regeneration Effects 0.000 description 1

- 238000011069 regeneration method Methods 0.000 description 1

- 229910052703 rhodium Inorganic materials 0.000 description 1

- 239000010948 rhodium Substances 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 229910052707 ruthenium Inorganic materials 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 150000004760 silicates Chemical class 0.000 description 1

- RMAQACBXLXPBSY-UHFFFAOYSA-N silicic acid Chemical compound O[Si](O)(O)O RMAQACBXLXPBSY-UHFFFAOYSA-N 0.000 description 1

- 150000003384 small molecules Chemical class 0.000 description 1

- 229910000030 sodium bicarbonate Inorganic materials 0.000 description 1

- 235000017557 sodium bicarbonate Nutrition 0.000 description 1

- 229910052596 spinel Inorganic materials 0.000 description 1

- 239000011029 spinel Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 238000010189 synthetic method Methods 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- 150000003568 thioethers Chemical class 0.000 description 1

- 229910000314 transition metal oxide Inorganic materials 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 238000001291 vacuum drying Methods 0.000 description 1

- 229910052720 vanadium Inorganic materials 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B39/00—Compounds having molecular sieve and base-exchange properties, e.g. crystalline zeolites; Their preparation; After-treatment, e.g. ion-exchange or dealumination

- C01B39/02—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof; Direct preparation thereof; Preparation thereof starting from a reaction mixture containing a crystalline zeolite of another type, or from preformed reactants; After-treatment thereof

- C01B39/30—Erionite or offretite type, e.g. zeolite T

- C01B39/305—Erionite or offretite type, e.g. zeolite T using at least one organic template directing agent

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B39/00—Compounds having molecular sieve and base-exchange properties, e.g. crystalline zeolites; Their preparation; After-treatment, e.g. ion-exchange or dealumination

- C01B39/02—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof; Direct preparation thereof; Preparation thereof starting from a reaction mixture containing a crystalline zeolite of another type, or from preformed reactants; After-treatment thereof

- C01B39/30—Erionite or offretite type, e.g. zeolite T

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/50—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the erionite or offretite type, e.g. zeolite T, as exemplified by patent document US2950952

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/50—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the erionite or offretite type, e.g. zeolite T, as exemplified by patent document US2950952

- B01J29/52—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the erionite or offretite type, e.g. zeolite T, as exemplified by patent document US2950952 containing iron group metals, noble metals or copper

- B01J29/56—Iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/30—Catalysts, in general, characterised by their form or physical properties characterised by their physical properties

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B39/00—Compounds having molecular sieve and base-exchange properties, e.g. crystalline zeolites; Their preparation; After-treatment, e.g. ion-exchange or dealumination

- C01B39/02—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof; Direct preparation thereof; Preparation thereof starting from a reaction mixture containing a crystalline zeolite of another type, or from preformed reactants; After-treatment thereof

- C01B39/026—After-treatment

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C29/00—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring

- C07C29/48—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring by oxidation reactions with formation of hydroxy groups

- C07C29/50—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring by oxidation reactions with formation of hydroxy groups with molecular oxygen only

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G11/00—Catalytic cracking, in the absence of hydrogen, of hydrocarbon oils

- C10G11/02—Catalytic cracking, in the absence of hydrogen, of hydrocarbon oils characterised by the catalyst used

- C10G11/04—Oxides

- C10G11/05—Crystalline alumino-silicates, e.g. molecular sieves

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G3/00—Production of liquid hydrocarbon mixtures from oxygen-containing organic materials, e.g. fatty oils, fatty acids

- C10G3/42—Catalytic treatment

- C10G3/44—Catalytic treatment characterised by the catalyst used

- C10G3/48—Catalytic treatment characterised by the catalyst used further characterised by the catalyst support

- C10G3/49—Catalytic treatment characterised by the catalyst used further characterised by the catalyst support containing crystalline aluminosilicates, e.g. molecular sieves

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G45/00—Refining of hydrocarbon oils using hydrogen or hydrogen-generating compounds

- C10G45/58—Refining of hydrocarbon oils using hydrogen or hydrogen-generating compounds to change the structural skeleton of some of the hydrocarbon content without cracking the other hydrocarbons present, e.g. lowering pour point; Selective hydrocracking of normal paraffins

- C10G45/60—Refining of hydrocarbon oils using hydrogen or hydrogen-generating compounds to change the structural skeleton of some of the hydrocarbon content without cracking the other hydrocarbons present, e.g. lowering pour point; Selective hydrocracking of normal paraffins characterised by the catalyst used

- C10G45/64—Refining of hydrocarbon oils using hydrogen or hydrogen-generating compounds to change the structural skeleton of some of the hydrocarbon content without cracking the other hydrocarbons present, e.g. lowering pour point; Selective hydrocracking of normal paraffins characterised by the catalyst used containing crystalline alumino-silicates, e.g. molecular sieves

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G47/00—Cracking of hydrocarbon oils, in the presence of hydrogen or hydrogen- generating compounds, to obtain lower boiling fractions

- C10G47/02—Cracking of hydrocarbon oils, in the presence of hydrogen or hydrogen- generating compounds, to obtain lower boiling fractions characterised by the catalyst used

- C10G47/10—Cracking of hydrocarbon oils, in the presence of hydrogen or hydrogen- generating compounds, to obtain lower boiling fractions characterised by the catalyst used with catalysts deposited on a carrier

- C10G47/12—Inorganic carriers

- C10G47/16—Crystalline alumino-silicate carriers

- C10G47/20—Crystalline alumino-silicate carriers the catalyst containing other metals or compounds thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/50—Zeolites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9404—Removing only nitrogen compounds

