EP4245950B1 - Türschlosshalterung, die auf einem rohrförmigen element montiert ist - Google Patents

Türschlosshalterung, die auf einem rohrförmigen element montiert ist Download PDFInfo

- Publication number

- EP4245950B1 EP4245950B1 EP22162703.7A EP22162703A EP4245950B1 EP 4245950 B1 EP4245950 B1 EP 4245950B1 EP 22162703 A EP22162703 A EP 22162703A EP 4245950 B1 EP4245950 B1 EP 4245950B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bolt

- nut

- tubular member

- elongated rectangular

- rectangular slot

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B9/00—Lock casings or latch-mechanism casings ; Fastening locks or fasteners or parts thereof to the wing

- E05B9/02—Casings of latch-bolt or deadbolt locks

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B15/00—Other details of locks; Parts for engagement by bolts of fastening devices

- E05B15/02—Striking-plates; Keepers; Bolt staples; Escutcheons

- E05B15/0205—Striking-plates, keepers, staples

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B65/00—Locks or fastenings for special use

- E05B65/0007—Locks or fastenings for special use for gates

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B9/00—Lock casings or latch-mechanism casings ; Fastening locks or fasteners or parts thereof to the wing

- E05B9/08—Fastening locks or fasteners or parts thereof, e.g. the casings of latch-bolt locks or cylinder locks to the wing

Definitions

- the present invention relates to a system comprising a tubular member and a door lock fixture fixed thereto.

- the door lock fixture comprises a faceplate and a fixture body and is mounted with its fixture body through an elongated rectangular slot in a wall portion of the tubular member, with the faceplate of the fixture being configured to engage an outer surface of said wall portion of the tubular member and to be fixed to said wall portion by means two bolts which are applied through an opening in said faceplate.

- the door lock fixture is in particular a mortice lock or a keep for a door lock.

- the word "door” is used in the present specification to embrace all kinds of closure members such as doors, having a full door panel, and gates.

- the door can either be a hinged or a sliding closure member.

- EP 3 153 645 discloses a system comprising a tubular member and a door lock fixture fixed thereto by a top bolt and a bottom bolt, the tubular member having a wall with an elongated rectangular slot therein, the elongated rectangular slot extending in a longitudinal direction and having an top short side and a bottom short side, the door lock fixture comprising a faceplate and a fixture body, the door lock fixture being configured to be mounted with its fixture body through said elongated rectangular slot with the faceplate engaging an outer surface of said wall, the faceplate comprising a top opening through which said top bolt extends and a bottom opening through which said bottom bolt extends.

- EP 3 153 645 further discloses that the fixture body includes moveable (e.g. slideable or pivotable) clamping levers which, when retracted, allow inserting the fixture body through the rectangular elongated slot, and, when extended, engage an inner surface of the tubular member thereby clamping a wall portion of the tubular member between the clamping lever and the faceplate.

- Each clamping lever comprises a threaded opening which, when the clamping levers are extended, axially aligns with a respective one of the top/bottom opening in the faceplate.

- the top/bottom bolt is fastened through a threaded opening in a respective clamping lever.

- a downside of this known system is the positional leeway between the door lock fixture and the tubular member both in the longitudinal direction of the support member and in the width direction of the elongated rectangular slot.

- EP 4 159 962 is prior art cited under Article 54(3) EPC and relevant for the assessment of novelty only.

- EP 4 159 962 discloses a system comprising a tubular member and a door lock fixture fixed thereto by a top bolt and a bottom bolt, the tubular member having a wall with an elongated rectangular slot therein, the elongated rectangular slot extending in a longitudinal direction and having an top short side and a bottom short side,

- the door lock fixture comprising a faceplate and a fixture body, the door lock fixture being configured to be mounted with its fixture body through said elongated rectangular slot with the faceplate engaging an outer surface of said wall, the faceplate comprising a top opening through which said top bolt extends and a bottom opening through which said bottom bolt extends, wherein the elongated rectangular slot comprises a top notch at the top short side and a bottom notch at the bottom short side, the notches extending away from one another, said top bolt extending at least partially through said top notch and said bottom bolt extending at

- the system according to the invention is characterised in that the elongated rectangular slot comprises a top notch at the top short side and a bottom notch at the bottom short side, the notches extending away from one another, said top bolt extending at least partially through said top notch and said bottom bolt extending at least partially through said bottom notch, the system further comprising a top nut and a bottom nut for fastening a respective bolt, wherein the elongated rectangular slot has a width comprised between 10 and 35 mm.

