EP3598967B1 - Personal cleansing compositions, methods and uses - Google Patents

Personal cleansing compositions, methods and uses Download PDFInfo

- Publication number

- EP3598967B1 EP3598967B1 EP18185894.5A EP18185894A EP3598967B1 EP 3598967 B1 EP3598967 B1 EP 3598967B1 EP 18185894 A EP18185894 A EP 18185894A EP 3598967 B1 EP3598967 B1 EP 3598967B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- surfactant

- composition

- personal cleansing

- sodium

- phase

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000203 mixture Substances 0.000 title claims description 336

- 238000000034 method Methods 0.000 title claims description 37

- 239000004094 surface-active agent Substances 0.000 claims description 156

- -1 fatty acyl isethionate Chemical compound 0.000 claims description 113

- 229920001282 polysaccharide Polymers 0.000 claims description 86

- 239000005017 polysaccharide Substances 0.000 claims description 86

- 239000007788 liquid Substances 0.000 claims description 78

- 229920000642 polymer Polymers 0.000 claims description 68

- 229920001285 xanthan gum Polymers 0.000 claims description 64

- 239000000230 xanthan gum Substances 0.000 claims description 64

- 235000010493 xanthan gum Nutrition 0.000 claims description 64

- 229940082509 xanthan gum Drugs 0.000 claims description 64

- 239000005264 High molar mass liquid crystal Substances 0.000 claims description 46

- 239000004615 ingredient Substances 0.000 claims description 34

- 229910052708 sodium Inorganic materials 0.000 claims description 33

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 claims description 32

- 239000003795 chemical substances by application Substances 0.000 claims description 32

- 238000010998 test method Methods 0.000 claims description 32

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 claims description 30

- 125000004432 carbon atom Chemical group C* 0.000 claims description 30

- 239000011734 sodium Substances 0.000 claims description 29

- 230000008901 benefit Effects 0.000 claims description 26

- 229920001525 carrageenan Polymers 0.000 claims description 23

- SUMDYPCJJOFFON-UHFFFAOYSA-N isethionic acid Chemical compound OCCS(O)(=O)=O SUMDYPCJJOFFON-UHFFFAOYSA-N 0.000 claims description 22

- 125000000217 alkyl group Chemical group 0.000 claims description 19

- 239000000679 carrageenan Substances 0.000 claims description 18

- 229940113118 carrageenan Drugs 0.000 claims description 18

- 239000003945 anionic surfactant Substances 0.000 claims description 17

- 238000000518 rheometry Methods 0.000 claims description 17

- 239000011780 sodium chloride Substances 0.000 claims description 16

- 239000002888 zwitterionic surfactant Substances 0.000 claims description 16

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 claims description 15

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 15

- 239000003921 oil Substances 0.000 claims description 15

- 235000002639 sodium chloride Nutrition 0.000 claims description 15

- 230000003287 optical effect Effects 0.000 claims description 14

- 239000002245 particle Substances 0.000 claims description 14

- 150000008051 alkyl sulfates Chemical class 0.000 claims description 12

- 239000002280 amphoteric surfactant Substances 0.000 claims description 12

- 239000002736 nonionic surfactant Substances 0.000 claims description 12

- 229940071089 sarcosinate Drugs 0.000 claims description 12

- 229920006395 saturated elastomer Polymers 0.000 claims description 12

- 239000007864 aqueous solution Substances 0.000 claims description 11

- 239000003792 electrolyte Substances 0.000 claims description 11

- 150000004676 glycans Chemical class 0.000 claims description 11

- 229920002907 Guar gum Polymers 0.000 claims description 10

- 229920000161 Locust bean gum Polymers 0.000 claims description 10

- 239000006096 absorbing agent Substances 0.000 claims description 10

- 239000003623 enhancer Substances 0.000 claims description 10

- 239000000665 guar gum Substances 0.000 claims description 10

- 235000010417 guar gum Nutrition 0.000 claims description 10

- 229960002154 guar gum Drugs 0.000 claims description 10

- 235000010420 locust bean gum Nutrition 0.000 claims description 10

- 239000000711 locust bean gum Substances 0.000 claims description 10

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 claims description 9

- 125000003342 alkenyl group Chemical group 0.000 claims description 9

- 230000003750 conditioning effect Effects 0.000 claims description 9

- 229910052700 potassium Inorganic materials 0.000 claims description 9

- 229960003975 potassium Drugs 0.000 claims description 9

- 239000011591 potassium Substances 0.000 claims description 9

- WCUXLLCKKVVCTQ-UHFFFAOYSA-M Potassium chloride Chemical compound [Cl-].[K+] WCUXLLCKKVVCTQ-UHFFFAOYSA-M 0.000 claims description 8

- 125000002252 acyl group Chemical group 0.000 claims description 8

- 239000003086 colorant Substances 0.000 claims description 7

- 238000003801 milling Methods 0.000 claims description 7

- 239000000377 silicon dioxide Substances 0.000 claims description 7

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 claims description 6

- 238000004140 cleaning Methods 0.000 claims description 6

- 239000003094 microcapsule Substances 0.000 claims description 6

- 239000003605 opacifier Substances 0.000 claims description 6

- 239000000049 pigment Substances 0.000 claims description 6

- NLKNQRATVPKPDG-UHFFFAOYSA-M potassium iodide Chemical compound [K+].[I-] NLKNQRATVPKPDG-UHFFFAOYSA-M 0.000 claims description 6

- FSYKKLYZXJSNPZ-UHFFFAOYSA-N sarcosine Chemical compound C[NH2+]CC([O-])=O FSYKKLYZXJSNPZ-UHFFFAOYSA-N 0.000 claims description 6

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 claims description 6

- ZNOZWUKQPJXOIG-XSBHQQIPSA-L [(2r,3s,4r,5r,6s)-6-[[(1r,3s,4r,5r,8s)-3,4-dihydroxy-2,6-dioxabicyclo[3.2.1]octan-8-yl]oxy]-4-[[(1r,3r,4r,5r,8s)-8-[(2s,3r,4r,5r,6r)-3,4-dihydroxy-6-(hydroxymethyl)-5-sulfonatooxyoxan-2-yl]oxy-4-hydroxy-2,6-dioxabicyclo[3.2.1]octan-3-yl]oxy]-5-hydroxy-2-( Chemical compound O[C@@H]1[C@@H](O)[C@@H](OS([O-])(=O)=O)[C@@H](CO)O[C@H]1O[C@@H]1[C@@H]2OC[C@H]1O[C@H](O[C@H]1[C@H]([C@@H](CO)O[C@@H](O[C@@H]3[C@@H]4OC[C@H]3O[C@H](O)[C@@H]4O)[C@@H]1O)OS([O-])(=O)=O)[C@@H]2O ZNOZWUKQPJXOIG-XSBHQQIPSA-L 0.000 claims description 5

- 239000006224 matting agent Substances 0.000 claims description 5

- 239000003607 modifier Substances 0.000 claims description 5

- 239000012748 slip agent Substances 0.000 claims description 5

- UXVMQQNJUSDDNG-UHFFFAOYSA-L Calcium chloride Chemical compound [Cl-].[Cl-].[Ca+2] UXVMQQNJUSDDNG-UHFFFAOYSA-L 0.000 claims description 4

- 229910052783 alkali metal Inorganic materials 0.000 claims description 4

- 150000001340 alkali metals Chemical class 0.000 claims description 4

- 239000001110 calcium chloride Substances 0.000 claims description 4

- 229910001628 calcium chloride Inorganic materials 0.000 claims description 4

- ZCCIPPOKBCJFDN-UHFFFAOYSA-N calcium nitrate Chemical compound [Ca+2].[O-][N+]([O-])=O.[O-][N+]([O-])=O ZCCIPPOKBCJFDN-UHFFFAOYSA-N 0.000 claims description 4

- 239000001103 potassium chloride Substances 0.000 claims description 4

- 235000011164 potassium chloride Nutrition 0.000 claims description 4

- 239000001508 potassium citrate Substances 0.000 claims description 4

- 229960002635 potassium citrate Drugs 0.000 claims description 4

- QEEAPRPFLLJWCF-UHFFFAOYSA-K potassium citrate (anhydrous) Chemical compound [K+].[K+].[K+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O QEEAPRPFLLJWCF-UHFFFAOYSA-K 0.000 claims description 4

- 235000011082 potassium citrates Nutrition 0.000 claims description 4

- JHJLBTNAGRQEKS-UHFFFAOYSA-M sodium bromide Chemical compound [Na+].[Br-] JHJLBTNAGRQEKS-UHFFFAOYSA-M 0.000 claims description 4

- 239000001509 sodium citrate Substances 0.000 claims description 4

- 150000003871 sulfonates Chemical class 0.000 claims description 4

- JIAARYAFYJHUJI-UHFFFAOYSA-L zinc dichloride Chemical compound [Cl-].[Cl-].[Zn+2] JIAARYAFYJHUJI-UHFFFAOYSA-L 0.000 claims description 4

- WQZGKKKJIJFFOK-GASJEMHNSA-N Glucose Natural products OC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-GASJEMHNSA-N 0.000 claims description 3

- ULUAUXLGCMPNKK-UHFFFAOYSA-N Sulfobutanedioic acid Chemical class OC(=O)CC(C(O)=O)S(O)(=O)=O ULUAUXLGCMPNKK-UHFFFAOYSA-N 0.000 claims description 3

- 235000011148 calcium chloride Nutrition 0.000 claims description 3

- 239000008103 glucose Substances 0.000 claims description 3

- 150000003893 lactate salts Chemical class 0.000 claims description 3

- AGGIJOLULBJGTQ-UHFFFAOYSA-N sulfoacetic acid Chemical class OC(=O)CS(O)(=O)=O AGGIJOLULBJGTQ-UHFFFAOYSA-N 0.000 claims description 3

- 125000004178 (C1-C4) alkyl group Chemical group 0.000 claims description 2

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 claims description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 claims description 2

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 claims description 2

- 229910052784 alkaline earth metal Inorganic materials 0.000 claims description 2