- B01D53/9409—Nitrogen oxides

- B01D53/9413—Processes characterised by a specific catalyst

- B01D53/9418—Processes characterised by a specific catalyst for removing nitrogen oxides by selective catalytic reduction [SCR] using a reducing agent in a lean exhaust gas

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2229/00—Aspects of molecular sieve catalysts not covered by B01J29/00

- B01J2229/10—After treatment, characterised by the effect to be obtained

- B01J2229/18—After treatment, characterised by the effect to be obtained to introduce other elements into or onto the molecular sieve itself

- B01J2229/186—After treatment, characterised by the effect to be obtained to introduce other elements into or onto the molecular sieve itself not in framework positions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2229/00—Aspects of molecular sieve catalysts not covered by B01J29/00

- B01J2229/30—After treatment, characterised by the means used

- B01J2229/42—Addition of matrix or binder particles

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2002/00—Crystal-structural characteristics

- C01P2002/70—Crystal-structural characteristics defined by measured X-ray, neutron or electron diffraction data

- C01P2002/72—Crystal-structural characteristics defined by measured X-ray, neutron or electron diffraction data by d-values or two theta-values, e.g. as X-ray diagram

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2004/00—Particle morphology

- C01P2004/30—Particle morphology extending in three dimensions

- C01P2004/40—Particle morphology extending in three dimensions prism-like

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2004/00—Particle morphology

- C01P2004/90—Other morphology not specified above

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G2400/00—Products obtained by processes covered by groups C10G9/00 - C10G69/14

- C10G2400/22—Higher olefins

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G2400/00—Products obtained by processes covered by groups C10G9/00 - C10G69/14

- C10G2400/30—Aromatics

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02C—CAPTURE, STORAGE, SEQUESTRATION OR DISPOSAL OF GREENHOUSE GASES [GHG]

- Y02C20/00—Capture or disposal of greenhouse gases

- Y02C20/10—Capture or disposal of greenhouse gases of nitrous oxide (N2O)

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/50—Improvements relating to the production of bulk chemicals

- Y02P20/52—Improvements relating to the production of bulk chemicals using catalysts, e.g. selective catalysts

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P30/00—Technologies relating to oil refining and petrochemical industry

- Y02P30/20—Technologies relating to oil refining and petrochemical industry using bio-feedstock

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- General Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Combustion & Propulsion (AREA)

- Health & Medical Sciences (AREA)

- Biomedical Technology (AREA)

- Environmental & Geological Engineering (AREA)

- Analytical Chemistry (AREA)

- Catalysts (AREA)

- Silicates, Zeolites, And Molecular Sieves (AREA)

Abstract

Description

DESCRIPCIÓNDESCRIPTION

Método para la preparación de un nuevo tamiz molecular de ERIMethod for the preparation of a new ERI molecular sieve

La presente invención se refiere a un método para la preparación de un nuevo tamiz molecular con el tipo de estructura de ERI.The present invention relates to a method for the preparation of a new molecular sieve with the ERI structure type.

En particular, la invención es un método para la preparación de un material de tamiz molecular cristalino que pertenece a la familia de estructura de ERI esencialmente sin intercrecimiento de OFF, con una relación elevada de sílice a alúmina y una morfología cristalina tabular a prismática.In particular, the invention is a method for the preparation of a crystalline molecular sieve material that belongs to the ERI structure family essentially without OFF intergrowth, with a high ratio of silica to alumina and a tabular to prismatic crystal morphology.

Las zeolitas son materiales microporosos cristalinos formados al compartir por las esquinas tetraedros de TO4 (T = Si, Al, P, Ge, B, Ti, Sn, etc.), interconectados mediante átomos de oxígeno para formar poros y cavidades de tamaño uniforme y forma definida precisamente mediante su estructura cristalina. Las zeolitas también se designan "tamices moleculares” debido a que los poros y cavidades son de tamaño similar a moléculas pequeñas. Esta clase de materiales tiene aplicaciones comerciales importantes como absorbentes, intercambiadores de iones y catalizadores.Zeolites are crystalline microporous materials formed by sharing tetrahedral TO4 corners (T = Si, Al, P, Ge, B, Ti, Sn, etc.), interconnected by oxygen atoms to form pores and cavities of uniform size and precisely defined by its crystal structure. Zeolites are also referred to as "molecular sieves" because the pores and cavities are similar in size to small molecules.This class of materials has important commercial applications as absorbers, ion exchangers and catalysts.

Los tamices moleculares zeolíticos se clasifican por la International Zeolite Association (IZA) según las reglas de la Comisión de la IUPAC sobre Nomenclatura de Tamices Moleculares. Una vez que se establece la topología de una nueva estructura, se asigna un código de tres letras. Este código define la estructura atómica de la estructura, a partir de la cual se puede describir un patrón de difracción de rayos X nítido.Zeolitic molecular sieves are classified by the International Zeolite Association (IZA) according to the rules of the IUPAC Commission on Molecular Sieve Nomenclature. Once the topology of a new structure is established, a three-letter code is assigned. This code defines the atomic structure of the structure, from which a clear X-ray diffraction pattern can be described.

La expresión tipo de estructura o topología de estructura como se usa aquí, se refiere a la estructura atómica única de un tamiz molecular específico, nombrado por un código de tres letras ideado por la International Zeolite Association [Atlas of Zeolite Framework Types, 6a edición revisada, 2007, Ch. Baerlocher, L.B. McCusker y D.H. Olson, ISBN: 978-0-444 53064-6].The term structure type or structure topology as used herein, refers to the unique atomic structure of a specific molecular sieve, named by a three-letter code devised by the International Zeolite Association [Atlas of Zeolite Framework Types, 6th revised edition , 2007, Ch. Baerlocher, LB McCusker and D.H. Olson, ISBN: 978-0-444 53064-6].

