EP3417464B1 - Disjoncteur à bouton avec élément de commande de balancement - Google Patents

Disjoncteur à bouton avec élément de commande de balancement Download PDFInfo

- Publication number

- EP3417464B1 EP3417464B1 EP16838069.9A EP16838069A EP3417464B1 EP 3417464 B1 EP3417464 B1 EP 3417464B1 EP 16838069 A EP16838069 A EP 16838069A EP 3417464 B1 EP3417464 B1 EP 3417464B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- push button

- circuit breaker

- wire spring

- transmitting member

- pressure transmitting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000012777 electrically insulating material Substances 0.000 claims description 3

- 229910000639 Spring steel Inorganic materials 0.000 claims description 2

- 230000008878 coupling Effects 0.000 description 23

- 238000010168 coupling process Methods 0.000 description 23

- 238000005859 coupling reaction Methods 0.000 description 23

- 230000000284 resting effect Effects 0.000 description 8

- 230000036961 partial effect Effects 0.000 description 5

- 238000004873 anchoring Methods 0.000 description 3

- 239000011888 foil Substances 0.000 description 3

- 230000000670 limiting effect Effects 0.000 description 3

- 230000000295 complement effect Effects 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 238000010616 electrical installation Methods 0.000 description 1

- 230000006355 external stress Effects 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000002829 reductive effect Effects 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 230000035807 sensation Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H13/00—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch

- H01H13/50—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member

- H01H13/56—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member the contact returning to its original state upon the next application of operating force

- H01H13/60—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member the contact returning to its original state upon the next application of operating force with contact-driving member moved alternately in opposite directions

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H1/00—Contacts

- H01H1/58—Electric connections to or between contacts; Terminals

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H1/00—Contacts

- H01H1/58—Electric connections to or between contacts; Terminals

- H01H1/5833—Electric connections to or between contacts; Terminals comprising an articulating, sliding or rolling contact between movable contact and terminal

Definitions

- the present description refers to the technical field of the electrical installations and, more particularly, it concerns a push button operated circuit breaker with rocking control member.

- Push button operated circuit breakers are known wherein the control of the electrical switching occurs by means of a rocking control member.

- US 4,748,298 discloses a lever operated switch.

- European patent EP1584096 discloses a push button operated circuit breaker including a supporting structure made of insulating material, or case, having the shape of a box and defining a recessed compartment for housing and for supporting the electromechanical components being part of the circuit breaker.

- the case has an open side.

- the circuit breaker also includes a push button slidingly coupled to the case by means of guide elements in order to close the open side.

- the mechanical coupling between the push button and the case allows a relative and guided sliding of the push button with respect to the case along a sliding axis. Such sliding is necessary to command by means of the push button an electrical switching of the circuit breaker.

- a pressure of the push button determines an advancement of the push button with respect to the case.

- a release of the push button determines a backward movement of the push button with respect to the case.

- the push button therefore moves between a forward position and a backward position, that represent two opposite stopping positions of the push button.

- the push button is coupled to a rotatable pressure transmitting member and the circuit breaker includes a rocking control member that controls the switching.

- the pressure transmitting member is adapted to rotate into two opposite directions starting from an angular resting position and the push button includes at least an elastic element adapted to bring the pressure transmitting member back to the angular resting position after one rotation.

- the elastic element is for example implemented by means of one or more foil springs, for example made of metal foil, folded and sheared off.

- the aforesaid elastic element opposes a certain resistance during the pressure of the push button starting from a certain point on during the push button stroke, particularly when the pressure transmitting member contacts the rocking control member.

- Such resistance is due to the fact that the elastic elements opposes to the pressure transmitting member rotation. This resistance determines the user's feeling of lack of sliding fluidity while pushing the push button.

- the object of the present description is to make available a push button operated circuit breaker with rocking control member being such as to fulfil the above described need with reference to the prior art circuit breaker.

- push button operated circuit breaker it is intended a circuit breaker operated manually through a push button in order to determine one, or at least one, electrical switching.

- the push button operated circuit breaker 10 is of modular type, that is destined to be mounted on a supporting frame for the wall installation beside other modular circuit breakers of the same type or in general other electrical modular appliances, as for example sockets.

- the circuit breaker 10 can be operated manually and can be used for example for controlling the electric power and/or the lighting in a residential or commercial building.

- circuit breaker it is meant both a device for opening and closing a single electrical contact and a device for opening an electrical contact with the contemporary closing of another electrical contact and vice versa (diverter).

- the push button operated switch 10 with rocking control member that, for ease of explanation, will be called in the present description also " circuit breaker” or “push button circuit breaker”, includes a supporting structure 20 made of electrically insulating material, e.g. plastic, preferably having, but not restrictively, approximatively the parallelepiped shape.

- the supporting structure 20, hereinafter called case includes a bottom wall 21 and four lateral walls 20a, 20b, 20c, 20d joined to the bottom wall 21.

- the case 20 includes an open side 21' opposite to the bottom wall 21.

- the lateral walls 20a, 20b, 20c, 20d and the bottom wall 21 define a recessed compartment adapted for housing the electromechanical components of the circuit breaker 10 and at least two electrical connection terminals C1, C2, C3.