- SWLVFNYSXGMGBS-UHFFFAOYSA-N ammonium bromide Chemical compound [NH4+].[Br-] SWLVFNYSXGMGBS-UHFFFAOYSA-N 0.000 claims description 2

- WDIHJSXYQDMJHN-UHFFFAOYSA-L barium chloride Chemical compound [Cl-].[Cl-].[Ba+2] WDIHJSXYQDMJHN-UHFFFAOYSA-L 0.000 claims description 2

- 229910001626 barium chloride Inorganic materials 0.000 claims description 2

- 229910001622 calcium bromide Inorganic materials 0.000 claims description 2

- WGEFECGEFUFIQW-UHFFFAOYSA-L calcium dibromide Chemical compound [Ca+2].[Br-].[Br-] WGEFECGEFUFIQW-UHFFFAOYSA-L 0.000 claims description 2

- 150000002190 fatty acyls Chemical group 0.000 claims description 2

- 229910052744 lithium Inorganic materials 0.000 claims description 2

- 229910052749 magnesium Inorganic materials 0.000 claims description 2

- 239000011777 magnesium Substances 0.000 claims description 2

- 235000015424 sodium Nutrition 0.000 claims description 2

- 229910052938 sodium sulfate Inorganic materials 0.000 claims description 2

- 235000011152 sodium sulphate Nutrition 0.000 claims description 2

- 239000011592 zinc chloride Substances 0.000 claims description 2

- 235000005074 zinc chloride Nutrition 0.000 claims description 2

- 239000012071 phase Substances 0.000 description 162

- 150000004804 polysaccharides Chemical class 0.000 description 77

- KWIUHFFTVRNATP-UHFFFAOYSA-N glycine betaine Chemical compound C[N+](C)(C)CC([O-])=O KWIUHFFTVRNATP-UHFFFAOYSA-N 0.000 description 42

- 230000035882 stress Effects 0.000 description 42

- 229960003237 betaine Drugs 0.000 description 26

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 23

- 229940079776 sodium cocoyl isethionate Drugs 0.000 description 19

- 238000002834 transmittance Methods 0.000 description 18

- 108700004121 sarkosyl Proteins 0.000 description 17

- KSAVQLQVUXSOCR-UHFFFAOYSA-M sodium lauroyl sarcosinate Chemical compound [Na+].CCCCCCCCCCCC(=O)N(C)CC([O-])=O KSAVQLQVUXSOCR-UHFFFAOYSA-M 0.000 description 17

- 229940045885 sodium lauroyl sarcosinate Drugs 0.000 description 17

- 239000000693 micelle Substances 0.000 description 15

- 239000000047 product Substances 0.000 description 15

- MRUAUOIMASANKQ-UHFFFAOYSA-N cocamidopropyl betaine Chemical compound CCCCCCCCCCCC(=O)NCCC[N+](C)(C)CC([O-])=O MRUAUOIMASANKQ-UHFFFAOYSA-N 0.000 description 13

- 235000019198 oils Nutrition 0.000 description 13

- WHUUTDBJXJRKMK-VKHMYHEASA-N L-glutamic acid Chemical compound OC(=O)[C@@H](N)CCC(O)=O WHUUTDBJXJRKMK-VKHMYHEASA-N 0.000 description 12

- 229930195712 glutamate Natural products 0.000 description 12

- 238000005259 measurement Methods 0.000 description 10

- 230000015572 biosynthetic process Effects 0.000 description 9

- 229940073507 cocamidopropyl betaine Drugs 0.000 description 9

- 239000003205 fragrance Substances 0.000 description 9

- 239000000499 gel Substances 0.000 description 9

- 239000004973 liquid crystal related substance Substances 0.000 description 9

- 230000003068 static effect Effects 0.000 description 9

- 239000003755 preservative agent Substances 0.000 description 8

- ZUFONQSOSYEWCN-UHFFFAOYSA-M sodium;2-(methylamino)acetate Chemical compound [Na+].CNCC([O-])=O ZUFONQSOSYEWCN-UHFFFAOYSA-M 0.000 description 8

- QXNVGIXVLWOKEQ-UHFFFAOYSA-N Disodium Chemical compound [Na][Na] QXNVGIXVLWOKEQ-UHFFFAOYSA-N 0.000 description 7

- 230000003098 cholesteric effect Effects 0.000 description 7

- 238000002360 preparation method Methods 0.000 description 7

- 230000002335 preservative effect Effects 0.000 description 7

- 108010077895 Sarcosine Proteins 0.000 description 6

- 238000000386 microscopy Methods 0.000 description 6

- 238000002156 mixing Methods 0.000 description 6

- 230000008569 process Effects 0.000 description 6

- 239000007787 solid Substances 0.000 description 6

- 239000006260 foam Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 239000000523 sample Substances 0.000 description 5

- 241000209140 Triticum Species 0.000 description 4

- 235000021307 Triticum Nutrition 0.000 description 4

- 230000032683 aging Effects 0.000 description 4

- 238000013459 approach Methods 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 4

- 229940071124 cocoyl glutamate Drugs 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

- 235000014113 dietary fatty acids Nutrition 0.000 description 4

- JOLYVEWZEPKDIJ-UTLKBRERSA-L dipotassium;(2s)-2-(dodecanoylamino)pentanedioate Chemical compound [K+].[K+].CCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O JOLYVEWZEPKDIJ-UTLKBRERSA-L 0.000 description 4

- HWUINYGRRJTXGE-UTLKBRERSA-L disodium;(2s)-2-(dodecanoylamino)pentanedioate Chemical compound [Na+].[Na+].CCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O HWUINYGRRJTXGE-UTLKBRERSA-L 0.000 description 4

- 239000000194 fatty acid Substances 0.000 description 4

- 229930195729 fatty acid Natural products 0.000 description 4

- 229930182478 glucoside Natural products 0.000 description 4

- 235000018102 proteins Nutrition 0.000 description 4

- 102000004169 proteins and genes Human genes 0.000 description 4

- 108090000623 proteins and genes Proteins 0.000 description 4

- 239000002453 shampoo Substances 0.000 description 4

- IKGKWKGYFJBGQJ-UHFFFAOYSA-M sodium;2-(dodecanoylamino)acetate Chemical compound [Na+].CCCCCCCCCCCC(=O)NCC([O-])=O IKGKWKGYFJBGQJ-UHFFFAOYSA-M 0.000 description 4

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 3

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 description 3

- 229940098323 ammonium cocoyl isethionate Drugs 0.000 description 3

- MRUAUOIMASANKQ-UHFFFAOYSA-O carboxymethyl-[3-(dodecanoylamino)propyl]-dimethylazanium Chemical compound CCCCCCCCCCCC(=O)NCCC[N+](C)(C)CC(O)=O MRUAUOIMASANKQ-UHFFFAOYSA-O 0.000 description 3

- 235000010418 carrageenan Nutrition 0.000 description 3

- 239000006071 cream Substances 0.000 description 3

- KCIDZIIHRGYJAE-YGFYJFDDSA-L dipotassium;[(2r,3r,4s,5r,6r)-3,4,5-trihydroxy-6-(hydroxymethyl)oxan-2-yl] phosphate Chemical compound [K+].[K+].OC[C@H]1O[C@H](OP([O-])([O-])=O)[C@H](O)[C@@H](O)[C@H]1O KCIDZIIHRGYJAE-YGFYJFDDSA-L 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 150000004665 fatty acids Chemical class 0.000 description 3

- 238000009472 formulation Methods 0.000 description 3

- 238000010316 high energy milling Methods 0.000 description 3

- 238000010348 incorporation Methods 0.000 description 3

- 229940075468 lauramidopropyl betaine Drugs 0.000 description 3

- 229940094506 lauryl betaine Drugs 0.000 description 3

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 3

- DVEKCXOJTLDBFE-UHFFFAOYSA-N n-dodecyl-n,n-dimethylglycinate Chemical compound CCCCCCCCCCCC[N+](C)(C)CC([O-])=O DVEKCXOJTLDBFE-UHFFFAOYSA-N 0.000 description 3

- 238000001907 polarising light microscopy Methods 0.000 description 3

- 229940048106 sodium lauroyl isethionate Drugs 0.000 description 3

- 229940060304 sodium myristoyl sarcosinate Drugs 0.000 description 3

- KHCOJQDJOCNUGV-UHFFFAOYSA-M sodium;2-[methyl(tetradecanoyl)amino]acetate Chemical compound [Na+].CCCCCCCCCCCCCC(=O)N(C)CC([O-])=O KHCOJQDJOCNUGV-UHFFFAOYSA-M 0.000 description 3

- BRMSVEGRHOZCAM-UHFFFAOYSA-M sodium;2-dodecanoyloxyethanesulfonate Chemical compound [Na+].CCCCCCCCCCCC(=O)OCCS([O-])(=O)=O BRMSVEGRHOZCAM-UHFFFAOYSA-M 0.000 description 3

- RTVVXRKGQRRXFJ-UHFFFAOYSA-N sodium;2-sulfobutanedioic acid Chemical compound [Na].OC(=O)CC(C(O)=O)S(O)(=O)=O RTVVXRKGQRRXFJ-UHFFFAOYSA-N 0.000 description 3

- 239000000243 solution Substances 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- DDGPBVIAYDDWDH-UHFFFAOYSA-N 3-[dodecyl(dimethyl)azaniumyl]-2-hydroxypropane-1-sulfonate Chemical compound CCCCCCCCCCCC[N+](C)(C)CC(O)CS([O-])(=O)=O DDGPBVIAYDDWDH-UHFFFAOYSA-N 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 2

- 229910019142 PO4 Inorganic materials 0.000 description 2

- 241000206572 Rhodophyta Species 0.000 description 2

- 235000021355 Stearic acid Nutrition 0.000 description 2

- QNAYBMKLOCPYGJ-UHFFFAOYSA-M alaninate Chemical compound CC(N)C([O-])=O QNAYBMKLOCPYGJ-UHFFFAOYSA-M 0.000 description 2

- 125000000129 anionic group Chemical group 0.000 description 2

- 239000008346 aqueous phase Substances 0.000 description 2

- 239000002585 base Substances 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 239000013256 coordination polymer Substances 0.000 description 2