La erionita (ERI) es una zeolita de aluminosilicato de origen natural [Staples, L.W. y Gard, J.A., Mineral. Mag., 32, 261-281 (1959)] con una relación de Si/Al de alrededor de 3. Se encuentra a menudo como un intercrecimiento con OFF [Schlenker, J.L., Pluth, J.J. y Smith, J.V., Acta Crystallogr., B33, 3265-3268 (1977)].Erionite (ERI) is an aluminosilicate zeolite of natural origin [Staples, LW and Gard, JA, Mineral. Mag., 32 , 261-281 (1959)] with a Si / Al ratio of around 3. It is often found as an intergrowth with OFF [Schlenker, JL, Pluth, JJ and Smith, JV, Acta Crystallogr., B33 , 3265-3268 (1977)].

Se han descrito varias maneras para preparar ERI mediante métodos sintéticos.Several ways have been described for preparing ERI by synthetic methods.

La patente US 2.950.952 describe la preparación de tamiz molecular tipo T, que se ha mostrado que es un intercrecimiento de ERI y OFF [J.M. Bennet et al., Nature, 1967, 214, 1005-1006. La patente US 3.699.139 describe la síntesis de ERI/OFF usando trimetilbencilamonio. La patente US 4.086.186 describe la síntesis de ZSM-34, que también es un intercrecimiento de ERI y OFF. La patente US 4.503.023 describe la síntesis de LZ-220, que es una forma ligeramente más silícea de tamiz molecular tipo T, y también es un intercrecimiento. También se ha dado a conocer que el uso de DABCO(I) y DABCO(II) da intercrecimientos de ERI y OFF [M. L. Ocelli et al., Zeolites, 1987, 7, 265-271].US Patent 2,950,952 describes the preparation of type T molecular sieve, which has been shown to be an intergrowth of ERI and OFF [J.M. Bennet et al., Nature, 1967, 214, 1005-1006. US Patent 3,699,139 describes the synthesis of ERI / OFF using trimethylbenzylammonium. US Patent 4,086,186 describes the synthesis of ZSM-34, which is also an intergrowth of ERI and OFF. US Patent 4,503,023 describes the synthesis of LZ-220, which is a slightly more siliceous form of T-type molecular sieve, and is also an intergrowth. It has also been reported that the use of DABCO (I) and DABCO (II) gives inter-growths of ERI and OFF [M. L. Ocelli et al., Zeolites, 1987, 7, 265-271].

Como se ilustra mediante las referencias anteriores, la preparación de ERI conduce típicamente a intercrecimientos con OFF. Estos intercrecimientos no se pueden considerar topologías de ERI pura y conducen a diferentes sistemas de canales y distribución de jaulas dentro de los materiales zeolíticos en comparación con ERI pura, lo que en conjunto influirá en las propiedades de esta clase de materiales.As illustrated by the above references, the preparation of ERI typically leads to intergrowths with OFF. These intergrowths can not be considered pure ERI topologies and lead to different channel systems and cage distribution within the zeolitic materials compared to pure ERI, which together will influence the properties of this class of materials.

Solamente unas pocas publicaciones se refieren a la síntesis de ERI esencialmente libre de intercrecimientos de OFF. La patente US 7.344.694 da a conocer la preparación de UZM-12, que se sugiere que tiene una relación de Si/Al por encima de 5,5 (= SiO2/Al2O3 > 11). Prácticamente, en los ejemplos no se dio ningún caso en el que se llevase a cabo la invención para lograr relaciones de sílice a alúmina (SiO2/Al2O3) mayores que 12,6. Además, UZM-12 se prepara usando un enfoque de disparidad de densidades, en el que se puede obtener material nanocristalino con cristalitos de 15 a 50 nm con morfologías cristalinas esferoidales a "de grano de arroz”. Especialmente, los nanocristalitos son difíciles de separar del licor de cristalización.Only a few publications refer to the synthesis of ERI essentially free of OFF inter-growth. US Patent 7,344,694 discloses the preparation of UZM-12, which is suggested to have a Si / Al ratio above 5.5 (= SiO2 / Al2O3> 11). Practically, in the examples there was no case in which the invention was carried out to achieve silica to alumina ratios (SiO2 / Al2O3) greater than 12.6. In addition, UZM-12 is prepared using a density disparity approach, in which nanocrystalline material can be obtained with crystallites of 15 to 50 nm with spherical crystalline morphologies to "rice grain." Especially, nanocrystallites are difficult to separate of the crystallization liquor.

Recientemente, otro tamiz molecular de ERI, designado SSZ-98, se dio a conocer en las patentes US 9.409.786, 9.416.017 y en la solicitud de patente US 2016/0001273. Este material también está esencialmente libre de intercrecimiento de OFF.Recently, another molecular sieve of ERI, designated SSZ-98, was disclosed in US Patents 9,409,786, 9,416,017 and in US Patent Application 2016/0001273. This material is also essentially free of OFF intergrowth.

Se reivindica que SSZ-98 tiene una relación de SiO2/Al2O3 entre 15 y 50, con una morfología cristalina similar a varillas o de lámina, y se prepara usando el dicatión de N,N’-dimetil-1,4diazobicido[2.2.2]octano como un agente director de la estructura.It is claimed that SSZ-98 has a SiO2 / Al2O3 ratio between 15 and 50, with a crystal-like morphology similar to rods or sheet, and is prepared using the dication of N, N'-dimethyl-1,4-diazobicido [2.2.2] octane as a directing agent of the structure.