- the recessed compartment of the case 20 houses, without any limitation, three electrical connecting terminals C1, C2, C3.

- the bottom wall 21 is integrated in the case 20, however in an alternative embodiment the bottom wall 21 may be a piece separated from the lateral walls 20a, 20b, 20c, 20d of the case 20 and coupled to them.

- the push button operated circuit breaker 10 includes a push button 30, being operated manually to command an electrical switching of the circuit breaker 10, having a body provided with lateral walls 30a, 30b, 30c, 30d crossing the open side 21' of the case 20.

- the push button 10 is adapted to slide with respect to the case 20 along a sliding axis Z-Z and along a delimited space between a forward position and a backward position.

- forward position it is meant an end of stroke position in the approaching movement of the push button 30 to the case 20, while by “backward position” it is intended an end of stroke position in the distancing movement of the push button 30 from the case 20. It is therefore clear that the terms “forward” and “backward” refer to the position of the push button 30 with respect to the case 20.

- the push button operated circuit breaker 10 includes a guiding system adapted to guide the sliding of the push button 30 with respect to the case 20 along the sliding axis Z-Z.

- the guiding system is a system of spatially distributed guides including first guide elements 22, 32 operatively interposed between the lateral walls 20a, 20b, 20c, 20d of the case 20 and the lateral walls 30a, 30b, 30c, 30d of the body of the push button 30.

- the system of spatially distributed guides also includes second guide elements 23, 24, 33, 34 spaced apart with respect to the first guide elements 22, 32 and placed with respect to the first guide elements 22, 32 at a lower distance from the bottom wall 21 of the case 20.

- friction surfaces cooperating between them of the first guide elements 22,32 have a distance from the bottom wall 21 of the case 20 higher than the distance with respect to the bottom wall 21 of the case 20 of friction surfaces cooperating between them of the second guide elements 23,24,33,34.

- the first guide elements 22, 32 include a first plurality of appendices 22 protruding from the lateral walls 20a, 20b, 20c, 20d of the case 20 towards the lateral walls 30a, 30b, 30c, 30d of the push button 30 and a second plurality of appendices 32 protruding from the lateral walls of the push button 30 towards the lateral walls 20a, 20b, 20c, 20d of the case 20 and each being adapted to contact a respective appendix 22 of the first plurality of appendix 22 in order to slide thereon when the push button 30 slides with respect to the case 20.

- the first plurality of appendices 22 and the second plurality of appendices 32 allow the lateral walls 30a, 30b, 30c, 30d of the push button 30 to be spaced from the lateral walls 20a, 20b, 20c, 20d of the case 20 when the push button 30 slides with respect to the case 20.

- the push button operated circuit breaker 10 is less vulnerable to an undesired dust or sand intrusion within the lateral walls 20a, 20b, 20c, 20d of the case 20 and lateral walls 30a, 30b, 30c, 30d of the push button 30 that would otherwise cause a jamming in a circuit breaker wherein, on the contrary, due to a wide overlapping between the lateral walls of the push button 30 and those of the case 20, there are wider friction surfaces.

- the aforesaid protruding appendices 22, 32 are linear appendices, which in the shown example extend linearly along axis that are parallel between them and parallel to the sliding axis Z-Z.

- the lateral walls of button 30 are parallel in twos and define edges 32', each of them being arranged by a pair of adjacent lateral walls 30a, 30b, 30c, 30d of button 30.

- Each appendix 32 of the second plurality of appendices is arranged on a corresponding edge 32' .

- the edges 32' are bevelled.

- the second guide elements 23, 24,33,34 are decentred with respect to the first guide elements 22, 32.

- the second guide elements 23, 24, 33, 34 are closer to some of the first guide elements 22, 32 and further from other first guide elements 22, 32.

- the second guide elements 23, 24, 33, 34 include a guide seat 23 and a guide pin 33 having an end portion 34 slidable in the guide seat 23.

- the guide pin 33 extends from the body of the push button 30 towards the bottom wall 21 of the case 20 while the guide seat 23 is fixed to the bottom wall 21 of the case 20.

- the guide pin 33 is integrated in the push button 30 and protrudes from the body of the push button 30 towards the bottom wall 21 of the case 20.

- the body of the push button 30 and the guide pin 33 form a single piece.

- the aforesaid end portion 34 of the guide pin 33 has a cross-shaped cross-section.

- cross-shaped cross-section it is intended a section on a plane that is perpendicular to the sliding axis Z-Z.

- the aforesaid cross-shaped cross-section includes a circular central part from which four arms originate forming a Greek cross.

- the guide pin 33 does not interfere with the lateral walls 20a, 20b, 20c, 20d of the case 20 during the sliding movements of the push button 30 with respect to the case 20.

- the guide pin 33 is spaced apart from the lateral walls 20a, 20b, 20c, 20d of the case 20 so as to avoid having friction surfaces among the lateral walls of the case 20 and the guide pin 33 itself.

- the guide seat 23 includes four lateral walls 24 parallel in twos.

- the lateral walls 24 of the guide seat 23 are separated from one another and joined to the bottom wall 21 of the case 20.

- the guide seat 33 may be a continuous collar, having a quadrangular or circular section.

- the lateral walls 24 are integrated in the bottom walls 21 of the case 20, protruding from it towards the push button 30.