- Providing the notches through which the bolts extend cause a desired positioning of the door lock fixture with respect to the support member. More specifically, as each bolt partially extends through a respective notch, both the height (i.e. longitudinal direction) and the width position of the bolts with respect to the support member is fixed. Likewise, since each bolt extends through a respective opening in the faceplate, the height/width position of the faceplate (i.e. the door lock fixture) is fixed with respect to the support member. The leeway possible with the known system is thus avoided.

- each nut is moveably mounted onto the fixture body between a retracted position in which the fixture body can be inserted through said elongated rectangular slot into the tubular member, and an extended position in which the nut at least partially engages an inner surface of said wall to clamp said wall between the faceplate and the nut.

- each bolt can be tightened strongly so that the wall of the tubular member is clamped strongly and reliably between the faceplate and the nut irrespective of the thickness of the wall of the tubular member.

- the nuts are formed as a threaded opening in a support, each support being moveably mounted on the fixture body between a retracted position in which the fixture body can be inserted through said elongated rectangular slot into the tubular member and an extended position in which the nut is axially aligned with a respective one of the top opening and bottom opening.

- the supports may be manually moveable from their retracted position to their extended position or they may be spring biased towards their extended position with a latch being provided for each support to hold its nut in its retracted position.

- the supports may be slideable or pivotable between their retracted position and their extended position.

- Such supports are disclosed in EP 3 153 645 and have various advantages. For example, such supports are suitable for varying wall thicknesses. Moreover, such supports do not hamper the insertion of the fixture body into the tubular member since it is held in its retracted position when the fixture body is inserted into the tubular member.

- a pivotable support is advantageous as the support can simply pivot within the tubular member from its retracted to its extended position until it engages the inner surface of the wall of the tubular member.

- a spring-biased support ensures that the support has only to be released to be brought automatically by the spring into its extended position.

- a corresponding latch can be actuated to release the support. Actuation of the latch can for example be done through the hole for the bolt in the faceplate.

- the door lock fixture may comprise a removable locking element which holds the support in its retracted position.

- the support is released and moves under the action of said spring in the tubular member until it projects behind the inner surface of the wall of the tubular member.

- the bolt can be inserted through said opening in the faceplate in the fixture and can be screwed in the screw threaded hole in the clamping lever to clamp the wall of the tubular member strongly between the faceplate of the fixture and the nut formed in the support.

- the nuts are irrotatably mounted on a support arm, each support arm being slideably mounted on the fixture body between a retracted position in which the fixture body can be inserted through said elongated rectangular slot into the tubular member and an extended position in which the nut is axially aligned with a respective one of the top opening and bottom opening, each nut being slideably mounted on a respective support arm along a transverse direction which is substantially perpendicular to the longitudinal direction and is preferably further perpendicular to the faceplate.

- This alternative embodiment is also suited for varying wall thicknesses. Furthermore, by having a separate nut and support, the risk of damaging the support is reduced when tensioning the bolt when compared to the first alternative embodiment where the nut is formed as an opening in the support.

- each bolt has a bolt head and a threaded part extending in a first direction, the bolt head defining a hypothetical circumscribed cylinder extending in said first direction, wherein a part of said wall adjacent said notches is located inside a respective hypothetical cylinder.

- a part of the tubular member is located directly underneath the bolt head.

- the tubular support is partially positioned directly between the bolt head and the nut which optimizes force transfer between the door lock fixture and the tubular member.

