EP4265790A1 - Armored steel having high hardness and excellent low-temperature impact toughness and manufacturing method therefor - Google Patents

Armored steel having high hardness and excellent low-temperature impact toughness and manufacturing method therefor Download PDFInfo

- Publication number

- EP4265790A1 EP4265790A1 EP21906845.9A EP21906845A EP4265790A1 EP 4265790 A1 EP4265790 A1 EP 4265790A1 EP 21906845 A EP21906845 A EP 21906845A EP 4265790 A1 EP4265790 A1 EP 4265790A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steel

- less

- high hardness

- armored

- excellent low

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/58—Ferrous alloys, e.g. steel alloys containing chromium with nickel with more than 1.5% by weight of manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/02—Hardening articles or materials formed by forging or rolling, with no further heating beyond that required for the formation

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/18—Hardening; Quenching with or without subsequent tempering

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/56—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering characterised by the quenching agents

- C21D1/60—Aqueous agents

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/004—Heat treatment of ferrous alloys containing Cr and Ni

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/008—Heat treatment of ferrous alloys containing Si

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0226—Hot rolling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

- C21D8/0263—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment following hot rolling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

- C21D8/0273—Final recrystallisation annealing

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/42—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for armour plate

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/46—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for sheet metals

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/001—Ferrous alloys, e.g. steel alloys containing N

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/002—Ferrous alloys, e.g. steel alloys containing In, Mg, or other elements not provided for in one single group C22C38/001 - C22C38/60

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/34—Ferrous alloys, e.g. steel alloys containing chromium with more than 1.5% by weight of silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/46—Ferrous alloys, e.g. steel alloys containing chromium with nickel with vanadium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/48—Ferrous alloys, e.g. steel alloys containing chromium with nickel with niobium or tantalum

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/50—Ferrous alloys, e.g. steel alloys containing chromium with nickel with titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/54—Ferrous alloys, e.g. steel alloys containing chromium with nickel with boron

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/001—Austenite

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/008—Martensite

Definitions

- the present disclosure relates to a material appropriate for armored vehicles, explosion-proof structures, and the like, and more particularly to armored steel having excellent low-temperature impact toughness and having high hardness, and a manufacturing method therefor.

- Armored steel is a material of which a surface is made very hard for its main function of blocking bullets, and is used where protection is required, such as for an exterior of armored vehicles used on the battlefield. Since bulletproof performance is directly related to human life, research to improve the performance of bulletproof materials has been actively conducted in the past, and recently, a non-ferrous material such as titanium and aluminum has been developed.

- the non-ferrous material has an advantage of weight reduction compared to a steel material, but is relatively expensive and has poor workability. As compared to the non-ferrous material, since the steel material is relatively inexpensive and may change physical properties such as harness relatively easily, the steel material is widely used as a material for self-propelled artillery, wheeled armored vehicles, and the like.

- Hardness is one of the most important physical properties for securing the performance of armored steel, but simple high hardness does not guarantee bulletproof performance.

- a high hardness characteristic is a factor that increases resistance to bullets penetrating through a material, but the material having high hardness may be relatively easily broken, so the high hardness characteristic cannot necessarily guarantee excellent bulletproof performance. Therefore, there is a need to develop a material that can simultaneously secure brittle fracture resistance to external impact as well as high hardness characteristics rather than simply promoting high hardness of the material.

- Patent Document Korean Patent Publication No. 10-2018-0043788 (published on April 30, 2018 )

- An aspect of the present disclosure is to provide armored steel having high hardness characteristics and excellent low-temperature impact toughness and a manufacturing method therefor.

- An object of the present disclosure is not limited to the above description.

- the object of the present disclosure will be understood from the entire content of the present specification, and a person skilled in the art to which the present disclosure pertains will understand an additional object of the present disclosure without difficulty.

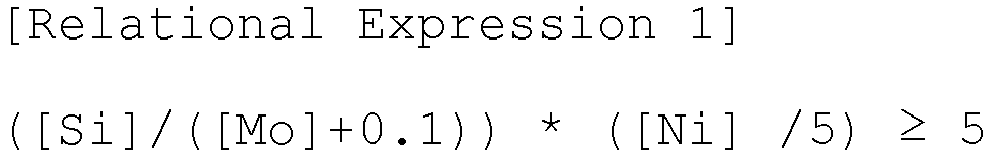

- a high- hardness armored steel having excellent low-temperature impact toughness includes, by weight: 0.31 to 0.40% of carbon (C), 1.0 to 2.0% of silicon (Si), 0.5 to 1.6% of manganese (Mn), 1.3 to 3.0% of nickel (Ni), 0.4 to 1.5% of chromium (Cr), 0.05% or less of phosphorus (P), 0.02% or less of sulfur (S), 0.006% or less of nitrogen (N), 0.07% or less of aluminum (Al) (excluding 0%), 0.03% or less of molybdenum (Mo) (including 0%), 0.01 to 0.05% of niobium (Nb), 0.0002 to 0.005% of boron (B), 0.0005 to 0.004% of calcium (Ca), with a balance of iron (Fe) and inevitable impurities, satisfying the following [Relational Expression 1], wherein a tempered martensite base structure including retained austenite is included as a microstructure.

- Si carbon

- Si silicon

- [Si], [Mo], and [Ni] refer to contents (weight %) of silicon (Si), molybdenum (Mo), and nickel (Ni) included in the steel, and 0 is substituted when the corresponding element is not intentionally added.

- the armored steel may further include, by weight: at least one of 0.005 to 0.025% of titanium (Ti) and 0.2% or less of vanadium (V).

- a fraction of the martensite may be 95% or more by area, and a fraction of the retained austenite may be 0.5% by area to 5% by area.

- the armored steel may have a surface hardness of 560 to 630 HB, and an impact absorption energy of 12 J or more at -40°C.

- the armored steel may have a thickness of 5 to 20 mm.

- a manufacturing method for armored steel having high hardness and excellent low-temperature impact toughness includes operations of: preparing a steel slab including, by weight: 0.31 to 0.40% of carbon (C), 1.0 to 2.0% of silicon (Si), 0.5 to 1.6% of manganese (Mn), 1.3 to 3.0% of nickel (Ni), 0.4 to 1.5% of chromium (Cr), 0.05% or less of phosphorus (P), 0.02% or less of sulfur (S), 0.006% or less of nitrogen (N), 0.07% or less of aluminum (Al) (excluding 0%), 0.03% or less of molybdenum (Mo) (including 0%), 0.01 to 0.05% of niobium (Nb), 0.0002 to 0.005% of boron (B), 0.0005 to 0.004% of calcium (Ca), with a balance of iron (Fe) and inevitable impurities, satisfying the following [Relational Expression 1]; heating the steel slab in a temperature range of 10

- [Si], [Mo], and [Ni] refer to contents (weight %) of silicon (Si), molybdenum (Mo), and nickel (Ni) included in the steel slab, and 0 is substituted when the corresponding element is not intentionally added.

- the steel slab may further include, by weight: at least one of 0.005 to 0.025% of titanium (Ti) and 0.2% or less of vanadium (V).

- a residence time during the reheating may be 1.3t * 10 minutes (t: plate thickness (mm)) or more.

- armored steel having excellent low-temperature toughness while having ultra-high hardness may be provided.

- the present disclosure may provide armored steel having a target level of physical properties without performing a further heat treatment from optimization of alloy compositions and manufacturing conditions, and thus, is economically favorable.