- the push button operated circuit breaker 10 includes at least one elastic element 40 adapted to exert a pushing force on the push button 30 in order to bring back or keep the push button 30 in the backward position in absence of external forces.

- the circuit breaker 10 includes two elastic elements 40 having the form of two coil springs 40.

- the circuit breaker 10 also includes a diaphragm 41 housed inside the case 20 and the elastic elements 40 are operatively inserted between the diaphragm 41 and the body of the push button 30, each having for example an end portion inserted in a correspondent recessed seat 39 provided in the body of the push button 30 ( Figure 6 ). Also in the diaphragm 41 recessed seats having the same function may be provided.

- the push button operated circuit breaker 10 in order to stop the push button 30 in the backward position, includes a first stopping system including contact surfaces 251, 351 of the lateral walls of the case 20 and of the lateral walls of the push button 30 respectively, which are abutting to each other when the push button 30 is in the backward position.

- the first stopping system includes a button alignment system including alignment elements 250, 350 engaging with each other starting from a given point on during the sliding movement of the push button 30 from the forward position towards the backward position before reaching the backward position.

- alignment elements 250, 350 allow to progressively align the push button 30 with respect to a reference plane R_P ( Figure 11 ) that is perpendicular to the sliding axis Z-Z.

- the aforesaid alignment elements 250, 350 include at least a variable cross-section guide 250, and a corresponding variable cross-section slider 350 adapted to be inserted inside the variable cross-section guide 250, starting from a given point on during the motion of the push button 30 before reaching the backward position and up until reaching it.

- the variable cross-section guide 250 is a tapered guide, having a decreasing cross-section in the direction towards the reference plane R_P).

- the variable cross-section slider 350 is wedge-shaped.

- the contact surfaces 251 and 351 are surfaces that, in the backward position of the push button 30, lie on a plane I_P inclined with respect to the reference plane R_P.

- the circuit breaker 10 includes complementary snap-fit coupling elements 25, 35 provided on the lateral walls of the case 20 and on the lateral walls of the body of the push button 30.

- the above said snap-fit coupling elements 25 are shaped in order to ease a forced insertion of the body of the push button 30 through the open side 21' of the case 20 in the assembling phase of the push button-case assembly and, once they pass a snapping position, to make interlocking snap fit coupling between the push button 30 and the case 20, based on which the push button 30 is slidingly constrained to the case 20.

- said snap-fit coupling elements 25, 35 include four snap-fit coupling teeth 25 on the lateral walls of the case 20 and four complementary snap-fit coupling teeth 35 arranged on the lateral walls of the body of the push button 30.

- the snap-fit coupling teeth 25, 35 are arranged at the corners of a rectangular or square lying on a plane that is perpendicular to the sliding axis Z-Z.

- the above described snap-fit coupling elements 25, 35 carry the above described alignment elements 250, 350 and preferably the above described contact surfaces 251, 351 too.

- the push button operated circuit breaker 10 in order to stop the push button 20 in the forward position, includes a second stopping system including contact elements 26, 36 respectively provided on the lateral walls of the case 20 and on the lateral walls of the body of the push button 30.

- the aforesaid contact elements 26, 36 include two small blocks 36 protruding from opposite walls 30b, 30d of the push button body 30 and stopping seats 26 provided on two opposite lateral walls 20b, 20d of the case 20.

- the push button operated switch 10 includes a supporting fulcrum 50 housed inside the case 20.

- a supporting fulcrum 50 serves as a supporting means for a mobile electrically conductive switching member, being in particular rotatable, carrying at least a mobile electrical contact element.

- the aforesaid mobile electrically conductive switching member will be called in the present description rotatable contact holder support.

- the supporting fulcrum 50 is for example made of metal foil folded and sheared off.

- the case 20 in order to guarantee a stable fixing of the supporting fulcrum 50 to the case 20, the case 20 includes a housing seat 27 of the supporting fulcrum 50 and the push button operated circuit breaker 10 includes a snap-fit coupling system adapted to fix the supporting fulcrum 50 to the case 20 in the housing seat 27.

- the housing seat 27 is arranged inside the case 20 on the bottom wall 21 and the snap-fit coupling system includes at least a coupling elastic tooth 28 adapted to hook the supporting fulcrum 50 to the bottom wall 21 of the case 20.

- the aforesaid coupling elastic tooth 28 is integrated in the bottom wall 21 of the case 20 and forms a single piece with the latter.

- the snap-fit coupling system includes a plurality of coupling elastic teeth 28, in particular three coupling elastic teeth 28.

- the bottom wall 21 of the case 20 has a pass-through opening 28'. Thereby, it is usefully avoided having to mould in the bottom wall 21 of the case 20 undercut opposite surfaces.

- the coupling elastic tooth 28 has a free end portion and an opposite end fastened to the bottom wall 21 of the case 20 and the free end portion is such that it engages with a peripheral portion of the supporting fulcrum 50.

- At least two snap-fit coupling teeth 28 are provided, arranged at opposite sides with respect to the supporting fulcrum 50.

- the housing seat 27 of the supporting fulcrum 50 is a recessed seat implemented in the bottom wall 21 of the case.

