EP2740887A1 - Ensemble d'injection de fluide de fond de trou et système de tubage de fond de trou - Google Patents

Ensemble d'injection de fluide de fond de trou et système de tubage de fond de trou Download PDFInfo

- Publication number

- EP2740887A1 EP2740887A1 EP12196093.4A EP12196093A EP2740887A1 EP 2740887 A1 EP2740887 A1 EP 2740887A1 EP 12196093 A EP12196093 A EP 12196093A EP 2740887 A1 EP2740887 A1 EP 2740887A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sleeve

- injection assembly

- fluid injection

- downhole

- space

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/02—Subsoil filtering

- E21B43/04—Gravelling of wells

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/02—Subsoil filtering

- E21B43/08—Screens or liners

- E21B43/086—Screens with preformed openings, e.g. slotted liners

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/25—Methods for stimulating production

- E21B43/26—Methods for stimulating production by forming crevices or fractures

- E21B43/27—Methods for stimulating production by forming crevices or fractures by use of eroding chemicals, e.g. acids

Definitions

- the present invention relates to a downhole fluid injection assembly for injecting a treatment fluid into an annulus surrounding a well casing.

- the invention furthermore relates to a downhole casing system and a method for treating an annulus by means of the fluid injection assembly.

- the hydrocarbon-containing fluid in the reservoir does not always flow out of the reservoir at a sufficiently high volume rate, and the formation is therefore treated to increase the volume rate of the fluid.

- One way of treating the formation is by injecting acid through the openings in the casing at a high velocity. However, this is not always sufficient to obtain the desired flow, and there is therefore a need for a more efficient way of treating the formation.

- a downhole fluid injection assembly for injecting a treatment fluid into an annulus surrounding a well casing, the downhole fluid injection assembly having a longitudinal axis and comprising:

- the sleeve may comprise a first opening and a second opening, the first opening being arranged closest to one of the ends and being larger than the second opening.

- the sleeve may comprise a sleeve section arranged between two adjacent openings, and the aperture may be arranged opposite the sleeve section.

- the sleeve section may taper radially towards the aperture.

- the sleeve section may have at least one flow channel.

- the downhole fluid injection assembly may further comprise a spacing element arranged in the space.

- the spacing element is arranged in the space to minimise the risk of the sleeve being pressed up against the tubular part so as to ensure that the space stays intact to enable the treatment fluid to flow in the space.

- the spacing element may taper towards at least one of the ends of the sleeve.

- a plurality of spacing elements may be arranged along the first axis.

- a plurality of spacing elements may be arranged in the space around a circumferential extension thereof.

- the spacing element may comprise a helical string or rod wound around the tubular part within the space.

- the spacing elements may be a plurality of balls arranged in the space.

- the spacing elements and/or the balls may be made of a corrodible material.

- the openings may be arranged in a predetermined pattern.

- the openings may be arranged with a mutual distance along the longitudinal axis.

- the mutual distance may decrease towards at least one of the ends of the sleeve.

- the distance between the openings may decrease towards at least one of the ends of the sleeve.

- each opening may have a size which increases towards at least one of the ends of the sleeve.

- the opening closest to one of the ends may be at least 20% larger than the opening closest to the aperture, preferably at least 30%, and more preferably at least 40%.

- a plurality of apertures may be arranged opposite the sleeve.

- the apertures may have a mutual distance along the longitudinal axis.

- the aperture may be closable.

- the treatment fluid may be an acid or a mixture of acids.

- the sleeve may be made of an acid-resistant metal.

- the present relation further relates to a downhole casing system comprising:

- the downhole casing system may further comprise an inflow section mounted as part of the casing string between the first and second annular barriers.

- the present invention relates to a method for treating an annulus by means of the fluid injection assembly as described above, the method comprising the steps of:

- the method may further comprise the step of corroding the corrodible spacing element or balls in the space.

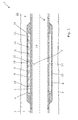

- Fig. 1 shows a downhole fluid injection assembly 1 for injecting a treatment fluid 5, illustrated by arrows, into an annulus 3 surrounding a well casing 2.

- the downhole fluid injection assembly comprises a tubular part 7 for mounting as part of the well casing and a sleeve 8 surrounding the tubular part.

- the sleeve has a first end 9 and a second end 10 and is at its ends connected with the tubular part, thereby defining an annular space 11 between the sleeve and the tubular part.

- the annular space is brought into fluid communication with an inside 14 of the tubular part by means of the aperture 12 arranged in the tubular part.