- each notch comprises a substantially semi-circular part, said part in particular having a diameter between 5 mm and 10 mm and more particularly between 6 mm and 7 mm.

- a leeway between each notch and its respective bolt is at most 1 mm, particularly at most 0,5 mm.

- each notch has an opening width which is measured along a line contiguous with its respective short side, the opening width being at most 50%, particularly at most 40%, and more particularly at most 30%, of a width of the elongated rectangular slot.

- the elongated rectangular slot has a height, the height being at least 4 times, particularly at least 6 times, and more particularly at least 7 times, larger than the width, the width preferably being between 15 and 30 mm and particularly between 20 and 25 mm.

- the various dimensions of the elongated rectangular slot are mainly determined in view of the dimensions of the lock fixture. Furthermore, the notch dimensions are mainly determined depending on the bolt diameter with higher diameter bolts typically leading to a stronger, albeit more expensive, connection.

- the notches are aligned with one another in the longitudinal direction. This leads to a symmetric design which reduces manufacturing and/or assembly errors.

- the present invention generally relates to a system comprising a tubular member 3 and a door lock fixture mounted thereon.

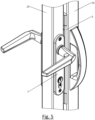

- the door lock fixture is a mortice lock 1 to be inserted into a closure member, in particular in a hollow tubular member 3 thereof.

- the door lock fixture is a morticed lock keep 2 which comprises a body portion that is inserted in the support onto which it is mounted.

- the support is generally formed by a hollow tubular member 3 and can either be a fixed post or a leaf of a double door or gate.

- the door lock fixture (i.e. the mortice lock 1 or the morticed lock keep 2) comprises a faceplate 4 and a fixture body 5.

- the tubular member 3 is generally part of a gate, as illustrated in the figures, or of a door or any other type of hinged closure member and generally comprises a rectangular elongated slot 6 in a wall portion 7.

- the rectangular elongated slot 6 has a top short side 8, a bottom short side 9, and two long sides 10 which extend in a longitudinal direction 11 (which is also the direction along which the tubular body 3 extends).

- the fixture body 5 is designed to be inserted through the rectangular elongated slot 6 with the faceplate 4 engaging an outer side of the wall portion 7.

- a top bolt 12 and a bottom bolt 13 which are placed through a corresponding top/bottom opening in the faceplate 4.

- Each bolt 12, 13 further at least partially extends through a corresponding one of a top notch 14 and a bottom notch 15 which are provided in a respective top/bottom short side 8, 9. This ensure that the faceplate 4 (and thus the door lock fixture) are correctly aligned with the rectangular elongated slot 6.

- Each bolt 12, 13 is bolted into a corresponding one of a top nut 16 and a bottom nut 17.

- the nuts 16, 17 are located inside the tubular member 3.

- the bolts may fully extend through the tubular member with the nuts being provided on the rear side thereof.

- the elongated rectangular slot 6 has a width W and a height H.

- the height H is at least 4 times, particularly at least 6 times, and more particularly at least 7 times, larger than the width W.

- the width is between 10 and 35 mm, particularly between 15 and 30 mm, and more particularly between 20 and 25 mm, with the width W being about 22 mm in the illustrated embodiment. These dimensions are mainly determined in view of the dimensions of the lock body.

- each notch 14, 15 comprises a semi-circular part 20 and two straight parts 21.

- the semi-circular part 20 in particular having a diameter between 5 mm and 10 mm and more particularly between 6 mm and 7 mm. These dimension of this semi-circular part 20 is mainly determined depending on the bolt diameter and a maximum leeway between the bolt diameter and the semi-circular part 20 is 1 mm and particularly 0,5 mm.

- the two straight parts 21 in the illustrated embodiment each have a length L of 2 mm, but other lengths are possible. The main reason for these straight parts 21 is to avoid the bolts 12, 13 centre-lines to coincide with the top/bottom short side 8, 9. In view of manufacturing tolerances, this could lead to bolts 12, 13 not being correctly positioned in their respective notch 14, 15.