- FIG. 1 is a microstructure observation photograph of specimen No. 11.

- the present disclosure relates to armored steel having high hardness and excellent low-impact impact toughness and a manufacturing method therefor.

- preferred embodiments of the present disclosure will be described.

- Embodiments of the present disclosure may be modified in various forms, and the scope of the present disclosure should not be construed as being limited to the embodiments described below.

- the present embodiments are provided to those skilled in the art to further elaborate the present disclosure.

- the present inventors have studied in depth, in order to provide a steel material having excellent physical properties such as high hardness characteristics, low-temperature impact toughness, and the like, which are essentially required physical properties, as a material which may be appropriately applied to wheeled armored vehicles, explosion-proof structures, and the like.

- the bulletproof performance of the steel material was intended to be improved by an economically favorable method, and thus, the present disclosure was provided.

- % represents a content of each element based on weight, unless otherwise particularly specified.

- Carbon (C) is an element which is effective for improving strength and hardness in steel having a low-temperature transformation phase such as a martensite or bainite phase, and is effective for improving hardenability. In order to sufficiently obtain the effect described above, 0.31% or more of carbon (C) may be included. Preferably, a lower limit of a content of carbon (C) may be 0.32%. However, when carbon (C) is excessively added, there may be a concern that weldability and toughness of steel are deteriorated, so in the present disclosure, an upper limit of the content of carbon (C) may be limited to 0.40%. Preferably, the upper limit of the content of carbon (C) may be 0.39%, and more preferably, the upper limit of the content of carbon (C) may be 0.37%.

- Silicon (Si) is an element which is effective for improving strength due to solid solution strengthening together with a deoxidation effect, and is also an element suppressing formation of carbides such as cementite in a steel material containing a certain amount or more of C to promote production of residual austenite.

- carbides such as cementite

- a steel material containing a certain amount or more of C may be included.

- silicon (Si) may be included.

- a lower limit of a content of silicon (Si) may be 1.1%, and more preferably, the lower limit of the content of silicon (Si) may be 1.2%.

- an upper limit of the content of silicon (Si) may be limited to 2.0%.

- the upper limit of the content of silicon (Si) may be 1.9%, and more preferably, the upper limit of the content of silicon (Si) may be 1.8%.

- Manganese (Mn) is an element favorable to suppress production of ferrite and lower an Ar3 temperature, thereby improving quenching properties of steel to increase strength and toughness.

- 0.5% or more of manganese (Mn) may be included.

- a lower limit of a content of manganese (Mn) may be 0.6%, and more preferably, the lower limit of the content of manganese (Mn) may be 0.7%.

- an upper limit of the content of manganese (Mn) may be limited to 1.6%.

- the upper limit of the content of manganese (Mn) may be 1.5%, and more preferably, the upper limit of the content of manganese (Mn) may be 1.45%.

- Nickel (Ni) is an element favorable to improve both strength and toughness of steel. In order to obtain the effect described above, in the present disclosure, 1.3% or more of nickel (Ni) may be included. Preferably, a lower limit of a content of nickel (Ni) may be 1.4%, and more preferably, the lower limit of the content of nickel (Ni) may be 1.5%. However, nickel (Ni) is an expensive element, when nickel (Ni) is excessively added, manufacturing costs may be greatly increased, so in the present disclosure, an upper limit of the content of nickel (Ni) may be limited to 3.0%. Preferably, the upper limit of the content of nickel (Ni) may be 2.9%.

- Chromium (Cr) is an element of increasing quenching properties of steel to improve strength, and effectively contributing to securing hardness in a surface part and a center part of steel.

- Cr chromium

- Cr is also an element for economically securing hardness and toughness.

- 0.4% or more of chromium (Cr) may be included.

- a lower limit of a content of chromium (Cr) may be 0.41%.

- an upper limit of the content of chromium (Cr) may be limited to 1.5%.

- the upper limit of the content of chromium (Cr) may be 1.3%, and more preferably, the upper limit of the content of chromium (Cr) may be 1.1%.

- Phosphorous (P) 0.05% or less

- Phosphorus (P) is an element which is inevitably contained in steel, and is also an element which deteriorates toughness of the steel. Thus, it is preferred to lower a content of P as much as possible.

- an upper limit of the content of phosphorus (P) may be limited to 0.05%. More favorably, the content thereof may be limited to 0.03% or less. However, 0% may be excluded considering an inevitably contained level.

- Sulfur (S) is an element which is inevitably contained in steel, and is also an element forming MnS inclusions to deteriorate toughness of steel. Thus, it is preferred to lower a content of S as much as possible.

- an upper limit of the content of sulfur (S) may be limited to 0.02%. More favorably, the content thereof may be limited to 0.01% or less. However, 0% may be excluded considering an inevitably contained level.

- Nitrogen (N) is an element which is favorable to improve strength of steel by forming precipitates in steel, but when a content of nitrogen (N) is more than a certain level, which may rather cause deterioration in toughness of steel.

- an upper limit of a content of nitrogen (N) may be limited to 0.006%. However, 0% may be excluded considering an inevitably contained level.

- Aluminum (Al) is an element effective for lowering an oxygen content in molten steel as a deoxidizing agent of steel. However, when aluminum (Al) is excessively added, cleanliness of steel may be impaired, so in the present disclosure, an upper limit of a content of aluminum (Al) may be limited to 0.07%.

- Molybdenum (Mo) is an element favorable to increase quenching properties of steel, and in particular, to improve hardness of a thick material having a certain thickness or more.

- Molybdenum (Mo) is excessively added, not only manufacturing costs may be increased, but also weldability may be deteriorated, so the present disclosure is intended to actively suppress the addition of molybdenum (Mo).

- An upper limit of the content of molybdenum (Mo) may be 0.03%, and more particularly, the upper limit of the content of molybdenum (Mo) may be 0.02%.

- Niobium (Nb) is an element which is effective for increasing hardenability of austenite by being dissolved in austenite, and increasing strength of steel and suppressing growth of austenite crystal grains by forming carbonitrides such as Nb(C,N).

- 0.01% or more of niobium (Ni) may be included.

- an upper limit of a content of niobium (Nb) may be limited to 0.05%.

- the upper limit of the content of niobium (Nb) may be 0.04%, and more preferably, the upper limit of the content of niobium (Nb) may be 0.03%.

- Boron (B) is an element effectively contributing to strength improvement by increasing quenching properties of steel even with a small addition amount thereof.

- 0.0002% or more of boron (B) may be contained.

- a lower limit of a content of boron (B) may be 0.0005%, and more preferably, the lower limit of the content of boron (B) may be 0.001%.

- an upper limit of the content of boron (B) may be limited to 0.005%.

- the upper limit of the content of boron (B) may be 0.004%, and more preferably, the upper limit of the content of boron (B) may be 0.003%.

- Ca an element having a good binding force with sulfur (S) and producing CaS on the periphery (around) MnS, thereby suppressing elongation of MnS to improve toughness in a direction perpendicular to a rolling direction.

- CaS produced by adding Ca has an effect of increasing corrosion resistance under a humid external environment.

- 0.0005% or more of Ca may be included.

- a lower limit of a content of calcium (Ca) may be 0.001%.

- an upper limit of the content of calcium (Ca) may be limited to 0.004%.

- armored steel of the present disclosure may further include the following elements for the purpose of favorably securing target physical properties.

- the armored steel of the present disclosure may further include at least one of titanium (Ti) and vanadium (V).

