EP3913291A1 - Air purifier - Google Patents

Air purifier Download PDFInfo

- Publication number

- EP3913291A1 EP3913291A1 EP21171308.6A EP21171308A EP3913291A1 EP 3913291 A1 EP3913291 A1 EP 3913291A1 EP 21171308 A EP21171308 A EP 21171308A EP 3913291 A1 EP3913291 A1 EP 3913291A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- water tank

- housing

- water

- water container

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F6/00—Air-humidification, e.g. cooling by humidification

- F24F6/02—Air-humidification, e.g. cooling by humidification by evaporation of water in the air

- F24F6/04—Air-humidification, e.g. cooling by humidification by evaporation of water in the air using stationary unheated wet elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F8/00—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying

- F24F8/10—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying by separation, e.g. by filtering

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/20—Casings or covers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/28—Arrangement or mounting of filters

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F6/00—Air-humidification, e.g. cooling by humidification

- F24F6/02—Air-humidification, e.g. cooling by humidification by evaporation of water in the air

- F24F6/04—Air-humidification, e.g. cooling by humidification by evaporation of water in the air using stationary unheated wet elements

- F24F6/043—Air-humidification, e.g. cooling by humidification by evaporation of water in the air using stationary unheated wet elements with self-sucking action, e.g. wicks

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F8/00—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying

- F24F8/10—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying by separation, e.g. by filtering

- F24F8/108—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying by separation, e.g. by filtering using dry filter elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F8/00—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying

- F24F8/80—Self-contained air purifiers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F6/00—Air-humidification, e.g. cooling by humidification

- F24F2006/008—Air-humidifier with water reservoir

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/20—Casings or covers

- F24F2013/205—Mounting a ventilator fan therein

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F2221/00—Details or features not otherwise provided for

- F24F2221/32—Details or features not otherwise provided for preventing human errors during the installation, use or maintenance, e.g. goofy proof

Definitions

- the present invention relates to an air purifier, and more specifically, the present invention relates to an air purifier as a humidified air purifier in which a water tank can be detached, and when the water tank is mounted, even if it is incorrectly positioned to deviate from the normal installation position, it is configured to move the water tank to the normal installation position in the process of mounting a water container in the water tank, and thus, it is possible to prevent incorrect mounting of a water tank.

- An air purifier is a device that forcibly inhales and purifies contaminated external air, and then discharges purified filtered air to the outside. Recently, in order to increase the utilization of air purifiers, air purifiers, to which additional other functions are added in addition to the air purifying function, have been introduced. An example of this is a humidified air purifier to which a humidifying function is added.

- the humidified air purifier needs management such as washing the water tank and the like to perform the humidifying function.

- the water tank is generally provided in a detachable form.

- the humidified air purifier provides a structure in which the water tank can be detached, there is a possibility that in the process of removing and remounting a water tank during use, the user may place it slightly out of position from the normal installation position in the housing. If the water tank is positioned incorrectly, the fastening between the water tank and the water container may not be properly performed, and the performance of the humidifying function may become impossible. Although the inability of the humidifying function can be easily resolved by correcting the position of the water tank, if the user recognizes it as a malfunction, it may lead to unnecessary repair requests and unfair image degradation of the product, and thus, improvement is required.

- conventional humidified air purifiers generally have a structure in which a water tank, a water container, and the like are detached in the lateral direction of the air purifier.

- the humidified air purifier of Korean Patent Laid-Open No. 10-2019-0029819 by Dayou Winia Co., Ltd. has a structure in which the water tank 300 is detached through the side surface of the main body 100 of the air purifier.

- the humidified air purifier of Korean Patent Laid-Open No. 10-2018-0073361 by Coway Co., Ltd. discloses a structure in which the water tank 130 is detachable in the direction of one side surface of the frame 120.

- the air purifier according to the present invention which is capable of detaching a water tank, aims to prevent incorrect mounting of a water tank, by moving the water tank to the correction position by a guide unit which is pressed by a water container in the process of mounting the water container on the water tank, even when the water tank is displaced and positioned away from the installation position.

- the air purifier according to an exemplary embodiment of the present invention aims to prevent incorrect mounting of a water tank more effectively, because a guide unit that is pressed by a water container in the process of mounting the water container on the water tank to allow the water tank to move to the correct position is doubly configured.

- the air purifier according to an exemplary embodiment of the present invention aims to improve user convenience through a structure in which a water tank can be detached from the front and a water container can be detached from the top.

- the air purifier includes a housing; an air blowing unit for providing an air blowing force such that external air is introduced into the housing; a filter unit disposed inside the housing to filter the external air introduced into the housing to make filtered air; and a humidifying unit disposed inside the housing to humidify the filtered air passing through the filter unit, wherein the humidifying unit includes a water tank in which a mounting portion is formed, a humidifying member mounted on one side of the mounting portion to receive water from the water tank and supply moisture to the filtered air, and a water container mounted on the other side of the mounting portion to supply water to the water tank, wherein the water tank is formed detachably from an installation position inside the housing to the outside of the housing, and further includes a guide unit protruding upwardly around the other side of the mounting portion on which the water container is mounted, wherein the guide unit is pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position by a pre

- the water tank is formed detachably from the installation position to the front of the housing, wherein the guide unit is pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position to the front of the housing by a predetermined range and is disposed inside the housing, and wherein the water tank is moved to the rear by the pressing force.

- the housing is provided with a water container insertion port on the upper surface, and the water container enters the mounting portion in a downward direction through the water container insertion port.

- the guide unit includes a first guide member formed of a wall extending forward from the rear sidewall of the water tank.

- the first guide member is provided with an inclined portion inclined upward from the front end to the rear side on the upper surface.

- the guide unit includes a second guide member provided around the mounting portion, wherein the second guide member includes at an upper end a head portion pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position by a predetermined range and is disposed inside the housing, and wherein the second guide member opens a flow path between the water container and the water tank in a pressed state to supply water in the water container to the water tank, and is formed by a flow path switch that closes the flow path between the water container and the water tank in an unpressed state.

- the water tank is formed detachably from the installation position to the front of the housing, wherein the head portion of the second guide member is pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position to the front of the housing by a predetermined range and is disposed inside the housing, and wherein the water tank is moved to the rear by the pressing force.

- the head portion of the second guide member is provided with an inclined portion formed to be inclined downwardly from the inside outwardly toward the mounting portion.

- the head portion of the second guide member is disposed at the rear of the mounting portion on which the water tank is mounted.

- a groove or protrusion is formed at a predetermined position on inner surfaces of one sidewall and the other sidewall of the housing forming the installation position, and wherein a protrusion inserted into the groove or a groove inserted into the protrusion at the installation position is formed on the outer surfaces of one sidewall and the other sidewall of the water tank.

- the air purifier according to the present invention which is capable of detaching a water tank, provides an effect of preventing incorrect mounting of a water tank, by moving the water tank to the correction position by a guide unit which is pressed by a water container in the process of mounting the water container on the water tank, even when the water tank is displaced and positioned away from the installation position.

- the air purifier according to an exemplary embodiment of the present invention provides an effect of preventing incorrect mounting of a water tank more effectively, because a guide unit that is pressed by a water container in the process of mounting the water container on the water tank to allow the water tank to move to the correct position is doubly configured.

