EP2736397B1 - Multi-functional cleaning and floor care system - Google Patents

Multi-functional cleaning and floor care system Download PDFInfo

- Publication number

- EP2736397B1 EP2736397B1 EP12766341.7A EP12766341A EP2736397B1 EP 2736397 B1 EP2736397 B1 EP 2736397B1 EP 12766341 A EP12766341 A EP 12766341A EP 2736397 B1 EP2736397 B1 EP 2736397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- assembly

- reservoir

- cleaning

- care system

- liquid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/29—Floor-scrubbing machines characterised by means for taking-up dirty liquid

- A47L11/30—Floor-scrubbing machines characterised by means for taking-up dirty liquid by suction

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4036—Parts or details of the surface treating tools

- A47L11/4044—Vacuuming or pick-up tools; Squeegees

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4052—Movement of the tools or the like perpendicular to the cleaning surface

- A47L11/4055—Movement of the tools or the like perpendicular to the cleaning surface for lifting the tools to a non-working position

Definitions

- This invention relates to cleaning and floor care machines, and more particularly, to multi-functional cleaning and floor care machines.

- US6105203 discloses a floor cleaning machine for wet cleaning of a floor surface having a frame; at least one cleaning member, particularly a brush or pad, arranged rotatably on the frame, a first conduit system for feeding a first treatment solution to the floor surface in the region of the cleaning member for carrying out a first cleaning step, a first suction unit having a squeegee; a second conduit system for feeding a second treatment solution to the floor surface located behind the first suction unit as seen in the direction of normal forward movement of the machine, for carrying out a second cleaning step, a second suction unit having a squeegee, and tanks for fresh respectively used cleaning solution. Both suction units are connected to the used cleaning solution tank.

- Another multi-functional cleaning and floor care system is already known

- the invention is defined by the subject-matter of claim 1.

- the particular multi-functional cleaning and floor care system embodiment 10 shown comprises a fresh liquid reservoir assembly 12, a wet/dry vacuum assembly 14, a four-bend handle 16, a liquid spreader assembly 18, a squeegee head assembly 20, and a length of vacuum hose 22 fluidly connecting the squeegee head assembly to the wet/dry vacuum assembly.

- the fresh liquid reservoir assembly 12 has a reservoir 24 and a wheeled chassis 26 integral with the reservoir.

- the reservoir has a circumferential sidewall 28, a bottom wall 30, and an upper end 32 - with the circumferential sidewall including a front wall 34, a back wall 36, a left sidewall 38, and a right sidewall 40.

- the reservoir defines an interior space, and the reservoir upper end defines an opening - with the reservoir capable of holding a fresh cleaning liquid (e.g., water or another cleaning liquid or solution).

- the chassis includes the structure that supports the wheels.

- the reservoir assembly has four wheels - two swivel casters at the front (as at 42), and two fixed-axle wheels at the back (as at 44).

- the chassis includes a reinforced post or leg at the front lower-left corner, and a reinforced post or leg at the front lower-right corner. Each of these legs includes a cylindrical bore for receiving the post of the corresponding caster.

- the chassis includes a wheel frame at the back lower-left corner, and a wheel frame at the back lower-right corner. If desired, the reservoir and integral wheeled chassis also may be referred to as a trolley-bucket.

- the reservoir assembly 12 further has a spigot 46 ( Fig. 6 ) fluidly connected to the reservoir interior space, with the spigot having a valve that is adjustable between a fully open position and a fully closed position.

- An extension arm 48 is connected to the spigot and includes an upwardly extending section. A user may operate the spigot between a fully open position and a fully closed position by rotating the extension arm. In this fashion, when the reservoir contains a fresh cleaning liquid (e.g., water or another cleaning liquid or solution), a user may turn or rotate the extension arm, thereby adjusting the spigot valve and regulating the flow of the fresh cleaning liquid from the reservoir through the spigot.

- a fresh cleaning liquid e.g., water or another cleaning liquid or solution

- the wet/dry vacuum assembly 14 has a vacuum recovery tank 50 and a vacuum motor assembly 52 fluidly connected to the vacuum recovery tank.