- the fulcrum 50 includes a support and contact portion 51 that is shaped so as to form a groove, for example having a V-shaped cross section, housed inside the recessed housing seat 27.

- the support fulcrum 50 also includes a connecting portion 52, being part of a connecting terminal 50 of the circuit breaker 10.

- the connecting terminal C1 includes a screw 54 and a clamping plate 55, and the screw 54 crosses the connecting portion 53 of the supporting fulcrum 50 to engage with the clamping plate 55.

- the supporting fulcrum 50 includes an intermediate portion 52 forming a connection inclined plane between the support and contact portion 51 and the connecting portion 53.

- the circuit breaker 10 also includes an anchoring system 59, 29 of the supporting fulcrum 50 to the case 20, in particular to the bottom wall 21 of the case 20.

- the anchoring system 59, 29 includes a folded little wing 59 integrated in the supporting fulcrum 50 and an anchoring seat 29 (visible in Figure 4 ) arranged inside the bottom wall 21 of the case 20 housing the folded little wing 59. This allows to stabilise the supporting fulcrum 50 position also with respect to the external stresses that affect for example the supporting fulcrum 50 during the wiring operations of the circuit breaker 10, for example caused by the clamping of the connecting terminal C1.

- circuit breaker 10 is a generic push button operated circuit breaker.

- the circuit breaker 10 is a push button operated circuit breaker with a rocking mechanism.

- An embodiment of a push button operated circuit breaker with rocking mechanism is for example disclosed in the European patent EP1866944 .

- button operated circuit breaker with rocking mechanism it is to be intended in general a circuit breaker operated by a sliding button including a rocking element that controls the switching, hereinafter called, for ease of explanation, rocking control member.

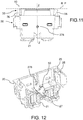

- the push button 30 includes a pressure transmitting member 60 rotatably fastened to the body of the push button 30.

- the pressure transmitting member 60 is adapted to rotate into two opposed directions starting from a resting position (or central position) and the push button 30 includes at least an elastic element 61 adapted to bring the pressure transmitting member 60 back to the angular resting position after one rotation.

- the pressure transmitting member 60 is adapted to rotate around the rotation axis A1-A1 (that will be called third rotation axis) .

- the aforesaid elastic element is, or includes, a wire spring 61 and preferably a rectilinear wire spring.

- the aforesaid wire spring 61 is, for example, a wire spring made of spring steel. It has been observed that a wire spring 61 with reduced section too, for example with a diameter included between 0,25 mm and 0,75 mm and for example equal to 0,5 mm, is able to bring the pressure transmitting member 60 back to the angular resting position and is able to resist to the stresses generated when the push button 30 is manually operated.

- the aforesaid wire spring 61 has two opposite end portions 62 constrained to the push button 30 and a central portion 63 adapted to exert an elastic strength on the pressure transmitting member 60.

- the pressure transmitting member 60 includes a central portion 600 and two appendices 601 and 602 originating from the central portion 600.

- the central portion 600 includes a channel 630, as for example a recess or hole, crossed by the central portion 63 of the wire spring 61.

- the body of the push button 30 includes a pass-through opening 360, crossed by the pressure transmitting member 60, thereby the wire spring 61 is arranged on one side of the pass-through opening 360 together with at least a part of the central portion 600 of the pressure transmitting member 60, while the remaining part of the pressure transmitting member 60 is arranged on the other side of said pass-through opening 360.

- the pressure transmitting member 60 includes two opposite hinge pins 610 that originate from the central portion 600 of the aforesaid member.

- the two hinge pins 610 are cylindrical pins.

- Such hinge pins 610 are oriented along the rotation axis A1-A1 of the pressure transmitting member 60.

- the latter in order to simplify the assembly of the push button 30, includes two semicircular recesses (visible in Figure 6 ), or generally having the shape of an arc of the circle, aligned along the rotation axis of the pressure transmitting member 60 each of which is adapted to partially receive a respective pin 610.

- the wire spring 61 apart from serving as elastic return to make the pressure transmitting member 60 return into its resting position, also serves favourably as fixing element of the member 60 to the push button 30.

- the push button 30 includes a fixing seat 361 of the wire spring 61 made in the thickness of the bottom wall 31 of the push button 30 and that in the embodiment is placed on top of the pass through opening 360 of the push button 30.

- such fixing seat 361 includes two grooves 362 aligned to each other along the direction of prevalent longitudinal extension of the wire spring 61 and are crossed by the end portions 62 of the wire spring 61.

- the end portions 62 of the wire spring 61 protrude beyond such grooves 362 from opposite sides with respect to the central portion 63 of the wire spring 61.

- the fixing seat 361 of the wire spring 61 includes stopping elements 365 adapted to limit or prevent an undesired translation of the wire spring 31 with respect to the push button 30. Such translation may in fact determine and undesired detachment of the wire spring 61 from the push button 30 and, thus, in the embodiment also of the pressure transmitting member 60.

- the aforesaid pressure transmitting member 60 contacts, from a certain point on during the sliding of the push button 30 from the backward position to the forward position, a commutation rocking control member 70, e.g. a bistable member, included in the push button operated circuit breaker 10.

- rocking control member it is meant a rocking control member adapted to control the switching.