- the air purifier according to an exemplary embodiment of the present invention provides an effect of improving user convenience through a structure in which a water tank can be detached from the front and a water container can be detached from the top.

- Words and terms used in the present specification and claims are not limited and interpreted to the conventional or dictionary meanings, and in accordance with the principle that the inventors may define terms and concepts in order to describe their invention in the best way, these should be interpreted as meanings and concepts consistent with the technical spirit of the present invention.

- That a component is at the "front”, “rear”, “above”, or “below” of another component not only includes cases where, unless otherwise specified, it is in direct contact with another component and is disposed at the "front”, “rear”, “above”, or “below”, but also cases where other components are placed in the middle.

- that a component is "connected” with another component includes cases where, unless otherwise specified, it is in direct contact with each other, but also cases where it is indirectly connected to each other.

- FIG. 1 is a perspective view of an air purifier according to an exemplary embodiment of the present invention

- FIG. 2 is an exploded perspective view of an air purifier according to an exemplary embodiment of the present invention

- FIG. 3 is an illustration of an air purifier according to an exemplary embodiment of the present invention, in which the lower portion is a longitudinal cross-sectional view of the central portion, and the upper portion is a cross-sectional view taken along line A-A' of FIG. 1 while the body portion of the water container is removed.

- a humidifying unit 40 is disposed above the filter unit 30. Accordingly, the air purifier 1 may perform a function as a humidifier in addition to purifying air. More specifically, the external air A1 is introduced into an intake port 121 formed in the lower front portion of a housing 10 of the air purifier 1 and is filtered by a filter unit 30.

- the air purifier 1 is configured to include a housing 10, an air blowing unit 20, a filter unit 30, a humidifying unit 40, a guide unit 50, and a flow path setting unit 60.

- the housing 10 forms the outer shape of the air purifier 1.

- the housing 10 provides a space in which the air blowing unit 20, the filter unit 30, the humidifying unit 40, the guide unit 50, and the flow path setting unit 60 may be disposed.

- an intake port 121 through which external air A1 is introduced, a first discharge port 111 through which filtered air A2 is discharged, a second discharge port 122 through which filtered humidified air A3 is discharged, a water container insertion port 112 for insertion of a water container 43, which will be described later, and the like are formed.

- the housing 10 may include a housing main body 11 and a front cover 12.

- the housing main body 11 may be formed in an open front surface to provide a space in which the air blowing unit 20, the filter unit 30, the humidifying unit 40, the guide unit 50, and the flow path setting unit 60 are arranged.

- the front cover 12 is disposed to cover the front surface of the housing main body 11.

- the first discharge port 111 and the water container insertion port 112 are formed on the upper surface of the housing main body 11. In this way, when the water container insertion port 112 is provided on the upper surface of the housing 10, the water container 43 of the humidifying unit 40 may enter in a downward direction through the water container insertion port 112 and be mounted in the water tank 41 of the humidifying unit 40. On the contrary, it may be withdrawn in an upward direction of the air purifier 1 when it is separated from the water tank 41.

- an intake port 121 for inflow of external air A1 is formed in the lower portion of the front cover 12, and a second discharge port 122 is formed in the upper portion of the front cover 12.

- the first discharge port 111 is formed in a grill shape, and the intake port 121 and the second discharge port 122 are formed by a plurality of through holes formed by penetrating through the front cover 12.

- both sides of the front cover 12 are formed to extend in the rear (on the side of the housing main body 11 in the drawing), and include a recessed portion 123 which is formed to be recessed forwardly in the upper portion thereof.

- the recessed portion 123 prevents noise from being generated by receiving excessive flow path resistance from the filtered humidified air A3 that is discharged from the second discharge port 122, and by providing a passage through which some filtered humidified air A3 may be discharged, it may reduce noise in the process of using the air purifier 1.

- the housing 10 forms a square cylindrical shape in a state in which the housing main body 11 and the front cover 12 are coupled.

- the shape of the housing 10 is not limited thereto, and may have other shapes.

- the positions and shapes of the intake port 121, the first discharge port 111, and the second discharge port 122 may also be changed as necessary.

- the intake port 121 may be formed on a plurality of surfaces of the front, rear, left, and right sides of the housing 10 so as to inhale air in various directions, and the locations, shapes, and the like of the first discharge port 111 and the second discharge port 122 may also be changed as needed.

- the air blowing unit 20 provides an air blowing force such that external air A1 is introduced into the housing 10.

- the air blowing unit 20 provides a flow force such that the air filtered inside the housing 10 may be discharged to the outside. More specifically, the air blowing unit 20 provides an air blowing force such that after the external air A1 introduced into the intake port 121 passes through a filter member 31 of the filter unit 30 and becomes filtered air A2, it flows toward the first discharge port or the second discharge port.

- the air blowing unit 20 may be configured to include a motor, an impeller, and the like.

- the air blowing unit 20 is disposed behind the filter unit 30 at the lower side inside the housing 10. Certainly, the location and shape of the air blowing unit 20 are not limited thereto, and may be changed depending on design needs.

- the filter unit 30 is disposed on the lower side inside the housing 10, and filters external air A1 to make filtered air A2.

- the filter unit 30 includes a filter member 31 through which the external air A1 passes through and is filtered.

- a pre-filter 32 may be disposed between the front of the filter member 31 and the rear of the front cover 12 with a plurality of inlet holes 32a through which the external air A1 passes through.

- the filter member 31 may be made of a dust collecting filter such as an ultra-low penetration air (ULPA) filter, a high efficiency particulate air (HEPA) filter, and a medium filter that collects and filters fine particulate matters of 0.1 ⁇ m to 0.3 ⁇ m or particulate matters of 0.3 ⁇ m or more contained in the air, or a functional filter that filters bacteria or microorganisms contained in the inhaled air.

- ULPA ultra-low penetration air

- HEPA high efficiency particulate air

- a medium filter that collects and filters fine particulate matters of 0.1 ⁇ m to 0.3 ⁇ m or particulate matters of 0.3 ⁇ m or more contained in the air

- a functional filter that filters bacteria or microorganisms contained in the inhaled air.

- the pre-filter 32 is formed in a square lattice shape.

- the pre-filter 32 is not limited thereto and may be formed in various shapes depending on dust collection efficiency.

- the humidifying unit 40 humidifies the filtered air A2 that has passed through the filter unit 30.

- the humidifying unit 40 is disposed on the upper side of the filter unit 30.

- the humidifying unit 40 forms filtered humidified air A3 by supplying moisture to the filtered air A2.

- the humidifying unit 40 of the air purifier 1 is configured to include a water tank 41, a humidifying member 42, and a water container 43.

- the water tank 41 includes mounting portions 411 and 412 formed in a container shape with an open top.

- the mounting portions 411 and 412 may include a first mounting portion 411 on which a humidifying member 42 is mounted, and a second mounting portion 412 on which a water container 43 for supplying water, which is to be supplied to the humidifying member 42, to the water tank 41 is mounted.

- the first mounting portion 411 and the second mounting portion 412 may be disposed adjacent to each other. Specifically, the first mounting portion 411 may be formed on one side of the water tank 41, and the second mounting portion 412 may be formed on the other side of the water tank 41 adjacent to the first mounting portion 411.