- the vacuum motor assembly is positioned on top of the vacuum recovery tank, and is releasably fastened to the vacuum recovery tank with latches.

- the vacuum recovery tank has a top wall 54, a bottom wall 56, a front wall 58, a back wall 60, a left sidewall 62, and a right sidewall 64.

- a suction inlet 66 is located toward the top of the front wall; and a discharge outlet 68 is located at the bottom of the front wall.

- Four swivel caster wheels (as at 70, Fig. 2 ) extend downward from the bottom wall.

- the wet/dry vacuum assembly 14 is removably positioned on top of the reservoir 24, and the four-bend handle 16 is removably connected to the reservoir.

- a strap assembly (as at 72) on each side of the vacuum recovery tank 50 releasably connects the wet/dry vacuum assembly to the four-bend handle.

- the wet/dry vacuum assembly is transportable on the reservoir.

- each of the reservoir assembly and the wet/dry vacuum assembly is operable both when the wet/dry vacuum assembly is positioned on top of the reservoir, and when the wet/dry vacuum assembly is separated from the reservoir.

- the reservoir assembly 12 is further shown and described in commonly-owned U.S. Patent Application No. 12/660,935 , entitled “Cleaning Cart Systems” and filed on March 4, 2010, and in commonly-owned U.S. Patent Application No. 13/477,040 , entitled “Modular Multi-Functional Cleaning and Floor Care System” and filed on May 21, 2012.

- the wet/dry vacuum assembly, and the interaction between the reservoir assembly and the wet/dry vacuum assembly 14, are further shown and described in commonly-owned U.S. Patent Application No. 13/477,040 .

- the liquid spreader assembly 18 and the squeegee head assembly 20 are releasably connected to the fresh liquid reservoir assembly 12 via a hitch assembly 74.

- the hitch assembly is connected to the reservoir bottom wall 30 at the back of the reservoir, and extends rearward from the reservoir assembly.

- the hitch assembly 74 has a pair of parallel brackets 76, 78 and a crossbar 80 mounted at the exterior surface of the reservoir bottom wall 30.

- Bracket 78 is positioned between the left rear wheel and the spigot 46

- Bracket 76 is positioned between the right rear wheel and the spigot.

- the bottom wall of each bracket has a pair of longitudinal slots (as at 82), so that each bracket may be adjusted forward and aft as desired.

- the crossbar 80 is circular in cross-section, and is held in position by the brackets.

- the liquid spreader assembly 18 has a frame 84, a spreader pad 86 releasably attached to a bottom surface of the frame, a pair of connecting arms 88, 90, and a strap 92. These items may be made of any suitable materials.

- the pad may be releasably attached to the frame using any suitable material(s) or method(s).

- the frame bottom surface may have one or more strips of hook-type fasteners (of the hook-and-loop variety) that engage an upper surface of the pad.

- the pad may be any suitable pad, with one example being a microfiber pad.

- One end of each connecting arm is attached to an upper surface of the frame; and the other end is releasably and rotatably attached to the hitch crossbar.

- the end 94 includes an integral resilient generally C-shaped member that releasably snap-fits onto and around the crossbar.

- the strap has male and female snap members along its length. The lower portion of the strap is affixed to connecting arm 83; and female snaps at different locations along an upper portion of the strap may be releasably connected to a male snap (not shown) at a rear wall member to the left of the extension arm, at the back of the reservoir 24.

- a user may put the liquid spreader assembly 18 in a down position or in an up position ( Fig. 4 ).

- the spreader pad 86 is in a floor contacting relationship with a floor surface.

- the spreader pad is in a non-contacting relationship with the floor surface ( Fig. 4 ).

- a user may install or remove the liquid spreader assembly quickly and easily, without the use of any tools.

- the user aligns the open portion of the C-shaped member of each connecting arm 88, 90 with the crossbar 80, exerts a pushing force on the arms thereby snap-fitting the C-shaped members onto the crossbar, and fastens the upper portion of the strap 92 to the reservoir 24.