- the sleeve has openings 15 arranged in the sleeve for bringing the annular space into fluid communication with the annulus.

- the aperture 12 is arranged opposite the sleeve 8, and the space 11 and the openings 15 in the sleeve distribute the treatment fluid 5 in such a way that only part of the treatment fluid is injected directly into the annulus 3 opposite the aperture, corroding merely one large hole in the formation 21.

- the treatment fluid 5 is distributed along a longitudinal axis of the assembly and along a circumference of the sleeve 8.

- the fluid 5 is distributed over a wider range than in prior art injection systems, thereby corroding a wider area of the formation 21.

- the sleeve 8 has an increased thickness at its ends 9, 10 for fastening the sleeve to an outside the tubular part 7 while providing the annular space 11 opposite the thinner part of the sleeve.

- the ends 9, 10 of the sleeve 8 may be welded onto the tubular part 7 or tightly fitted around the tubular part.

- the annular space 11 functions as a distributing channel distributing the treatment fluid in such a way that it flows through all the openings 15 in the sleeve 8, as illustrated by arrows in Fig. 1 .

- the treatment fluid 5 is thus distributed along the longitudinal axis and along the circumference of the sleeve 8.

- the sleeve 8 comprises a sleeve section 16 arranged between two adjacent openings 15, and the aperture 12 is arranged opposite the sleeve section so as to ensure that the treatment fluid 5 is not distributed directly into an opening but is forced towards both ends 9, 10 of the sleeve.

- a first opening 15a of the sleeve 8 arranged closest to one of the ends is larger than a second opening 15b of the sleeve to be able to distribute the treatment fluid even better than the sleeve of Fig. 1 .

- the pressure drops across the annular space, and by providing the sleeve 8 with larger openings near its ends, more treatment fluid is let out of the first opening.

- the pressure of the treatment fluid near he ends of the sleeve 8 is lower than that of the fluid injected through the openings closer to the aperture 12.

- each opening 15a, 15b has a size d which increases towards at least one of the ends of the sleeve 8.

- the opening 15 closest to one of the ends may be at least 20% larger than the opening closest to the aperture 12, preferably at least 30%, and more preferably at least 40%.

- the openings 15 arranged between the opening closest to the one end and the opening closest to the aperture vary in size between the size of the first opening 15a and the opening 15e closest to the aperture.

- the openings 15 are arranged with a mutual distance x along the longitudinal axis 6.

- the distance between the openings 15 decreases towards at least one of the ends of the sleeve 8 so that the openings are arranged more closely near the ends of the sleeve than near the aperture 12 of the tubular part 7.

- the distance between a couple of adjacent openings may be the same, e.g. near the ends of the sleeve, while the distance between the next openings increases towards the aperture 12.

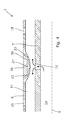

- the sleeve section 16 of Fig. 4 tapers radially towards the aperture 12, and the sleeve 8 is thus thicker opposite the aperture.

- the treatment fluid is diverted from flowing radially to flowing axially towards the ends of the sleeve 8.

- the sleeve section 16 may be pushed radially inwards during installation of the downhole fluid injection assembly 1 so that the sleeve section 16 covers the aperture 12.

- the sleeve section 16 is therefore provided with flow channels 20 enabling the treatment fluid to push the sleeve section radially outwards and to initiate distribution of the treatment fluid along the annular space 11.

- the sleeve section 16 has a round shape when seen in cross-section, and in Fig. 5 showing another embodiment of the sleeve section, the sleeve section has a more triangular cross-sectional shape.

- the flow channel 20 in the embodiments of Figs. 4 and 5 has an inlet 22 arranged opposite the aperture 12 and outlets 23 facing the ends of the sleeve 8.

- the downhole fluid injection assembly further comprises a spacing element 17 arranged in the annular space 11, as shown in Fig. 6 .

- the spacing element 17 is arranged in the annular space 11 to minimise the risk of the sleeve being pressed up against the tubular part 7 and to ensure that the annular space stays intact to enable the treatment fluid to flow in the annular space.

- the downhole fluid injection assembly 1 is shown with the sleeve 8 partly removed to make the spacing elements 17 visible.

- the sleeve covers the spacing elements 17 and the apertures 12, and the spacing elements 17 is fastened to an outer face 24 of the tubular part 7 extending along the longitudinal axis of the downhole fluid injection assembly 1.