- the water tank 41 is formed detachably from the installation position inside the housing 10 to the outside of the housing 10. More specifically, in an exemplary embodiment of the present invention, the water tank 41 is formed detachably to the front of the housing 10. Accordingly, according to an exemplary embodiment of the present invention, even if the space is narrow due to the presence of other items on the side surface of the air purifier 1, the user may easily perform detachment of the water tank 41, because only the front cover 12 may be removed from the usage position of the air purifier 1 to detach the water tank 41.

- the water tank 41 is provided with a water receiving portion 413 for storing water overflowed from the water tank 41.

- the water receiving portion 413 prevents water inside the water tank 41 from overflowing when an external force is applied when the water tank 41 is detached or in the process of using the air purifier 1.

- the water receiving portion 413 may be provided in the front of the water tank 41. Specifically, the water receiving portion 413 may be provided to be connected to the front of the water tank 41 such that the front sidewalls 41a of the mounting portions 411 and 412 of the water tank 41 become the rear sidewall of the water receiving portion 413.

- the height of the front sidewall 413a of the water receiving portion 413 is formed to be equal to the height of the front sidewalls 41a of the mounting portions 411 and 412 of the water tank 41.

- the height of the front sidewalls 41a of the mounting portions 411 and 412 is formed to be lower than both sides of the central portion, and accordingly, the height of the front sidewall 413a of the water receiving portion 413 is formed such that the central portion is lower than both sides.

- a groove 113 may be formed at a predetermined position on the inner surfaces of one sidewall and the other sidewall of the housing 10 forming an installation position, and a protrusion 414, which is formed to be inserted into the groove 113 at the installation position, may be formed on the outer surfaces of one sidewall and the other sidewall of the water tank 41.

- the user may easily determine whether the water tank 41 is properly positioned at the established installation position when the water tank 41 is inserted.

- the groove 113 and the protrusion 414 may be formed opposite to each other. In other words, it is possible that a protrusion may be formed at a predetermined position on the inner surfaces of one sidewall and the other sidewall of the housing 10, and a groove may be formed on the outer surfaces of one sidewall and the other sidewall of the water tank 41.

- the humidifying member 42 is mounted on the first mounting portion 411 to receive water from the water tank 41 and supply moisture to the filtered air A2.

- the humidifying member 42 uses water supplied to the first mounting portion 411 of the water tank 41 to perform humidification by evaporation (air-blowing type).

- the humidifying member 42 is installed in parallel with the front surface of the housing 10 at the rear of the second discharge port 122.

- the humidifying member 42 is disposed at the rear end of the air blowing unit 20 in the air flow path.

- the air having increased humidity passing through the humidifying member 42 passes through the air blowing unit 20, and thus, there may be a problem that causes a breakdown in the air blowing unit 20.

- the flow path is formed in the humidification mode by the flow path setting unit 60 to be described below, the external air A1 introduced by the operation of the air blowing unit 20 becomes filtered air A2 through the filter member 31 of the filter unit 30. Then, through the humidifying member 42, it is discharged as filtered humidified air A3 through the second discharge port 122.

- the filter unit 30 is disposed at the front end of the air blowing unit 20 on the air flow path, and the humidifying member 42 is disposed at the rear end of the air blowing unit 20.

- the air filtered by the filter unit 30 is restricted from flowing to the humidifying member 42 such that air purifying efficiency may be increased. Accordingly, even if the impeller provided in the air blowing unit 20 is operated at a relatively low RPM and low power, a sufficient discharge amount may be secured, and noise may be reduced.

- the humidifying member 42 may be configured to have a material or shape having excellent hygroscopicity so as to sufficiently absorb water accommodated in the water tank 41.

- the humidifying member 42 may have a structure that is immersed in water accommodated in the water tank 41.

- the humidifying member 42 is not limited to the above-described structure, and if vaporization humidification is possible, various forms of known vaporization humidification structures such as a rotationally operated disk form and the like may be used.

- the water container 43 is mounted on the second mounting portion 412 to supply water to the water tank 41.

- the water supplied by the water container 43 is supplied to the first mounting portion 411 of the water tank 41 to immerse the humidifying member 42.

- the water container 43 is configured to include a water container main body 431 for accommodating water for humidification, and a valve member 432 that is opened and closed to allow the discharge of water accommodated in the water container main body 431.

- the water container 43 has a structure that may be separated from the air purifier 1 such that water may be easily filled inside the water container main body 431.

- the valve member 432 may be installed in a cap structure that is screwed to the inlet (inlet port) of the water container main body 431.

- the valve member 432 may be provided with an opening/closing portion 432a that is elastically supported by an elastic means (e.g., a spring), and may have a mechanical valve structure that maintains a closed state when the opening/closing portion 432a is not pressed and maintains an open state when the opening/closing portion 432a is pressed.

- an elastic means e.g., a spring

- the guide unit 50 is formed to protrude upward around the second mounting portion 412 of the water tank 41 on which the water container 43 is mounted.

- the guide unit 50 is pressed by the water container 43 when the water container 43 enters around the second mounting portion 412 while the water tank 41 is deviated from the installation position in a predetermined range and is disposed inside the housing 10.

- the guide unit 50 is pressed by the water container 43, the water tank 41 is moved in the direction of the installation position by the pressing force provided to the guide unit 50.

- the guide unit 50 may be formed at the rear of the second mounting portion 412. Accordingly, when the water tank 41 is deviated from the normal installation position in a predetermined range forward and is incorrectly disposed inside the housing 10, the water tank 41 is pressed by the water container 43 in contact with the guide unit 50 and may be moved to the correct position at the rear, when the water container 43 enters around the second mounting part 412.

- the guide unit 50 may include any one or more of a first guide member 51 and a second guide member 52.

- the first guide member 51 may be formed as a wall extending forward from the rear sidewalls 41b of the mounting portions 411 and 412. Specifically, the first guide member 51 may be formed as a wall extending forward from the rear sidewall 41b of the second mounting portion 412 of the water tank 41.

- the first guide member 51 may include an inclined portion 51a inclined upward from the front end to the rear side on the upper surface. In this way, when the first guide member 51 includes an inclined portion 51a that is inclined upward from the front end to the rear side, a part of the valve member 432 of the water container 43 may descend along an inclined portion 51a and provide mobility effectively to the rear side of the water tank 41 in the process where the water container 43 enters the second mounting portion 412 of the water tank 41.

- the second guide member 52 may be provided around the second mounting portion 412 and open the flow path between the water container 43 and the water tank 41 in a pressed state to supply water in the water container 43 to the water tank 41, and it may be formed as a flow path switch that closes the flow path between the water container 43 and the water tank 41 in an unpressed state.

- the second guide member 52 is provided with a head portion 521 at the upper end that is pressed by the water container, when the water container 43 enters around the second mounting part 412, while the water tank 41 is deviated from the installation position by a predetermined range and is disposed inside the housing 10.

- the head portion 521 of the second guide member 52 may be disposed at the rear of the second mounting portion 412 on which the water container 43 is mounted.