- 239000002537 cosmetic Substances 0.000 description 2

- 239000013078 crystal Substances 0.000 description 2

- 238000010790 dilution Methods 0.000 description 2

- 239000012895 dilution Substances 0.000 description 2

- PXEDJBXQKAGXNJ-QTNFYWBSSA-L disodium L-glutamate Chemical compound [Na+].[Na+].[O-]C(=O)[C@@H](N)CCC([O-])=O PXEDJBXQKAGXNJ-QTNFYWBSSA-L 0.000 description 2

- 229940079779 disodium cocoyl glutamate Drugs 0.000 description 2

- QKQCPXJIOJLHAL-UHFFFAOYSA-L disodium;2-[2-(carboxylatomethoxy)ethyl-[2-(dodecanoylamino)ethyl]amino]acetate Chemical compound [Na+].[Na+].CCCCCCCCCCCC(=O)NCCN(CC([O-])=O)CCOCC([O-])=O QKQCPXJIOJLHAL-UHFFFAOYSA-L 0.000 description 2

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000000839 emulsion Substances 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 150000002191 fatty alcohols Chemical class 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 238000005187 foaming Methods 0.000 description 2

- 235000021588 free fatty acids Nutrition 0.000 description 2

- 238000005227 gel permeation chromatography Methods 0.000 description 2

- 150000008131 glucosides Chemical class 0.000 description 2

- BXWNKGSJHAJOGX-UHFFFAOYSA-N hexadecan-1-ol Chemical compound CCCCCCCCCCCCCCCCO BXWNKGSJHAJOGX-UHFFFAOYSA-N 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 229940071145 lauroyl sarcosinate Drugs 0.000 description 2

- 239000006210 lotion Substances 0.000 description 2

- 230000003020 moisturizing effect Effects 0.000 description 2

- LPUQAYUQRXPFSQ-DFWYDOINSA-M monosodium L-glutamate Chemical compound [Na+].[O-]C(=O)[C@@H](N)CCC(O)=O LPUQAYUQRXPFSQ-DFWYDOINSA-M 0.000 description 2

- GLDOVTGHNKAZLK-UHFFFAOYSA-N octadecan-1-ol Chemical compound CCCCCCCCCCCCCCCCCCO GLDOVTGHNKAZLK-UHFFFAOYSA-N 0.000 description 2

- QIQXTHQIDYTFRH-UHFFFAOYSA-N octadecanoic acid Chemical compound CCCCCCCCCCCCCCCCCC(O)=O QIQXTHQIDYTFRH-UHFFFAOYSA-N 0.000 description 2

- OQCDKBAXFALNLD-UHFFFAOYSA-N octadecanoic acid Natural products CCCCCCCC(C)CCCCCCCCC(O)=O OQCDKBAXFALNLD-UHFFFAOYSA-N 0.000 description 2

- 238000000399 optical microscopy Methods 0.000 description 2

- 239000002304 perfume Substances 0.000 description 2

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 2

- 239000010452 phosphate Substances 0.000 description 2

- UEZVMMHDMIWARA-UHFFFAOYSA-M phosphonate Chemical compound [O-]P(=O)=O UEZVMMHDMIWARA-UHFFFAOYSA-M 0.000 description 2

- 229940082006 potassium cocoyl glutamate Drugs 0.000 description 2

- 229940099874 potassium lauroyl glutamate Drugs 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000013049 sediment Substances 0.000 description 2

- 229940079781 sodium cocoyl glutamate Drugs 0.000 description 2

- 229940065859 sodium cocoyl glycinate Drugs 0.000 description 2

- 229940045944 sodium lauroyl glutamate Drugs 0.000 description 2

- 229940045888 sodium myristoyl isethionate Drugs 0.000 description 2

- NTYZDAJPNNBYED-UHFFFAOYSA-M sodium;2-(2-dodecanoyloxypropanoyloxy)propanoate Chemical compound [Na+].CCCCCCCCCCCC(=O)OC(C)C(=O)OC(C)C([O-])=O NTYZDAJPNNBYED-UHFFFAOYSA-M 0.000 description 2

- MCFLGJDKSROECH-KVVVOXFISA-M sodium;2-[(z)-octadec-9-enoyl]oxyethanesulfonate Chemical compound [Na+].CCCCCCCC\C=C/CCCCCCCC(=O)OCCS([O-])(=O)=O MCFLGJDKSROECH-KVVVOXFISA-M 0.000 description 2

- KWFZLOFTBBTQIE-UHFFFAOYSA-M sodium;2-hexadecanoyloxyethanesulfonate Chemical compound [Na+].CCCCCCCCCCCCCCCC(=O)OCCS([O-])(=O)=O KWFZLOFTBBTQIE-UHFFFAOYSA-M 0.000 description 2

- LEEHDJJMXGSXDH-UHFFFAOYSA-M sodium;2-octadecanoyloxyethanesulfonate Chemical compound [Na+].CCCCCCCCCCCCCCCCCC(=O)OCCS([O-])(=O)=O LEEHDJJMXGSXDH-UHFFFAOYSA-M 0.000 description 2

- WEXQJKLTLYEHLQ-UHFFFAOYSA-M sodium;2-tetradecanoyloxyethanesulfonate Chemical compound [Na+].CCCCCCCCCCCCCC(=O)OCCS([O-])(=O)=O WEXQJKLTLYEHLQ-UHFFFAOYSA-M 0.000 description 2

- 230000007928 solubilization Effects 0.000 description 2

- 238000005063 solubilization Methods 0.000 description 2

- 230000003381 solubilizing effect Effects 0.000 description 2

- 239000008117 stearic acid Substances 0.000 description 2

- DIORMHZUUKOISG-UHFFFAOYSA-N sulfoformic acid Chemical compound OC(=O)S(O)(=O)=O DIORMHZUUKOISG-UHFFFAOYSA-N 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- 239000003760 tallow Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 230000000699 topical effect Effects 0.000 description 2

- 150000004043 trisaccharides Chemical class 0.000 description 2

- DCQFFOLNJVGHLW-RDQKPOQOSA-N (1r,3s,4r,5s,8s)-2,6-dioxabicyclo[3.2.1]octane-3,4,8-triol Chemical compound O1[C@H](O)[C@H](O)[C@H]2OC[C@@H]1[C@@H]2O DCQFFOLNJVGHLW-RDQKPOQOSA-N 0.000 description 1

- TUBPSFQENHCYBW-HVDRVSQOSA-N (2s)-2-aminopentanedioic acid;2-[bis(2-hydroxyethyl)amino]ethanol Chemical compound OC(=O)[C@@H](N)CCC(O)=O.OCCN(CCO)CCO TUBPSFQENHCYBW-HVDRVSQOSA-N 0.000 description 1

- FYGDTMLNYKFZSV-WFYNLLPOSA-N (2s,3r,4s,5s,6r)-2-[(2r,4r,5r,6s)-4,5-dihydroxy-2-(hydroxymethyl)-6-[(2r,3s,4r,5r,6s)-4,5,6-trihydroxy-2-(hydroxymethyl)oxan-3-yl]oxyoxan-3-yl]oxy-6-(hydroxymethyl)oxane-3,4,5-triol Chemical compound O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@H]1OC1[C@@H](CO)O[C@@H](O[C@@H]2[C@H](O[C@H](O)[C@H](O)[C@H]2O)CO)[C@H](O)[C@H]1O FYGDTMLNYKFZSV-WFYNLLPOSA-N 0.000 description 1

- LUEWUZLMQUOBSB-FSKGGBMCSA-N (2s,3s,4s,5s,6r)-2-[(2r,3s,4r,5r,6s)-6-[(2r,3s,4r,5s,6s)-4,5-dihydroxy-2-(hydroxymethyl)-6-[(2r,4r,5s,6r)-4,5,6-trihydroxy-2-(hydroxymethyl)oxan-3-yl]oxyoxan-3-yl]oxy-4,5-dihydroxy-2-(hydroxymethyl)oxan-3-yl]oxy-6-(hydroxymethyl)oxane-3,4,5-triol Chemical compound O[C@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@H]1O[C@@H]1[C@@H](CO)O[C@@H](O[C@@H]2[C@H](O[C@@H](OC3[C@H](O[C@@H](O)[C@@H](O)[C@H]3O)CO)[C@@H](O)[C@H]2O)CO)[C@H](O)[C@H]1O LUEWUZLMQUOBSB-FSKGGBMCSA-N 0.000 description 1

- QURLONWWPWCPIC-UHFFFAOYSA-N 2-(2-aminoethoxy)ethanol;3,6-dichloro-2-methoxybenzoic acid Chemical compound NCCOCCO.COC1=C(Cl)C=CC(Cl)=C1C(O)=O QURLONWWPWCPIC-UHFFFAOYSA-N 0.000 description 1

- HZAXFHJVJLSVMW-UHFFFAOYSA-N 2-Aminoethan-1-ol Chemical compound NCCO HZAXFHJVJLSVMW-UHFFFAOYSA-N 0.000 description 1

- ACCAIGJKLCJFHP-UQKRIMTDSA-N 2-[bis(2-hydroxyethyl)amino]ethanol;(2s)-2-(dodecanoylamino)pentanedioic acid Chemical compound OCCN(CCO)CCO.CCCCCCCCCCCC(=O)N[C@H](C(O)=O)CCC(O)=O ACCAIGJKLCJFHP-UQKRIMTDSA-N 0.000 description 1

- BEABHZRODBBUAU-UHFFFAOYSA-N 2-[bis(2-hydroxyethyl)amino]ethanol;2-(methylamino)acetic acid Chemical compound CNCC(O)=O.OCCN(CCO)CCO BEABHZRODBBUAU-UHFFFAOYSA-N 0.000 description 1

- FUUGOUJDTGRGMR-GMFCBQQYSA-N 2-[bis(2-hydroxyethyl)amino]ethanol;2-[methyl-[(z)-octadec-9-enoyl]amino]acetic acid Chemical compound OCCN(CCO)CCO.CCCCCCCC\C=C/CCCCCCCC(=O)N(C)CC(O)=O FUUGOUJDTGRGMR-GMFCBQQYSA-N 0.000 description 1