- Titanium (Ti) is an element which maximizes the effect of boron (B), which is an element favorable to improve quenching properties of steel. That is, titanium (Ti) is bonded to nitrogen (N) in steel to be precipitated into TiN to reduce the content of solid-solubilized N, while suppressing formation of BN of B therefrom to increase solid-solubilized B, thereby maximizing improvement of quenching properties. In order to sufficiently obtain the effect described above, 0.005% or more of titanium (Ti) may be contained. However, when titanium (Ti) is excessively added, coarse TiN precipitates may be formed and toughness of steel may be deteriorated, so in the present disclosure, an upper limit of the content of titanium (Ti) may be limited to 0.025%.

- V Vanadium (V): 0.2% or less (including 0%)

- Vanadium (V) is an element favorable to form a VC carbide when reheating after hot rolling, thereby suppressing growth of austenite crystal grains and improving quenching properties of steel to secure strength and toughness.

- vanadium (V) is a relatively expensive element, an upper limit of a content of vanadium (V) may be limited to 0.2% in consideration of manufacturing costs.

- the armored steel according to an aspect of the present disclosure may include a remainder of Fe and other inevitable impurities in addition to the components described above.

- the component since in the common manufacturing process, unintended impurities may be inevitably incorporated from raw materials or the surrounding environment, the component may not be excluded. Since these impurities are known to any person skilled in the common manufacturing process, the entire contents thereof are not particularly mentioned in the present specification. In addition, further addition of effective ingredients other than the above-mentioned ingredients is not entirely excluded.

- the armored steel according to an aspect of the present disclosure may satisfy the following [Relational Expression 1]. Si / Mo + 0.1 * Ni / 5 ⁇ 5

- the inventors of the present disclosure have conducted in-depth research on a method capable of securing high-hardness characteristics and excellent low-temperature impact toughness of a steel sheet at the same time, and have derived that it is effective to control not only a content range of each respective alloy composition, but also a relative content range of the specific alloy composition included in the steel sheet.

- not only the content range of each respective alloy composition included in the steel sheet is controlled to be within a certain range, but also the relative content range of silicon (Si), molybdenum (Mo), and nickel (Ni) is controlled to be within a certain range, as illustrated in [Relational Expression 1], so that high hard characteristics and excellent low-temperature impact toughness may be effectively compatible.

- the armored steel of the present disclosure having the alloy composition described above may have a tempered martensite base structure including retained austenite as a microstructure, and may further include other inevitable structures.

- a fraction of retained austenite may be 0.5% by area to 5% by area, and a fraction of martensite may be 95% or more by area.

- Retained austenite is a structure remaining without being completely phase transformed into martensite during a rapid cooling heat treatment, and has relatively low hardness but excellent toughness as compared to martensite.

- the armored steel of the present disclosure may include 0.5% or more by area of retained austenite, more preferably 1% or more by area of retained austenite.

- an upper limit of the fraction of the retained austenite may be set to be 5% by area.

- the upper limit of the fraction of the retained austenite may be 4% by area, and a lower limit of the fraction of the martensite may be 96% by area.

- the armored steel of the present disclosure may have the above-described microstructural configuration over the entire thickness.

- the armored steel of the present disclosure having the above-described alloy composition and the proposed microstructure may have a thickness of 5 to 20 mm and have a surface hardness of 560 to 630 HB, exhibiting ultra-high hardness and an impact absorption energy of 12 J or more at -40°C, exhibiting excellent low-temperature toughness.

- the surface hardness refers to an average value of three measurements after milling a surface of the armored steel at 2 mm in a thickness direction using a Brinell hardness tester (load: 3000 kgf, 10 mm tungsten injection port).

- a steel slab having a predetermined component is prepared. Since the steel slab of the present disclosure has an alloy composition corresponding to the alloy composition of the hot-rolled steel sheet described above (including [Relational Expression 1]), a description of the alloy composition of the steel slab is substituted for the description of the alloy composition of the above-described hot-rolled steel sheet.

- the armored steel may be manufactured by preparing a steel slab satisfying the alloy composition described above, and then subjecting the steel slab to the processes of [heating - rolling - heat treatment (quenching)].

- the processes of [heating - rolling - heat treatment (quenching)] will be described in detail.

- a steel slab having the alloy composition proposed in the present disclosure is prepared, which may be then heated in a temperature range of 1050 to 1250°C.

- the steel slab may be heated in a temperature range of 1050 to 1250°C.

- the steel slab heated as described above may be rolled, and then may be subjected to rough rolling and finish hot rolling to manufacture a hot-rolled steel sheet.

- the heated steel slab is roughly rolled in a temperature range of 950 to 1150°C to be manufactured into a bar, which may be then subjected to finish hot rolling in a temperature range of 850 to 950°C.

- the hot-rolled steel sheet manufactured through the rolling process described above is air cooled to room temperature, and then reheated to a residence time of 1.3t + 10 minutes (t: plate thickness (mm)) or more in a temperature range of 880 to 930°C.

- the reheating is performed for reverse transformation of a hot-rolled steel sheet composed of ferrite and pearlite into an austenite single phase.

- a reheating temperature is lower than 880°C, austenitization is not sufficiently achieved, and coarse soft ferrite is mixed, and thus hardness of a final product may be deteriorated.

- the temperature thereof is higher than 930°C, there is an effect of increasing quenching properties due to coarse austenite crystal grains, but there is a disadvantage in terms of thermal efficiency during mass production. Therefore, reheating during a quenching heat treatment is preferably performed in a range of 880 to 930°C.

- a lower limit of the reheating temperature is more preferably 885°C, even more preferably 890°C, and most preferably 895°C.

- an upper limit of the heating temperature is more preferably 925°C, even more preferably 920°C, and most preferably 915°C.

- the residence time during the reheating is preferably 1.3 t + 10 minutes (t: plate thickness (mm)) or more.

- the residence time during the reheating is more preferably 1.3 t + 12 minutes (t: plate thickness (mm)) or more, even more preferably 1.3t + 13 minutes (t: plate thickness (mm)) or more, and most preferably 1.5t + 15 minutes (t: plate thickness (mm)) or more.

- an upper limit of the residence time during the reheating is not particularly limited.

- the residence time during the reheating exceeds 1.3 t + 60 minutes (t: plate thickness (mm))

- austenite crystal grains become coarse, so that quenching properties may increase, but there may be a disadvantage in that productivity is relatively lowered. Therefore, the residence time during the reheating is preferably 1.3t + 60 minutes (t: plate thickness (mm)) or less.

- the residence time during the reheating is more preferably 1.3 t + 50 minutes (t: plate thickness (mm)) or less, even more preferably 1.3 t + 40 minutes (t: plate thickness (mm)) or less, and most preferably 1.3 t + 30 minutes (t: plate thickness (mm)) or less.

- the reheated hot-rolled steel sheet may be cooled to 120°C or lower at a cooling rate of 10°C/s or more with respect to a plate thickness center portion(e.g., 1/2t point, t: plate thickness (mm)).

- the cooling is preferably rapid cooling through water cooling.

- the cooling rate is less than 10°C/s or the cooling end temperature is higher than 120°C, there is a concern that a ferrite phase may be formed or a bainite phase may be excessively formed during cooling. Therefore, the cooling is preferably performed to 120°C or lower at a cooling rate of 10°C/s or more. The faster the cooling rate, the more favorable it is to form the microstructure to be obtained in the present disclosure.