- the rocking control member 70 remains in the second operative position, at the moment of a further pressure of the push button 30 through a sequence of movements similar to the above described one, it will be able to return in the first operative position and remain there despite the push button 30 is released and until a later pressure of the push button 30.

- the push button operated circuit breaker (10) includes at least a fixed electrical contact element 92, 92' (hereinafter also called fixed contact element) and at least a mobile element of mobile contact 82, 82' (hereinafter also called mobile contact element) and the rocking control member 70, by moving as a result of the pressure transmitted by the pressure transmitting member 60, determines a rotation of the rotatable contact holder support 81 around a rotation axis A3-A3 (hereinafter also called a first rotation axis) that in its turn, rotates the mobile electrical contact element 82 between a first and a second operative position, being angularly spaced from one another.

- a fixed electrical contact element 92, 92' hereinafter also called fixed contact element

- mobile contact element mobile element of mobile contact 82, 82'

- the rocking control member 70 by moving as a result of the pressure transmitted by the pressure transmitting member 60, determines a rotation of the rotatable contact holder support 81 around a rotation axis

- the switch 10 includes two opposite mobile electrical elements 82, 82' and two fixed electrical contact elements 92, 92', being spaced apart and each other fronted.

- the circuit breaker 10 is thus a two-way diverter, whereby in one of the aforesaid operative positions the mobile contact element 82 is in contact with a fixed contact element 92 and the mobile contact element 82' is separated from the other fixed contact element 92' while in the other operative position the mobile contact element 82 is separated from the fixed contact element 92 and the mobile contact element 82' is in contact with the other fixed contact element 92'.

- the teachings of the present description can be easily applied from an expert in the field even to the case of a push button operated circuit breaker 10 having a single fixed electrical contact element and a single mobile electrical contact element.

- the mobile electrical contact element is 82, 82' rotates around a rotation axis A3-A3 among two operative positions angularly spaced in order to interrupt or deviate an electrical circuit.

- the circuit breaker 10 includes two mobile electrical contact elements 82, 82' and two fixed electrical contact elements 92, 92'.

- the circuit breaker 10 includes two fixed contact holder supports 91, 91' to which the fixed contact elements 92, 92' are respectively fixed, e.g. welded.

- the fixed contact holder supports 91, 91' are made of electrically conductive material, e.g. copper, and each one includes a connecting portion 93, 93'.

- Each connecting portion 93,93' is for example part of a corresponding electrical connecting terminal C2, C3 of the circuit breaker 10.

- Each connecting clamp C2, C3 includes a screw 94, 94' and a clamping plate 95, 95' and each screw 94, 94' crosses the respective connecting portion 93, 93' for engaging with an associated clamping plate 95, 95'.

- the mobile electrical contact elements 82, 82' are for example two opposite electrically conductive pads, e.g. made of sintered silver, fixed, e.g. welded, at the opposite sides of an end portion of a mobile contact holder support 81, also made of electrically conductive material, e.g. copper. It is thus clear that in this embodiment the mobile electrical contact elements 82, 82' are electrically connected between them.

- the opposite end portion of the mobile contact support 81 lies on the supporting fulcrum 50 and in particular on the portion and support and contact 51 of the supporting fulcrum 50.

- the mobile contact holder support 81 rotates around a first rotation axis A3-A3, in the example defined by the supporting fulcrum 50, in order to rotate the mobile electrical contact element 82, 82' between the first and the second operative portion and vice versa.

- the mobile contact holder support 81 is an L-shaped plate having a larger base 810 lying on the supporting fulcrum 50 and a more narrow arm 811 than the base 810 that protrudes from the base 810 and on whose end portion opposite to the base 810 the mobile electrical contact elements 82,82' are fixed.

- the rocking control member 70 includes a body 75, preferably made of electrically insulating material, e.g. plastic, rotatable with respect to the case 20 so as to rotate around a rotation axis A2-A2 (herein also called second rotation axis), parallel to a first rotation axis A3-A3, in order to rotate the rotatable contact holder support 81.

- a rotation axis A2-A2 herein also called second rotation axis

- the second rotation axis A2-A2 is parallel both to the third rotation axis A1-A1 and to the first rotation axis A3-A3.

- the body 75 of the rocking control member 70 is rotatably hinged to the case 20.

- the body 75 of the rocking control member 70 is shaped in such a way that the rotatable contact holder support 81 in the rotation around the first rotation axis A3-A3 can cross the second rotation axis A2-A, that is the rotation axis of the body 75 of the rocking control member 70.

- the body 75 of the rocking control member 70 includes a contact portion 72 having two shaped surfaces 701, 702 intended to be alternatively contacted and pushed by the pressure transmitting member 60, and in particular by the two appendices 601,602.

- the two shaped surfaces 701, 702 are two stepped surfaces.

- the body 75 of the rocking control member 70 includes a bridge portion 71 bypassing an operative space 710 in which the rotatable contact holder support 81, or an end portion thereof, as for example an end portion of the arm 811 is free to rotate.

- the bridge portion 71 includes at least a bended bridge arm 711, 712, 713, preferably two coplanar bended bridge arms 711, 713 originating from two different points of the body 75 and joining in the same point.