- AMRBZKOCOOPYNY-QXMHVHEDSA-N 2-[dimethyl-[(z)-octadec-9-enyl]azaniumyl]acetate Chemical compound CCCCCCCC\C=C/CCCCCCCC[N+](C)(C)CC([O-])=O AMRBZKOCOOPYNY-QXMHVHEDSA-N 0.000 description 1

- HJDITXMCJQRQLU-UHFFFAOYSA-N 2-[dodecanoyl(methyl)amino]acetate;tris(2-hydroxyethyl)azanium Chemical compound OCCN(CCO)CCO.CCCCCCCCCCCC(=O)N(C)CC(O)=O HJDITXMCJQRQLU-UHFFFAOYSA-N 0.000 description 1

- IXOCGRPBILEGOX-UHFFFAOYSA-N 3-[3-(dodecanoylamino)propyl-dimethylazaniumyl]-2-hydroxypropane-1-sulfonate Chemical compound CCCCCCCCCCCC(=O)NCCC[N+](C)(C)CC(O)CS([O-])(=O)=O IXOCGRPBILEGOX-UHFFFAOYSA-N 0.000 description 1

- WQPMYSHJKXVTME-UHFFFAOYSA-N 3-hydroxypropane-1-sulfonic acid Chemical compound OCCCS(O)(=O)=O WQPMYSHJKXVTME-UHFFFAOYSA-N 0.000 description 1

- CYDQOEWLBCCFJZ-UHFFFAOYSA-N 4-(4-fluorophenyl)oxane-4-carboxylic acid Chemical compound C=1C=C(F)C=CC=1C1(C(=O)O)CCOCC1 CYDQOEWLBCCFJZ-UHFFFAOYSA-N 0.000 description 1

- 229920000189 Arabinogalactan Polymers 0.000 description 1

- 229920002498 Beta-glucan Polymers 0.000 description 1

- 241000195940 Bryophyta Species 0.000 description 1

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 1

- 229920002101 Chitin Polymers 0.000 description 1

- 229920001661 Chitosan Polymers 0.000 description 1

- 208000001840 Dandruff Diseases 0.000 description 1

- RWSOTUBLDIXVET-UHFFFAOYSA-N Dihydrogen sulfide Chemical class S RWSOTUBLDIXVET-UHFFFAOYSA-N 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 229920000926 Galactomannan Polymers 0.000 description 1

- 229920002581 Glucomannan Polymers 0.000 description 1

- 229920001202 Inulin Polymers 0.000 description 1

- 239000004976 Lyotropic liquid crystal Substances 0.000 description 1

- 229920000057 Mannan Polymers 0.000 description 1

- 239000004909 Moisturizer Substances 0.000 description 1

- SGAQYTGHTWYTNW-UHFFFAOYSA-N NCCO.CCCCCCCCCCCC(N)=O Chemical compound NCCO.CCCCCCCCCCCC(N)=O SGAQYTGHTWYTNW-UHFFFAOYSA-N 0.000 description 1

- GNMAJAFGCGXYGH-ZOWNYOTGSA-M N[C@@H](CCC(=O)[O-])C(=O)OC(CCCCCCCCC=C)=O.[Na+] Chemical compound N[C@@H](CCC(=O)[O-])C(=O)OC(CCCCCCCCC=C)=O.[Na+] GNMAJAFGCGXYGH-ZOWNYOTGSA-M 0.000 description 1

- ACAXXPXMEBRGLB-IZHYLRJQSA-L N[C@@H](CCC(=O)[O-])C(=O)OC(CCCCCCCCC=C)=O.[Na+].[Na+].C(CCCCCCCCC=C)(=O)OC([C@@H](N)CCC(=O)[O-])=O Chemical compound N[C@@H](CCC(=O)[O-])C(=O)OC(CCCCCCCCC=C)=O.[Na+].[Na+].C(CCCCCCCCC=C)(=O)OC([C@@H](N)CCC(=O)[O-])=O ACAXXPXMEBRGLB-IZHYLRJQSA-L 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 229920001218 Pullulan Polymers 0.000 description 1

- 239000004373 Pullulan Substances 0.000 description 1

- 239000004990 Smectic liquid crystal Substances 0.000 description 1

- 241000589636 Xanthomonas campestris Species 0.000 description 1

- 229920002000 Xyloglucan Polymers 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000013019 agitation Methods 0.000 description 1

- 235000010443 alginic acid Nutrition 0.000 description 1

- 229920000615 alginic acid Polymers 0.000 description 1

- 125000001931 aliphatic group Chemical group 0.000 description 1

- 150000003973 alkyl amines Chemical class 0.000 description 1

- 150000003863 ammonium salts Chemical class 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 230000000845 anti-microbial effect Effects 0.000 description 1

- 239000004599 antimicrobial Substances 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 235000006708 antioxidants Nutrition 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 235000019312 arabinogalactan Nutrition 0.000 description 1

- 229920000617 arabinoxylan Polymers 0.000 description 1

- 150000004783 arabinoxylans Chemical class 0.000 description 1

- 238000000149 argon plasma sintering Methods 0.000 description 1

- 235000003704 aspartic acid Nutrition 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- VDXDJNXCULYUIU-UHFFFAOYSA-N azane 2-dodecoxy-2-oxoethanesulfonic acid Chemical compound N.CCCCCCCCCCCCOC(=O)CS(O)(=O)=O VDXDJNXCULYUIU-UHFFFAOYSA-N 0.000 description 1

- OCSIXPGPUXCISD-UHFFFAOYSA-N azane;2-[dodecanoyl(methyl)amino]acetic acid Chemical compound N.CCCCCCCCCCCC(=O)N(C)CC(O)=O OCSIXPGPUXCISD-UHFFFAOYSA-N 0.000 description 1

- LLOHIFXFHGMBNO-UHFFFAOYSA-N azane;2-hydroxyethanesulfonic acid Chemical compound [NH4+].OCCS([O-])(=O)=O LLOHIFXFHGMBNO-UHFFFAOYSA-N 0.000 description 1

- WQZGKKKJIJFFOK-FPRJBGLDSA-N beta-D-galactose Chemical compound OC[C@H]1O[C@@H](O)[C@H](O)[C@@H](O)[C@H]1O WQZGKKKJIJFFOK-FPRJBGLDSA-N 0.000 description 1

- 125000001488 beta-D-galactosyl group Chemical group C1([C@H](O)[C@@H](O)[C@@H](O)[C@H](O1)CO)* 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000000872 buffer Substances 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 239000001768 carboxy methyl cellulose Substances 0.000 description 1

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 1

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 229920006317 cationic polymer Polymers 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 229960000541 cetyl alcohol Drugs 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000012512 characterization method Methods 0.000 description 1

- 239000002738 chelating agent Substances 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 229940096362 cocoamphoacetate Drugs 0.000 description 1

- 229940047648 cocoamphodiacetate Drugs 0.000 description 1

- 239000003240 coconut oil Substances 0.000 description 1

- 235000019864 coconut oil Nutrition 0.000 description 1

- 239000008406 cosmetic ingredient Substances 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 229940073499 decyl glucoside Drugs 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- SHLKYEAQGUCTIO-UHFFFAOYSA-N diazanium;4-dodecoxy-4-oxo-3-sulfobutanoate Chemical compound [NH4+].[NH4+].CCCCCCCCCCCCOC(=O)C(S(O)(=O)=O)CC([O-])=O.CCCCCCCCCCCCOC(=O)C(S(O)(=O)=O)CC([O-])=O SHLKYEAQGUCTIO-UHFFFAOYSA-N 0.000 description 1

- DRTBPCASGTVPLF-VWLOTQADSA-N didodecanoyl (2s)-2-aminopentanedioate Chemical compound CCCCCCCCCCCC(=O)OC(=O)CC[C@H](N)C(=O)OC(=O)CCCCCCCCCCC DRTBPCASGTVPLF-VWLOTQADSA-N 0.000 description 1

- 238000007865 diluting Methods 0.000 description 1

- 239000003085 diluting agent Substances 0.000 description 1

- 239000000539 dimer Substances 0.000 description 1

- 125000000118 dimethyl group Chemical group [H]C([H])([H])* 0.000 description 1

- YWGWUEXUIOPNMW-FJSYBICCSA-L dipotassium;(2s)-2-(octadecanoylamino)pentanedioate Chemical compound [K+].[K+].CCCCCCCCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O YWGWUEXUIOPNMW-FJSYBICCSA-L 0.000 description 1

- TWRWROOHGNQOQC-XRIOVQLTSA-L dipotassium;(2s)-2-(octanoylamino)pentanedioate Chemical compound [K+].[K+].CCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O TWRWROOHGNQOQC-XRIOVQLTSA-L 0.000 description 1

- IKNWNODSTRNMLD-SQKCAUCHSA-L dipotassium;(2s)-2-(tetradecanoylamino)pentanedioate Chemical compound [K+].[K+].CCCCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O IKNWNODSTRNMLD-SQKCAUCHSA-L 0.000 description 1

- ACNAFCGCINVEDL-GXKRWWSZSA-L dipotassium;(2s)-2-(undec-10-enoylamino)pentanedioate Chemical compound [K+].[K+].[O-]C(=O)CC[C@@H](C([O-])=O)NC(=O)CCCCCCCCC=C ACNAFCGCINVEDL-GXKRWWSZSA-L 0.000 description 1

- 125000000600 disaccharide group Chemical group 0.000 description 1

- 229940079868 disodium laureth sulfosuccinate Drugs 0.000 description 1

- 229940079881 disodium lauroamphodiacetate Drugs 0.000 description 1

- 229940079886 disodium lauryl sulfosuccinate Drugs 0.000 description 1

- 229940047038 disodium myristoyl glutamate Drugs 0.000 description 1

- 229940079784 disodium stearoyl glutamate Drugs 0.000 description 1

- WODOUQLMOIMKAL-FJSYBICCSA-L disodium;(2s)-2-(octadecanoylamino)pentanedioate Chemical compound [Na+].[Na+].CCCCCCCCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O WODOUQLMOIMKAL-FJSYBICCSA-L 0.000 description 1