Solicitudes de patentes posteriores también reivindican cationes de N,N-dimetilpiperidinio, cationes de 1,3-diciclohexilimidazalio, y su combinación, en las solicitudes de patentes US 2017/0088432, 2017/0073240 y 2016/0375428, respectivamente.Subsequent patent applications also claim N, N-dimethylpiperidinium cations, 1,3-dicyclohexylimidazole cations, and their combination, in patent applications US 2017/0088432, 2017/0073240 and 2016/0375428, respectively.

Es normalmente conocido en la técnica que la estabilidad hidrotérmica de tamices moleculares de aluminosilicatos se hace más elevada cuando se incrementa la relación molar de SiO2/Al2O3. En consecuencia, existe la necesidad de incrementar las relaciones molares de SiO2/Al2O3 de los materiales de tamices moleculares de ERI conocidos, en particular para aplicaciones en las que la estabilidad hidrotérmica es un problema. Además, también se conoce normalmente en la técnica que la morfología cristalina tiene un gran impacto sobre el comportamiento del tamiz molecular en aplicaciones catalíticas. En [S. Teketel, L. F. Lundegaard, W. Skistad, S. M. Chavan, U. Olsbye, K. P. Lillerud, P. Beato, S. Svelle, J. Catal. 2015, 327, 22-32] se puede encontrar una descripción del comportamiento de las diferentes morfologías cristalinas en la catálisis zeolítica. De este modo, también existe la necesidad de preparar materiales con morfologías específicas para aplicaciones catalíticas específicas.It is commonly known in the art that the hydrothermal stability of molecular sieves of aluminosilicates becomes higher when the molar ratio of SiO2 / Al2O3 is increased. Accordingly, there is a need to increase the molar ratios of SiO2 / Al2O3 of the known ERI molecular sieve materials, in particular for applications in which hydrothermal stability is a problem. In addition, it is also commonly known in the art that crystalline morphology has a great impact on the behavior of the molecular sieve in catalytic applications. In [S. Teketel, LF Lundegaard, W. Skistad, SM Chavan, U. Olsbye, KP Lillerud, P. Beato, S. Svelle, J. Catal. 2015 , 327, 22-32] a description of the behavior of the different crystalline morphologies in zeolitic catalysis can be found. Thus, there is also a need to prepare materials with specific morphologies for specific catalytic applications.

Para distinguir diferentes morfologías cristalinas, se define un parámetro (rc/ra), que describe la relación entre las diferentes dimensiones a lo largo (rc) y ortogonal (ra) al eje c único de los cristalitos preparados, por ejemplo determinadas mediante métodos de microscopía electrónica (para cristales hexagonales, el eje c único es paralelo al eje de simetría de seis veces). Las morfologías del cristalito se describirán usando las palabras lámina, tabular, prismática, aguja y similar a varilla. La relación entre estas descripciones y los valores de rc/ra se define en la Tabla a continuaciónTo distinguish different crystalline morphologies, a parameter (rc / ra) is defined , which describes the relationship between the different dimensions along (rc) and orthogonal (ra) to the single c-axis of the prepared crystallites, for example determined by methods of electron microscopy (for hexagonal crystals, the single c-axis is parallel to the six-fold axis of symmetry). The morphologies of the crystallite will be described using the words sheet, tabular, prismatic, needle and rod-like. The relationship between these descriptions and the rc / ra values is defined in the Table below

De este modo, un objeto general de esta invención es proporcionar un tamiz molecular cristalino de ERI esencialmente libre de intercrecimientos de OFF, con relaciones molares de SiO2/Al2O3 elevadas y morfologías cristalinas diferentes a lo que ya se conoce. Thus, a general object of this invention is to provide an ERI crystalline molecular sieve essentially free of OFF inter-flows, with high molar ratios of SiO2 / Al2O3 and crystal morphologies different from what is already known.

Hemos encontrado que el uso de un dicatión de cidohexano-1,4-bis(trialquilamonio) como un agente director de la estructura orgánica (OSDA) da como resultado la consecución exitosa de ERI pura con relaciones elevadas de sílice a alúmina de hasta 100, y con morfologías cristalinas diferentes a aquella de SSZ-98.We have found that the use of a dication of cidohexane-1,4-bis (trialkylammonium) as a directing agent of the organic structure (OSDA) results in the successful achievement of pure ERI with high silica to alumina ratios of up to 100, and with crystalline morphologies different from that of SSZ-98.

De acuerdo con el hallazgo anterior la presente invención proporciona un método para la preparación de un producto de tamiz molecular con el tipo de estructura de ERI, que comprende las etapas deAccording to the above finding, the present invention provides a method for the preparation of a molecular sieve product with the ERI structure type, comprising the steps of

i) preparar una mezcla de síntesis que comprende al menos una fuente de sílice y al menos una fuente de alúmina, o una fuente combinada tanto de sílice como de alúmina, una fuente de metal alcalino o metal alcalino-térreo (A), al menos un OSDA que es un dicatión de ciclohexano-1,4-bis(trialquilamonio), y agua en relaciones molares de:i) preparing a synthesis mixture comprising at least one source of silica and at least one source of alumina, or a combined source of both silica and alumina, a source of alkali metal or alkaline earth metal (A), at least an OSDA that is a dication of cyclohexane-1,4-bis (trialkylammonium), and water in molar ratios of:

ii) someter la mezcla a condiciones capaces de hacer cristalizar el tamiz molecular; yii) subjecting the mixture to conditions capable of crystallizing the molecular sieve; Y

iii) separar el producto del tamiz molecular para obtener el tamiz molecular según se sintetiza.iii) separating the product from the molecular sieve to obtain the molecular sieve as it is synthesized.