- the sleeve comprises a plurality of openings 15 arranged in a predetermined pattern.

- the spacing element 17 may taper towards at least one of the ends of the sleeve, and one spacing element extends from the sleeve section 16 towards the one end of the sleeve while another spacing element extends from the sleeve section 16 towards the other end of the sleeve.

- the spacing element 17 may also be a helical string or rod wound around the tubular part 7 within the space 11.

- the downhole fluid injection assembly 1 comprises a plurality of balls 18 arranged in the annular space 11.

- the balls 18 function as spacing elements in that they prevent the sleeve 8 from bulging radially inwards.

- the spacing elements 17 and/or the balls 18 are made of a corrodible material, such as aluminium, but may also be made of a ceramic material.

- the acid corrodes the spacing elements 17 and/or the balls 18, allowing the fluid to flow freely in the space 11.

- the pressure is no longer decreased as much as when the spacing elements 17 and/or the balls 18 are still in the space 11.

- the tubular part 7 comprises a plurality of apertures 12 arranged opposite the sleeve 8.

- the apertures 12 have a mutual distance along the longitudinal axis 6.

- the apertures are closable by means of a sliding sleeve 26 sliding in a groove 27 in the tubular part 7.

- the downhole fluid injection assembly 1 can be closed off, e.g. while pressurising the casing for inflating/expanding other components, such as a packer or an annular barrier.

- the sleeve 8 is fastened to the tubular part 7 by means of two connection parts 28.

- the sleeve 8 may be fastened in the connection parts 28 by means of a threaded or welded connection.

- the sleeve 8 and the tubular part 7 may be made of an acid-resistant metal.

- Fig. 8 shows a downhole casing system 100 comprising a casing string 2, the downhole fluid injection assembly 1 described above and a first and a second annular barrier 50 each mounted as part of the casing string on opposite sides of the fluid injection assembly enclosing a production zone.

- the downhole casing system 100 further comprises an inflow section 60 mounted as part of the casing string between the first and second annular barriers for letting hydrocarbon-containing fluid into the casing after the treatment of the formation has ended.

- the inflow section 60 comprises a screen or a filtering element ensuring that only oil and gas is let into the casing. After passing the screen or filter, the hydrocarbon-containing fluid is let into inflow channels, out through a valve 61 and into the casing.

- the annular barriers comprise en expandable sleeve which, prior to injection of treatment fluid, is expanded, thereby isolating the annulus surrounding the fluid injection assembly 1. Then, the treatment fluid is let into the annular space of the downhole fluid injection assembly 1 via the aperture 12 in the tubular part 7 and is distributed along the longitudinal axis of the fluid injection assembly and let out through the openings 15 to treat the annulus.

- well fluid any kind of fluid that may be present in oil or gas wells downhole, such as natural gas, oil, oil mud, crude oil, water, etc.

- gas any kind of gas composition present in a well, completion, or open hole

- oil any kind of oil composition, such as crude oil, an oil-containing fluid, etc.

- Gas, oil, and water fluids may thus all comprise other elements or substances than gas, oil, and/or water, respectively.

- treatment fluid any kind of fluid for treating the formation or reservoir to help the hydrocarbon-containing fluid, such as oil or gas, flow easier.

- the treament fluid may be any kind of acid, such as HCl, H 2 S or H 2 SO 4 or any combination thereof.

- the treatment fluid may also comprise proppants.

- a casing any kind of pipe, tubing, tubular, liner, string etc. used downhole in relation to oil or natural gas production.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Geology (AREA)

- Mining & Mineral Resources (AREA)

- Physics & Mathematics (AREA)

- Environmental & Geological Engineering (AREA)

- Fluid Mechanics (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Production Of Liquid Hydrocarbon Mixture For Refining Petroleum (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12196093.4A EP2740887A1 (fr) | 2012-12-07 | 2012-12-07 | Ensemble d'injection de fluide de fond de trou et système de tubage de fond de trou |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12196093.4A EP2740887A1 (fr) | 2012-12-07 | 2012-12-07 | Ensemble d'injection de fluide de fond de trou et système de tubage de fond de trou |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2740887A1 true EP2740887A1 (fr) | 2014-06-11 |