- JRHWWJSWHFFZRY-XRIOVQLTSA-L disodium;(2s)-2-(octanoylamino)pentanedioate Chemical compound [Na+].[Na+].CCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O JRHWWJSWHFFZRY-XRIOVQLTSA-L 0.000 description 1

- SXBBFOVRSQCYFE-SQKCAUCHSA-L disodium;(2s)-2-(tetradecanoylamino)pentanedioate Chemical compound [Na+].[Na+].CCCCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O SXBBFOVRSQCYFE-SQKCAUCHSA-L 0.000 description 1

- GLSRFBDXBWZNLH-UHFFFAOYSA-L disodium;2-chloroacetate;2-(4,5-dihydroimidazol-1-yl)ethanol;hydroxide Chemical compound [OH-].[Na+].[Na+].[O-]C(=O)CCl.OCCN1CCN=C1 GLSRFBDXBWZNLH-UHFFFAOYSA-L 0.000 description 1

- YGAXLGGEEQLLKV-UHFFFAOYSA-L disodium;4-dodecoxy-4-oxo-2-sulfonatobutanoate Chemical compound [Na+].[Na+].CCCCCCCCCCCCOC(=O)CC(C([O-])=O)S([O-])(=O)=O YGAXLGGEEQLLKV-UHFFFAOYSA-L 0.000 description 1

- KHIQYZGEUSTKSB-UHFFFAOYSA-L disodium;4-dodecoxy-4-oxo-3-sulfobutanoate Chemical compound [Na+].[Na+].CCCCCCCCCCCCOC(=O)C(S(O)(=O)=O)CC([O-])=O.CCCCCCCCCCCCOC(=O)C(S(O)(=O)=O)CC([O-])=O KHIQYZGEUSTKSB-UHFFFAOYSA-L 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 239000012153 distilled water Substances 0.000 description 1

- GVGUFUZHNYFZLC-UHFFFAOYSA-N dodecyl benzenesulfonate;sodium Chemical compound [Na].CCCCCCCCCCCCOS(=O)(=O)C1=CC=CC=C1 GVGUFUZHNYFZLC-UHFFFAOYSA-N 0.000 description 1

- JRBPAEWTRLWTQC-UHFFFAOYSA-N dodecylamine Chemical compound CCCCCCCCCCCCN JRBPAEWTRLWTQC-UHFFFAOYSA-N 0.000 description 1

- SYELZBGXAIXKHU-UHFFFAOYSA-N dodecyldimethylamine N-oxide Chemical compound CCCCCCCCCCCC[N+](C)(C)[O-] SYELZBGXAIXKHU-UHFFFAOYSA-N 0.000 description 1

- 239000003974 emollient agent Substances 0.000 description 1

- 238000011067 equilibration Methods 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 150000002194 fatty esters Chemical class 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000004088 foaming agent Substances 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 229940083124 ganglion-blocking antiadrenergic secondary and tertiary amines Drugs 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229940046240 glucomannan Drugs 0.000 description 1

- 125000002791 glucosyl group Chemical group C1([C@H](O)[C@@H](O)[C@H](O)[C@H](O1)CO)* 0.000 description 1

- 229940049906 glutamate Drugs 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 230000036571 hydration Effects 0.000 description 1

- 238000006703 hydration reaction Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 230000009878 intermolecular interaction Effects 0.000 description 1

- 229940029339 inulin Drugs 0.000 description 1

- JYJIGFIDKWBXDU-MNNPPOADSA-N inulin Chemical compound O[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)OC[C@]1(OC[C@]2(OC[C@]3(OC[C@]4(OC[C@]5(OC[C@]6(OC[C@]7(OC[C@]8(OC[C@]9(OC[C@]%10(OC[C@]%11(OC[C@]%12(OC[C@]%13(OC[C@]%14(OC[C@]%15(OC[C@]%16(OC[C@]%17(OC[C@]%18(OC[C@]%19(OC[C@]%20(OC[C@]%21(OC[C@]%22(OC[C@]%23(OC[C@]%24(OC[C@]%25(OC[C@]%26(OC[C@]%27(OC[C@]%28(OC[C@]%29(OC[C@]%30(OC[C@]%31(OC[C@]%32(OC[C@]%33(OC[C@]%34(OC[C@]%35(OC[C@]%36(O[C@@H]%37[C@@H]([C@@H](O)[C@H](O)[C@@H](CO)O%37)O)[C@H]([C@H](O)[C@@H](CO)O%36)O)[C@H]([C@H](O)[C@@H](CO)O%35)O)[C@H]([C@H](O)[C@@H](CO)O%34)O)[C@H]([C@H](O)[C@@H](CO)O%33)O)[C@H]([C@H](O)[C@@H](CO)O%32)O)[C@H]([C@H](O)[C@@H](CO)O%31)O)[C@H]([C@H](O)[C@@H](CO)O%30)O)[C@H]([C@H](O)[C@@H](CO)O%29)O)[C@H]([C@H](O)[C@@H](CO)O%28)O)[C@H]([C@H](O)[C@@H](CO)O%27)O)[C@H]([C@H](O)[C@@H](CO)O%26)O)[C@H]([C@H](O)[C@@H](CO)O%25)O)[C@H]([C@H](O)[C@@H](CO)O%24)O)[C@H]([C@H](O)[C@@H](CO)O%23)O)[C@H]([C@H](O)[C@@H](CO)O%22)O)[C@H]([C@H](O)[C@@H](CO)O%21)O)[C@H]([C@H](O)[C@@H](CO)O%20)O)[C@H]([C@H](O)[C@@H](CO)O%19)O)[C@H]([C@H](O)[C@@H](CO)O%18)O)[C@H]([C@H](O)[C@@H](CO)O%17)O)[C@H]([C@H](O)[C@@H](CO)O%16)O)[C@H]([C@H](O)[C@@H](CO)O%15)O)[C@H]([C@H](O)[C@@H](CO)O%14)O)[C@H]([C@H](O)[C@@H](CO)O%13)O)[C@H]([C@H](O)[C@@H](CO)O%12)O)[C@H]([C@H](O)[C@@H](CO)O%11)O)[C@H]([C@H](O)[C@@H](CO)O%10)O)[C@H]([C@H](O)[C@@H](CO)O9)O)[C@H]([C@H](O)[C@@H](CO)O8)O)[C@H]([C@H](O)[C@@H](CO)O7)O)[C@H]([C@H](O)[C@@H](CO)O6)O)[C@H]([C@H](O)[C@@H](CO)O5)O)[C@H]([C@H](O)[C@@H](CO)O4)O)[C@H]([C@H](O)[C@@H](CO)O3)O)[C@H]([C@H](O)[C@@H](CO)O2)O)[C@@H](O)[C@H](O)[C@@H](CO)O1 JYJIGFIDKWBXDU-MNNPPOADSA-N 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 230000007794 irritation Effects 0.000 description 1

- 229940045996 isethionic acid Drugs 0.000 description 1

- 229940115478 isopropyl lauroyl sarcosinate Drugs 0.000 description 1

- 229940048866 lauramine oxide Drugs 0.000 description 1

- 229940071188 lauroamphodiacetate Drugs 0.000 description 1

- 125000000400 lauroyl group Chemical group O=C([*])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 229940048848 lauryl glucoside Drugs 0.000 description 1

- IZWSFJTYBVKZNK-UHFFFAOYSA-N lauryl sulfobetaine Chemical compound CCCCCCCCCCCC[N+](C)(C)CCCS([O-])(=O)=O IZWSFJTYBVKZNK-UHFFFAOYSA-N 0.000 description 1

- AIHDCSAXVMAMJH-GFBKWZILSA-N levan Chemical compound O[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)OC[C@@H]1[C@@H](O)[C@H](O)[C@](CO)(CO[C@@H]2[C@H]([C@H](O)[C@@](O)(CO)O2)O)O1 AIHDCSAXVMAMJH-GFBKWZILSA-N 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 230000002535 lyotropic effect Effects 0.000 description 1

- LUEWUZLMQUOBSB-GFVSVBBRSA-N mannan Chemical class O[C@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@H]1O[C@@H]1[C@@H](CO)O[C@@H](O[C@@H]2[C@H](O[C@@H](O[C@H]3[C@H](O[C@@H](O)[C@@H](O)[C@H]3O)CO)[C@@H](O)[C@H]2O)CO)[C@H](O)[C@H]1O LUEWUZLMQUOBSB-GFVSVBBRSA-N 0.000 description 1

- 238000013507 mapping Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229920000609 methyl cellulose Polymers 0.000 description 1

- 239000001923 methylcellulose Substances 0.000 description 1

- 235000013336 milk Nutrition 0.000 description 1

- 210000004080 milk Anatomy 0.000 description 1

- 230000001333 moisturizer Effects 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 235000011929 mousse Nutrition 0.000 description 1

- 125000001419 myristoyl group Chemical group O=C([*])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- GOQYKNQRPGWPLP-UHFFFAOYSA-N n-heptadecyl alcohol Natural products CCCCCCCCCCCCCCCCCO GOQYKNQRPGWPLP-UHFFFAOYSA-N 0.000 description 1

- 229930014626 natural product Natural products 0.000 description 1

- 125000002811 oleoyl group Chemical group O=C([*])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])/C([H])=C([H])\C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 239000003002 pH adjusting agent Substances 0.000 description 1

- 239000003346 palm kernel oil Substances 0.000 description 1

- 235000019865 palm kernel oil Nutrition 0.000 description 1

- 125000001312 palmitoyl group Chemical group O=C([*])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- XYFCBTPGUUZFHI-UHFFFAOYSA-O phosphonium Chemical compound [PH4+] XYFCBTPGUUZFHI-UHFFFAOYSA-O 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229940079988 potassium cocoyl glycinate Drugs 0.000 description 1

- RJLXQRRDQRGFJR-ZOWNYOTGSA-M potassium;(2s)-5-hydroxy-5-oxo-2-(undec-10-enoylamino)pentanoate Chemical compound [K+].OC(=O)CC[C@@H](C([O-])=O)NC(=O)CCCCCCCCC=C RJLXQRRDQRGFJR-ZOWNYOTGSA-M 0.000 description 1