- Each notch 14, 15 has an opening width W o which measured along a line contiguous with its respective short side 8, 9.

- the opening width W o is at most 50%, particularly at most 40%, and more particularly at most 30%, of a width W of the elongated rectangular slot 6. This dimension is mainly determined depending on the bolt diameter and is preferably equal to the diameter of the semi-circular part 20.

- the notches 14, 15 are aligned in the longitudinal direction 11 leading to a symmetric design.

- FIG. 5 illustrates a double wing gate having a mortice lock 1 in a tubular member of a first gate wing 22 and a morticed lock keep 2 in a tubular member of a second gate wing 23.

- the second gate wing may also be a fixed support.

- the lock 1 may have a locking mechanism of any type and comprises a faceplate 4 and a lock body 5.

- the lock 1 may comprise a latch bolt 24 which is operated by means of handles 25, a deadbolt 26 which is operated by means of a key in particular through the intermediary of a lock cylinder 27 (for example a single-barrel euro-profile cylinder), or it may comprise a combination of a latch bolt 24 and a deadbolt 26 as in the embodiments illustrated in the drawings.

- the latch bolt 24 and the deadbolt 26 are slideably mounted in the lock 1 to slide between a retracted and an extended position.

- the deadbolt 26 is however hook-shaped and pivots in the lock 1 between its extended and its retracted positions.

- the lock illustrated in figure 6 is in particular a lock as disclosed in EP 2 186 974 and EP 3 153 645 and further details about this lock can be found therein.

- the morticed lock keep 2 comprises a faceplate 4 and a partially hollow body 5.

- the faceplate 4 comprises an elongated opening 28 and the partially hollow body 5 forms a corresponding elongated slot 29 in which the latch bolt 24 and/or the deadbolt 26 are received as shown in figure 6 .

- the morticed lock keep 2 illustrated in the figures is in particular a morticed lock keep as disclosed in EP 3 153 645 and further details about this morticed lock keep can be found therein.

- the fixture body 5 of the morticed lock keep 2 is provided with two support arms 30 which are (manually) slideably mounted onto the fixture body 5 along the longitudinal direction 11 between a retracted position in which the fixture body 5 can be inserted through the rectangular elongated slot 6 into the tubular member 3 and an extended position (shown in figures 6 and 7 ).

- Each nut 16, 17 comprises a threaded opening configured to receive a bolt 12, 13 used to mount the morticed lock keep 10 on the tubular member 3.

- the nut 16, 17 is irrotatable with respect to the support arm 30 due to its square (in general non-circular) outer shape.

- the fixture body 5 of the mortice lock 1 is provided with two supports 32 that are moveable (e.g. slideable or pivotable) between a retracted position in which the fixture body 5 can be inserted into the elongated opening 6 and an extended position in which each support 32 engages an inner surface of the tubular member 3.

- Each support 32 is provided with a threaded opening which forms a respective one of the nuts 16, 17.

- the supports 32 are pivotable and spring-biased due to a spring member 33 and latches 34 are provided to maintain the supports 32 in their retracted position.

- the supports 32 are identical to those described in EP 3 153 645 A1 which is incorporated herein by reference.

- each bolt has a bolt head and a threaded part extending in direction 31.

- the bolt head defines a hypothetical circumscribed cylinder extending in direction 31, wherein a part of said wall 7 adjacent said notches 14, 15 is located inside a respective hypothetical cylinder.