- the bridge portion 71 includes three bended bridge arms 711, 712, 713 originating from three different points of the body 75 and joining in the same point to form a cage structure that defines the operative area 710 within which the rotatable contact holder support 81, or an end portion thereof, as for example an end portion of the arm 811, is free to rotate.

- the bridge portion 71 may include a continuous bridge wall provided with a recess or a pocket within which the rotatable contact holder support 81, or an end portion thereof, is free to rotate.

- the bridge portion 71 bypasses also a space occupied by the fixed contact holder support 91, 91', by the fixed electrical contact element 92, 92' and by the mobile electrical contact element 82, 82'. In such a way, the bridge portion 71 bypasses a space region of the circuit breaker 10 in which the joining and separation between the mobile electrical contact element 82, 82' and the fixed electrical contact element 92, 92' occurs.

- the rocking control member 70 includes two opposite coupling elements that allow the rotatably coupling of the control member 70 with two opposite lateral walls of the case 20.

- the aforesaid coupling elements include two opposite cylindrical shaped pins 76 protruding from the body 75 along the rotation axis A2-A2 towards opposite directions.

- one of the aforesaid pins 76 protrudes from the contact portion 72 and the other one of said pins protrudes from the bridge portion 71.

- such pins 76 are inserted in corresponding pass through holes or recesses 276 arranged in two opposite lateral walls of the case 20.

- the body 75 of the rocking control member 70 includes a portion 73 containing an internally hollow seat adapted to receive an elastic element, e.g. a coil spring 77, operatively inserted between the rocking control member 70 and the mobile contact holder support 81.

- an elastic element e.g. a coil spring 77

- a wall 79 with a recess (not visible in the drawings because it points to the bottom wall 21 of the case 20) adapted to receive an end of an elastic element (as for example a coil spring) adapted to make the rocking control member 70 a monostable member.

- the proposed button operated circuit breaker with rocking control member 10 allows to fully achieve the planned scopes in terms of overcoming the drawbacks of the circuit breakers of the prior art.

- experimental evidence has demonstrated that, thanks to the provision of an elastic element which is or includes a wire spring 61, if compared to the push button circuit breakers of the prior art, it is possible to significantly reduce the resistance perceived when pushing the push button 30 starting from the moment when the pressure transmitting member 60 contacts the rocking control member 70. This contributes to produce a sensation of greater fluidity when pushing the push button.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Breakers (AREA)

- Push-Button Switches (AREA)

- Tumbler Switches (AREA)

- Switches With Compound Operations (AREA)

Claims (10)

- Disjoncteur à bouton-poussoir (10) doté d'un élément de commande de balancement comprenant :- un boîtier (20) en matériau électriquement isolant, ayant une paroi inférieure (21), des parois latérales (20a, 20b, 20c, 20d) étant jointes à la paroi inférieure (21) et un côté ouvert (21') opposé à la paroi inférieure (21) ;- un bouton-poussoir (30) pouvant être actionné pour commander une commutation électrique du disjoncteur (10) et ayant un corps pourvu de parois latérales (30a, 30b, 30c, 30d) traversant ledit côté ouvert (21'), le bouton-poussoir (10) étant conçu pour coulisser par rapport au boîtier (20) le long d'un axe de coulissement (Z-Z), entre une position avant et une position arrière ;- un élément de commande de balancement (70) conçu pour commander une commutation électrique ;- un élément de transmission de pression (60) contraint en rotation au corps du bouton-poussoir (30) et conçu pour tourner par rapport à une position angulaire de repos autour d'un axe de rotation (A1-A1) ;- un élément élastique (61) conçu pour ramener l'élément de transmission de pression (60) dans la position angulaire de repos après sa rotation ;caractérisé en ce que :- l'élément élastique susmentionné est, ou comprend, un ressort en fils (61) ;- le corps du bouton-poussoir (30) comprend une ouverture de passage (360), traversée par l'élément de transmission de pression (60), ainsi le ressort en fils (61) est disposé sur un côté de l'ouverture de passage (360) conjointement avec au moins une partie d'une portion centrale (600) de l'élément de transmission de pression (60), pendant que la partie restante de l'élément de transmission de pression (60) est disposée de l'autre côté de ladite ouverture de passage (360).

- Disjoncteur à bouton-poussoir (10) selon la revendication 1, dans lequel le ressort en fils (61) est un ressort en fils rectiligne.

- Disjoncteur à bouton-poussoir (10) selon la revendication 1 ou 2, dans lequel le ressort en fils (61) a un diamètre compris entre 0,25 mm et 0,75 mm.

- Disjoncteur à bouton-poussoir (10) selon l'une quelconque des revendications précédentes, dans lequel le ressort en fils (61) possède deux portions d'extrémité opposées (62) contraintes au corps du bouton-poussoir (30) et une portion centrale (63) conçue pour exercer une force élastique sur l'élément de transmission de pression (60).

- Disjoncteur à bouton-poussoir (10) selon la revendication 4, dans lequel l'élément de transmission de pression (60) comprend deux appendices (601, 602) provenant de la portion centrale (600), dans lequel la portion centrale (600) de l'élément de transmission de pression (60) comprend un canal (630) traversé par la portion centrale (63) du ressort en fils (61).