- KCQOKZAQSWTPIL-BDQAORGHSA-M potassium;(4s)-5-hydroxy-4-(octadecanoylamino)-5-oxopentanoate Chemical compound [H+].[K+].CCCCCCCCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O KCQOKZAQSWTPIL-BDQAORGHSA-M 0.000 description 1

- WONHSIFWFDNSCE-PPHPATTJSA-M potassium;(4s)-5-hydroxy-4-(octanoylamino)-5-oxopentanoate Chemical compound [H+].[K+].CCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O WONHSIFWFDNSCE-PPHPATTJSA-M 0.000 description 1

- KYLDDUZJZSKJER-NTISSMGPSA-M potassium;(4s)-5-hydroxy-5-oxo-4-(tetradecanoylamino)pentanoate Chemical compound [H+].[K+].CCCCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O KYLDDUZJZSKJER-NTISSMGPSA-M 0.000 description 1

- WLPORNKIACJZBO-UHFFFAOYSA-M potassium;2-(dodecanoylamino)acetate Chemical compound [K+].CCCCCCCCCCCC(=O)NCC([O-])=O WLPORNKIACJZBO-UHFFFAOYSA-M 0.000 description 1

- JEMLSRUODAIULV-UHFFFAOYSA-M potassium;2-[dodecanoyl(methyl)amino]acetate Chemical compound [K+].CCCCCCCCCCCC(=O)N(C)CC([O-])=O JEMLSRUODAIULV-UHFFFAOYSA-M 0.000 description 1

- XLCIFRJORZNGEV-UHFFFAOYSA-N propan-2-yl 2-[dodecanoyl(methyl)amino]acetate Chemical compound CCCCCCCCCCCC(=O)N(C)CC(=O)OC(C)C XLCIFRJORZNGEV-UHFFFAOYSA-N 0.000 description 1

- 239000003380 propellant Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 235000019423 pullulan Nutrition 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 239000006254 rheological additive Substances 0.000 description 1

- 150000003384 small molecules Chemical class 0.000 description 1

- 239000000344 soap Substances 0.000 description 1

- 229940096501 sodium cocoamphoacetate Drugs 0.000 description 1

- APSBXTVYXVQYAB-UHFFFAOYSA-M sodium docusate Chemical group [Na+].CCCCC(CC)COC(=O)CC(S([O-])(=O)=O)C(=O)OCC(CC)CCCC APSBXTVYXVQYAB-UHFFFAOYSA-M 0.000 description 1

- 229940080264 sodium dodecylbenzenesulfonate Drugs 0.000 description 1

- 229940045998 sodium isethionate Drugs 0.000 description 1

- 239000001540 sodium lactate Substances 0.000 description 1

- 235000011088 sodium lactate Nutrition 0.000 description 1

- 229940005581 sodium lactate Drugs 0.000 description 1

- 229940007636 sodium lauroyl methyl isethionate Drugs 0.000 description 1

- 229940075560 sodium lauryl sulfoacetate Drugs 0.000 description 1

- 229940048109 sodium methyl cocoyl taurate Drugs 0.000 description 1

- 229940077092 sodium myristoyl glutamate Drugs 0.000 description 1

- 229940045898 sodium stearoyl glutamate Drugs 0.000 description 1

- FCBUGCHAVCFTHW-NTISSMGPSA-N sodium;(2s)-2-(tetradecanoylamino)pentanedioic acid Chemical compound [Na].CCCCCCCCCCCCCC(=O)N[C@H](C(O)=O)CCC(O)=O FCBUGCHAVCFTHW-NTISSMGPSA-N 0.000 description 1

- KLIFRVSZGDONER-FERBBOLQSA-M sodium;(4s)-4-(hexadecanoylamino)-5-hydroxy-5-oxopentanoate Chemical compound [H+].[Na+].CCCCCCCCCCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O KLIFRVSZGDONER-FERBBOLQSA-M 0.000 description 1

- KDHFCTLPQJQDQI-BDQAORGHSA-M sodium;(4s)-4-amino-5-octadecanoyloxy-5-oxopentanoate Chemical compound [Na+].CCCCCCCCCCCCCCCCCC(=O)OC(=O)[C@@H](N)CCC([O-])=O KDHFCTLPQJQDQI-BDQAORGHSA-M 0.000 description 1

- BCGXTKYOBWQPCN-PPHPATTJSA-M sodium;(4s)-5-hydroxy-4-(octanoylamino)-5-oxopentanoate Chemical compound [H+].[Na+].CCCCCCCC(=O)N[C@H](C([O-])=O)CCC([O-])=O BCGXTKYOBWQPCN-PPHPATTJSA-M 0.000 description 1

- SLBXZQMMERXQAL-UHFFFAOYSA-M sodium;1-dodecoxy-4-hydroxy-1,4-dioxobutane-2-sulfonate Chemical compound [Na+].CCCCCCCCCCCCOC(=O)C(S(O)(=O)=O)CC([O-])=O SLBXZQMMERXQAL-UHFFFAOYSA-M 0.000 description 1

- HVFAVOFILADWEZ-UHFFFAOYSA-M sodium;2-[2-(dodecanoylamino)ethyl-(2-hydroxyethyl)amino]acetate Chemical compound [Na+].CCCCCCCCCCCC(=O)NCCN(CCO)CC([O-])=O HVFAVOFILADWEZ-UHFFFAOYSA-M 0.000 description 1

- CAVXVRQDZKMZDB-UHFFFAOYSA-M sodium;2-[dodecanoyl(methyl)amino]ethanesulfonate Chemical compound [Na+].CCCCCCCCCCCC(=O)N(C)CCS([O-])(=O)=O CAVXVRQDZKMZDB-UHFFFAOYSA-M 0.000 description 1

- AUHKUMFBHOJIMU-UHFFFAOYSA-M sodium;2-[hexadecanoyl(methyl)amino]acetate Chemical compound [Na+].CCCCCCCCCCCCCCCC(=O)N(C)CC([O-])=O AUHKUMFBHOJIMU-UHFFFAOYSA-M 0.000 description 1

- VLKIFCBXANYYCK-GMFCBQQYSA-M sodium;2-[methyl-[(z)-octadec-9-enoyl]amino]acetate Chemical compound [Na+].CCCCCCCC\C=C/CCCCCCCC(=O)N(C)CC([O-])=O VLKIFCBXANYYCK-GMFCBQQYSA-M 0.000 description 1

- IZWPGJFSBABFGL-GMFCBQQYSA-M sodium;2-[methyl-[(z)-octadec-9-enoyl]amino]ethanesulfonate Chemical compound [Na+].CCCCCCCC\C=C/CCCCCCCC(=O)N(C)CCS([O-])(=O)=O IZWPGJFSBABFGL-GMFCBQQYSA-M 0.000 description 1

- HYHAWELIVMOSBT-UHFFFAOYSA-M sodium;2-aminopentadecanoate Chemical compound [Na+].CCCCCCCCCCCCCC(N)C([O-])=O HYHAWELIVMOSBT-UHFFFAOYSA-M 0.000 description 1

- NVIZQHFCDBQNPH-UHFFFAOYSA-M sodium;2-dodecanoyloxypropane-1-sulfonate Chemical compound [Na+].CCCCCCCCCCCC(=O)OC(C)CS([O-])(=O)=O NVIZQHFCDBQNPH-UHFFFAOYSA-M 0.000 description 1

- UAJTZZNRJCKXJN-UHFFFAOYSA-M sodium;2-dodecoxy-2-oxoethanesulfonate Chemical compound [Na+].CCCCCCCCCCCCOC(=O)CS([O-])(=O)=O UAJTZZNRJCKXJN-UHFFFAOYSA-M 0.000 description 1

- LADXKQRVAFSPTR-UHFFFAOYSA-M sodium;2-hydroxyethanesulfonate Chemical compound [Na+].OCCS([O-])(=O)=O LADXKQRVAFSPTR-UHFFFAOYSA-M 0.000 description 1

- IWMMSZLFZZPTJY-UHFFFAOYSA-M sodium;3-(dodecylamino)propane-1-sulfonate Chemical compound [Na+].CCCCCCCCCCCCNCCCS([O-])(=O)=O IWMMSZLFZZPTJY-UHFFFAOYSA-M 0.000 description 1

- DUXXGJTXFHUORE-UHFFFAOYSA-M sodium;4-tridecylbenzenesulfonate Chemical compound [Na+].CCCCCCCCCCCCCC1=CC=C(S([O-])(=O)=O)C=C1 DUXXGJTXFHUORE-UHFFFAOYSA-M 0.000 description 1

- 239000008247 solid mixture Substances 0.000 description 1

- 241000894007 species Species 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000010561 standard procedure Methods 0.000 description 1

- 229960004274 stearic acid Drugs 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 1

- 239000000375 suspending agent Substances 0.000 description 1

- 230000008719 thickening Effects 0.000 description 1

- 239000002562 thickening agent Substances 0.000 description 1

- 229940048912 triethanolamine cocoyl glutamate Drugs 0.000 description 1

- 238000005199 ultracentrifugation Methods 0.000 description 1

- 239000011782 vitamin Substances 0.000 description 1

- 229930003231 vitamin Natural products 0.000 description 1

- 229940088594 vitamin Drugs 0.000 description 1

- 235000013343 vitamin Nutrition 0.000 description 1

- 238000005303 weighing Methods 0.000 description 1

- UHVMMEOXYDMDKI-JKYCWFKZSA-L zinc;1-(5-cyanopyridin-2-yl)-3-[(1s,2s)-2-(6-fluoro-2-hydroxy-3-propanoylphenyl)cyclopropyl]urea;diacetate Chemical compound [Zn+2].CC([O-])=O.CC([O-])=O.CCC(=O)C1=CC=C(F)C([C@H]2[C@H](C2)NC(=O)NC=2N=CC(=CC=2)C#N)=C1O UHVMMEOXYDMDKI-JKYCWFKZSA-L 0.000 description 1

- 239000004711 α-olefin Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/46—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing sulfur

- A61K8/466—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing sulfur containing sulfonic acid derivatives; Salts

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/02—Cosmetics or similar toiletry preparations characterised by special physical form

- A61K8/0295—Liquid crystals

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/40—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing nitrogen

- A61K8/44—Aminocarboxylic acids or derivatives thereof, e.g. aminocarboxylic acids containing sulfur; Salts; Esters or N-acylated derivatives thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/73—Polysaccharides

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/73—Polysaccharides

- A61K8/731—Cellulose; Quaternized cellulose derivatives

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/73—Polysaccharides

- A61K8/736—Chitin; Chitosan; Derivatives thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q19/00—Preparations for care of the skin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q19/00—Preparations for care of the skin

- A61Q19/10—Washing or bathing preparations

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q5/00—Preparations for care of the hair

- A61Q5/02—Preparations for cleaning the hair

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K2800/00—Properties of cosmetic compositions or active ingredients thereof or formulation aids used therein and process related aspects

- A61K2800/20—Chemical, physico-chemical or functional or structural properties of the composition as a whole

- A61K2800/30—Characterized by the absence of a particular group of ingredients

Definitions

- the present application generally relates to personal cleansing compositions, their methods of making such compositions, and their uses.

