EP2999859B1 - Turbomachine comportant un temoin d'usure du carter - Google Patents

Turbomachine comportant un temoin d'usure du carter Download PDFInfo

- Publication number

- EP2999859B1 EP2999859B1 EP14729423.5A EP14729423A EP2999859B1 EP 2999859 B1 EP2999859 B1 EP 2999859B1 EP 14729423 A EP14729423 A EP 14729423A EP 2999859 B1 EP2999859 B1 EP 2999859B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- opening

- wall

- turbine engine

- casing

- wear indicator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D21/00—Shutting-down of machines or engines, e.g. in emergency; Regulating, controlling, or safety means not otherwise provided for

- F01D21/14—Shutting-down of machines or engines, e.g. in emergency; Regulating, controlling, or safety means not otherwise provided for responsive to other specific conditions

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D21/00—Shutting-down of machines or engines, e.g. in emergency; Regulating, controlling, or safety means not otherwise provided for

- F01D21/003—Arrangements for testing or measuring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D21/00—Shutting-down of machines or engines, e.g. in emergency; Regulating, controlling, or safety means not otherwise provided for

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D27/00—Control, e.g. regulation, of pumps, pumping installations or pumping systems specially adapted for elastic fluids

- F04D27/001—Testing thereof; Determination or simulation of flow characteristics; Stall or surge detection, e.g. condition monitoring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/42—Casings; Connections of working fluid for radial or helico-centrifugal pumps

- F04D29/4206—Casings; Connections of working fluid for radial or helico-centrifugal pumps especially adapted for elastic fluid pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/30—Application in turbines

- F05D2220/32—Application in turbines in gas turbines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/30—Application in turbines

- F05D2220/32—Application in turbines in gas turbines

- F05D2220/329—Application in turbines in gas turbines in helicopters

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2260/00—Function

- F05D2260/80—Diagnostics

Definitions

- the present invention relates to the field of turbomachines, more particularly that of gas turbine engine compressors, in particular centrifugal compressors.

- the invention provides a means for detecting, in a simple manner, the state of wear of certain parts of the turbomachine.

- the gas turbine engines used for driving the rotor blades of a helicopter consist of radial or axial flow air veins for part of the trajectory.

- a known motor comprises a first rotor consisting of a set of two centrifugal compressors in series - this assembly is driven by an axial turbine - and a second free turbine rotor, downstream of the turbine of the first rotor, for the driving a power shaft.

- Another example of a known motor comprises a first rotor formed of an assembly of a three-stage axial compressor and a centrifugal compressor, arranged in series and driven by two axial turbines; a second rotor is formed of a twin turbine receiving the gases of the turbine of the first rotor and driving a power shaft.

- the object of the invention is a means for detecting and quantifying the erosion caused by the ingestion of particles in the air stream.

- the invention relates more particularly to certain areas of the air stream that are not subject to strong erosion and for which simplified monitoring would be desirable.

- This is for example the inner wall of the bend downstream of the diffuser of the coating of abradable material or the housing without such a coating, vis-à-vis the tops of the blades of the axial rotor.

- the cover of the compressor wheel which is covered on its inner face with an abradable coating comprises in a substantially middle part thereof, machined markers in the form of countersink and given depths in the abradable material.

- Wear monitoring is performed by endoscopic examinations. An endoscope is introduced into the compressor and an active end of the endoscope is positioned opposite the markings to provide an image signal of the markings. The endoscopic signal is a function of the number of markers and the wear in their place; it is treated to provide a motor removal decision criterion for changing and repairing worn parts.

- Concerning this problem of wear indicator other patent applications have been filed, such as FR 2938651 or FR 2942267 relating to wear indicators provided on the blades of the wheel of a compressor or on the wheel itself

- a turbomachine comprising a casing with an inner wall delimiting a stream of air and the casing having at least one opening, opening into said vein and forming a passage for a endoscope, the opening, during the operation of the turbomachine, being closed by a cap having an end surface portion ensuring the continuity of the inner wall of the housing, is characterized in that a wear indicator of the internal wall of the housing is associated with the plug or the inner wall of the housing, at the edge of the opening or opening into the opening.

- the invention it is possible, simply and without necessarily the implementation of any apparatus, to monitor the wear in areas of the turbomachine that are not directly accessible and that previously required disassembly operations and removing the engine. Depending on the state of the wear indicator, it is easy to decide whether to disassemble the turbomachine to perform the repair.

- the wear indicator is in the form of a countersink machined in said end surface portion of the plug.

- This embodiment is suitable when said surface portion of the plug is flush with the inner wall of the housing.

- the plug is made of the same material as this one.

- the wear indicator is a notch machined in the inner wall of the housing and which is visible from the outside through said opening forming an endoscope passage. According to this embodiment the plug may not be flush with the air stream.