- Disjoncteur à bouton-poussoir (10) selon l'une quelconque des revendications précédentes, dans lequel le bouton-poussoir (30) comprend un siège de fixation (361) du ressort en fils (61) réalisé dans l'épaisseur de la paroi inférieure (31) du bouton-poussoir (30) et placé au-dessus de l'ouverture de passage (360) du bouton-poussoir (30).

- Disjoncteur à bouton-poussoir (10) selon l'une quelconque des revendications précédentes, dans lequel :- l'élément de transmission de pression (60) comprend deux broches d'articulation opposées (610) dirigées le long de l'axe de rotation (A1-A1) de l'élément de transmission de pression (60) ;- le corps du bouton-poussoir (30) comprend deux évidements en forme d'arc semi-circulaire ou circulaire (310), alignés le long de l'axe de rotation (A1-A1), chacun d'eux étant conçu pour recevoir partiellement une broche respective (610).

- Disjoncteur à bouton-poussoir (10) selon la revendication 6, dans lequel le siège de fixation (361) du ressort en fils (61) comprend deux rainures (362) alignées l'une par rapport à l'autre le long de la direction d'extension longitudinale dominante du ressort en fils (61) et traversées par les portions d'extrémité (62) du ressort en fils (61), les portions d'extrémité (62) du ressort en fils (61) faisant saillie au-delà de ces rainures (362) sur des côtés opposés par rapport à la portion centrale (63) du ressort en fils (61).

- Disjoncteur à bouton-poussoir (10) selon la revendication 8, dans lequel le siège de fixation (361) du ressort en fils (61) comprend des éléments d'arrêt (365) conçus pour limiter ou empêcher la translation du ressort en fils (31) par rapport au bouton-poussoir (30).

- Disjoncteur à bouton-poussoir (10) selon l'une quelconque des revendications précédentes, dans lequel le ressort en fils (61) est en acier à ressort.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL16838069T PL3417464T3 (pl) | 2016-02-15 | 2016-12-21 | Obsługiwany przyciskiem przerywacz obwodu z wahliwym członem sterującym |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITUB2016A000760A ITUB20160760A1 (it) | 2016-02-15 | 2016-02-15 | Interruttore azionato a pulsante con organo oscillante di controllo |

| PCT/IB2016/057866 WO2017141091A1 (fr) | 2016-02-15 | 2016-12-21 | Disjoncteur à bouton avec élément de commande de balancement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3417464A1 EP3417464A1 (fr) | 2018-12-26 |

| EP3417464B1 true EP3417464B1 (fr) | 2020-04-15 |

Family

ID=55969340

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16838069.9A Active EP3417464B1 (fr) | 2016-02-15 | 2016-12-21 | Disjoncteur à bouton avec élément de commande de balancement |

Country Status (15)

| Country | Link |

|---|---|

| EP (1) | EP3417464B1 (fr) |

| CN (1) | CN108604507B (fr) |

| AU (1) | AU2016392770B2 (fr) |

| BR (1) | BR112018071172B1 (fr) |

| CL (1) | CL2018002061A1 (fr) |

| CO (1) | CO2018008162A2 (fr) |

| CR (1) | CR20180439A (fr) |

| ES (1) | ES2806639T3 (fr) |

| HU (1) | HUE049691T2 (fr) |

| IT (1) | ITUB20160760A1 (fr) |

| MX (1) | MX2018009324A (fr) |

| PL (1) | PL3417464T3 (fr) |

| PT (1) | PT3417464T (fr) |

| RU (1) | RU2717580C2 (fr) |

| WO (1) | WO2017141091A1 (fr) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT201800006224A1 (it) * | 2018-06-12 | 2019-12-12 | Interruttore a quattro vie |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2708371A (en) * | 1954-03-15 | 1955-05-17 | Honeywell Regulator Co | Alternate action mechanism |

| US4748298A (en) * | 1986-04-18 | 1988-05-31 | Jaeger | Bistable switch, in particular for use as a headlamp dipswitch on a motor vehicle |

| DE10250262A1 (de) * | 2001-11-02 | 2003-05-15 | Marquardt Gmbh | Elektrischer Schalter |

| ITRM20030018A1 (it) * | 2003-01-17 | 2004-07-18 | Bticino Spa | Interruttore a pulsante. |

| KR100850422B1 (ko) * | 2007-08-20 | 2008-08-04 | 엘에스산전 주식회사 | 기중차단기의 투입스프링 차징장치 |

| KR100882398B1 (ko) * | 2007-08-20 | 2009-02-05 | 엘에스산전 주식회사 | 자동 풀림 링크 기구를 구비한 회로 차단기 및 이에사용되는 자동풀림 링크 기구 |

| KR100882399B1 (ko) * | 2007-08-20 | 2009-02-05 | 엘에스산전 주식회사 | 자동 풀림 링크 기구를 구비한 회로 차단기 및 이에사용되는 자동풀림 링크 기구 |

| CN204884915U (zh) * | 2015-08-05 | 2015-12-16 | Tcl-罗格朗国际电工(惠州)有限公司 | 开关组件 |

-

2016

- 2016-02-15 IT ITUB2016A000760A patent/ITUB20160760A1/it unknown

- 2016-12-21 CN CN201680080089.4A patent/CN108604507B/zh active Active

- 2016-12-21 RU RU2018126812A patent/RU2717580C2/ru active

- 2016-12-21 MX MX2018009324A patent/MX2018009324A/es unknown

- 2016-12-21 CR CR20180439A patent/CR20180439A/es unknown

- 2016-12-21 WO PCT/IB2016/057866 patent/WO2017141091A1/fr active Application Filing