- the head portion 521 of the second guide member 52 is pressed by the water container 43 when the water container 43 enters around the second mounting portion 412, while the water tank 41 is deviated from the installation position in the front of the housing 10 by a predetermined range and is disposed inside the housing 10, and the water tank 41 is moved to the rear by the pressing force.

- the head portion 521 of the second guide member 52 may be provided with an inclined portion 521a which is formed to be inclined downward from the inside toward the second mounting portion 412. In this way, when the head portion 521 of the second guide member 52 is provided with an inclined portion 521a which is inclined downward from the inside to the outside, a part of the valve member 432 of the water container 43 may descend along the inclined portion 521a and provide mobility effectively to the rear side of the water tank 41 in the process where the water container 43 enters the second mounting portion 412 of the water tank 41.

- the head portions 521 of the first guide member 51 and the second guide member 52 are disposed at the rear of the second mounting portion 412, respectively, and may be disposed in parallel with each other. In this way, when the guide unit 50 is provided with both of the first guide member 51 and the second guide member 52, the transfer of the pressing force by the water bottle 43 may be transferred to the water tank 41 more reliably and stably when the water tank 43 enters while the water tank 41 is incorrectly mounted, and as a result, the movement of the water tank 41 to the installation position may be secured more reliably.

- FIG. 6 is a view showing a state in which a water tank is displaced and positioned away from an installation position in an air purifier according to an exemplary embodiment of the present invention

- FIG. 7 is a view showing a state in which a water tank is moved to an installation position by pressing a first guide member and a second guide member while a water container is mounted on the water tank in FIG. 6 .

- the water container 43 may not be mounted in the correct position such that the humidification function may not be performed normally.

- the guide unit 50 that is, the first guide member 51 and the second guide member 52 come into contact with the valve member 432 of the water container 43.

- the first guide member 51 and the second guide member 52 of the guide unit 50 are pressed by the load of the water container 43 or the force by the pressing of the user, and accordingly, mobility (F) is transferred to the rear side of the water tank 41.

- mobility (F) is transferred to the rear side of the water tank 41.

- the water tank 41 moves to the rear and is placed in the correct position, and the water container 43 may be normally fastened to the second mounting portion 412.

- the proper position of the water tank 41 and the normal coupling of the water container 43 may be made when the water container 43 is mounted, and accordingly, the humidification function may be performed normally.

- the second guide member 52 is provided around the second mounting portion 412, and is formed as a flow path switch that opens the flow path between the water container 43 and the water tank 41 in a pressed state to supply water in the water container 43 to the water tank 41, and closes the flow path between the water container 43 and the water tank 41 in an unpressed state.

- the configuration and function of the second guide member 52 as a flow path switch will be described with reference to FIGS. 8 and 9 .

- the second guide member 52 is exposed around the second mounting portion 412, and a head portion 521, which is formed to be pressed by the flow path setting unit 60, which will be described below, in the humidification mode, is provided on one side, and a pressing portion 522, which is disposed to press the opening/closing portion 432a of the valve member 432 when the head portion 521 is pressed, is provided on the other side.

- the guide unit 50 is provided with a body portion 523 which is disposed to connect between the head portion 521 and the pressing portion 522, and is also provided with a rotation shaft portion 524 which is formed between the body portion 523 and the head portion 521 to rotate the second guide member 52 such that the pressing portion 522 presses the opening/closing portion 432a when the head portion 521 is pressed.

- the second guide member 52 is configured such that when the head portion 521 is pressed, a seesaw movement is performed around the rotation shaft portion 524 to raise the pressing portion 522 to press the opening/closing portion 432a to open, and when the pressing of the head portion 521 is released, the pressing portion 522 is lowered by the self-weight of the second guide member 52 or the elastic force of an elastic member (not illustrated) to close the opening/closing portion 432a.

- the flow path setting unit 60 is rotatably disposed in the air flow path inside the housing 10 to control the air flow to discharge ports 111 and 122. As shown in FIG. 3 , the flow path setting unit 60 is configured to set a flow path such that the air filtered by passing through the filter unit 30 may be discharged through at least one of the first discharge port 111 and the second discharge port 122.

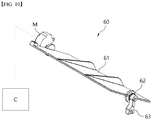

- the flow path setting unit 60 is provided with a body portion 61 formed to cross the air flow path to open or close at least a portion of the air flow path, a rotation shaft portion 62 forming a rotational center of the body portion 61, and a pressing portion 63 for pressing the head portion 51 of the guide unit 50 as the body portion 61 rotates around the rotation shaft portion 62.

- the flow path setting unit 60 may be configured to be rotated by a driving unit M made of a motor and the like. Accordingly, by controlling the driving unit M through the control unit C, the flow path setting unit 60 may be rotated.

- the housing 10 is provided with an inner wall 114 defining an air flow path therein, and the second guide member 52 is located outside the inner wall 114.

- the body portion 61 of the flow path setting part 60 is located on the air flow path inside the inner wall 114, and the pressing portion 63 of the flow path setting unit 60 penetrates the inner wall 114 and is disposed outside the air flow path so as to press the head portion 521 of the second guide member 52.

- the flow path setting unit 60 is positioned in the vertical direction so as to flow filtered air A2 in the direction of the first discharge port 111 formed on the upper portion of the housing 10.

- the body portion 61 of the flow path setting part 60 is positioned in the vertical direction, the filtered air A2 blown from the air blowing unit 20 is induced to be discharged through the first discharge port 111 formed on the upper portion of the housing 10 due to the flow path resistance of the humidifying member 42.

- the pressing portion 63 of the flow path setting unit 60 is spaced apart from the head portion 521 of the second guide member 52, the pressing portion 522 of the second guide member 52 does not press the opening/closing portion 432a of the valve member 432. Accordingly, the opening/closing portion 432a maintains a closed state, and water is not supplied from the water container 43 to the water tank 41.

- the flow path setting unit 60 is disposed to be inclined such that filtered air A2 rising from the lower portion of the housing 10 is guided toward the humidifying unit 40 to block air flow toward the first discharge port 111.

- the upper end of the body portion 61 of the flow path setting unit 60 is adjacent to the inner partition wall W partitioning the air flow path of the housing 10, and the lower end is adjacent to the opposite side of the partition wall (W).

- the rise of air is blocked, and the flowing air is introduced into the humidifying unit 40 through a penetration hole WH formed in the partition wall W.

- the air blown by the air blowing unit 20 becomes filtered humidified air (A3) that is humidified through the humidifying member 42 of the humidifying unit 40 and discharged to the outside of the housing 10 through the second discharge port 122.

- the pressing portion 63 of the flow path setting unit 60 contacts the head portion 521 of the second guide member 52 such that it becomes a state where the head portion 521 is pressed, the head portion 521 of the second guide member 52 moves in a downward direction based on the rotation shaft portion 523, and the pressing portion 522 moves in an upward direction based on the rotation shaft portion 523. Accordingly, the pressing portion 522 of the second guide member 52 presses the opening/closing portion 432a of the valve member 432 upward such that the opening/closing portion 432a moves upward. Accordingly, the opening/closing portion 432a is in an open state such that water is supplied from the water container 43 to the water tank 41.

- the flow path setting unit 60 may have a third position (drying mode position) located between the clean mode position and the humidification mode position. In this case, drying of the humidifying member 42 and/or the water tank 41 may be performed.