- the depth of the counterbore is preferably chosen to correspond to the internal wall thickness that can be removed by erosion in the event of acceptable erosion of the zone. In this way, when the countersink is no longer visible, it is time to repair the part.

- the invention aims in particular a centrifugal compressor whose opening, forming a passage for an endoscope, with wear indicator is located in the downstream bend of the diffuser, at the output of a compressor stage.

- the invention also relates to an axial compressor or the axial part of a compressor, the opening forming a passage for an endoscope is located near an abradable coating vis-à-vis the tops of the rotor blades of the compressor.

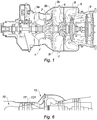

- a gas turbine engine 1 known per se for driving the blades of a helicopter rotor. It comprises a gas generator part with a bi-centrifugal compressor that is to say with two compression wheels 2 and 4 respectively integral with a coaxial turbine 6.

- the air stream 3 inside the housing is annular and extends from an air inlet 3a which guides the air to the axial inlet of the compressor 2.

- the compressed air by the compressor is guided radially through the diffuser 3b.

- the air stream then forms a bend 3c so as to bring the air towards the axis of the machine to the axial inlet of the second compression wheel 4.

- the air is then guided to the chamber of combustion 5 which supplies the turbine 6 with hot gas.

- the expansion of the gases continues in the turbine 9 of a second rotor secured to a power take-off shaft for driving the load.

- the air stream is delimited by two coaxial walls whose inner wall 3i of the casing 7.

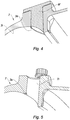

- FIG 2 which represents in section a portion of the casing 7 of the engine of the figure 1 we see the elbow 3c of the air vein, downstream of the diffuser 3b.

- This elbow serves to deflect the air flow from the diffuser to the axis of the machine.

- a radial opening 7r is arranged in the casing 7 at the elbow 3c. This opening opens into the vein of air and allows the passage of an unrepresented endoscope by which an inspection of the interior of the air vein can be performed.

- This opening 7r is normally closed by a plug 8 which is seen in section on the figure 2 .

- the plug comprises a 8f that fits into the opening 7r so as to fill it and prevent air leakage during operation of the machine; it is secured to a transverse locking plate 8v through which the cap is bolted to the casing 7.

- the plug 8 On the opposite side, the plug 8 has an end surface portion 8s conforming to the inner wall 3i so as to to ensure continuity.

- a wear indicator is provided on the plug. It advantageously consists of a countersink 8l machined on the surface portion 8s of the plug.

- the shape of the counterbore can be circular, oval or any other profile.

- This countersink 81 is visible on the figure 3 .

- the depth of the counterbore corresponds to the erosion potential of the inner wall 3i. It is thus very easy to check the state of wear of the part. If the countersink is no longer visible when removing the plug 8, it means that the erosion potential is consumed. The part is then to be repaired or replaced.

- the end surface portion 8s of the plug is slightly set back relative to the inner wall 3i.

- Practicing the erosion witness in the form of a notch 3s in the inner wall on the edge of the opening 7r makes it possible not to be hindered by such withdrawal from the end of the plug.

- This notch 3s opening into the opening 7r is visible from outside the housing when the cap has been removed.

- This situation is represented on the figure 5 .

- the depth of the notch in the inner wall 3i corresponds to the erosion potential thereof. If the notch 3s is no longer visible to the naked eye or the endoscope, it means that the potential for internal wall erosion is consumed. A repair is indicated.

- the erosion of the inner wall does not occur symmetrically around the axis of the machine, it depends on the position of the engine on the aircraft or the shape of the air inlet. It is then appropriate to provide an opening for the passage of the endoscope in the area likely to be most affected by erosion. It must also take into account the accessibility of the opening for the endoscope.

- FIG. 6 there is shown a gas turbine engine 10 with a compressor 12, axial and centrifugal; the first stages 121 of the compressor are axial.

- the housing 17 enveloping the first stages 121 has an opening for the passage of an endoscope, the present invention is advantageously applied to the monitoring of erosion of the inner wall of the housing in this area.