- an upper limit of the cooling rate is not particularly limited, and it may be appropriately set in consideration of facility limitations by any person skilled in the art.

- the cooling end temperature is more preferably 100°C or lower, even more preferably 80°C or lower, and most preferably 50°C or lower.

- the hot-rolled steel sheet obtained through the above-described series of manufacturing processes is a steel material having a thickness of 5 to 20 mm, and can provide excellent bullet-proof resistance by securing high hardness and high toughness.

- microstructure of each hot-rolled steel sheet was cut into an arbitrary size as a specimen to manufacture a mirror surface, a Nital etching solution was used to corrode the specimen, and then an optical microscope and a scanning electron microscope (SEM) were used to observe a 1/2t point which was a thickness center portion. In this case, a fraction of the microstructure was measured by electron back-scattered diffraction (EBSD) analysis.

- EBSD electron back-scattered diffraction

- specimens satisfying the alloy composition and process conditions of the present disclosure have a surface harness of 560 to 630 HB and an impact absorption energy of 12 J or more at -40°C, but specimens not satisfying at least one of the alloy compositions or process conditions of the present disclosure do not have a surface hardness of 560 to 630 HB or an impact absorption energy of 12 J or more at -40°C at the same time.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Heat Treatment Of Steel (AREA)

- Rod-Shaped Construction Members (AREA)

Abstract

Description

- The present disclosure relates to a material appropriate for armored vehicles, explosion-proof structures, and the like, and more particularly to armored steel having excellent low-temperature impact toughness and having high hardness, and a manufacturing method therefor.

- Armored steel is a material of which a surface is made very hard for its main function of blocking bullets, and is used where protection is required, such as for an exterior of armored vehicles used on the battlefield. Since bulletproof performance is directly related to human life, research to improve the performance of bulletproof materials has been actively conducted in the past, and recently, a non-ferrous material such as titanium and aluminum has been developed.

- The non-ferrous material has an advantage of weight reduction compared to a steel material, but is relatively expensive and has poor workability. As compared to the non-ferrous material, since the steel material is relatively inexpensive and may change physical properties such as harness relatively easily, the steel material is widely used as a material for self-propelled artillery, wheeled armored vehicles, and the like.

- Hardness is one of the most important physical properties for securing the performance of armored steel, but simple high hardness does not guarantee bulletproof performance. A high hardness characteristic is a factor that increases resistance to bullets penetrating through a material, but the material having high hardness may be relatively easily broken, so the high hardness characteristic cannot necessarily guarantee excellent bulletproof performance. Therefore, there is a need to develop a material that can simultaneously secure brittle fracture resistance to external impact as well as high hardness characteristics rather than simply promoting high hardness of the material.

- (Patent Document)

Korean Patent Publication No. 10-2018-0043788 (published on April 30, 2018 - An aspect of the present disclosure is to provide armored steel having high hardness characteristics and excellent low-temperature impact toughness and a manufacturing method therefor.

- An object of the present disclosure is not limited to the above description. The object of the present disclosure will be understood from the entire content of the present specification, and a person skilled in the art to which the present disclosure pertains will understand an additional object of the present disclosure without difficulty.

- According to an aspect of the present disclosure, a high- hardness armored steel having excellent low-temperature impact toughness includes, by weight: 0.31 to 0.40% of carbon (C), 1.0 to 2.0% of silicon (Si), 0.5 to 1.6% of manganese (Mn), 1.3 to 3.0% of nickel (Ni), 0.4 to 1.5% of chromium (Cr), 0.05% or less of phosphorus (P), 0.02% or less of sulfur (S), 0.006% or less of nitrogen (N), 0.07% or less of aluminum (Al) (excluding 0%), 0.03% or less of molybdenum (Mo) (including 0%), 0.01 to 0.05% of niobium (Nb), 0.0002 to 0.005% of boron (B), 0.0005 to 0.004% of calcium (Ca), with a balance of iron (Fe) and inevitable impurities, satisfying the following [Relational Expression 1], wherein a tempered martensite base structure including retained austenite is included as a microstructure.

- In Relational Expression 1, [Si], [Mo], and [Ni] refer to contents (weight %) of silicon (Si), molybdenum (Mo), and nickel (Ni) included in the steel, and 0 is substituted when the corresponding element is not intentionally added.

- The armored steel may further include, by weight: at least one of 0.005 to 0.025% of titanium (Ti) and 0.2% or less of vanadium (V).

- A fraction of the martensite may be 95% or more by area, and a fraction of the retained austenite may be 0.5% by area to 5% by area.

- The armored steel may have a surface hardness of 560 to 630 HB, and an impact absorption energy of 12 J or more at -40°C.

- The armored steel may have a thickness of 5 to 20 mm.

- According to an aspect of the present disclosure, a manufacturing method for armored steel having high hardness and excellent low-temperature impact toughness includes operations of: preparing a steel slab including, by weight: 0.31 to 0.40% of carbon (C), 1.0 to 2.0% of silicon (Si), 0.5 to 1.6% of manganese (Mn), 1.3 to 3.0% of nickel (Ni), 0.4 to 1.5% of chromium (Cr), 0.05% or less of phosphorus (P), 0.02% or less of sulfur (S), 0.006% or less of nitrogen (N), 0.07% or less of aluminum (Al) (excluding 0%), 0.03% or less of molybdenum (Mo) (including 0%), 0.01 to 0.05% of niobium (Nb), 0.0002 to 0.005% of boron (B), 0.0005 to 0.004% of calcium (Ca), with a balance of iron (Fe) and inevitable impurities, satisfying the following [Relational Expression 1]; heating the steel slab in a temperature range of 1050 to 1250°C; rough rolling the heated steel slab in a temperature range of 950 to 1150°C; subjecting the heated steel slab to finish hot rolling in a temperature range of 850 to 950°C after the rough rolling to manufacture a hot-rolled steel sheet; performing a heat treatment of reheating the hot-rolled steel sheet to a temperature range of 880 to 930°C and then cooling the same to a cooling end temperature of 150°C or lower at a cooling rate of 10°C/s or more.

- In Relational Expression 1, [Si], [Mo], and [Ni] refer to contents (weight %) of silicon (Si), molybdenum (Mo), and nickel (Ni) included in the steel slab, and 0 is substituted when the corresponding element is not intentionally added.

- The steel slab may further include, by weight: at least one of 0.005 to 0.025% of titanium (Ti) and 0.2% or less of vanadium (V).

- A residence time during the reheating may be 1.3t * 10 minutes (t: plate thickness (mm)) or more.

- The solution to the above problems does not enumerate all the features of the present disclosure, and various beneficial merits of the present disclosure are not limited to the descriptions above, and may be more easily understood in a process of describing specific exemplary embodiments in the present disclosure.

- As set forth above, according to the present disclosure, armored steel having excellent low-temperature toughness while having ultra-high hardness may be provided.

- The present disclosure may provide armored steel having a target level of physical properties without performing a further heat treatment from optimization of alloy compositions and manufacturing conditions, and thus, is economically favorable.

- The effect of the present disclosure is not limited to the above, and may be interpreted as including an effect that can be inferred from the description described below by those skilled in the art.

-

FIG. 1 is a microstructure observation photograph of specimen No. 11. - The present disclosure relates to armored steel having high hardness and excellent low-impact impact toughness and a manufacturing method therefor. Hereinafter, preferred embodiments of the present disclosure will be described. Embodiments of the present disclosure may be modified in various forms, and the scope of the present disclosure should not be construed as being limited to the embodiments described below. The present embodiments are provided to those skilled in the art to further elaborate the present disclosure.