La fuente de sílice puede comprender sílice, sílice pirolizada, ácido silícico, silicatos amorfos o cristalinos, sílice coloidal, ortosilicatos de tetraalquilo, y mezclas de los mismos.The silica source may comprise silica, fumed silica, silicic acid, amorphous or crystalline silicates, colloidal silica, tetraalkyl orthosilicates, and mixtures thereof.

La fuente de alúmina puede comprender alúmina, boehmita, aluminatos, y mezclas de los mismos.The alumina source may comprise alumina, boehmite, aluminates, and mixtures thereof.

Una fuente combinada de sílice y alúmina puede ser sílice-alúmina amorfa coprecipitada, caolín, materiales mesoporosos, aluminosilicatos microporosos cristalinos, y mezclas de los mismos. A combined source of silica and alumina can be amorphous amorphous silica-alumina, kaolin, mesoporous materials, crystalline microporous aluminosilicates, and mixtures thereof.

En una realización de la invención, el producto del tamiz molecular tiene, en el estado según se sintetiza y anhidro, una composición con las relaciones molares dadas en la tabla:In one embodiment of the invention, the product of the molecular sieve has, in the state as it is synthesized and anhydrous, a composition with the molar ratios given in the table:

El OSDA es un dicatión de ciclohexano-1,4-bis(trialquilamonio) que tiene las estructuras (R = grupo alquilo) como se muestran a continuación.OSDA is a dication of cyclohexane-1,4-bis (trialkylammonium) having the structures (R = alkyl group) as shown below.

Preferiblemente, el OSDA se selecciona del grupo que consiste en ciclohexano-1,4-bis(trimetilamonio), ciclohexano-1,4-bis(trietilamonio), ciclohexano-1,4-bis(etildimetilamonio), ciclohexano-1,4-bis(dietilmetilamonio).Preferably, the OSDA is selected from the group consisting of cyclohexane-1,4-bis (trimethylammonium), cyclohexane-1,4-bis (triethylammonium), cyclohexane-1,4-bis (ethyldimethylammonium), cyclohexane-1,4- bis (diethylmethylammonium).

Actualmente, el OSDA más preferido es ciclohexano-1,4-bis(trimetilamonio).Currently, the most preferred OSDA is cyclohexane-1,4-bis (trimethylammonium).

El catión del OSDA está asociado con aniones, que pueden ser típicamente hidróxido, cloruro, bromuro, yoduro, etc., en tanto que no sean perjudiciales para la formación del tamiz molecular.The cation of OSDA is associated with anions, which may typically be hydroxide, chloride, bromide, iodide, etc., as long as they are not detrimental to the formation of the molecular sieve.