- the solution is not illustrated in the figure but is easily deduced from the solution described for the inner wall of the housing in the area of the downstream elbow of a centrifugal compressor.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Supercharger (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL14729423T PL2999859T3 (pl) | 2013-05-21 | 2014-05-13 | Maszyna wirowa zawierająca wskaźnik zużycia obudowy |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1354556A FR3006013B1 (fr) | 2013-05-21 | 2013-05-21 | Turbomachine comportant un temoin d'usure du carter |

| PCT/FR2014/051113 WO2014188107A1 (fr) | 2013-05-21 | 2014-05-13 | Turbomachine comportant un temoin d'usure du carter |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2999859A1 EP2999859A1 (fr) | 2016-03-30 |

| EP2999859B1 true EP2999859B1 (fr) | 2017-01-25 |

Family

ID=49753251

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14729423.5A Active EP2999859B1 (fr) | 2013-05-21 | 2014-05-13 | Turbomachine comportant un temoin d'usure du carter |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US10156155B2 (enExample) |

| EP (1) | EP2999859B1 (enExample) |

| JP (1) | JP6411470B2 (enExample) |

| KR (1) | KR102219495B1 (enExample) |

| CN (1) | CN105229266B (enExample) |

| CA (1) | CA2911875C (enExample) |

| ES (1) | ES2616886T3 (enExample) |

| FR (1) | FR3006013B1 (enExample) |

| PL (1) | PL2999859T3 (enExample) |

| RU (1) | RU2657391C2 (enExample) |

| WO (1) | WO2014188107A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201415201D0 (en) * | 2014-08-28 | 2014-10-15 | Rolls Royce Plc | A wear monitor for a gas turbine engine fan |

| GB202115178D0 (en) | 2021-10-22 | 2021-12-08 | Rolls Royce Plc | Gas passage |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1159071A (fr) | 1955-10-21 | 1958-06-23 | Borg Warner | Dispositif de commande automatique de programmes d'opérations |

| US3936217A (en) * | 1975-01-31 | 1976-02-03 | Westinghouse Electric Corporation | Inspection port for turbines |

| SU567847A1 (ru) * | 1976-04-12 | 1977-08-05 | Всесоюзный научно-исследовательский институт природных газов | Центробежный компрессор |

| US4406580A (en) * | 1981-07-23 | 1983-09-27 | United Technologies Corporation | Inspection hole plug for gas turbine engine |

| SU1408119A1 (ru) * | 1986-04-07 | 1988-07-07 | Всесоюзный научно-исследовательский и конструкторско-технологический институт компрессорного машиностроения | Сигнализатор износа элементов проточной части компрессора |

| US5472315A (en) * | 1993-11-09 | 1995-12-05 | Sundstrand Corporation | Abradable coating in a gas turbine engine |

| US7967554B2 (en) * | 2007-06-18 | 2011-06-28 | Honeywell International Inc. | Turbine cooling air centrifugal particle separator |

| FR2938651B1 (fr) * | 2008-11-14 | 2011-03-04 | Turbomeca | Procede et ensemble de determination de l'usure du bord d'attaque d'une pale |

| FR2942267B1 (fr) * | 2009-02-19 | 2011-05-06 | Turbomeca | Temoin d'erosion pour roue de compresseur |

| FR2946267B1 (fr) | 2009-06-05 | 2012-06-29 | Centre Nat Rech Scient | Procede de preparation d'une composition organocompatible et hydrocompatible de nanocristaux metalliques et composition obtenue |

| US8684669B2 (en) * | 2011-02-15 | 2014-04-01 | Siemens Energy, Inc. | Turbine tip clearance measurement |

| FR2973003B1 (fr) * | 2011-03-21 | 2013-03-29 | Jpb Systeme | Dispositif d'obturation a verrouillage auto-activable |

| US9322280B2 (en) * | 2011-08-12 | 2016-04-26 | United Technologies Corporation | Method of measuring turbine blade tip erosion |

| FR2981131B1 (fr) * | 2011-10-07 | 2013-11-01 | Turbomeca | Compresseur centrifuge equipe d'un marqueur de mesure d'usure et procede de suivi d'usure utilisant ce marqueur |

| GB201216703D0 (en) * | 2012-09-19 | 2012-10-31 | Rolls Royce Plc | A boroscope and a method of laser processing a component within an assembled apparatus using a boroscope |

-

2013

- 2013-05-21 FR FR1354556A patent/FR3006013B1/fr active Active

-

2014

- 2014-05-13 PL PL14729423T patent/PL2999859T3/pl unknown

- 2014-05-13 JP JP2016514457A patent/JP6411470B2/ja not_active Expired - Fee Related

- 2014-05-13 US US14/891,641 patent/US10156155B2/en active Active

- 2014-05-13 EP EP14729423.5A patent/EP2999859B1/fr active Active

- 2014-05-13 CA CA2911875A patent/CA2911875C/fr active Active

- 2014-05-13 ES ES14729423.5T patent/ES2616886T3/es active Active

- 2014-05-13 CN CN201480028937.8A patent/CN105229266B/zh active Active

- 2014-05-13 KR KR1020157033855A patent/KR102219495B1/ko not_active Expired - Fee Related