- the upper end of the flow path setting unit 60 is slightly spaced from the partition wall (W) partitioning the air flow path, and the lower end is slightly spaced from the opposite side of the partition wall (W) such that some air flows upward, and some air is introduced into the humidifying unit 40 through the penetration hole WH formed in the partition wall W.

- the air passing through the humidifying member 42 may perform drying of the humidifying member 42.

- the humidifying member 42 may have a structure capable of absorbing water accommodated in the water tank 41, and in this case, the water accommodated in the water tank 41 may be dried according to the drying of the humidifying member 42.

- the position of the flow path setting unit 60 in the drying mode may be set to sufficiently secure the amount of air blown to the humidifying unit 40.

- the position of the flow path setting unit 60 in the drying mode may be configured to a slightly rotated degree from a humidification mode position so as to release the contact between the pressing portion 63 and the head portion 521 of the second guide member 52 such that the opening/closing portion 432a may be closed.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Air Humidification (AREA)

Abstract

Description

- This application claims priority to and the benefit of Korean Patent Application No

10-2020-0061550 filed on May 22, 2020 - The present invention relates to an air purifier, and more specifically, the present invention relates to an air purifier as a humidified air purifier in which a water tank can be detached, and when the water tank is mounted, even if it is incorrectly positioned to deviate from the normal installation position, it is configured to move the water tank to the normal installation position in the process of mounting a water container in the water tank, and thus, it is possible to prevent incorrect mounting of a water tank.

- An air purifier is a device that forcibly inhales and purifies contaminated external air, and then discharges purified filtered air to the outside. Recently, in order to increase the utilization of air purifiers, air purifiers, to which additional other functions are added in addition to the air purifying function, have been introduced. An example of this is a humidified air purifier to which a humidifying function is added.

- The humidified air purifier needs management such as washing the water tank and the like to perform the humidifying function. For this purpose, the water tank is generally provided in a detachable form.

- If the humidified air purifier provides a structure in which the water tank can be detached, there is a possibility that in the process of removing and remounting a water tank during use, the user may place it slightly out of position from the normal installation position in the housing. If the water tank is positioned incorrectly, the fastening between the water tank and the water container may not be properly performed, and the performance of the humidifying function may become impossible. Although the inability of the humidifying function can be easily resolved by correcting the position of the water tank, if the user recognizes it as a malfunction, it may lead to unnecessary repair requests and unfair image degradation of the product, and thus, improvement is required.

- Meanwhile, conventional humidified air purifiers generally have a structure in which a water tank, a water container, and the like are detached in the lateral direction of the air purifier. For example, "the humidified air purifier" of Korean Patent Laid-Open No.

10-2019-0029819 10-2018-0073361 -

- (Patent Document 0001) Korean Patent Laid-Open No.

10-2019-0029819 - (Patent Document 0002) Korean Patent Laid-Open No.

10-2018-0073361 - In order to solve the above problems, the air purifier according to the present invention, which is capable of detaching a water tank, aims to prevent incorrect mounting of a water tank, by moving the water tank to the correction position by a guide unit which is pressed by a water container in the process of mounting the water container on the water tank, even when the water tank is displaced and positioned away from the installation position.

- Even when a water tank is displaced and positioned away from the installation position, the air purifier according to an exemplary embodiment of the present invention aims to prevent incorrect mounting of a water tank more effectively, because a guide unit that is pressed by a water container in the process of mounting the water container on the water tank to allow the water tank to move to the correct position is doubly configured.

- The air purifier according to an exemplary embodiment of the present invention aims to improve user convenience through a structure in which a water tank can be detached from the front and a water container can be detached from the top.

- In order to solve the above problems, the air purifier according to the present invention includes a housing; an air blowing unit for providing an air blowing force such that external air is introduced into the housing; a filter unit disposed inside the housing to filter the external air introduced into the housing to make filtered air; and a humidifying unit disposed inside the housing to humidify the filtered air passing through the filter unit, wherein the humidifying unit includes a water tank in which a mounting portion is formed, a humidifying member mounted on one side of the mounting portion to receive water from the water tank and supply moisture to the filtered air, and a water container mounted on the other side of the mounting portion to supply water to the water tank, wherein the water tank is formed detachably from an installation position inside the housing to the outside of the housing, and further includes a guide unit protruding upwardly around the other side of the mounting portion on which the water container is mounted, wherein the guide unit is pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position by a predetermined range and is disposed inside the housing, and wherein the water tank is moved in the direction of the installation position by a pressing force provided by the guide unit, when the guide unit is pressed by the water container.

- In the air purifier according to an exemplary embodiment of the present invention, the water tank is formed detachably from the installation position to the front of the housing, wherein the guide unit is pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position to the front of the housing by a predetermined range and is disposed inside the housing, and wherein the water tank is moved to the rear by the pressing force.

- In the air purifier according to an exemplary embodiment of the present invention, the housing is provided with a water container insertion port on the upper surface, and the water container enters the mounting portion in a downward direction through the water container insertion port.

- In the air purifier according to an exemplary embodiment of the present invention, the guide unit includes a first guide member formed of a wall extending forward from the rear sidewall of the water tank.

- In the air purifier according to an exemplary embodiment of the present invention, the first guide member is provided with an inclined portion inclined upward from the front end to the rear side on the upper surface.

- In the air purifier according to an exemplary embodiment of the present invention, the guide unit includes a second guide member provided around the mounting portion, wherein the second guide member includes at an upper end a head portion pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position by a predetermined range and is disposed inside the housing, and wherein the second guide member opens a flow path between the water container and the water tank in a pressed state to supply water in the water container to the water tank, and is formed by a flow path switch that closes the flow path between the water container and the water tank in an unpressed state.

- In the air purifier according to an exemplary embodiment of the present invention, the water tank is formed detachably from the installation position to the front of the housing, wherein the head portion of the second guide member is pressed by the water container when the water container enters around the mounting portion while the water tank is deviated from the installation position to the front of the housing by a predetermined range and is disposed inside the housing, and wherein the water tank is moved to the rear by the pressing force.

- In the air purifier according to an exemplary embodiment of the present invention, the head portion of the second guide member is provided with an inclined portion formed to be inclined downwardly from the inside outwardly toward the mounting portion.

- In the air purifier according to an exemplary embodiment of the present invention, the head portion of the second guide member is disposed at the rear of the mounting portion on which the water tank is mounted.

- In the air purifier according to an exemplary embodiment of the present invention, a groove or protrusion is formed at a predetermined position on inner surfaces of one sidewall and the other sidewall of the housing forming the installation position, and wherein a protrusion inserted into the groove or a groove inserted into the protrusion at the installation position is formed on the outer surfaces of one sidewall and the other sidewall of the water tank.

- According to the above configurations, the air purifier according to the present invention, which is capable of detaching a water tank, provides an effect of preventing incorrect mounting of a water tank, by moving the water tank to the correction position by a guide unit which is pressed by a water container in the process of mounting the water container on the water tank, even when the water tank is displaced and positioned away from the installation position.