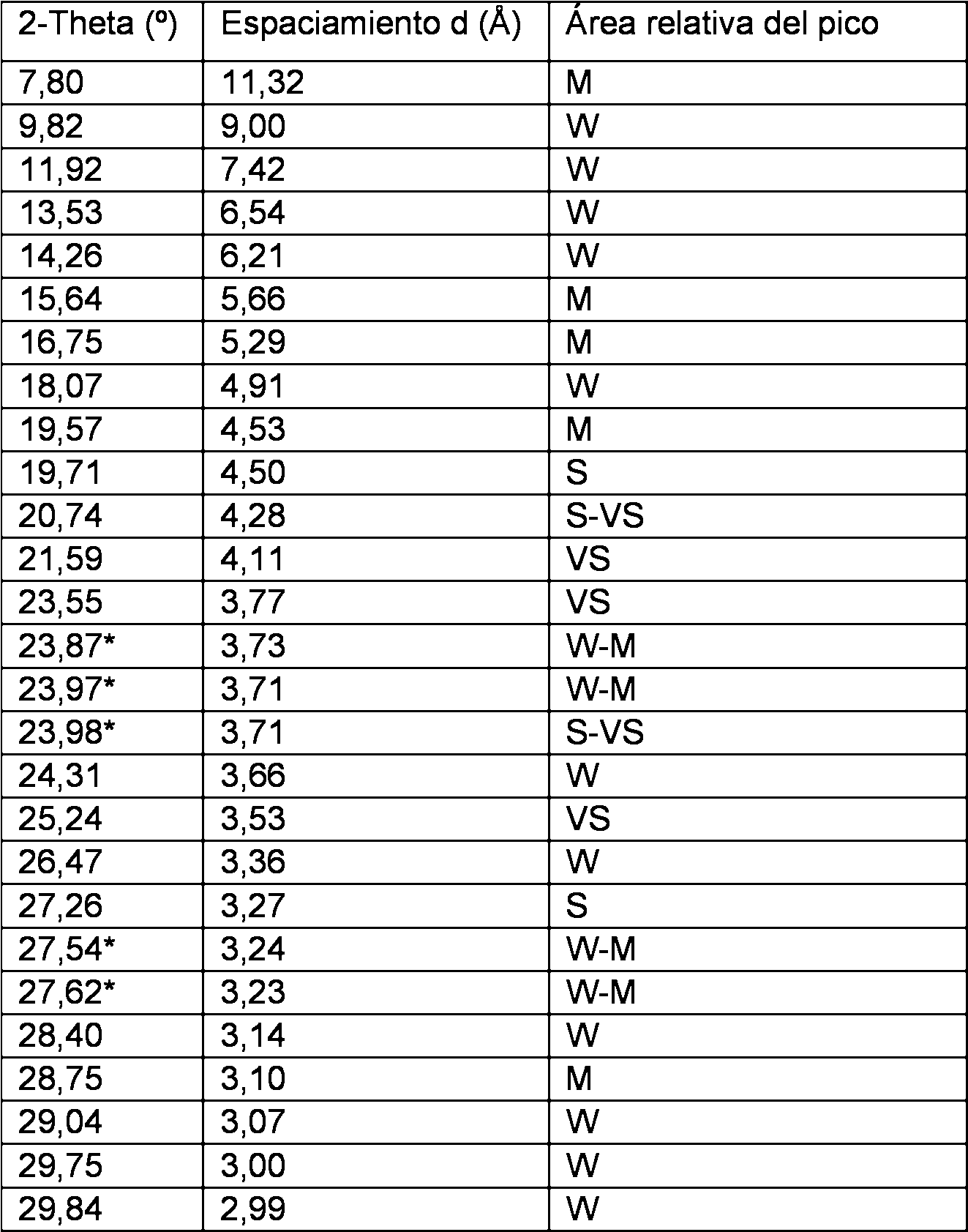

En una realización, la forma según se sintetiza del tamiz molecular tiene un patrón de difracción de rayos X de polvo, recogido en geometría de Bragg-Brentano con una ranura de divergencia variable usando radiación de Cu K-alfa, esencialmente como se muestra en la siguiente Tabla:In one embodiment, the shape as synthesized from the molecular sieve has a powder X-ray diffraction pattern, collected in Bragg-Brentano geometry with a variable divergence groove using Cu K-alpha radiation, essentially as shown in FIG. Next Table:

* Las intensidades de los picos y la asignación de las letras es incierta debido al solapamiento significativo de los picos.* The intensities of the peaks and the assignment of the letters is uncertain due to the significant overlap of the peaks.

en la que las áreas relativas de los picos observados en el intervalo 2-Theta se muestran según: W = débil: 0-20%; M = medio: 20-40%; S = fuerte: 40-60% y VS = muy fuerte: 60-100%. Los valores de 2-Theta son ± 0,20°.in which the relative areas of the peaks observed in the 2-Theta interval are shown according to: W = weak: 0-20%; M = medium: 20-40%; S = strong: 40-60% and VS = very strong: 60-100%. The values of 2-Theta are ± 0.20 °.

El catión del OSDA orgánico todavía retenido en el tamiz molecular según se sintetiza es eliminado en la mayoría de los casos, excepto que se use en la forma según se sintetiza, mediante tratamiento térmico en presencia de oxígeno. La temperatura del tratamiento térmico debería de ser suficiente para eliminar las moléculas orgánicas ya sea mediante evaporación, descomposición, combustión, o una combinación de las mismas. Típicamente, se aplica una temperatura entre 150 y 750°C durante un período de tiempo suficiente para eliminar la molécula o moléculas orgánicas. Una persona experta en la técnica será capaz fácilmente de determinar una temperatura y tiempo mínimos para este tratamiento térmico. Otros métodos para eliminar el material o materiales orgánicos retenidos en el tamiz molecular según se sintetiza incluyen extracción, calcinación a vacío, fotolisis, o tratamiento con ozono.The cation of the organic OSDA still retained in the molecular sieve as it is synthesized is eliminated in most cases, except that it is used in the form as it is synthesized, by heat treatment in the presence of oxygen. The temperature of the heat treatment should be sufficient to remove the organic molecules either by evaporation, decomposition, combustion, or a combination thereof. Typically, a temperature between 150 and 750 ° C is applied for a period of time sufficient to remove the organic molecule or molecules. A person skilled in the art will readily be able to determine a minimum temperature and time for this heat treatment. Other methods for removing the material or organic materials retained in the molecular sieve as synthesized include extraction, vacuum calcination, photolysis, or treatment with ozone.

En una realización, la forma calcinada del producto del tamiz molecular tiene un patrón de difracción de rayos X de polvo, recogido en geometría de Bragg-Brentano con una ranura de divergencia variable usando radiación de Cu K-alfa, esencialmente como se muestra en la siguiente Tabla:In one embodiment, the calcined form of the molecular sieve product has a dust X-ray diffraction pattern, collected in Bragg-Brentano geometry with a variable divergence groove using Cu K-alpha radiation, essentially as shown in FIG. Next Table:

* Las intensidades de los picos y la asignación de las letras es incierta debido al solapamiento significativo de los picos.* The intensities of the peaks and the assignment of the letters is uncertain due to the significant overlap of the peaks.

en la que las áreas relativas de los picos observados en el intervalo 2-Theta se muestran según: W = débil: 0-20%; M = medio: 20-40%; S = fuerte: 40-60% y VS = muy fuerte: 60-100%. Los valores de 2-Theta son ± 0,20°. in which the relative areas of the peaks observed in the 2-Theta interval are shown according to: W = weak: 0-20%; M = medium: 20-40%; S = strong: 40-60% and VS = very strong: 60-100%. The values of 2-Theta are ± 0.20 °.

El nuevo tamiz molecular con el tipo de estructura de ERI tiene una relación en moles de sílice a alúmina de alrededor de 8 a alrededor de 100 y una morfología cristalina, definida por la relación entre las dimensiones rc a lo largo de y ra ortogonal al eje c único, entre 0,5 y 2,0.The new molecular sieve structure type ERI has a mole ratio of silica to alumina of about 8 to about 100 and a crystal morphology, defined by the relationship between rc dimensions along orthogonal ra axis c only, between 0.5 and 2.0.

La morfología cristalina del nuevo tamiz molecular de ERI con una relación rc/ra de entre 0,5 y 2 tiene una morfología cristalina prismática a tabular, como se muestra en las Figuras 2 y 4 en los ejemplos más abajo, que es diferente a una morfología cristalina similar a varillas o de lámina del tamiz molecular de ERI conocido SSZ-98.The crystalline morphology of the new molecular sieve of ERI with a rc / ra ratio of between 0.5 and 2 has a prismatic to tabular crystalline morphology, as shown in Figures 2 and 4 in the examples below, which is different from a Crystal-like morphology similar to rods or molecular sieve sheet from ERI known SSZ-98.