- 2016-12-21 PT PT168380699T patent/PT3417464T/pt unknown

- 2016-12-21 PL PL16838069T patent/PL3417464T3/pl unknown

- 2016-12-21 EP EP16838069.9A patent/EP3417464B1/fr active Active

- 2016-12-21 AU AU2016392770A patent/AU2016392770B2/en active Active

- 2016-12-21 BR BR112018071172-1A patent/BR112018071172B1/pt active IP Right Grant

- 2016-12-21 ES ES16838069T patent/ES2806639T3/es active Active

- 2016-12-21 HU HUE16838069A patent/HUE049691T2/hu unknown

-

2018

- 2018-07-31 CL CL2018002061A patent/CL2018002061A1/es unknown

- 2018-07-31 CO CONC2018/0008162A patent/CO2018008162A2/es unknown

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2717580C2 (ru) | 2020-03-24 |

| MX2018009324A (es) | 2018-11-09 |

| CL2018002061A1 (es) | 2018-09-07 |

| AU2016392770B2 (en) | 2020-12-17 |

| ES2806639T3 (es) | 2021-02-18 |

| ITUB20160760A1 (it) | 2017-08-15 |

| PL3417464T3 (pl) | 2020-11-02 |

| BR112018071172A2 (fr) | 2023-07-25 |

| RU2018126812A (ru) | 2020-01-20 |

| BR112018071172B1 (pt) | 2023-12-26 |

| CR20180439A (es) | 2019-02-06 |

| PT3417464T (pt) | 2020-07-15 |

| CN108604507B (zh) | 2019-10-11 |

| CO2018008162A2 (es) | 2018-08-21 |

| CN108604507A (zh) | 2018-09-28 |

| AU2016392770A1 (en) | 2018-08-23 |

| RU2018126812A3 (fr) | 2020-02-11 |

| HUE049691T2 (hu) | 2020-10-28 |

| WO2017141091A1 (fr) | 2017-08-24 |

| EP3417464A1 (fr) | 2018-12-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3417469B1 (fr) | Interrupteur à bouton-poussoir avec système de guidage anti-brouillage | |

| EP3417466B1 (fr) | Interrupteur à bouton-poussoir avec système d'alignement de boutons | |

| US9218918B2 (en) | Single pole switching unit and switchgear device comprising one such unit | |

| EP2180487B1 (fr) | Microrupteur | |

| EP3417464B1 (fr) | Disjoncteur à bouton avec élément de commande de balancement | |

| CN102165546A (zh) | 紧急止动设备 | |

| US11404229B2 (en) | Flat wall switch assembly | |

| SK4792000A3 (en) | Electric switch for devices | |

| WO2017141093A1 (fr) | Disjoncteur modulaire comportant un système d'accouplement du pivot de support | |

| US7935905B2 (en) | Contact system | |

| WO2017141090A1 (fr) | Disjoncteur modulaire avec élément oscillant de commande | |

| US9287060B2 (en) | Conversion device for converting a mechanical position into an electric state | |

| EP3807917B1 (fr) | Disjoncteur à quatre voies | |

| RU2816578C1 (ru) | Механизм для электрического переключателя, соответствующие электрический узел и электрический переключатель | |

| BR112018015572B1 (pt) | Interruptor operado por botão com sistema de guias antiemperramento | |

| BR112018015573B1 (pt) | Interruptor operado por botão |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180709 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAV | Requested validation state of the european patent: fee paid |

Extension state: MA Effective date: 20180709 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| INTG | Intention to grant announced |

Effective date: 20200210 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602016034242 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1258262 Country of ref document: AT Kind code of ref document: T Effective date: 20200515 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: VALIPAT S.A. C/O BOVARD SA NEUCHATEL, CH Ref country code: PT Ref legal event code: SC4A Ref document number: 3417464 Country of ref document: PT Date of ref document: 20200715 Kind code of ref document: T Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20200710 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20200415 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E049691 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200715 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200716 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200815 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200715 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602016034242 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2806639 Country of ref document: ES Kind code of ref document: T3 Effective date: 20210218 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| 26N | No opposition filed |

Effective date: 20210118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| VS25 | Lapsed in a validation state [announced via postgrant information from nat. office to epo] |

Ref country code: MA Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20201221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201221 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 1258262 Country of ref document: AT Kind code of ref document: T Effective date: 20200415 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20231127 Year of fee payment: 8 Ref country code: RO Payment date: 20231219 Year of fee payment: 8 Ref country code: PT Payment date: 20231122 Year of fee payment: 8 Ref country code: HU Payment date: 20231204 Year of fee payment: 8 Ref country code: FR Payment date: 20231122 Year of fee payment: 8 Ref country code: DE Payment date: 20231121 Year of fee payment: 8 Ref country code: AT Payment date: 20231123 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20231127 Year of fee payment: 8 Ref country code: BE Payment date: 20231121 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20240102 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20240101 Year of fee payment: 8 |