- Even when a water tank is displaced and positioned away from the installation position, the air purifier according to an exemplary embodiment of the present invention provides an effect of preventing incorrect mounting of a water tank more effectively, because a guide unit that is pressed by a water container in the process of mounting the water container on the water tank to allow the water tank to move to the correct position is doubly configured.

- The air purifier according to an exemplary embodiment of the present invention provides an effect of improving user convenience through a structure in which a water tank can be detached from the front and a water container can be detached from the top.

-

-

FIG. 1 is a perspective view of an air purifier according to an exemplary embodiment of the present invention. -

FIG. 2 is an exploded perspective view of an air purifier according to an exemplary embodiment of the present invention. -

FIG. 3 is an illustration of an air purifier according to an exemplary embodiment of the present invention, in which the lower portion is a longitudinal cross-sectional view of the central portion, and the upper portion is a cross-sectional view taken along line A-A' ofFIG. 1 while the water container is partially removed. -

FIG. 4 is a perspective view of a humidifying unit of an air purifier according to an exemplary embodiment of the present invention. -

FIG. 5 is an exploded perspective view of a humidifying unit of an air purifier according to an exemplary embodiment of the present invention. -

FIG. 6 is a view showing a state in which a water tank is displaced and positioned away from an installation position in an air purifier according to an exemplary embodiment of the present invention. -

FIG. 7 is a view showing a state in which a water tank is moved to an installation position by pressing a first guide member and a second guide member while a water container is mounted on the water tank inFIG. 6 . -

FIG. 8 is a perspective view of a second guide member of an air purifier according to an exemplary embodiment of the present invention. -

FIG. 9 is a cross-sectional perspective view taken along line A-A' ofFIG. 1 after partially removing a water container from an air purifier according to an exemplary embodiment of the present invention. -

FIG. 10 is a perspective view of a flow path setting unit of an air purifier according to an exemplary embodiment of the present invention. -

FIG. 11 is a view showing a clean mode state with respect to part B ofFIG. 3 . -

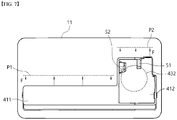

FIG. 12 is a view showing a humidification mode state with respect to part B ofFIG. 3 . -

FIG. 13 is a view showing a drying mode state with respect to part B ofFIG. 3 . - Words and terms used in the present specification and claims are not limited and interpreted to the conventional or dictionary meanings, and in accordance with the principle that the inventors may define terms and concepts in order to describe their invention in the best way, these should be interpreted as meanings and concepts consistent with the technical spirit of the present invention.

- Since the exemplary embodiment described in the present specification and the configuration illustrated in the drawings correspond to a preferred exemplary embodiment of the present invention and do not represent all of the technical spirit of the present invention, the corresponding configuration may have various equivalents and modifications to replace the same at the time of filing of the present invention.

- In the present specification, terms such as "include" or "have" are intended to describe the presence of features, numbers, steps, operations, components, parts, or a combination thereof described in the specification, but it is to be understood that it does not preclude the possibility of the presence or addition of one or more other features, numbers, steps, operations, components, parts, or a combination thereof.

- That a component is at the "front", "rear", "above", or "below" of another component not only includes cases where, unless otherwise specified, it is in direct contact with another component and is disposed at the "front", "rear", "above", or "below", but also cases where other components are placed in the middle. In addition, that a component is "connected" with another component includes cases where, unless otherwise specified, it is in direct contact with each other, but also cases where it is indirectly connected to each other.

-

FIG. 1 is a perspective view of an air purifier according to an exemplary embodiment of the present invention, andFIG. 2 is an exploded perspective view of an air purifier according to an exemplary embodiment of the present invention. In addition,FIG. 3 is an illustration of an air purifier according to an exemplary embodiment of the present invention, in which the lower portion is a longitudinal cross-sectional view of the central portion, and the upper portion is a cross-sectional view taken along line A-A' ofFIG. 1 while the body portion of the water container is removed. - In the

air purifier 1 according to an exemplary embodiment of the present invention, ahumidifying unit 40 is disposed above the filter unit 30. Accordingly, theair purifier 1 may perform a function as a humidifier in addition to purifying air. More specifically, the external air A1 is introduced into anintake port 121 formed in the lower front portion of a housing 10 of theair purifier 1 and is filtered by a filter unit 30. Then, it is discharged as filtered air A2 through afirst discharge port 111 formed on the upper portion of the housing 10 without passing through ahumidifying unit 40 according to the flow path setting within the air purifier 100, or it is discharged as filtered humidified air A3 through thehumidifying unit 40 after filtration and through asecond discharge port 122 formed in the upper front portion of the housing. - Referring to

FIGS. 1 to 3 , theair purifier 1 according to an exemplary embodiment of the present invention is configured to include a housing 10, anair blowing unit 20, a filter unit 30, ahumidifying unit 40, a guide unit 50, and a flowpath setting unit 60. - Hereinafter, each configuration of the

air purifier 1 according to an exemplary embodiment of the present invention will be described in detail. - The housing 10 forms the outer shape of the

air purifier 1. The housing 10 provides a space in which theair blowing unit 20, the filter unit 30, thehumidifying unit 40, the guide unit 50, and the flowpath setting unit 60 may be disposed. In addition, on the outer surface of the housing 10, anintake port 121 through which external air A1 is introduced, afirst discharge port 111 through which filtered air A2 is discharged, asecond discharge port 122 through which filtered humidified air A3 is discharged, a watercontainer insertion port 112 for insertion of awater container 43, which will be described later, and the like are formed. - The housing 10 may include a housing

main body 11 and afront cover 12. The housingmain body 11 may be formed in an open front surface to provide a space in which theair blowing unit 20, the filter unit 30, thehumidifying unit 40, the guide unit 50, and the flowpath setting unit 60 are arranged. In addition, thefront cover 12 is disposed to cover the front surface of the housingmain body 11. - The

first discharge port 111 and the watercontainer insertion port 112 are formed on the upper surface of the housingmain body 11. In this way, when the watercontainer insertion port 112 is provided on the upper surface of the housing 10, thewater container 43 of thehumidifying unit 40 may enter in a downward direction through the watercontainer insertion port 112 and be mounted in thewater tank 41 of thehumidifying unit 40. On the contrary, it may be withdrawn in an upward direction of theair purifier 1 when it is separated from thewater tank 41. - In addition, an

intake port 121 for inflow of external air A1 is formed in the lower portion of thefront cover 12, and asecond discharge port 122 is formed in the upper portion of thefront cover 12. In an exemplary embodiment of the present invention, thefirst discharge port 111 is formed in a grill shape, and theintake port 121 and thesecond discharge port 122 are formed by a plurality of through holes formed by penetrating through thefront cover 12. - Meanwhile, both sides of the

front cover 12 are formed to extend in the rear (on the side of the housingmain body 11 in the drawing), and include a recessedportion 123 which is formed to be recessed forwardly in the upper portion thereof. The recessedportion 123 prevents noise from being generated by receiving excessive flow path resistance from the filtered humidified air A3 that is discharged from thesecond discharge port 122, and by providing a passage through which some filtered humidified air A3 may be discharged, it may reduce noise in the process of using theair purifier 1. - In an exemplary embodiment of the present invention, the housing 10 forms a square cylindrical shape in a state in which the housing