En una realización adicional, la relación en moles de sílice a alúmina del nuevo tamiz molecular de ERI está entre 8 y 100, preferiblemente entre 10 y 60.In a further embodiment, the molar ratio of silica to alumina of the new molecular sieve of ERI is between 8 and 100, preferably between 10 and 60.

También se pueden introducir en la mezcla de síntesis otros elementos tetravalentes. Tales elementos incluyen estaño, circonio, titanio, hafnio, germanio, y combinaciones de los mismos. También se pueden incluir en la mezcla de síntesis elementos trivalentes, ya sea junto con aluminio o sin la presencia de aluminio. Tales elementos trivalentes incluyen boro, hierro, indio, galio, y combinaciones de los mismos. Tanto los elementos tetravalentes como trivalentes se pueden añadir en forma de metales, sales, óxidos, sulfuros, y combinaciones de los mismos.Other tetravalent elements can also be introduced into the synthesis mixture. Such elements include tin, zirconium, titanium, hafnium, germanium, and combinations thereof. Trivalent elements can also be included in the synthesis mixture, either together with aluminum or without the presence of aluminum. Such trivalent elements include boron, iron, indium, gallium, and combinations thereof. Both tetravalent and trivalent elements can be added in the form of metals, salts, oxides, sulfides, and combinations thereof.

De este modo, en una realización adicional, al menos una parte del aluminio en la fuente de alúmina y/o del silicio en la fuente de sílice en la mezcla de síntesis se sustituye por uno o más elementos seleccionados de estaño, circonio, titanio, hafnio, germanio, boro, hierro, indio y galio.Thus, in a further embodiment, at least a portion of the aluminum in the source of alumina and / or the silicon in the silica source in the synthesis mixture is replaced by one or more elements selected from tin, zirconium, titanium, hafnium, germanium, boron, iron, indium and gallium.

En la mezcla de síntesis se pueden incluir metales de transición, ya sea como sales simples o como complejos que protegen al metal de transición de la precipitación en las condiciones cáusticas dictadas por la mezcla de síntesis. Especialmente, los complejos de poliaminas son útiles para proteger iones de metales de transición de cobre y hierro durante la preparación, y también pueden actuar para dirigir la síntesis hacia tamices moleculares específicos (véase, por ejemplo, el uso de poliaminas en combinación con iones de cobre en la solicitud de patente US 2016/271596). De tal manera, los iones de metales de transición se pueden introducir en el interior del tamiz molecular fácilmente durante la cristalización. Transition metals may be included in the synthesis mixture, either as simple salts or as complexes that protect the transition metal from precipitation under the caustic conditions dictated by the synthesis mixture. Especially, the polyamine complexes are useful for protecting transition metal ions of copper and iron during the preparation, and can also act to direct the synthesis towards specific molecular sieves (see, for example, the use of polyamines in combination with ions of copper in the patent application US 2016/271596). In such a manner, the transition metal ions can be introduced into the interior of the molecular sieve easily during crystallization.

La mezcla de síntesis también puede contener agentes de llenado de poros baratos, que pueden ayudar en la preparación de productos más silíceos. Tales agentes de llenado de poros pueden ser éteres corona (por ejemplo, 18-corona-6), aminas simples (por ejemplo trimetil- y trietilamina), y otras moléculas no cargadas.The synthesis mixture can also contain inexpensive pore filling agents, which can aid in the preparation of more siliceous products. Such pore-filling agents may be crown (eg, 18-crown-6) ethers, simple amines (eg trimethyl- and triethylamine), and other uncharged molecules.

La cristalización de la mezcla de síntesis para formar el nuevo tamiz molecular se lleva a cabo a temperaturas elevadas hasta que se forma el tamiz molecular. Habitualmente se realiza la cristalización hidrotérmica de una manera para generar una presión autógena a temperaturas de 100-200°C en un autoclave y durante períodos de tiempo entre dos horas y 20 días. La mezcla de síntesis se puede someter a agitación durante la cristalización.The crystallization of the synthesis mixture to form the new molecular sieve is carried out at elevated temperatures until the molecular sieve is formed. Hydrothermal crystallization is usually carried out in a manner to generate an autogenous pressure at temperatures of 100-200 ° C in an autoclave and for periods of time between two hours and 20 days. The synthesis mixture can be subjected to stirring during crystallization.

Una vez que la cristalización se ha terminado, el producto del tamiz molecular sólido resultante se separa de la mezcla de síntesis líquida que queda mediante técnicas de separación convencionales tales como decantación, filtración (a vacío) o centrifugación. Los sólidos recuperados se enjuagan entonces típicamente con agua y se secan usando métodos convencionales (por ejemplo, calentando hasta 75-150°C a presión atmosférica, secado a vacío o liofilización, etc.), para obtener el tamiz molecular "según se sintetiza”. El producto "según se sintetiza” se refiere aquí al tamiz molecular tras la cristalización y antes de la eliminación del agente o agentes directores de la estructura u otros aditivos orgánicos.Once the crystallization is complete, the resulting solid molecular sieve product is separated from the remaining liquid synthesis mixture by conventional separation techniques such as decantation, filtration (in vacuo) or centrifugation. The recovered solids are then typically rinsed with water and dried using conventional methods (e.g., heating to 75-150 ° C at atmospheric pressure, vacuum drying or lyophilization, etc.), to obtain the "as synthesized" molecular sieve. The product "as synthesized" refers here to the molecular sieve after crystallization and before the elimination of the agent or agents directing the structure or other organic additives.