- fixation systems described above for the mortice lock 1 and the morticed lock keep 2 are interchangeable and still others may be used in accordance with the present invention related to the provision of notches 14, 15 for the alignment of the fixation bolts 12, 13.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Control Of Vending Devices And Auxiliary Devices For Vending Devices (AREA)

- Clamps And Clips (AREA)

Claims (15)

- Ein System, welches ein rohrförmiges Element (3) und eine Türschlosshalterung (1, 2) umfasst, daran befestigt durch eine obere Schraube (12) und eine untere Schraube (13), wobei das rohrförmige Element eine Wand (7) mit einem länglichen rechteckigen Schlitz (6) darin hat, wobei sich der längliche rechteckige Schlitz in eine Längsrichtung (11) ausdehnt und eine obere kurze Seite (8) und eine untere kurze Seite (9) hat, wobei die Türschlosshalterung einen Stulp (4) und einen Schlosskasten (5) umfasst, wobei die Türschlosshalterung konfiguriert ist, um mit ihrem Schlosskasten durch den erwähnten länglichen rechteckigen Schlitz montiert zu werden, wobei der Stulp in eine Außenfläche der erwähnten Wand eingreift, wobei der Stulp eine obere Öffnung, durch die sich die erwähnte obere Schraube erstreckt, und eine untere Öffnung, durch die sich die erwähnte untere Schraube erstreckt, umfasst,dadurch gekennzeichnet, dass der längliche rechteckige Schlitz eine obere Kerbe (14) an der oberen kurzen Seite und eine untere Kerbe (15) an der unteren kurzen Seite umfasst, wobei sich die Kerben voneinander weg ausdehnen, wobei sich die erwähnte obere Schraube zumindest teilweise durch die erwähnte obere Kerbe erstreckt und sich die erwähnte untere Schraube zumindest teilweise durch die erwähnte untere Kerbe erstreckt, wobei das System ferner eine obere Mutter (16) und eine untere Mutter (17) umfasst, um eine zugehörige Schraube zu fixieren,wobei der längliche rechteckige Schlitz eine Weite (W) von zwischen 10 und 35 mm hat.

- Das System nach Anspruch 1, dadurch gekennzeichnet, dass jede Mutter auf dem Schlosskasten beweglich montiert ist zwischen einer zurückgezogenen Position, in der der Schlosskasten durch den erwähnten länglichen rechteckigen Schlitz in das rohrförmige Element eingeführt werden kann, und einer ausgestreckten Position, in der die Mutter zumindest teilweise in eine Innenfläche der erwähnten Wand eingreift, um die erwähnte Wand zwischen dem Stulp und der Mutter festzuklemmen.

- Das System nach Anspruch 2, dadurch gekennzeichnet, dass die Muttern als eine mit einem Gewinde versehene Öffnung in einem Träger (32) geformt sind, wobei jeder Träger auf dem Schlosskasten beweglich montiert ist zwischen einer zurückgezogenen Position, in der der Schlosskasten durch den erwähnten länglichen rechteckigen Schlitz in das rohrförmige Element eingeführt werden kann, und einer ausgestreckten Position, in der die Mutter axial mit einer Zugehörigen der oberen und untere Öffnung ausgerichtet ist.

- Das System nach Anspruch 3, dadurch gekennzeichnet, dass die Träger manuell von ihrer zurückgezogenen Position in ihre ausgestreckte Position beweglich sind.

- Das System nach Anspruch 3, dadurch gekennzeichnet, dass die Träger federvorgespannt hin zu ihrer ausgestreckten Position sind und ein Riegel (34) für jeden Träger vorgesehen ist, um seine Mutter in seiner zurückgezogenen Position zu halten.

- Das System nach irgendeinem der Ansprüche 3 bis 5, dadurch gekennzeichnet, dass die Träger zwischen ihrer zurückgezogenen Position und ihrer ausgestreckten Position verschiebbar sind.

- Das System nach irgendeinem der Ansprüche 3 bis 5, dadurch gekennzeichnet, dass die Träger zwischen ihrer zurückgezogenen Position und ihrer ausgestreckten Position drehbar sind.

- Das System nach Anspruch 2, dadurch gekennzeichnet, dass die Muttern nicht drehbar an einem Haltearm (30) montiert sind, wobei jeder Haltearm am Schlosskasten verschiebbar montiert ist zwischen einer zurückgezogenen Position, in der der Schlosskasten durch den erwähnten länglichen rechteckigen Schlitz in das rohrförmige Element eingeführt werden kann, und einer ausgestreckten Position, in der die Mutter axial mit einer Zugehörigen der oberen Öffnung und der unteren Öffnung ausgerichtet ist, wobei jede Mutter auf einem zugehörigen Haltearm verschiebbar entlang einer Querrichtung (31) montiert ist, welche im Wesentlichen senkrecht zur Längsrichtung verläuft und bevorzugt ferner senkrecht zum Stulp ist.