main body 11 and thefront cover 12 are coupled. Certainly, the shape of the housing 10 is not limited thereto, and may have other shapes. In addition, the positions and shapes of theintake port 121, thefirst discharge port 111, and thesecond discharge port 122 may also be changed as necessary. For example, theintake port 121 may be formed on a plurality of surfaces of the front, rear, left, and right sides of the housing 10 so as to inhale air in various directions, and the locations, shapes, and the like of thefirst discharge port 111 and thesecond discharge port 122 may also be changed as needed. - The

air blowing unit 20 provides an air blowing force such that external air A1 is introduced into the housing 10. In addition, theair blowing unit 20 provides a flow force such that the air filtered inside the housing 10 may be discharged to the outside. More specifically, theair blowing unit 20 provides an air blowing force such that after the external air A1 introduced into theintake port 121 passes through afilter member 31 of the filter unit 30 and becomes filtered air A2, it flows toward the first discharge port or the second discharge port. Specifically, theair blowing unit 20 may be configured to include a motor, an impeller, and the like. - The

air blowing unit 20 is disposed behind the filter unit 30 at the lower side inside the housing 10. Certainly, the location and shape of theair blowing unit 20 are not limited thereto, and may be changed depending on design needs. - The filter unit 30 is disposed on the lower side inside the housing 10, and filters external air A1 to make filtered air A2. The filter unit 30 includes a

filter member 31 through which the external air A1 passes through and is filtered. In addition, a pre-filter 32 may be disposed between the front of thefilter member 31 and the rear of thefront cover 12 with a plurality ofinlet holes 32a through which the external air A1 passes through. - The

filter member 31 may be made of a dust collecting filter such as an ultra-low penetration air (ULPA) filter, a high efficiency particulate air (HEPA) filter, and a medium filter that collects and filters fine particulate matters of 0.1 µm to 0.3 µm or particulate matters of 0.3 µm or more contained in the air, or a functional filter that filters bacteria or microorganisms contained in the inhaled air. - Meanwhile, in an exemplary embodiment of the present invention, the pre-filter 32 is formed in a square lattice shape. However, this is an example, and the pre-filter 32 is not limited thereto and may be formed in various shapes depending on dust collection efficiency.

- The

humidifying unit 40 humidifies the filtered air A2 that has passed through the filter unit 30. In the air purifier 100 according to an exemplary embodiment of the present invention, thehumidifying unit 40 is disposed on the upper side of the filter unit 30. When a flow path is formed to perform humidification after filtration, the filtered air A2 filtered through thefilter member 31 of the filter unit 30 flows to thehumidifying unit 40, and thehumidifying unit 40 forms filtered humidified air A3 by supplying moisture to the filtered air A2. - Referring to

FIGS. 2 to 5 , thehumidifying unit 40 of theair purifier 1 according to an exemplary embodiment of the present invention is configured to include awater tank 41, a humidifyingmember 42, and awater container 43. - The

water tank 41 includes mountingportions portions portion 411 on which ahumidifying member 42 is mounted, and a second mountingportion 412 on which awater container 43 for supplying water, which is to be supplied to the humidifyingmember 42, to thewater tank 41 is mounted. The first mountingportion 411 and the second mountingportion 412 may be disposed adjacent to each other. Specifically, the first mountingportion 411 may be formed on one side of thewater tank 41, and the second mountingportion 412 may be formed on the other side of thewater tank 41 adjacent to the first mountingportion 411. - In addition, the

water tank 41 is formed detachably from the installation position inside the housing 10 to the outside of the housing 10. More specifically, in an exemplary embodiment of the present invention, thewater tank 41 is formed detachably to the front of the housing 10. Accordingly, according to an exemplary embodiment of the present invention, even if the space is narrow due to the presence of other items on the side surface of theair purifier 1, the user may easily perform detachment of thewater tank 41, because only thefront cover 12 may be removed from the usage position of theair purifier 1 to detach thewater tank 41. - Meanwhile, the

water tank 41 is provided with awater receiving portion 413 for storing water overflowed from thewater tank 41. Thewater receiving portion 413 prevents water inside thewater tank 41 from overflowing when an external force is applied when thewater tank 41 is detached or in the process of using theair purifier 1. Thewater receiving portion 413 may be provided in the front of thewater tank 41. Specifically, thewater receiving portion 413 may be provided to be connected to the front of thewater tank 41 such that thefront sidewalls 41a of the mountingportions water tank 41 become the rear sidewall of thewater receiving portion 413. - The height of the

front sidewall 413a of thewater receiving portion 413 is formed to be equal to the height of thefront sidewalls 41a of the mountingportions water tank 41. In an exemplary embodiment of the present invention, the height of thefront sidewalls 41a of the mountingportions front sidewall 413a of thewater receiving portion 413 is formed such that the central portion is lower than both sides. This structure makes it possible to maximize the capacity of the water receiving portion while minimizing flow resistance applied to the filtered humidified air A3 that has passed through the humidifyingmember 42. - Meanwhile, as best shown in

FIG. 2 , in an exemplary embodiment of the present invention, agroove 113 may be formed at a predetermined position on the inner surfaces of one sidewall and the other sidewall of the housing 10 forming an installation position, and aprotrusion 414, which is formed to be inserted into thegroove 113 at the installation position, may be formed on the outer surfaces of one sidewall and the other sidewall of thewater tank 41. - Through such a

groove 113 andprotrusion 414, the user may easily determine whether thewater tank 41 is properly positioned at the established installation position when thewater tank 41 is inserted. Certainly, thegroove 113 and theprotrusion 414 may be formed opposite to each other. In other words, it is possible that a protrusion may be formed at a predetermined position on the inner surfaces of one sidewall and the other sidewall of the housing 10, and a groove may be formed on the outer surfaces of one sidewall and the other sidewall of thewater tank 41. - The humidifying

member 42 is mounted on the first mountingportion 411 to receive water from thewater tank 41 and supply moisture to the filtered air A2. The humidifyingmember 42 uses water supplied to the first mountingportion 411 of thewater tank 41 to perform humidification by evaporation (air-blowing type). In an exemplary embodiment of the present invention, the humidifyingmember 42 is installed in parallel with the front surface of the housing 10 at the rear of thesecond discharge port 122. - The humidifying

member 42 is disposed at the rear end of theair blowing unit 20 in the air flow path. When the humidifyingmember 42 is located at the front end of theair blowing unit 20 in the air flow path, the air having increased humidity passing through the humidifyingmember 42 passes through theair blowing unit 20, and thus, there may be a problem that causes a breakdown in theair blowing unit 20. When the flow path is formed in the humidification mode by the flowpath setting unit 60 to be described below, the external air A1 introduced by the operation of theair blowing unit 20 becomes filtered air A2 through thefilter member 31 of the filter unit 30. Then, through the humidifyingmember 42, it is discharged as filtered humidified air A3 through thesecond discharge port 122. - Meanwhile, the filter unit 30 is disposed at the front end of the

air blowing unit 20 on the air flow path, and the humidifyingmember 42 is disposed at the rear end of theair blowing unit 20. Thus, when only the air purifying function is performed according to the flow path setting of the flow path setting unit 180, the air filtered by the filter unit 30 is restricted from flowing to the humidifyingmember 42 such that air purifying efficiency may be increased. Accordingly, even if the impeller provided in theair blowing unit 20 is operated at a relatively low RPM and low power, a sufficient discharge amount may be secured, and noise may be reduced. - The humidifying