- The present inventors have studied in depth, in order to provide a steel material having excellent physical properties such as high hardness characteristics, low-temperature impact toughness, and the like, which are essentially required physical properties, as a material which may be appropriately applied to wheeled armored vehicles, explosion-proof structures, and the like.

- In particular, the bulletproof performance of the steel material was intended to be improved by an economically favorable method, and thus, the present disclosure was provided.

- Hereinafter, armored steel according to an aspect of the present disclosure will be described in more detail.

- Hereinafter, a steel composition of the present disclosure will be described in more detail. Hereinafter, % represents a content of each element based on weight, unless otherwise particularly specified.

- Carbon (C) is an element which is effective for improving strength and hardness in steel having a low-temperature transformation phase such as a martensite or bainite phase, and is effective for improving hardenability. In order to sufficiently obtain the effect described above, 0.31% or more of carbon (C) may be included. Preferably, a lower limit of a content of carbon (C) may be 0.32%. However, when carbon (C) is excessively added, there may be a concern that weldability and toughness of steel are deteriorated, so in the present disclosure, an upper limit of the content of carbon (C) may be limited to 0.40%. Preferably, the upper limit of the content of carbon (C) may be 0.39%, and more preferably, the upper limit of the content of carbon (C) may be 0.37%.

- Silicon (Si) is an element which is effective for improving strength due to solid solution strengthening together with a deoxidation effect, and is also an element suppressing formation of carbides such as cementite in a steel material containing a certain amount or more of C to promote production of residual austenite. In particular, since residual austenite which is uniformly distributed in steel having a low-temperature transformation phase such as martensite and bainite may effectively contribute to improvement of impact toughness without strength reduction. Therefore, in order to sufficiently obtain the effect described above, in the present disclosure, 1.0% or more of silicon (Si) may be included. Preferably, a lower limit of a content of silicon (Si) may be 1.1%, and more preferably, the lower limit of the content of silicon (Si) may be 1.2%. However, when silicon (Si) is excessively added, weldability may be rapidly deteriorated, so in the present disclosure, an upper limit of the content of silicon (Si) may be limited to 2.0%. Preferably, the upper limit of the content of silicon (Si) may be 1.9%, and more preferably, the upper limit of the content of silicon (Si) may be 1.8%.

- Manganese (Mn) is an element favorable to suppress production of ferrite and lower an Ar3 temperature, thereby improving quenching properties of steel to increase strength and toughness. In order to obtain a target level of hardness in the present disclosure, 0.5% or more of manganese (Mn) may be included. Preferably, a lower limit of a content of manganese (Mn) may be 0.6%, and more preferably, the lower limit of the content of manganese (Mn) may be 0.7%. However, when manganese (Mn) is excessively added, there may be a concern that weldability is deteriorated and center segregation is encouraged to deteriorate the physical properties in the center part of steel, so in the present disclosure, an upper limit of the content of manganese (Mn) may be limited to 1.6%. Preferably, the upper limit of the content of manganese (Mn) may be 1.5%, and more preferably, the upper limit of the content of manganese (Mn) may be 1.45%.

- Nickel (Ni) is an element favorable to improve both strength and toughness of steel. In order to obtain the effect described above, in the present disclosure, 1.3% or more of nickel (Ni) may be included. Preferably, a lower limit of a content of nickel (Ni) may be 1.4%, and more preferably, the lower limit of the content of nickel (Ni) may be 1.5%. However, nickel (Ni) is an expensive element, when nickel (Ni) is excessively added, manufacturing costs may be greatly increased, so in the present disclosure, an upper limit of the content of nickel (Ni) may be limited to 3.0%. Preferably, the upper limit of the content of nickel (Ni) may be 2.9%.

- Chromium (Cr) is an element of increasing quenching properties of steel to improve strength, and effectively contributing to securing hardness in a surface part and a center part of steel. In addition, since chromium (Cr) is a relatively inexpensive element, chromium (Cr) is also an element for economically securing hardness and toughness. In order to obtain the effect described above, in the present disclosure, 0.4% or more of chromium (Cr) may be included. Preferably, a lower limit of a content of chromium (Cr) may be 0.41%. However, when chromium (Cr) is excessively added, weldability may be deteriorated, so in the present disclosure, an upper limit of the content of chromium (Cr) may be limited to 1.5%. Preferably, the upper limit of the content of chromium (Cr) may be 1.3%, and more preferably, the upper limit of the content of chromium (Cr) may be 1.1%.

- Phosphorus (P) is an element which is inevitably contained in steel, and is also an element which deteriorates toughness of the steel. Thus, it is preferred to lower a content of P as much as possible. In the present disclosure, even in the case of including phosphorus (P) up to 0.05%, the physical properties of the steel are not significantly influenced, and thus, an upper limit of the content of phosphorus (P) may be limited to 0.05%. More favorably, the content thereof may be limited to 0.03% or less. However, 0% may be excluded considering an inevitably contained level.

- Sulfur (S) is an element which is inevitably contained in steel, and is also an element forming MnS inclusions to deteriorate toughness of steel. Thus, it is preferred to lower a content of S as much as possible. In the present disclosure, even in the case of including sulfur (S) up to 0.02%, the physical properties of the steel are not significantly influenced, and thus, an upper limit of the content of sulfur (S) may be limited to 0.02%. More favorably, the content thereof may be limited to 0.01% or less. However, 0% may be excluded considering an inevitably contained level.

- Nitrogen (N) is an element which is favorable to improve strength of steel by forming precipitates in steel, but when a content of nitrogen (N) is more than a certain level, which may rather cause deterioration in toughness of steel. In the present disclosure, there is no difficulty in securing strength even when N is not contained, so in the present disclosure, an upper limit of a content of nitrogen (N) may be limited to 0.006%. However, 0% may be excluded considering an inevitably contained level.

- Aluminum (Al) is an element effective for lowering an oxygen content in molten steel as a deoxidizing agent of steel. However, when aluminum (Al) is excessively added, cleanliness of steel may be impaired, so in the present disclosure, an upper limit of a content of aluminum (Al) may be limited to 0.07%.

- On the other hand, when the content of aluminum (Al) is excessively lowered, a load may occur in a steelmaking process and manufacturing costs may be increased, and thus, in the present disclosure, 0% may be excluded from a lower limit of the content of aluminum (Al), and the lower limit thereof may be 0.01%.

- Molybdenum (Mo) is an element favorable to increase quenching properties of steel, and in particular, to improve hardness of a thick material having a certain thickness or more. However, when molybdenum (Mo) is excessively added, not only manufacturing costs may be increased, but also weldability may be deteriorated, so the present disclosure is intended to actively suppress the addition of molybdenum (Mo). An upper limit of the content of molybdenum (Mo) may be 0.03%, and more particularly, the upper limit of the content of molybdenum (Mo) may be 0.02%.

- Niobium (Nb) is an element which is effective for increasing hardenability of austenite by being dissolved in austenite, and increasing strength of steel and suppressing growth of austenite crystal grains by forming carbonitrides such as Nb(C,N). In order to sufficiently obtain the effect described above, in the present disclosure, 0.01% or more of niobium (Ni) may be included. However, when niobium (Ni) is excessively added, coarse precipitates may be formed to become a starting point of brittle fracture, so in the present disclosure, an upper limit of a content of niobium (Nb) may be limited to 0.05%. Preferably, the upper limit of the content of niobium (Nb) may be 0.04%, and more preferably, the upper limit of the content of niobium (Nb) may be 0.03%.