- Das System nach irgendeinem der vorigen Ansprüche, dadurch gekennzeichnet, dass jede Schraube einen Schraubenkopf und einen Gewindeteil hat, der sich in eine erste Richtung erstreckt, wobei der Schraubenkopf einen hypothetisch umschriebenen Zylinder definiert, der sich in die erwähnte erste Richtung erstreckt, wobei sich ein Teil der erwähnten Wand angrenzend an die erwähnten Kerben innerhalb eines zugehörigen hypothetischen Zylinders befindet.

- Das System nach irgendeinem der vorigen Ansprüche, dadurch gekennzeichnet, dass jede Kerbe einen im Wesentlichen halbkreisförmigen Teil (20) umfasst, wobei der erwähnte Teil insbesondere einen Durchmesser von zwischen 5 mm und 10 mm und genauer von zwischen 6 mm und 7 mm hat.

- Das System nach irgendeinem der vorigen Ansprüche, dadurch gekennzeichnet, dass ein Spielraum zwischen jeder Kerbe und ihrer zugehörigen Schraube höchstens 1 mm, insbesondere höchstens 0,5 mm beträgt.

- Das System nach irgendeinem der vorigen Ansprüche, dadurch gekennzeichnet, dass die Kerben miteinander in der Längsrichtung ausgerichtet sind.

- Das System nach irgendeinem der vorigen Ansprüche, dadurch gekennzeichnet, dass jede Kerbe eine Öffnungsweite Wo hat, die entlang einer Linie angrenzend an ihre zugehörige kurze Seite gemessen wird, wobei die Öffnungsweite höchstens 50 %, insbesondere höchstens 40 %, und noch genauer höchstens 30 % einer Weite des länglichen rechteckigen Schlitzes beträgt.

- Das System nach irgendeinem der vorigen Ansprüche, dadurch gekennzeichnet, dass der längliche rechteckige Schlitz eine Höhe (H) hat, wobei die Höhe mindestens 4-mal, insbesondere mindestens 6-mal, und noch genauer mindestens 7-mal größer ist als die Weite, wobei die Weite bevorzugt zwischen 15 und 30 mm und insbesondere zwischen 20 und 25 mm beträgt.

- Das System nach irgendeinem der vorigen Ansprüche, dadurch gekennzeichnet, dass die Türschlosshalterung ein Schließhaken für ein Türschloss oder ein Einsteckschloss ist.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP22162703.7A EP4245950B1 (de) | 2022-03-17 | 2022-03-17 | Türschlosshalterung, die auf einem rohrförmigen element montiert ist |

| PL22162703.7T PL4245950T3 (pl) | 2022-03-17 | 2022-03-17 | Osprzęt ryglujący drzwi zamontowany na członie rurowym |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP22162703.7A EP4245950B1 (de) | 2022-03-17 | 2022-03-17 | Türschlosshalterung, die auf einem rohrförmigen element montiert ist |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP4245950A1 EP4245950A1 (de) | 2023-09-20 |

| EP4245950B1 true EP4245950B1 (de) | 2025-01-22 |

| EP4245950C0 EP4245950C0 (de) | 2025-01-22 |

Family

ID=80787194

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP22162703.7A Active EP4245950B1 (de) | 2022-03-17 | 2022-03-17 | Türschlosshalterung, die auf einem rohrförmigen element montiert ist |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP4245950B1 (de) |

| PL (1) | PL4245950T3 (de) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4567230A1 (de) | 2023-12-04 | 2025-06-11 | Locinox | Mit zapfen versehene bolzenhalterung und verschlusssystem damit |