- 2014-05-13 RU RU2015151391A patent/RU2657391C2/ru active

- 2014-05-13 WO PCT/FR2014/051113 patent/WO2014188107A1/fr not_active Ceased

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2616886T3 (es) | 2017-06-14 |

| KR102219495B1 (ko) | 2021-02-23 |

| CN105229266A (zh) | 2016-01-06 |

| CA2911875A1 (fr) | 2014-11-27 |

| KR20160009578A (ko) | 2016-01-26 |

| CA2911875C (fr) | 2021-02-23 |

| PL2999859T3 (pl) | 2017-07-31 |

| EP2999859A1 (fr) | 2016-03-30 |

| CN105229266B (zh) | 2017-12-12 |

| RU2657391C2 (ru) | 2018-06-13 |

| WO2014188107A1 (fr) | 2014-11-27 |

| RU2015151391A (ru) | 2017-06-26 |

| JP2016519255A (ja) | 2016-06-30 |

| JP6411470B2 (ja) | 2018-10-24 |

| FR3006013A1 (fr) | 2014-11-28 |

| US10156155B2 (en) | 2018-12-18 |

| FR3006013B1 (fr) | 2017-10-13 |

| RU2015151391A3 (enExample) | 2018-04-03 |

| US20160084107A1 (en) | 2016-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3071792B1 (fr) | Moteur modulaire | |

| CA2752487C (fr) | Temoin d'erosion pour roue de compresseur | |

| EP3097272B1 (fr) | Enceinte de palier d'une turbomachine | |

| EP2764253B1 (fr) | Compresseur centrifuge equipe d'un marqueur de mesure d'usure et procede de suivi d'usure utilisant ce marqueur | |

| FR2937371A1 (fr) | Ventilation d'une turbine haute-pression dans une turbomachine | |

| FR2872870A1 (fr) | Commande de jeu de pale | |

| FR3016936A1 (fr) | Disque de rotor a dispositif de prelevement d'air centripete, compresseur comportant ledit disque et turbomachine avec un tel compresseur | |

| WO2013083917A1 (fr) | Systeme pour assurer l'etancheite entre une enceinte d'huile et un volume exterieur attenant et turbomachine equipee d'un tel systeme d'etancheite | |

| CA2876347C (fr) | Tourillon de turbomachine comportant une couronne de recuperation d'un flux d'huile de lubrification avec une pluralite d'orifices d'evacuation d'huile de lubrification | |

| EP2999859B1 (fr) | Turbomachine comportant un temoin d'usure du carter | |

| EP3344901A1 (fr) | Turbine de moteur a turbine a gaz comprenant un élément de joint d'étanchéité a labyrinthe | |

| FR2956206A1 (fr) | Stimulateur vibratoire pour le controle d'une aube d'une roue aubagee d'une turbomachine | |

| CA2919596A1 (fr) | Couvercle de compresseur centrifuge de turbomachine apte a etre fixe par l'aval pres de son bord amont, turbomachine comportant ce couvercle | |

| FR3009747A1 (fr) | Chambre de combustion de turbomachine pourvue d'un passage d'entree d'air ameliore en aval d'un orifice de passage de bougie | |

| FR2983909A1 (fr) | Enceinte lubrifiee logeant un palier inter-turbine et fermee par un joint a labyrinthe a faible usure | |

| FR3009583A1 (fr) | Turbomachine a organe de deviation d’objets etrangers | |

| FR3103521A1 (fr) | Ensemble pour une turbomachine | |

| FR3026776B1 (fr) | Dispositif de transmission de puissance pour une turbomachine d'aeronef | |

| CA2952755C (fr) | Arbre de turbomachine | |

| FR3065030A1 (fr) | Moteur a combustion interne | |

| WO2018055299A1 (fr) | Système de déshuilage d'un mélange air/huile de pressurisation d'étanchéités d'une turbomachine | |

| FR3117529A1 (fr) | Turbomachine avec canalisation d’air secondaire comportant un systeme de deshuilage | |

| FR3115086A1 (fr) | Dispositif d’accouplement mécanique entre deux arbres , boîtier d’engrenage de turbomachine l’ayant | |

| WO2025248182A1 (fr) | Procédé de nettoyage d'une zone interne d'une turbomachine par injection d'eau | |

| FR2966200A1 (fr) | Architecture de turbine a gaz, en particulier de turbomoteur, sans palier dans la zone inter-turbines |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20151102 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160928 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SAFRAN HELICOPTER ENGINES |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 864282 Country of ref document: AT Kind code of ref document: T Effective date: 20170215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602014006397 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 4 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170125 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2616886 Country of ref document: ES Kind code of ref document: T3 Effective date: 20170614 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 864282 Country of ref document: AT Kind code of ref document: T Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170525 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170425 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170525 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170425 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602014006397 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26N | No opposition filed |

Effective date: 20171026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170513 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240419 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240418 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20240603 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20240423 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240418 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20240423 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20240418 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250526 Year of fee payment: 12 |