- Boron (B) is an element effectively contributing to strength improvement by increasing quenching properties of steel even with a small addition amount thereof. In order to sufficiently obtain the effect, in the present disclosure, 0.0002% or more of boron (B) may be contained. Preferably, a lower limit of a content of boron (B) may be 0.0005%, and more preferably, the lower limit of the content of boron (B) may be 0.001%. However, when boron (B) is excessively added, toughness and weldability of steel may be rather deteriorated, so in the present disclosure, an upper limit of the content of boron (B) may be limited to 0.005%. Preferably, the upper limit of the content of boron (B) may be 0.004%, and more preferably, the upper limit of the content of boron (B) may be 0.003%.

- Calcium (Ca) an element having a good binding force with sulfur (S) and producing CaS on the periphery (around) MnS, thereby suppressing elongation of MnS to improve toughness in a direction perpendicular to a rolling direction. In addition, CaS produced by adding Ca has an effect of increasing corrosion resistance under a humid external environment. In order to sufficiently obtain the effect described above, 0.0005% or more of Ca may be included. Preferably, a lower limit of a content of calcium (Ca) may be 0.001%. However, when calcium (Ca) is excessively added, defects such as nozzle clogging, or the like, may be caused in a steelmaking operation, so in the present disclosure, an upper limit of the content of calcium (Ca) may be limited to 0.004%.

- In addition to the above-described alloy composition, armored steel of the present disclosure may further include the following elements for the purpose of favorably securing target physical properties.

- Specifically, the armored steel of the present disclosure may further include at least one of titanium (Ti) and vanadium (V).

- Titanium (Ti) is an element which maximizes the effect of boron (B), which is an element favorable to improve quenching properties of steel. That is, titanium (Ti) is bonded to nitrogen (N) in steel to be precipitated into TiN to reduce the content of solid-solubilized N, while suppressing formation of BN of B therefrom to increase solid-solubilized B, thereby maximizing improvement of quenching properties. In order to sufficiently obtain the effect described above, 0.005% or more of titanium (Ti) may be contained. However, when titanium (Ti) is excessively added, coarse TiN precipitates may be formed and toughness of steel may be deteriorated, so in the present disclosure, an upper limit of the content of titanium (Ti) may be limited to 0.025%.

- Vanadium (V) is an element favorable to form a VC carbide when reheating after hot rolling, thereby suppressing growth of austenite crystal grains and improving quenching properties of steel to secure strength and toughness. However, since vanadium (V) is a relatively expensive element, an upper limit of a content of vanadium (V) may be limited to 0.2% in consideration of manufacturing costs.

- The armored steel according to an aspect of the present disclosure may include a remainder of Fe and other inevitable impurities in addition to the components described above. However, since in the common manufacturing process, unintended impurities may be inevitably incorporated from raw materials or the surrounding environment, the component may not be excluded. Since these impurities are known to any person skilled in the common manufacturing process, the entire contents thereof are not particularly mentioned in the present specification. In addition, further addition of effective ingredients other than the above-mentioned ingredients is not entirely excluded.

-

- In Relational Expression 1, [Si], [Mo], and [Ni]refer to contents (weight %) of silicon (Si), molybdenum (Mo), and nickel (Ni) included in the steel, and 0 is substituted if the corresponding element is not intentionally added.

- The inventors of the present disclosure have conducted in-depth research on a method capable of securing high-hardness characteristics and excellent low-temperature impact toughness of a steel sheet at the same time, and have derived that it is effective to control not only a content range of each respective alloy composition, but also a relative content range of the specific alloy composition included in the steel sheet. In the present disclosure, not only the content range of each respective alloy composition included in the steel sheet is controlled to be within a certain range, but also the relative content range of silicon (Si), molybdenum (Mo), and nickel (Ni) is controlled to be within a certain range, as illustrated in [Relational Expression 1], so that high hard characteristics and excellent low-temperature impact toughness may be effectively compatible.

- The armored steel of the present disclosure having the alloy composition described above may have a tempered martensite base structure including retained austenite as a microstructure, and may further include other inevitable structures. In this case, preferably, a fraction of retained austenite may be 0.5% by area to 5% by area, and a fraction of martensite may be 95% or more by area.

- Retained austenite is a structure remaining without being completely phase transformed into martensite during a rapid cooling heat treatment, and has relatively low hardness but excellent toughness as compared to martensite. For this effect, the armored steel of the present disclosure may include 0.5% or more by area of retained austenite, more preferably 1% or more by area of retained austenite. On the other hand, when the retained austenite is excessively formed, the low-temperature impact toughness greatly increases, but it is difficult to secure target hardness characteristics. Therefore, in the present disclosure, an upper limit of the fraction of the retained austenite may be set to be 5% by area. The upper limit of the fraction of the retained austenite may be 4% by area, and a lower limit of the fraction of the martensite may be 96% by area.

- Meanwhile, the armored steel of the present disclosure may have the above-described microstructural configuration over the entire thickness.

- The armored steel of the present disclosure having the above-described alloy composition and the proposed microstructure may have a thickness of 5 to 20 mm and have a surface hardness of 560 to 630 HB, exhibiting ultra-high hardness and an impact absorption energy of 12 J or more at -40°C, exhibiting excellent low-temperature toughness.

- Here, the surface hardness refers to an average value of three measurements after milling a surface of the armored steel at 2 mm in a thickness direction using a Brinell hardness tester (load: 3000 kgf, 10 mm tungsten injection port).

- Hereinafter, a manufacturing method for armored steel according to an aspect of the present disclosure will be described in more detail.

- A steel slab having a predetermined component is prepared. Since the steel slab of the present disclosure has an alloy composition corresponding to the alloy composition of the hot-rolled steel sheet described above (including [Relational Expression 1]), a description of the alloy composition of the steel slab is substituted for the description of the alloy composition of the above-described hot-rolled steel sheet.

- In brief, the armored steel may be manufactured by preparing a steel slab satisfying the alloy composition described above, and then subjecting the steel slab to the processes of [heating - rolling - heat treatment (quenching)]. Hereinafter, each process condition will be described in detail.

- First, a steel slab having the alloy composition proposed in the present disclosure is prepared, which may be then heated in a temperature range of 1050 to 1250°C.

- When the temperature is lower than 1050°C during the heating, deformation resistance of steel is increased, so that a subsequent rolling process may not be effectively performed. On the other hand, when the temperature is higher than 1250°C, austenite crystal grains are coarsened, so that non-uniform structure may be formed.

- Therefore, the steel slab may be heated in a temperature range of 1050 to 1250°C.

- The steel slab heated as described above may be rolled, and then may be subjected to rough rolling and finish hot rolling to manufacture a hot-rolled steel sheet.

- First, the heated steel slab is roughly rolled in a temperature range of 950 to 1150°C to be manufactured into a bar, which may be then subjected to finish hot rolling in a temperature range of 850 to 950°C.

- When the temperature is lower than 950°C during the rough rolling, a rolling load is increased to reduce the steel slab relatively weakly, and thus, deformation is not sufficiently transferred to a center of the slab in the thickness direction, and as a result, defects such as voids may not be removed. On the other hand, when the temperature thereof is higher than 1150°C, recrystallization granularity is coarsened, which may be harmful to toughness.