| EP4567231A1 (de) | 2023-12-04 | 2025-06-11 | Locinox | Mit zapfen versehene bolzenhalterung und verschlusssystem damit |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4159962A1 (de) * | 2021-10-01 | 2023-04-05 | Locinox | Doppelflügeltor und verfahren zur konstruktion davon |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20022248U1 (de) * | 2000-12-13 | 2001-05-17 | BOS GmbH, 48282 Emsdetten | Fallenverstelleinheit |

| EP2186974B1 (de) | 2008-11-14 | 2012-12-19 | Joseph Talpe | Zylinderschloss mit schwenkbar montiertem Bolzen |

| BE1023032B1 (nl) | 2015-10-06 | 2016-11-09 | Locinox Nv | Deursloteenheid die ingericht is om te worden gemonteerd op een buisvormig element |

-

2022

- 2022-03-17 EP EP22162703.7A patent/EP4245950B1/de active Active

- 2022-03-17 PL PL22162703.7T patent/PL4245950T3/pl unknown

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4159962A1 (de) * | 2021-10-01 | 2023-04-05 | Locinox | Doppelflügeltor und verfahren zur konstruktion davon |

Also Published As

| Publication number | Publication date |

|---|---|

| EP4245950A1 (de) | 2023-09-20 |

| PL4245950T3 (pl) | 2025-03-31 |

| EP4245950C0 (de) | 2025-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP4245951B1 (de) | Türschlossvorrichtung zur montage auf einem rohrförmigen element | |

| EP4245950B1 (de) | Türschlosshalterung, die auf einem rohrförmigen element montiert ist | |

| US6651389B2 (en) | Casement window with improved tie bar guide and striker | |

| EP3153645B1 (de) | Türschlosshalterung zur montage auf einem rohrförmigen element | |

| US6502435B2 (en) | Locks | |

| US7707862B2 (en) | Multi-point door lock and offset extension bolt assembly | |

| NO160535B (no) | Festeanordninger for glidedoerer og -vinduer. | |

| WO2010001170A2 (en) | Door latch face plate assembly | |

| CA2151689C (en) | Lockset having adjustable backset | |

| WO2008003977A1 (en) | Door latch face plate assembly | |

| US7207608B2 (en) | System, method and apparatus for an adjustable door striker | |

| AU2009311262B2 (en) | A multipoint lock assembly | |

| HK1044180A1 (en) | Adjustable deadbolt and method of adjusting thereof | |

| US7533551B1 (en) | Door lock with key cylinder | |

| AU2022252743B2 (en) | Multi-lock and method of use | |

| US4033044A (en) | Lock alignment tool | |

| US7249476B2 (en) | Method and apparatus for locking a container | |

| EP0117744B1 (de) | Verschlussmechanismus | |

| US20040205936A1 (en) | Escutcheon plate assembly | |

| GB2211882A (en) | Improvements in or relating to fasteners | |

| US12297665B2 (en) | Tubular exit device and method of installation | |

| US5081771A (en) | Alignment tool for mounting door lock assembly | |

| EP1801325B1 (de) | Schliessanlage | |

| US20060131897A1 (en) | Door latch mounting bracket | |

| DE9306262U1 (de) | Scharnierbeschlag für einen Fenster- oder Türladen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20240315 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20240801 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20241011 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602022009698 Country of ref document: DE |

|

| U01 | Request for unitary effect filed |

Effective date: 20250213 |

|

| U07 | Unitary effect registered |

Designated state(s): AT BE BG DE DK EE FI FR IT LT LU LV MT NL PT RO SE SI Effective date: 20250219 |

|

| U20 | Renewal fee for the european patent with unitary effect paid |

Year of fee payment: 4 Effective date: 20250311 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20250220 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250422 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250522 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250422 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250423 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250122 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: H13 Free format text: ST27 STATUS EVENT CODE: U-0-0-H10-H13 (AS PROVIDED BY THE NATIONAL OFFICE) Effective date: 20251023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250122 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |