EP2957516B1 - Container and method of production thereof - Google Patents

Container and method of production thereof Download PDFInfo

- Publication number

- EP2957516B1 EP2957516B1 EP15167161.7A EP15167161A EP2957516B1 EP 2957516 B1 EP2957516 B1 EP 2957516B1 EP 15167161 A EP15167161 A EP 15167161A EP 2957516 B1 EP2957516 B1 EP 2957516B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- container

- coated

- process according

- coated plates

- plates

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000000034 method Methods 0.000 title claims description 18

- 238000004519 manufacturing process Methods 0.000 title description 3

- 239000000463 material Substances 0.000 claims description 17

- 239000011248 coating agent Substances 0.000 claims description 9

- 238000000576 coating method Methods 0.000 claims description 9

- 229920001971 elastomer Polymers 0.000 claims description 8

- 239000005060 rubber Substances 0.000 claims description 8

- 230000035939 shock Effects 0.000 claims description 8

- 239000004033 plastic Substances 0.000 claims description 7

- 229920003023 plastic Polymers 0.000 claims description 7

- 230000003014 reinforcing effect Effects 0.000 claims description 6

- 239000011247 coating layer Substances 0.000 claims description 4

- 229920001296 polysiloxane Polymers 0.000 claims description 4

- 229920001944 Plastisol Polymers 0.000 claims description 3

- 239000006261 foam material Substances 0.000 claims description 3

- 239000004999 plastisol Substances 0.000 claims description 3

- 239000011347 resin Substances 0.000 claims description 3

- 229920005989 resin Polymers 0.000 claims description 3

- 238000007493 shaping process Methods 0.000 claims description 3

- 238000005406 washing Methods 0.000 claims description 3

- 230000000703 anti-shock Effects 0.000 claims description 2

- 230000000379 polymerizing effect Effects 0.000 claims description 2

- 238000003466 welding Methods 0.000 claims description 2

- 239000002318 adhesion promoter Substances 0.000 claims 1

- 239000000203 mixture Substances 0.000 description 6

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 238000001816 cooling Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 239000011253 protective coating Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D25/00—Details of other kinds or types of rigid or semi-rigid containers

- B65D25/14—Linings or internal coatings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D19/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D19/02—Rigid pallets with side walls, e.g. box pallets

- B65D19/06—Rigid pallets with side walls, e.g. box pallets with bodies formed by uniting or interconnecting two or more components

- B65D19/08—Rigid pallets with side walls, e.g. box pallets with bodies formed by uniting or interconnecting two or more components made wholly or mainly of metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/02—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents specially adapted to protect contents from mechanical damage

- B65D81/022—Containers made of shock-absorbing material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00014—Materials for the load supporting surface

- B65D2519/00024—Metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00014—Materials for the load supporting surface

- B65D2519/00034—Plastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00014—Materials for the load supporting surface

- B65D2519/00044—Combination, e.g. different elements made of different materials, laminates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00049—Materials for the base surface

- B65D2519/00059—Metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00154—Materials for the side walls

- B65D2519/00164—Metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00154—Materials for the side walls

- B65D2519/00174—Plastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00154—Materials for the side walls

- B65D2519/00184—Combination, e.g. different elements made of different materials, laminates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00009—Materials

- B65D2519/00223—Materials for the corner elements or corner frames

- B65D2519/00233—Metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00258—Overall construction

- B65D2519/00263—Overall construction of the pallet

- B65D2519/00273—Overall construction of the pallet made of more than one piece

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00258—Overall construction

- B65D2519/00283—Overall construction of the load supporting surface

- B65D2519/00293—Overall construction of the load supporting surface made of more than one piece

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00258—Overall construction

- B65D2519/00313—Overall construction of the base surface

- B65D2519/00323—Overall construction of the base surface made of more than one piece

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00258—Overall construction

- B65D2519/00313—Overall construction of the base surface

- B65D2519/00328—Overall construction of the base surface shape of the contact surface of the base

- B65D2519/00333—Overall construction of the base surface shape of the contact surface of the base contact surface having a stringer-like shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00258—Overall construction

- B65D2519/00398—Overall construction reinforcements

- B65D2519/00402—Integral, e.g. ribs

- B65D2519/00422—Integral, e.g. ribs on the walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00258—Overall construction

- B65D2519/00492—Overall construction of the side walls

- B65D2519/00502—Overall construction of the side walls whereby at least one side wall is made of two or more pieces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00547—Connections

- B65D2519/00552—Structures connecting the constitutive elements of the pallet to each other, i.e. load supporting surface, base surface and/or separate spacer

- B65D2519/00557—Structures connecting the constitutive elements of the pallet to each other, i.e. load supporting surface, base surface and/or separate spacer without separate auxiliary elements

- B65D2519/00562—Structures connecting the constitutive elements of the pallet to each other, i.e. load supporting surface, base surface and/or separate spacer without separate auxiliary elements chemical connection, e.g. glued, welded, sealed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00547—Connections

- B65D2519/00552—Structures connecting the constitutive elements of the pallet to each other, i.e. load supporting surface, base surface and/or separate spacer

- B65D2519/00572—Structures connecting the constitutive elements of the pallet to each other, i.e. load supporting surface, base surface and/or separate spacer with separate auxiliary element, e.g. screws, nails, bayonets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00547—Connections

- B65D2519/00577—Connections structures connecting side walls, including corner posts, to each other

- B65D2519/00616—Connections structures connecting side walls, including corner posts, to each other structures not intended to be disassembled

- B65D2519/00626—Connections structures connecting side walls, including corner posts, to each other structures not intended to be disassembled sidewalls connected via corner posts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00547—Connections

- B65D2519/00636—Connections structures connecting side walls to the pallet

- B65D2519/00666—Structures not intended to be disassembled

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00547—Connections

- B65D2519/00671—Connections structures connecting corner posts to the pallet

- B65D2519/00701—Structures not intended to be disassembled

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00736—Details

- B65D2519/00776—Accessories for manipulating the pallet

- B65D2519/00786—Accessories for manipulating the pallet for lifting, e.g. hooks, loops

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00736—Details

- B65D2519/00825—Finishing of the external surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2519/00—Pallets or like platforms, with or without side walls, for supporting loads to be lifted or lowered

- B65D2519/00004—Details relating to pallets

- B65D2519/00736—Details

- B65D2519/00935—Details with special means for nesting or stacking

- B65D2519/00955—Details with special means for nesting or stacking stackable

- B65D2519/00965—Details with special means for nesting or stacking stackable when loaded

- B65D2519/0097—Details with special means for nesting or stacking stackable when loaded through corner posts

Definitions

- the present invention relates to a container of industrial type. More in particular, the present invention relates to an industrial container, preferably a metallic and stackable one, coated inside with a protective coating.

- such containers have side walls and a bottom made of metal and the products are inserted inside thereof.

- the walls often are folded by forming ribs guaranteeing greater resistance to the container.

- US 3,647,100 discloses a coating-free container assembled from metallic plates comprising reinforcing ribs.

- US 5,226,373 discloses a pallet assembled using rubber coated elements.

- the object of the present invention is then to overcome the above-illustrated problems and this is obtained with a container as defined in claim 6.

- An additional object of the present invention is a process for the production of a container as defined in claim 1.

- the present invention by overcoming the problems of known art, involves several and evident advantages.

- the inner coating of the container according to the present invention has protective, anti-shock and sound-absorbing features.

- the inner coating of the container according to the present invention has protective, anti-shock and sound-absorbing features.

- it can be used in any industrial and not-industrial field.

- the properties of the walls and of the bottom of the coated container have the aim of guaranteeing the integrity of the products inserted inside thereof, as the contact of the products with the stiff sheets made of iron often scratches the surface thereof.

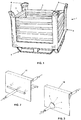

- FIG 1 shows a container 1 according to the present invention.

- the container 1 first of all has side walls and a bottom. Thereamong, at least a wall and/or the bottom is coated with a material apt to absorb shocks.

- the side walls and said bottom are made of metallic material.

- the material of the inner coating apt to absorb shocks is a plastic material or a rubber or a foam material.

- it can be PVC or a mixture deriving from the PVC such as for example plastisol, a plastic composition in liquid form given by a mixture of plastifying oils and PVC.

- PVC polyvinyl styrene

- plastisol a plastic composition in liquid form given by a mixture of plastifying oils and PVC.

- it can be rubber, resin or a silicone material or any other material suitable to the purpose.

- the container provides a supporting and reinforcing structure 5 having angular supporting elements 6.

- the container 1 can even provide one or more bases for inserting a fork of a lift truck.

- the container 1 has a shape suitable to be stacked together with other equal containers.

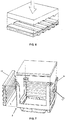

- the subsequent figures 2 to 7 relate to a process for implementing a container according to the present invention.

- metallic plates 10 are provided ( figures 2 and 3 ) which, at the end of the process, will form the walls and the bottom of a container with inner coating.

- the process provides assembling the coated plates 11 to form the real container.

- the process can comprise even a step of washing said metallic plates 10 and a possible subsequent step of applying an adherence promoter for plastics, rubber, silicone and resins, before applying the coating layer.

- Such washing step is shown, schematically, in figure 2 .

- the material used for the coating which will have to absorb shocks, preferably is a plastic material or a rubber or a foam material.

- a plastic material or a rubber or a foam material preferably is PVC, or a mixture deriving from the PVC such as for example plastisol, a plastic composition in liquid form given by a mixture of plastifying oils and PVC.

- plastisol a plastic composition in liquid form given by a mixture of plastifying oils and PVC.

- it can be a material like rubbers and/o silicones or any other material suitable to the purpose.

- the process can provide an additional step of polymerizing the coating material in a desiccator, followed by a possible cooling step.

- the coated plates 11 are subjected to a shaping step, before assembly, as illustrated in figure 6 .

- the assembly step is performed, for example by welding, bolting, riveting, bonding or interlocking system of coated plates 11 on a supporting and reinforcing structure 5 having preferably angular (not excluding tubular) supporting elements 6, of course by making that the coated face of each one of the plates is on the inner side of the container.

- the formed container can, or cannot, be painted outside and subsequently put on the market.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

Description

- The present invention relates to a container of industrial type. More in particular, the present invention relates to an industrial container, preferably a metallic and stackable one, coated inside with a protective coating.

- In the state of art, the containers of industrial type on the market are implemented in metal, through a process of assembling the various parts composing the container itself.

- Generally, such containers have side walls and a bottom made of metal and the products are inserted inside thereof.

- The walls often are folded by forming ribs guaranteeing greater resistance to the container.

- It is clear that there could be the need of inserting fragile products, or products which can be easily damaged after shocks, inside containers of this type.

- Therefore, their direct contact with the walls or the bottom of the metallic container can result to be particularly critical from this type of view.

-

US 3,647,100 discloses a coating-free container assembled from metallic plates comprising reinforcing ribs.US 5,226,373 discloses a pallet assembled using rubber coated elements. - The object of the present invention is then to overcome the above-illustrated problems and this is obtained with a container as defined in

claim 6. - An additional object of the present invention is a process for the production of a container as defined in

claim 1. - Additional features of the present invention are defined in the corresponding depending claims.

- The present invention, by overcoming the problems of known art, involves several and evident advantages.

- In particular, the inner coating of the container according to the present invention has protective, anti-shock and sound-absorbing features. For such properties it can be used in any industrial and not-industrial field.

- Furthermore, the properties of the walls and of the bottom of the coated container have the aim of guaranteeing the integrity of the products inserted inside thereof, as the contact of the products with the stiff sheets made of iron often scratches the surface thereof.

- All this allows minimizing and/or eliminating the blisters on the products, as the insertion of the products in the containers takes place in very short time, neglecting the stiffness of the bottom and of the walls, blistering the product.

- Furthermore, even the acoustic stress caused by the insertion of the product into the container is minimized, thanks to the sound-absorbing properties of the plastic and the rubbers.

- Additional advantages, together with the features and use modes of the present invention will result clear from the following detailed description of preferred embodiments thereof, shown by way of example and not for limitative purpose.

- The figures of the enclosed drawings will be referred to, wherein:

-

figure 1 is a perspective view of a container according to the present invention; and -

figures 2 to 7 illustrate a production process according to the present invention. - The present invention will be described hereinafter by referring to the above-mentioned figures.

- By firstly making reference to

figure 1 , this shows acontainer 1 according to the present invention. - The

container 1 first of all has side walls and a bottom. Thereamong, at least a wall and/or the bottom is coated with a material apt to absorb shocks. - The side walls and said bottom are made of metallic material.

- According to a preferred embodiment of the present invention, the material of the inner coating apt to absorb shocks is a plastic material or a rubber or a foam material.

- For example it can be PVC or a mixture deriving from the PVC such as for example plastisol, a plastic composition in liquid form given by a mixture of plastifying oils and PVC. Alternatively it can be rubber, resin or a silicone material or any other material suitable to the purpose.

- According to an embodiment, the container provides a supporting and reinforcing

structure 5 having angular supportingelements 6. - Advantageously, the

container 1 can even provide one or more bases for inserting a fork of a lift truck. - According to a preferred embodiment, it can be provided that the

container 1 has a shape suitable to be stacked together with other equal containers. - The subsequent

figures 2 to 7 relate to a process for implementing a container according to the present invention. - In particular, first of all it is provided that

metallic plates 10 are provided (figures 2 and 3 ) which, at the end of the process, will form the walls and the bottom of a container with inner coating. - On each one of such plates 10 a coating is then applied (

figure 4 ), according to known techniques, variable depending upon the type of material used for the coating itself. The material used for the coating will have to be apt to absorb shocks. Coatedplates 11 are obtained, as illustrated infigure 5 . - At last, the process provides assembling the coated

plates 11 to form the real container. - According to an embodiment, the process can comprise even a step of washing said

metallic plates 10 and a possible subsequent step of applying an adherence promoter for plastics, rubber, silicone and resins, before applying the coating layer. Such washing step is shown, schematically, infigure 2 . - In case, even a subsequent drying step can be provided, as illustrated in

figure 3 . - As already indicated, the material used for the coating, which will have to absorb shocks, preferably is a plastic material or a rubber or a foam material. For example it can be PVC, or a mixture deriving from the PVC such as for example plastisol, a plastic composition in liquid form given by a mixture of plastifying oils and PVC. Alternatively it can be a material like rubbers and/o silicones or any other material suitable to the purpose.

- After having implemented the coating layer on the plate, the process can provide an additional step of polymerizing the coating material in a desiccator, followed by a possible cooling step.

- The coated

plates 11 are subjected to a shaping step, before assembly, as illustrated infigure 6 . This to the purpose of implementing reinforcing ribs or real shapings, functional to the transportation of objects and/or specific products, on the walls and the bottom of the container. - At the end of the process, the assembly step is performed, for example by welding, bolting, riveting, bonding or interlocking system of coated

plates 11 on a supporting and reinforcingstructure 5 having preferably angular (not excluding tubular) supportingelements 6, of course by making that the coated face of each one of the plates is on the inner side of the container. - At the end of such process the formed container can, or cannot, be painted outside and subsequently put on the market.

Claims (6)

- A process for implementing a container (1) with coated inner side walls and bottom, comprising the steps of:- providing metallic plates (10) to form the walls and the bottom of said container;- applying on a whole surface of each plate (10) an anti-shock coating layer made of a material apt to absorb shocks, obtaining coated plates (11);- assembling said coated plates (11) to form said container in such a manner that said coated surfaces realize the inner walls and bottom of said container,the process further comprising a step of shaping said coated plates (11) for implementing reinforcing ribs, before assembly.

- The process according to claim 1, comprising a step of washing said coated plates (11) and, preferably, applying adhesion promoters, before applying the coating layer.

- The process according to claim 1 or 2, wherein said material apt to absorb shocks is selected from a group comprising: plastic material, rubber, foam material, silicone, resins, plastisol.

- The process according to claim 3, further comprising a step of polymerizing the coating material in a desiccator.

- The process according to one of claims 1 to 4, wherein the assembly takes place by welding, bolting, riveting, bonding or interlocking system of coated plates on a supporting and reinforcing structure (5) preferably having angular supporting elements (6).

- An industrial container (1), having side walls (2) and a bottom, characterized in that said side walls and said bottom are coated with a material apt to absorb shocks, implemented through a process according to anyone of the claims 1 to 5.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RS20171098A RS56683B1 (en) | 2014-06-16 | 2015-05-11 | Container and method of production thereof |

| PL15167161T PL2957516T3 (en) | 2014-06-16 | 2015-05-11 | Container and method of production thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITRM20140316 | 2014-06-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2957516A1 EP2957516A1 (en) | 2015-12-23 |

| EP2957516B1 true EP2957516B1 (en) | 2017-08-02 |

Family

ID=51399695

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15167161.7A Not-in-force EP2957516B1 (en) | 2014-06-16 | 2015-05-11 | Container and method of production thereof |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2957516B1 (en) |

| ES (1) | ES2645496T3 (en) |

| PL (1) | PL2957516T3 (en) |

| RS (1) | RS56683B1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT201700070864A1 (en) * | 2017-06-26 | 2018-12-26 | Davide Squitieri | CART AND PRODUCTION METHOD |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3647100A (en) * | 1969-12-30 | 1972-03-07 | Boothe Airside Services | Cargo container construction |

| US5226373A (en) * | 1989-10-17 | 1993-07-13 | Firma Kornitol International Gmbh | Pallet, especially flat pool pallet |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5238715A (en) * | 1989-12-26 | 1993-08-24 | Aluminum Company Of America | Food or beverage container or container panel |

| KR100817251B1 (en) * | 2006-06-28 | 2008-03-27 | 주식회사 삼정산업 | Iron Pallet |

-

2015

- 2015-05-11 PL PL15167161T patent/PL2957516T3/en unknown

- 2015-05-11 RS RS20171098A patent/RS56683B1/en unknown

- 2015-05-11 ES ES15167161.7T patent/ES2645496T3/en active Active

- 2015-05-11 EP EP15167161.7A patent/EP2957516B1/en not_active Not-in-force

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3647100A (en) * | 1969-12-30 | 1972-03-07 | Boothe Airside Services | Cargo container construction |

| US5226373A (en) * | 1989-10-17 | 1993-07-13 | Firma Kornitol International Gmbh | Pallet, especially flat pool pallet |

Also Published As

| Publication number | Publication date |

|---|---|

| RS56683B1 (en) | 2018-03-30 |

| ES2645496T3 (en) | 2017-12-05 |

| PL2957516T3 (en) | 2018-03-30 |

| EP2957516A1 (en) | 2015-12-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8876193B2 (en) | Inner wall liner for a refrigerated trailer wall panel | |

| JP2017074985A (en) | Cargo-handling pallet | |

| JP2019505447A (en) | Transport container system and transport container | |

| JP6267899B2 (en) | Food containers | |

| EP2957516B1 (en) | Container and method of production thereof | |

| JP5682843B2 (en) | Long fiber reinforced resin molded body and method for producing the same | |

| WO2017101897A8 (en) | Method for producing a plastic-metal hybrid component | |

| RU2017102482A (en) | TARA CONTAINING MOBILE WALL | |

| CA3010614A1 (en) | Shipping and display container and method of making the same | |

| WO2018112117A3 (en) | Methods for producing polymer-containing coatings upon cured inner liners, methods for producing tires containing such inner liners, and tires containing such inner liners | |

| ES2338473T3 (en) | PLASTIC PALLET WITH LOADING SURFACE WITH ANTI-SLIP COATING. | |

| MY189120A (en) | Thermoplastic adhesive film | |

| US9688437B1 (en) | Cover for a stackable transport pallet | |

| WO2006133433A3 (en) | Powder-coatable molding compositions | |

| US20190329934A1 (en) | Packaging container | |

| JP2019043819A (en) | Composite body and method for manufacturing the same | |

| US20120102880A1 (en) | Plastic container with reinforced base and closure and system and method of making same | |

| CN104271349A (en) | Large format polystyrene panel | |

| JP3212223U (en) | Packing material | |

| US10800575B2 (en) | Recyclable cardboard pallet | |

| JP6407637B2 (en) | Food containers | |

| JP7350471B2 (en) | container | |

| JP7059334B1 (en) | Goods transport tray and its manufacturing method | |

| JP7004237B2 (en) | Manufacturing method of sheet molded body, injection molded container and injection molded container | |

| JP2018167862A (en) | Container with lid |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20160621 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170123 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAL | Information related to payment of fee for publishing/printing deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR3 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| INTG | Intention to grant announced |

Effective date: 20170623 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 914176 Country of ref document: AT Kind code of ref document: T Effective date: 20170815 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602015003825 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2645496 Country of ref document: ES Kind code of ref document: T3 Effective date: 20171205 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170802 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 914176 Country of ref document: AT Kind code of ref document: T Effective date: 20170802 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171102 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171103 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171102 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171202 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602015003825 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20180503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181115 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170802 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20181120 Year of fee payment: 4 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180531 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180531 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20181123 Year of fee payment: 5 Ref country code: ES Payment date: 20181123 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180531 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602015003825 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190511 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170802 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20150511 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190512 |