- When the temperature is lower than 850°C during the finish hot rolling, two-phase region rolling is performed, so that there is a concern that ferrite may be produced in the microstructure. On the other hand, when the temperature thereof is higher than 950°C, the granularity of the final structure is coarsened to deteriorate low-temperature toughness.

- The hot-rolled steel sheet manufactured through the rolling process described above is air cooled to room temperature, and then reheated to a residence time of 1.3t + 10 minutes (t: plate thickness (mm)) or more in a temperature range of 880 to 930°C.

- The reheating is performed for reverse transformation of a hot-rolled steel sheet composed of ferrite and pearlite into an austenite single phase. When a reheating temperature is lower than 880°C, austenitization is not sufficiently achieved, and coarse soft ferrite is mixed, and thus hardness of a final product may be deteriorated. On the other hand, when the temperature thereof is higher than 930°C, there is an effect of increasing quenching properties due to coarse austenite crystal grains, but there is a disadvantage in terms of thermal efficiency during mass production. Therefore, reheating during a quenching heat treatment is preferably performed in a range of 880 to 930°C. A lower limit of the reheating temperature is more preferably 885°C, even more preferably 890°C, and most preferably 895°C. In addition, an upper limit of the heating temperature is more preferably 925°C, even more preferably 920°C, and most preferably 915°C.

- Meanwhile, when a residence time during the reheating is less than 1.3 t+10 minutes (t: plate thickness (mm)), austenitization does not sufficiently occur, so that phase transformation by subsequent rapid cooling, that is, a martensitic structure cannot be sufficiently obtained. Therefore, the residence time during the reheating is preferably 1.3 t + 10 minutes (t: plate thickness (mm)) or more. The residence time during the reheating is more preferably 1.3 t + 12 minutes (t: plate thickness (mm)) or more, even more preferably 1.3t + 13 minutes (t: plate thickness (mm)) or more, and most preferably 1.5t + 15 minutes (t: plate thickness (mm)) or more.

- In the present disclosure, an upper limit of the residence time during the reheating is not particularly limited. However, when the residence time during the reheating exceeds 1.3 t + 60 minutes (t: plate thickness (mm)), austenite crystal grains become coarse, so that quenching properties may increase, but there may be a disadvantage in that productivity is relatively lowered. Therefore, the residence time during the reheating is preferably 1.3t + 60 minutes (t: plate thickness (mm)) or less. The residence time during the reheating is more preferably 1.3 t + 50 minutes (t: plate thickness (mm)) or less, even more preferably 1.3 t + 40 minutes (t: plate thickness (mm)) or less, and most preferably 1.3 t + 30 minutes (t: plate thickness (mm)) or less.

- Thereafter, the reheated hot-rolled steel sheet may be cooled to 120°C or lower at a cooling rate of 10°C/s or more with respect to a plate thickness center portion(e.g., 1/2t point, t: plate thickness (mm)). In this case, the cooling is preferably rapid cooling through water cooling. When the cooling rate is less than 10°C/s or the cooling end temperature is higher than 120°C, there is a concern that a ferrite phase may be formed or a bainite phase may be excessively formed during cooling. Therefore, the cooling is preferably performed to 120°C or lower at a cooling rate of 10°C/s or more. The faster the cooling rate, the more favorable it is to form the microstructure to be obtained in the present disclosure. Meanwhile, in the present disclosure, an upper limit of the cooling rate is not particularly limited, and it may be appropriately set in consideration of facility limitations by any person skilled in the art. The cooling end temperature is more preferably 100°C or lower, even more preferably 80°C or lower, and most preferably 50°C or lower.

- The hot-rolled steel sheet obtained through the above-described series of manufacturing processes is a steel material having a thickness of 5 to 20 mm, and can provide excellent bullet-proof resistance by securing high hardness and high toughness.

- In particular, according to the present disclosure, since a subsequent tempering process is not required during the cooling process, armored steel can be manufactured more economically.

- Hereinafter, armored steel of the present disclosure and a manufacturing method therefor will be described in more detail through specific examples. It should be noted that the following examples are only for understanding of the present invention, and are not intended to specify the scope of the present invention. The scope of the present invention may be determined by the matters described in the claims and the matters reasonably inferred therefrom.

- After preparing a steel slab having alloy compositions of Table 1 below, [heating - rolling - heat treatment (quenching)] were performed according to process conditions illustrated in Table 2 below to manufacture each hot-rolled steel sheet. In this case, after being water cooled to a cooling end temperature, air cooling was applied to room temperature. Alloy compositions not listed in Table 1 refer to unavoidable impurities and iron (Fe) . In addition, a part marked with"-" in Table 1 means that the corresponding component was not intentionally added, which is preferable to be interpreted as 0% by weight within an error range.

[Table 1] St ee 1 ty pe Alloy composition(weight %) [Relatio nal Expressi on 1] C Si Mn P* S* Ni Cr Mo Nb V Al Ca* Ti B* N* A 0.2 7 1.3 4 1.0 6 79 15 2.8 8 0.4 2 0.0 5 0.0 1 - 0.0 4 29 0.01 2 22 47 5.15 B 0.3 4 0.2 5 0.6 5 81 23 0.1 5 0.7 0.3 2 - 0.0 4 0.0 3 27 - 18 50 0.02 C 0.3 2 1.3 3 1.4 5 76 19 1.9 3 0.6 8 - 0.0 3 0.0 1 0.0 4 33 0.01 1 20 52 5.13 D 0.3 7 1.4 5 0.9 6 80 16 2.8 4 0.4 1 - 0.0 2 - 0.0 3 30 0.01 2 23 49 8.24 E 0.3 5 1.3 9 1.2 1 77 18 2.3 7 0.5 6 - 0.0 3 0.0 2 0.0 3 28 - 21 51 6.59 F 0.3 3 1.6 7 0.8 4 80 25 1.2 2 0.5 2 - 0.0 2 - 0.0 3 28 - 19 51 4.07 G 0.31 1.12 0.53 78 20 2.16 0.45 - 0.02 0.01 0.03 29 0.012 20 48 4.84 P*, S*, Ca*, B*, and N* are represented in units of ppm [Table 2] Spec imen No. Steel type Thick ness (mm) Slab heating (°C) Rolling Heat treatment (quenching) Rough rolling (°C) Finish hot rolling (°C) Reheati ng tempera ture (°C) Residen ce time (min.) Cooling end temperatur e (°C) Cooling rate (°C/s) 1 A 5 1184 1069 885 923 18 26 78 2 A 10 1176 1045 902 914 25 23 62 3 A 20 1162 1040 913 916 40 25 51 4 B 12 1156 1031 904 908 31 21 53 5 B 15 1161 1025 926 911 42 24 51 6 B 16 1149 1031 928 912 36 24 48 7 C 6 1201 1065 883 905 23 18 70 8 C 8 1179 1053 911 876 22 25 66 9 C 12 1137 1026 942 914 24 22 54 10 D 10 1194 1049 926 910 27 19 60 11 D 15 1156 1026 924 916 33 23 53 12 D 20 1120 1041 930 902 39 157 45 13 E 5 1189 1073 871 907 19 21 69 14 E 10 1163 1034 896 916 28 20 56 15 E 15 1147 1018 913 894 20 24 52 16 E 20 1138 1042 939 905 40 18 48 17 F 15 1151 1028 924 909 38 17 50 18 G 10 1155 1036 898 908 35 66 63 - Thereafter, a microstructure and mechanical properties of each hot-rolled steel sheet were measured, and the results thereof were shown in Table 3.

- The microstructure of each hot-rolled steel sheet was cut into an arbitrary size as a specimen to manufacture a mirror surface, a Nital etching solution was used to corrode the specimen, and then an optical microscope and a scanning electron microscope (SEM) were used to observe a 1/2t point which was a thickness center portion. In this case, a fraction of the microstructure was measured by electron back-scattered diffraction (EBSD) analysis.

- In addition, hardness and toughness of each hot-rolled steel sheet were measured using a Brinell hardness tester (load: 3000 kgf, 10 mm tungsten injection port) and a Charpy impact tester, respectively. In this case, in the surface hardness, an average value of three measurements after a milling process of the surface of the hot-rolled sheet at 2 mm was used, and in the Charpy impact test, a specimen was collected at 1/4t point in the thickness direction, and then an average value of three measurements at -40°C was used.

[Table 3] Specime n No. Steel type Microstructure (area %) Surface hardness (HB) Impact toughness (J, @-40°C) M F or B R-γ 1 A 98 - 2 522 43 2 A 98 - 2 527 39 3 A 99 - 1 541 28 4 B 100 - 0 584 7 5 B 100 - 0 592 5 6 B 100 - 0 596 6 7 C 99 - 1 568 23 8 C 37 B: 63 0 396 86 9 C 98 - 2 580 21 10 D 97 - 3 603 27 11 D 98 - 2 609 24 12 D 72 B: 28 0 530 37 13 E 97 - 3 592 31 14 E 98 - 2 597 30 15 E 65 B:14, F:21 0 412 103 16 E 98 - 2 605 25 17 F 99 - 1 675 10 18 G 98 - 2 551 29 M: Martensite, B: Bainite, F: Ferrite R-γ: Retained austenite - As shown in Tables 1 to 3, it can be seen that specimens satisfying the alloy composition and process conditions of the present disclosure have a surface harness of 560 to 630 HB and an impact absorption energy of 12 J or more at -40°C, but specimens not satisfying at least one of the alloy compositions or process conditions of the present disclosure do not have a surface hardness of 560 to 630 HB or an impact absorption energy of 12 J or more at -40°C at the same time.

- While example embodiments have been shown and described above, it will be apparent to those skilled in the art that modifications and variations could be made without departing from the scope of the present disclosure as defined by the appended claims.

Claims (8)

- Armored steel having high hardness and excellent low-temperature impact toughness comprising, by weight:0.31 to 0.40% of carbon (C), 1.0 to 2.0% of silicon (Si), 0.5 to 1.6% of manganese (Mn), 1.3 to 3.0% of nickel (Ni), 0.4 to 1.5% of chromium (Cr), 0.05% or less of phosphorus (P), 0.02% or less of sulfur (S), 0.006% or less of nitrogen (N), 0.07% or less of aluminum (Al) (excluding 0%), 0.03% or less of molybdenum (Mo) (including 0%), 0.01 to 0.05% of niobium (Nb), 0.0002 to 0.005% of boron (B), 0.0005 to 0.004% of calcium (Ca), with a balance of iron (Fe) and inevitable impurities, satisfying the following [Relational Expression 1], wherein a tempered martensite base structure including retained austenite is included as a microstructure,in Relational Expression 1, [Si], [Mo], and [Ni] refer to contents (weight %?) of silicon (Si), molybdenum (Mo), and nickel (Ni) included in the steel, and 0 is substituted when the corresponding element is not intentionally added.

- The armored steel having high hardness and excellent low-temperature impact toughness of claim 1, wherein the armored steel further comprises, by weight: at least one of 0.005 to 0.025% of titanium (Ti) and 0.2% or less of vanadium (V).

- The armored steel having high hardness and excellent low-temperature impact toughness of claim 1, wherein a fraction of the retained austenite is 0.5% by area to 5% by area.

- The armored steel having high hardness and excellent low-temperature impact toughness of claim 1, wherein the armored steel has a surface hardness of 560 to 630 HB and an impact absorption energy of 12 J or more at - 40°C.

- The armored steel having high hardness and excellent low-temperature impact toughness of claim 1, wherein the armored steel has a thickness of 5 to 20 mm.

- A manufacturing method for armored steel having high hardness and excellent low-temperature impact toughness, comprising operations of: preparing a steel slab including, by weight: 0.31 to 0.40% of carbon (C), 1.0 to 2.0% of silicon (Si), 0.5 to 1.6% of manganese (Mn), 1.3 to 3.0% of nickel (Ni), 0.4 to 1.5% of chromium (Cr), 0.05% or less of phosphorus (P), 0.02% or less of sulfur (S), 0.006% or less of nitrogen (N), 0.07% or less of aluminum (Al) (excluding 0%), 0.03% or less of molybdenum (Mo) (including 0%), 0.01 to 0.05% of niobium (Nb), 0.0002 to 0.005% of boron (B), 0.0005 to 0.004% of calcium (Ca), with a balance of iron (Fe) and inevitable impurities, satisfying the following [Relational Expression 1];heating the steel slab in a temperature range of 1050 to 1250°C;rough rolling the heated steel slab in a temperature range of 950 to 1150°C;subjecting the heated steel slab to finish hot rolling in a temperature range of 850 to 950°C after the rough rolling to manufacture a hot-rolled steel sheet; andperforming a heat treatment of reheating the hot-rolled steel sheet to a temperature range of 880 to 930°C and then cooling the same to a cooling end temperature of 150°C or lower at a cooling rate of 10°C/s or more,in Relational Expression 1, [Si], [Mo], and [Ni] refer to contents (weight %) of silicon (Si), molybdenum (Mo), and nickel (Ni) included in the steel slab, and 0 is substituted when the corresponding element is not intentionally added.

- The manufacturing method for armored steel having high hardness and excellent low-temperature impact toughness of claim 6, wherein the steel slab further comprises, by weight: at least one of 0.005 to 0.025% of titanium (Ti) and 0.2 % or less of vanadium (V).

- The manufacturing method for armored steel having high hardness and excellent low-temperature impact toughness of claim 6, wherein a residence time during the reheating is 1.3t + 10 minutes (t: plate thickness (mm)) or more.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020200179080A KR102498144B1 (en) | 2020-12-18 | 2020-12-18 | Armored steel havinh high hardness and excellent low-temperature impact toughness and method for manufacturing thereof |

| PCT/KR2021/015877 WO2022131540A1 (en) | 2020-12-18 | 2021-11-04 | Armored steel having high hardness and excellent low-temperature impact toughness and manufacturing method therefor |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP4265790A1 true EP4265790A1 (en) | 2023-10-25 |

| EP4265790A4 EP4265790A4 (en) | 2025-06-04 |

Family

ID=82059644

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP21906845.9A Pending EP4265790A4 (en) | 2020-12-18 | 2021-11-04 | Armored steel having high hardness and excellent low-temperature impact toughness and manufacturing method therefor |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP4265790A4 (en) |

| KR (1) | KR102498144B1 (en) |

| AU (1) | AU2021400779B2 (en) |

| WO (1) | WO2022131540A1 (en) |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2847270B1 (en) | 2002-11-19 | 2004-12-24 | Usinor | METHOD FOR MANUFACTURING AN ABRASION RESISTANT STEEL SHEET AND OBTAINED SHEET |