member 42 may be configured to have a material or shape having excellent hygroscopicity so as to sufficiently absorb water accommodated in thewater tank 41. For example, the humidifyingmember 42 may have a structure that is immersed in water accommodated in thewater tank 41. However, the humidifyingmember 42 is not limited to the above-described structure, and if vaporization humidification is possible, various forms of known vaporization humidification structures such as a rotationally operated disk form and the like may be used. - The

water container 43 is mounted on the second mountingportion 412 to supply water to thewater tank 41. The water supplied by thewater container 43 is supplied to the first mountingportion 411 of thewater tank 41 to immerse the humidifyingmember 42. In an exemplary embodiment of the present invention, thewater container 43 is configured to include a water containermain body 431 for accommodating water for humidification, and avalve member 432 that is opened and closed to allow the discharge of water accommodated in the water containermain body 431. - The

water container 43 has a structure that may be separated from theair purifier 1 such that water may be easily filled inside the water containermain body 431. In addition, thevalve member 432 may be installed in a cap structure that is screwed to the inlet (inlet port) of the water containermain body 431. - The

valve member 432 may be provided with an opening/closing portion 432a that is elastically supported by an elastic means (e.g., a spring), and may have a mechanical valve structure that maintains a closed state when the opening/closing portion 432a is not pressed and maintains an open state when the opening/closing portion 432a is pressed. Detailed contents related to the opening through the pressurization of the opening/closing portion 432a and the closing according to the release of the pressed state will be described below. - The guide unit 50 is formed to protrude upward around the second mounting

portion 412 of thewater tank 41 on which thewater container 43 is mounted. The guide unit 50 is pressed by thewater container 43 when thewater container 43 enters around the second mountingportion 412 while thewater tank 41 is deviated from the installation position in a predetermined range and is disposed inside the housing 10. When the guide unit 50 is pressed by thewater container 43, thewater tank 41 is moved in the direction of the installation position by the pressing force provided to the guide unit 50. - When the front and rear directions of the

air purifier 1 into which thewater tank 41 is inserted are established as standard, the guide unit 50 may be formed at the rear of the second mountingportion 412. Accordingly, when thewater tank 41 is deviated from the normal installation position in a predetermined range forward and is incorrectly disposed inside the housing 10, thewater tank 41 is pressed by thewater container 43 in contact with the guide unit 50 and may be moved to the correct position at the rear, when thewater container 43 enters around the second mountingpart 412. - The guide unit 50 may include any one or more of a

first guide member 51 and asecond guide member 52. - The

first guide member 51 may be formed as a wall extending forward from therear sidewalls 41b of the mountingportions first guide member 51 may be formed as a wall extending forward from therear sidewall 41b of the second mountingportion 412 of thewater tank 41. - The

first guide member 51 may include aninclined portion 51a inclined upward from the front end to the rear side on the upper surface. In this way, when thefirst guide member 51 includes aninclined portion 51a that is inclined upward from the front end to the rear side, a part of thevalve member 432 of thewater container 43 may descend along aninclined portion 51a and provide mobility effectively to the rear side of thewater tank 41 in the process where thewater container 43 enters the second mountingportion 412 of thewater tank 41. - The

second guide member 52 may be provided around the second mountingportion 412 and open the flow path between thewater container 43 and thewater tank 41 in a pressed state to supply water in thewater container 43 to thewater tank 41, and it may be formed as a flow path switch that closes the flow path between thewater container 43 and thewater tank 41 in an unpressed state. Thesecond guide member 52 is provided with ahead portion 521 at the upper end that is pressed by the water container, when thewater container 43 enters around the second mountingpart 412, while thewater tank 41 is deviated from the installation position by a predetermined range and is disposed inside the housing 10. In this case, thehead portion 521 of thesecond guide member 52 may be disposed at the rear of the second mountingportion 412 on which thewater container 43 is mounted. - The

head portion 521 of thesecond guide member 52 is pressed by thewater container 43 when thewater container 43 enters around the second mountingportion 412, while thewater tank 41 is deviated from the installation position in the front of the housing 10 by a predetermined range and is disposed inside the housing 10, and thewater tank 41 is moved to the rear by the pressing force. - The

head portion 521 of thesecond guide member 52 may be provided with aninclined portion 521a which is formed to be inclined downward from the inside toward the second mountingportion 412. In this way, when thehead portion 521 of thesecond guide member 52 is provided with aninclined portion 521a which is inclined downward from the inside to the outside, a part of thevalve member 432 of thewater container 43 may descend along theinclined portion 521a and provide mobility effectively to the rear side of thewater tank 41 in the process where thewater container 43 enters the second mountingportion 412 of thewater tank 41. - In an exemplary embodiment of the present invention, the

head portions 521 of thefirst guide member 51 and thesecond guide member 52 are disposed at the rear of the second mountingportion 412, respectively, and may be disposed in parallel with each other. In this way, when the guide unit 50 is provided with both of thefirst guide member 51 and thesecond guide member 52, the transfer of the pressing force by thewater bottle 43 may be transferred to thewater tank 41 more reliably and stably when thewater tank 43 enters while thewater tank 41 is incorrectly mounted, and as a result, the movement of thewater tank 41 to the installation position may be secured more reliably. -

FIG. 6 is a view showing a state in which a water tank is displaced and positioned away from an installation position in an air purifier according to an exemplary embodiment of the present invention, andFIG. 7 is a view showing a state in which a water tank is moved to an installation position by pressing a first guide member and a second guide member while a water container is mounted on the water tank inFIG. 6 . - Referring to

FIG. 6 , when thewater tank 41 is inserted from the front of the air purifier 10, it is incorrectly positioned because it is not sufficiently pushed to the correct position, and the first mountingportion 411 and the second mountingportion 412 are spaced apart at a predetermined interval forward from the rear normal position reference line P1 of the first mountingpart 411 and the normal position reference line P2 of the second mountingpart 412. - In this state, if the

water container 43 is mounted while thewater tank 41 is not moved to the originally established installation position, thewater container 43 may not be mounted in the correct position such that the humidification function may not be performed normally. - As shown in

FIG. 7 , according to an exemplary embodiment of the present invention, when thewater container 43 enters in the lower direction through a watercontainer insertion hole 112 formed on the upper surface of the housing 10, the guide unit 50, that is, thefirst guide member 51 and thesecond guide member 52 come into contact with thevalve member 432 of thewater container 43. Thefirst guide member 51 and thesecond guide member 52 of the guide unit 50 are pressed by the load of thewater container 43 or the force by the pressing of the user, and accordingly, mobility (F) is transferred to the rear side of thewater tank 41. As a result, thewater tank 41 moves to the rear and is placed in the correct position, and thewater container 43 may be normally fastened to the second mountingportion 412. Therefore, even if thewater tank 41 is incorrectly fastened due to the user's carelessness, the proper position of thewater tank 41 and the normal coupling of thewater container 43 may be made when thewater container 43 is mounted, and accordingly, the humidification function may be performed normally. - As described above, the