Family

ID=47290827

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12196093.4A Withdrawn EP2740887A1 (fr) | 2012-12-07 | 2012-12-07 | Ensemble d'injection de fluide de fond de trou et système de tubage de fond de trou |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2740887A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20160237792A1 (en) * | 2015-02-17 | 2016-08-18 | Weatherford Technology Holdings, Llc | Injection distribution device |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5165476A (en) * | 1991-06-11 | 1992-11-24 | Mobil Oil Corporation | Gravel packing of wells with flow-restricted screen |

| US20020125006A1 (en) * | 2001-03-06 | 2002-09-12 | Hailey Travis T. | Apparatus and method for gravel packing an interval of a wellbore |

| US20020189809A1 (en) * | 2001-06-13 | 2002-12-19 | Nguyen Philip D. | Methods and apparatus for gravel packing, fracturing or frac packing wells |

| US20030066651A1 (en) * | 2001-10-09 | 2003-04-10 | Johnson Craig David | Apparatus and methods for flow control gravel pack |

| US20030221828A1 (en) * | 2002-05-31 | 2003-12-04 | Mcgregor Ronald W. | Apparatus and method for gravel packing an interval of a wellbore |

-

2012

- 2012-12-07 EP EP12196093.4A patent/EP2740887A1/fr not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5165476A (en) * | 1991-06-11 | 1992-11-24 | Mobil Oil Corporation | Gravel packing of wells with flow-restricted screen |

| US20020125006A1 (en) * | 2001-03-06 | 2002-09-12 | Hailey Travis T. | Apparatus and method for gravel packing an interval of a wellbore |

| US20020189809A1 (en) * | 2001-06-13 | 2002-12-19 | Nguyen Philip D. | Methods and apparatus for gravel packing, fracturing or frac packing wells |

| US20030066651A1 (en) * | 2001-10-09 | 2003-04-10 | Johnson Craig David | Apparatus and methods for flow control gravel pack |

| US20030221828A1 (en) * | 2002-05-31 | 2003-12-04 | Mcgregor Ronald W. | Apparatus and method for gravel packing an interval of a wellbore |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20160237792A1 (en) * | 2015-02-17 | 2016-08-18 | Weatherford Technology Holdings, Llc | Injection distribution device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9027637B2 (en) | Flow control screen assembly having an adjustable inflow control device | |

| RU2639344C2 (ru) | Скважинная разжимная труба | |

| US7909097B2 (en) | Well liner segments for in situ petroleum upgrading and recovery, and method of in situ upgrading and recovery | |

| US20140060837A1 (en) | Method and apparatus for treating a well | |

| US9399902B2 (en) | Expandable screen completion tool | |

| EP2644819A1 (fr) | Barrière annulaire dotée de tubes d'expansion | |

| US20170122081A1 (en) | Systems And Methods To Reduce Erosion In Wire Wrap Screen On Perforated Base Pipe | |

| RU2622572C2 (ru) | Способ стабилизации полости скважины | |

| CA2916646A1 (fr) | Dispositifs de controle des ecoulements comprenant une crepine a sables et un dispositif pour la maitrise des venues, destines a etre utilises dans des trous de forage | |

| AU2013385834B2 (en) | Flow control screen assembly having an adjustable inflow control device | |

| EP3388618B1 (fr) | Tube de drainage externe pour ensembles de crépine de puits | |

| EP2740887A1 (fr) | Ensemble d'injection de fluide de fond de trou et système de tubage de fond de trou | |

| US10208571B2 (en) | Flow conditioning flow control device | |

| US10677013B2 (en) | Annular barrier with shunt tube | |

| CN102257241B (zh) | 用于原位石油改质与回收的井衬管分段以及原位改质与回收的方法 | |

| WO2016028414A1 (fr) | Dispositif de réglage de débit bidirectionnel destiné à faciliter les traitements de stimulation dans une formation souterraine | |

| US10408022B2 (en) | Enhanced erosion resistance wire shapes | |

| US10202829B2 (en) | Inflow control device having elongated slots for bridging off during fluid loss control | |

| US10041336B2 (en) | Crimped nozzle for alternate path well screen | |

| CN203488159U (zh) | 新型立体防砂筛管 | |

| RU2619615C1 (ru) | Расширяемый скважинный фильтр и способ его установки | |

| US12110774B2 (en) | Artificial porosity-pressure adjustable formation fluid-gas control system and method | |

| RU94627U1 (ru) | Скважинный фильтр | |

| WO2019068164A1 (fr) | Appareil de régulation de débit pour la stimulation et la production de puits de forage | |

| CA2641281C (fr) | Segments de cuvelage de puits pour valorisation et recuperation de petrole in situ, et methode applicable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20121207 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20141212 |