- the personal cleansing compositions have desirable rheologic properties and structure when the personal cleansing composition has a surfactant system comprising a fatty acyl isethionate surfactant and when the personal cleansing composition is free of alkyl sulfate and alkyl ether sulfate type of surfactants.

- Personal cleansing compositions have been traditionally marketed in a variety of forms such as bar soaps, creams, lotions, and gels. Typically, these products must satisfy a number of criteria to be acceptable to consumers. These criteria include cleansing effectiveness, skin feel, mildness to skin, hair, and ocular mucosae, and lather volume. Ideal personal cleansers should gently cleanse the skin or hair, cause little or no irritation, and should not leave the skin or hair overly dry after frequent use.

- Anionic surfactants are widely used in personal cleansing compositions. Many of these anionic surfactants contain elongated micelles and are viscoelastic, which is of great importance, especially in the design of shampoos and body washes. In most personal cleansing compositions, alkyl sulfate and alkyl ether sulfate as the anionic surfactants predominate.

- sulfate-free personal cleansing compositions are difficult to thicken sufficiently to afford the user good usage qualities.

- Two approaches are leveraged to attempt to thicken such formulas.

- One approach for instance is to use high levels of surfactants to benefit from the self-assembling properties of such ingredients. This approach is most common but it is also costly.

- the second approach for instance is to use high levels of rheology modifiers which can adversely impact the properties of the composition such as by decreasing the foam and ease of distribution of the composition.

- WO 2011/120780 A2 is related to super mild surfactant systems, optionally in combination with skin or hair benefit agent.

- WO2008/074617 A1 is related to liquid cleanser compositions which can use fatty acyl isethionates mixtures, regardless of free fatty acid content of isethionates mixture or chain length distribution of isethionates mixture.

- Personal cleansing compositions having a surfactant system comprising a fatty acyl isethionate surfactant and being free of alkyl sulfate and alkyl ether sulfate type of surfactants have been developed.

- Fatty acyl isethionates are mild anionic surfactants highly desirable in personal cleansing products for hair or skin, because fatty acyl isethionates can lather well, are mild to the skin and have good emollient properties.

- fatty acyl isethionates are not readily used in liquid personal cleansing compositions, because of their relatively low solubility in water. This may result in unstable personal cleansing compositions which can exhibit inconsistent rheology profiles.

- a personal cleansing composition comprising a fatty acyl isethionate surfactant and being free of alkyl sulfate and alkyl ether sulfate type of surfactants and having a satisfactory consistent rheology profile.

- Benefit agents in the form of solid particles, liquid droplets are of interest for personal cleansing compositions.

- Benefit agents can be used as pigments or coloring agents, opacifiers, pearlescent agents, feel modifiers, oil absorbers, skin protectants, matting agents, friction enhancers, slip agents, conditioning agents, exfoliants, odor absorbers, or cleaning enhancers.

- a personal cleansing composition comprising a fatty acyl isethionate surfactant imparted with a sufficient structure to hold benefit agents such as solid particles, liquid droplets.

- a personal cleansing composition is provided and comprises:

- Another aspect is related to a method for making the personal cleansing composition according to any of the preceding claims comprising the following steps, preferably in that order:

- a personal cleansing composition is provided and can be made by the method as set out hereinbefore.

- the personal cleansing composition as set out hereinbefore is used for improving the lather of the composition.

- the personal cleansing composition as set out hereinbefore is used for suspending benefits agents selected from the group consisting of hair care and skin care benefit agents, particulates, particles, preferably silica and titanium oxide, microcapsules, oils, droplets, pigments or coloring agents, opacifiers, pearlescent agents, feel modifiers, oil absorbers, skin protectants, matting agents, friction enhancers, slip agents, conditioning agents, exfoliants, odor absorbers, or cleaning enhancers, and mixtures thereof.

- benefits agents selected from the group consisting of hair care and skin care benefit agents, particulates, particles, preferably silica and titanium oxide, microcapsules, oils, droplets, pigments or coloring agents, opacifiers, pearlescent agents, feel modifiers, oil absorbers, skin protectants, matting agents, friction enhancers, slip agents, conditioning agents, exfoliants, odor absorbers, or cleaning enhancers, and mixtures thereof.

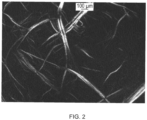

- the polymer liquid crystals may form elongated structures and may be nematic or cholesteric.

- QSP or "q.s.” means sufficient quantity for 100% or for 100g. "+/-" indicates the standard deviation. All ranges are inclusive and combinable. The number of significant digits conveys neither a limitation on the indicated amount nor on the accuracy of the measurement.

- Relative humidity refers to the ratio (stated as a percent) of the moisture content of air compared to the saturated moisture level at the same temperature and pressure. Relative humidity can be measured with a hygrometer, in particular with a probe hygrometer from VWR ® International.

- compositions, methods, and uses of the present invention can comprise, consist of, and consist essentially of the elements and limitations of the invention described herein, as well as any of the additional or optional ingredients, components, steps, or limitations described herein.

- Embodiments and aspects described herein may comprise or be combinable with elements, features or components of other embodiments and/or aspects despite not being expressly exemplified in combination, unless an incompatibility is stated.

- composition comprises from 1% to 5% fatty alcohol

- a composition comprising 2% stearyl alcohol and 1% cetyl alcohol and no other fatty alcohol, would fall within this scope.

- the amount of each particular ingredient or mixtures thereof described hereinafter can account for up to 100% (or 100%) of the total amount of the ingredient(s) in the composition.

- mixtures as used herein is meant to include a simple combination of materials and any compounds that may result from their combination.

- molecular weight or "M.Wt.” as used herein refers to the weight average molecular weight unless otherwise stated.

- the weight average molecular weight can be measured by gel permeation chromatography ("GPC").

- personal cleansing composition refers to compositions intended for topical application to the skin or hair for cleansing.

- the personal cleansing composition may be aqueous.

- isotropic refers to a particular phase of the composition wherein the structure is "identical along any three orthogonal directions in space, and is therefore dark or 'nonbirefringent' when viewed between crossed polarized light filters. (One direction is 'orthogonal' to another if the vector component of the first, in the direction of the second, is zero.)" (Laughlin, R. G. (1994). "The Aqueous Phase Behavior of Surfactants," 182, 8.2).

- anisotropic refers a particular phase of the composition wherein the structure exhibits properties with different values when measured in different directions.

- An anisotropic phase is not identical along any three orthogonal directions in space, and is birefringent when viewed between crossed polarized light filters.

- liquid crystals refers to anisotropic fluids or mesophases.

- Liquid crystals as used herein are polymeric liquid crystals.

- the polymeric liquid crystalline phase of the personal cleansing composition is lyotrophic meaning that the polymer liquid crystalline phase contains a solvent, namely water.

- This type of polymer liquid crystals is distinguished in the art from thermotropic, heat, and magnetically induced liquid crystals.

- the liquid crystalline state exists between the boundaries of the solid crystalline phase and the isotropic liquid phase (i.e. an intermediate between the three dimensionally ordered crystalline state and the disordered dissolved state).

- Liquid crystals are also known as anisotropic fluids, a fourth state of matter, polymer association structure or mesophases. Those terms are used interchangeably. Lyotropic means a material is formed through changes in solution behavior (and hence by definition contains a solvent, e.g. water) of the ingredients. The changes involve thermal and salvation energies.

- lyotropic liquid crystal refers to a liquid crystalline phase distinctive by the presence of birefringence under polarized light microscopy.

- birefringence refers the property of the material to capable of transmitting light when viewed with cross polars under static conditions.

- micelle refers structure comprising individual surfactant molecules aggregated to form a hydrophobic core region with externally facing polar head groups in equilibrium with surfactant monomers in a polar phase, having a characteristic dimension that is a single digit multiple of the surfactant length, i.e., generally less than about 10 nm in diameter.

- doctor-off means the intended product usage includes application to skin and/or hair followed by rinsing and/or wiping the product from the skin and/or hair within a few seconds to minutes of the application step.

- the product is generally applied and rinsed in the same usage event, for example, a shower.

- static stability refers to a personal cleansing composition that comprises at least two compositions that maintain at least two "separate" phases with at least two separate benefit concentration zones contained within a single chamber package at ambient conditions for a period of at least about 180 days.

- static stability can be determined by accelerated protocol at elevated temperature.

- One accelerated protocol is based on passing static stability after 10 days at 50° C.

- separatate is meant that there is substantially no mixing of compositions contained in the zones, detected by the benefit analysis method, described hereinafter, prior to dispensing of the composition.

- substantially free of means less than 1%, less than 0.8%, less than 0.5%, less than 0.3%, or less than an immaterial amount of a stated ingredient by total weight of the composition.

- surfactant refers to amphiphilic molecules which can aggregate to form micelles and other surfactant structures, which are soluble in an aqueous phase and contribute to foaming during a cleansing event, i.e., stabilizing an air interface.