Habitualmente, es deseable eliminar los iones alcalinos o alcalino-térreos restantes (por ejemplo Na+) del tamiz molecular esencialmente libre de moléculas orgánicas ocluidas mediante intercambio iónico u otros métodos conocidos. El intercambio iónico con amonio y/o hidrógeno son métodos bien reconocidos para obtener la forma de NH4 o la forma de H del tamiz molecular. También se pueden incluir en el procedimiento de intercambio iónico iones metálicos deseados, o se pueden llevar a cabo separadamente. La forma de NH4 del material también se puede convertir en la forma de H mediante tratamiento térmico simple, de una manera similar a como se describe anteriormente.Usually, it is desirable to remove the remaining alkali or alkaline earth (for example Na +) ions from the molecular sieve essentially free of occluded organic molecules by ion exchange or other known methods. Ion exchange with ammonium and / or hydrogen are well-recognized methods for obtaining the NH4 form or the H form of the molecular sieve. Also, desired metal ions can be included in the ion exchange process, or they can be carried out separately. The NH 4 form of the material can also be converted to the H form by simple heat treatment, in a manner similar to that described above.

En ciertos casos, también puede ser deseable alterar la composición química del tamiz molecular obtenido, tal como alterando la relación molar de sílice a alúmina. Sin estar atados por cualquier orden de los tratamientos post-sintéticos, en este caso pueden ser útiles la lixiviación de ácidos (se pueden usar inorgánicos y orgánicos usando agentes complejantes tales como EDTA, etc.), el tratamiento con vapor, la desilicación, y combinaciones de los mismos, u otros métodos de desmetalación. In certain cases, it may also be desirable to alter the chemical composition of the molecular sieve obtained, such as by altering the molar ratio of silica to alumina. Without being bound by any order of the post-synthetic treatments, in this case the leaching of acids can be useful (they can be used inorganic and organic using complexing agents such as EDTA, etc.), steam treatment, desilication, and combinations thereof, or other methods of demetalation.

Para promover aplicaciones catalíticas específicas, se pueden introducir ciertos metales en el nuevo tamiz molecular para obtener un tamiz molecular sustituido con metal, impregnado con metal o intercambiado con metal. Los iones metálicos se pueden introducir mediante intercambio iónico, impregnación, procedimientos en estado sólido, y otras técnicas conocidas. Los metales se pueden introducir para producir esencialmente iones metálicos atómicamente dispersados, o se pueden introducir para producir pequeños agrupamientos o nanopartículas con carácter iónico o metálico. Como alternativa, los metales se pueden precipitar simplemente sobre la superficie y en los poros del tamiz molecular. En el caso en el que se prefieran nanopartículas, puede ser útil el tratamiento consecutivo en, por ejemplo, una atmósfera reductora. En otros casos, también puede ser deseable calcinar el material tras la introducción de metales o iones metálicos.To promote specific catalytic applications, certain metals can be introduced into the new molecular sieve to obtain a molecular sieve substituted with metal, impregnated with metal or exchanged with metal. Metal ions can be introduced by ion exchange, impregnation, solid state processes, and other known techniques. The metals can be introduced to produce essentially atomically dispersed metal ions, or they can be introduced to produce small groupings or nanoparticles with ionic or metallic character. Alternatively, the metals can be simply precipitated on the surface and in the pores of the molecular sieve. In the case where nanoparticles are preferred, consecutive treatment in, for example, a reducing atmosphere may be useful. In other cases, it may also be desirable to calcine the material after the introduction of metals or metal ions.

De este modo, en otra realización, el método según la invención comprende la etapa adicional de introducir cobre y/o hierro sobre o en el producto del tamiz molecular.Thus, in another embodiment, the method according to the invention comprises the additional step of introducing copper and / or iron onto or in the product of the molecular sieve.

El tamiz molecular según la invención es particularmente útil en reacciones de conversión catalíticas heterogéneas, tal como cuando el tamiz molecular cataliza la reacción de moléculas en fase gaseosa o fase líquida. También se puede formular para otras aplicaciones no catalíticas comercialmente importantes, tal como la separación de gases. El tamiz molecular proporcionado por la invención y procedente de cualquiera de las etapas de preparación descritas anteriormente se puede conformar en una variedad de formas físicas útiles para aplicaciones específicas. Por ejemplo, el tamiz molecular se puede usar en forma de polvo, o se le puede dar la forma de peletes, extrusados o formas monolíticas moldeadas, por ejemplo como un sustrato de cuerpo totalmente corrugado que contiene el tamiz molecular.The molecular sieve according to the invention is particularly useful in heterogeneous catalytic conversion reactions, such as when the molecular sieve catalyses the reaction of molecules in gas phase or liquid phase. It can also be formulated for other commercially important non-catalytic applications, such as gas separation. The molecular sieve provided by the invention and from any of the preparation steps described above can be formed into a variety of physical forms useful for specific applications. For example, the molecular sieve may be used in the form of a powder, or it may be in the form of pellets, extruded or molded monolithic forms, for example as a fully corrugated body substrate containing the molecular sieve.

A la hora de dar forma al tamiz molecular, típicamente será útil aplicar componentes orgánicos o inorgánicos adicionales. Para aplicaciones catalíticas, es particularmente útil aplicar una combinación con alúmina, sílice, titania, ceria, circonia, diversas estructuras de espinela, u otros óxidos o combinaciones de las mismas. También se puede formular con otros compuestos activos tales como metales activos u otros tamices moleculares, etc.When shaping the molecular sieve, it will typically be useful to apply additional organic or inorganic components. For catalytic applications, it is particularly useful to apply a combination with alumina, silica, titania, ceria, zirconia, various spinel structures, or other oxides or combinations thereof. It can also be formulated with other active compounds such as active metals or other molecular sieves, etc.