- structured means having a rheology that confers stability on the personal cleansing composition.

- the degree of structure is determined by rheologic characteristics such as the yield stress determined by the Herschel-Bulkley Rheology Test Method or the viscosity obtained by the Ultracentrifugation Test Method, all in the Test Method section below.

- the objects of the present invention are to provide personal cleansing compositions and uses of the compositions as described in the Summary or as described hereinbelow for fulfilling the technical effects or goals as set out herein.

- Thickeners are useful for adjusting the viscosity and the rheological behavior of personal cleansing compositions in order to make them easy to pour and dose.

- Structurants thicken, but also provide a suspensive benefit, allowing ingredients such as oils, particulates, and the like, to be stably suspended in the personal cleansing composition.

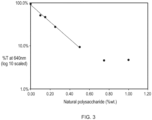

- a natural polysaccharide such as xanthan gum can lead to the formation of a polymer liquid crystalline phase in the personal cleansing composition and even at a relatively low amount from 0.25% to 2% of the natural polysaccharide total weight of the composition.

- the personal cleansing composition comprises a first and second phase.

- the first phase is an isotropic and micellar surfactant phase.

- the second phase is a polymer liquid crystalline phase.

- the first and second phases of the personal cleansing composition may be separated by ultracentrifuge.

- the polymer liquid crystalline phase is characterized by birefringence.

- the polymer liquid crystalline phase and the personal cleansing composition may have a specific rheologic profile.

- the polymer liquid crystalline phase of the composition provides the structure of the personal cleansing composition.

- the polymer liquid crystalline phase comprises polymer liquid crystals.

- the polymer liquid crystals include the natural polysaccharide.

- the polymer liquid crystalline phase can help the personal cleansing composition to suspend a benefit agent selected from the group consisting of hair care and skin care benefit agents, particulates, particles, preferably silica and titanium oxide, microcapsules, oils, droplets, pigments or coloring agents, opacifiers, pearlescent agents, feel modifiers, oil absorbers, skin protectants, matting agents, friction enhancers, slip agents, conditioning agents, exfoliants, odor absorbers, or cleaning enhancers, and mixtures thereof.

- a benefit agent selected from the group consisting of hair care and skin care benefit agents, particulates, particles, preferably silica and titanium oxide, microcapsules, oils, droplets, pigments or coloring agents, opacifiers, pearlescent agents, feel modifiers, oil absorbers, skin protectants, matting agents,

- the personal cleansing composition may have specific yield stress ⁇ y , as an elastic component of the composition, measured according to the Herschel-Burlley Rheology Test Method.

- the personal cleansing composition may comprise the polymer liquid crystalline phase, and at a sufficient yield stress ⁇ y from 0.005 to 3 Pa measured according to the Herschel-Bulkley Rheology Test Method.

- the personal cleansing composition may also exhibit a flow viscosity from 3 Pa.s to 100 Pa.s at 25°C at a shear rate of 1.5 s-1 according to the Flow Viscosity Test Method.

- a stable personal cleansing composition able to suspend benefits agents and comprising fatty acyl isethionate can be provided when the composition comprises a polymer liquid crystalline phase comprising polymer liquid crystals, wherein the polymer liquid crystals include the natural polysaccharide.

- the personal cleansing composition is free of alkyl sulfate and alkyl ether sulfate type of surfactant.

- the personal cleansing composition does not comprise any alkyl sulfate which comprises C 12 -C 18 alkyl sulfate or any alkyl ether sulfate including alkyl glyceryl ether sulfates.

- the personal cleansing composition may not comprise any alkyl ether sulfates which are those having the formula: RO(CH 2 CH 2 O) n SO 3 M wherein R is an alkyl or alkenyl having 8 to 18 carbons, preferably 12 to 18 carbons, n has an average value of greater than at least 0.5, preferably between 2 and 3; and M is a solubilizing cation such as sodium, potassium, ammonium or substituted ammonium.

- the personal cleansing composition may not comprise any ammonium and sodium lauryl ether sulfates.

- the personal cleansing composition does contain alkyl sulfate and/or alkyl ether sulfate type of surfactant, its content of such a weight proportion of: alkyl sulfates or alkyl ether sulfate type surfactant is less than or equal to the sum of 0.6, more preferably less than or equal to the sum of 0.2, even more preferably equal to 0.

- the personal cleansing composition comprises a surfactant system.

- the surfactant system comprises from 0.1% to 5%, preferably from 0.2% to 4%, more preferably from 0.5% to 3.5% of a fatty acyl isethionate surfactant by weight of the composition; and from 0.5% to 40%, preferably from 1% to 25%, more preferably from 5% to 15% of a co-surfactant by weight of the composition.

- the fatty acyl isethionate surfactant may be defined as an isethionate according to the general formula (I): wherein R 1 is a saturated or unsaturated, straight or branched, alkyl or alkenyl chain with from 6 to 30 carbon atoms, preferably from 8 to 22 carbon atoms, more preferably from 9 to 18 carbon atoms, R 2 and R 3 are each independently H or (C 1 -C 4 ) alkyl, and M + is an alkali metal, preferably lithium, sodium, potassium; or M + is an alkali-earth metal, preferably magnesium; or M + is an ammonium or a substituted ammonium cation; or

- Suitable fatty acyl isethionate surfactants may include the reaction product of fatty acids esterified with isethionic acid and neutralized with sodium hydroxide. Suitable fatty acids for isethionate surfactants can be derived from coconut oil or palm kernel oil, for instance. Additional examples of suitable isethionic anionic surfactants are described in U.S. Pat. No. 2,486,921 ; U.S. Pat. No. 2,486,922 ; and U.S. Pat. No. 2,396,278 .

- the fatty acyl isethionate surfactant may be selected from the group consisting of sodium lauroyl isethionate, sodium lauroyl methyl isethionate, sodium oleoyl isethionate, sodium oleoyl methyl isethionate, sodium stearoyl isethionate, sodium stearoyl methyl isethionate, sodium myristoyl isethionate, sodium myristoyl methyl isethionate, sodium palmitoyl isethionate, sodium palmitoyl methyl isethionate, sodium cocoyl isethionate, sodium cocoyl methyl isethionate, a blend of stearic acid and sodium cocoyl isethionate, ammonium cocoyl isethionate, ammonium cocoyl methyl isethionate, and mixtures thereof.

- the fatty acyl isethionate surfactant may be preferably selected from the group consisting of sodium lauroyl isethionate, sodium myristoyl isethionate, sodium palmitoyl isethionate, sodium stearoyl isethionate, sodium oleoyl isethionate, sodium cocoyl isethionate, ammonium cocoyl isethionate, and mixtures thereof.

- the fatty acyl isethionate surfactant may be more preferably selected from the group consisting of sodium lauroyl isethionate, sodium cocoyl isethionate, ammonium cocoyl isethionate, and mixtures thereof.

- Corresponding commercial products are available, for example, from the company Innospec under the trade name "Iselux ® " and from Clariant or Uniquema under the trade names "Hostapon ® “ or "Arlatone ® ".

- Examples of other commercial fatty acyl isethionates that may be used can be Hostapon ® surfactants from Clariant such as for sodium cocoyl isethionate: Hostapon ® SCI-85C, Hostapon ® SCI-78C, or a blend of stearic acid with sodium cocoyl isethionate: Hostapon ® SCI-65C.

- Examples of other commercial fatty acyl isethionates that may be used can be "Jordapon ® " surfactants from BASF such as Jordapon ® CI prill or Jordapon ® CI65; and sodium cocoyl isethionate from Yongan Daily Chemical Co. such as YA-SCI-85 ® or YA-SCI-65 ® .

- Fatty acyl isethionates surfactants are typically prepared by the reaction of an isethionate salt such as metal or ammonium isethionate and an a saturated or unsaturated, straight or branched, alkyl or alkenyl chain fatty acid having from 6 to 30 carbon atoms, preferably from 8 to 22 carbon atoms, more preferably from 6 to 18 carbon atoms.

- an isethionate salt such as metal or ammonium isethionate

- an a saturated or unsaturated, straight or branched, alkyl or alkenyl chain fatty acid having from 6 to 30 carbon atoms, preferably from 8 to 22 carbon atoms, more preferably from 6 to 18 carbon atoms.

- the resulting fatty acyl isethionate surfactant can be a mixture of 45 to 95% by weight of fatty acyl isethionates and 40 to 0 wt.% of free fatty acids, in addition to isethionates salts, typically less than 5 wt.%, and trace (less than 2 wt.%) of other impurities, by total weight of the resulting fatty acyl isethionate surfactant.

- a mixture of aliphatic fatty acids may be used for the preparation of commercial fatty acyl isethionates surfactants.

- the personal cleansing composition comprises a surfactant system.

- the surfactant system comprises from 0.1% to 5%, preferably from 0.2% to 4%, more preferably from 0.5% to 3.5% of a fatty acyl isethionate surfactant by weight of the composition.

- concentrations mentioned here are total concentration ranges in case more than one fatty acyl isethionate surfactant is present.

- the specified ranges are provided by weight and relate to the total weight of the personal cleansing composition.

- Fatty acyl isethionate surfactants have not typically been used in preparation of personal cleansing compositions because they might readily form solid crystals (when used alone and/or with a co-surfactant) and consequently might make it difficult to form stable liquid personal cleansing compositions.

- the surfactant system comprises from 0.5% to 40%, preferably from 1% to 25%, more preferably from 5% to 15% of a co-surfactant by weight of the composition.

- the co-surfactant may be selected from the group consisting of an anionic surfactant being not an isethionate surfactant, a non-ionic surfactant, an amphoteric surfactant, a zwitterionic surfactant and mixtures thereof.

- the anionic surfactant of the co-surfactant being not an isethionate surfactant may be selected from the group consisting of fatty acyl sarcosinates, sulfosuccinates, sulfonates, sulfoacetates, acyl glycinates, acyl alaninates, acyl glutamates, lactates, lactylates, glucose carboxylates, amphoacetates, taurates, and mixtures thereof.