- the user may unfasten the upper portion of the strap, and then exert a pulling force on the arms to release the arms from the crossbar.

- the squeegee head assembly 20 has a frame assembly 96, a pair of connecting arms 98, 100, and a strap 102. These items may be made of any suitable materials.

- the frame assembly has a frame 104, squeegee blades (as at 106 and 108), and wheels (as at 110 along the length of the frame.

- the frame has a front, a back, a top, a first end, a second end, and a crown.

- a first row of squeegee blades (aligned end-to-end) depends from the front; and a second row of squeegee blades (aligned end-to-end) depends from the back.

- a tube segment of circular cross-section extends from the crown and serves to define a suction outlet for the assembly.

- the tube segment also serves as a connector, by which a user can releasably connect (e.g., via a friction fit) the assembly to an end portion of a length of vacuum hose - with the other end of the length of vacuum hose being releasably connectable to the suction inlet of the vacuum recovery tank.

- the squeegee head assembly 20 has a plow member 114, 116 at each of the frame first and second ends.

- Each plow member has a first section that extends forward and down from the frame front, and a second section integral with the first section, the second section extending across the top of the frame, from the frame front toward the frame back.

- Each plow member can be helpful in facilitating power cord management.

- the plow facilitates smooth movement of the power cord portion - either up and over the squeegee head assembly, or laterally away from the squeegee head assembly.

- each connecting arm is attached to an upper surface of the squeegee head assembly frame (as at 118); and the other end is releasably and rotatably attached to the hitch crossbar (as at 120).

- the end 120 includes an integral resilient generally C-shaped member that releasably snap-fits onto and around the crossbar.

- the strap has male and female snap members along its length. The lower portion of the strap is affixed to connecting arm 100; and female snaps at different locations along upper portions of the strap may be releasably connected to a male snap (not shown) at a rear wall member to the right of the extension arm, at the back of the reservoir 24.

- a user may put the squeegee head assembly in a down position or in an up position ( Fig. 4 ).

- the first and second rows of squeegee blades are in a floor contacting relationship with a floor surface.

- the first and second rows are in a non-contacting relationship with the floor surface ( Fig. 4 ).

- a user may install or remove the squeegee head assembly quickly and easily, without the use of any tools.

- the user aligns the open portion of the C-shaped member of each connecting arm with the crossbar, exerts a pushing force on the arms thereby snap-fitting the C-shaped members onto the crossbar, and fastens an upper portion of the strap to the reservoir.

- the user may unfasten an upper portion of the strap, and then exert a pulling force on the arms to release the arms from the crossbar.

- the user may open the reservoir spigot and turn on the wet-dry vacuum. Then the user may pull or push the multi-functional cleaning and floor care system (e.g., in a serpentine pattern) over the floor surface to be cleaned. As the user pulls or pushes the system along, cleaning solution is dispensed, spread, and vacuumed in one easy step.

- the multi-functional cleaning and floor care system e.g., in a serpentine pattern

- the modular design of the multi-functional cleaning and floor care system allows for quick and easy part replacement and changing from one cleaning mode to another.

- the design makes this process as simple as snapping on and snapping off.

- the modular design also allows the user to shift quickly and easily between a spread-only mode, a vacuum-only mode, and a spread-and-vacuum mode.

- the connecting arms are designed so that, if a user catches part of the liquid spreader assembly or squeegee head assembly on an obstacle (e.g., a corner of wall or heavy table), the connecting arms may detach (i.e., snap off) from the hitch - thereby preventing the liquid spreader assembly and the squeegee head assembly from breaking. Also, the connecting arms are designed to have some degree of twist; in this fashion, if either end of the squeegee head assembly frame brushes up against an obstacle, the squeegee head assembly can flex to get around the obstacle.

- an obstacle e.g., a corner of wall or heavy table

- the connecting arms are free to rotate around the hitch. This allows the arms to be rotated and stored in the upward-most position. In the upward position, the user can easily have access to the spreader pad (e.g., a microfiber pad) for replacement.

- the rigid design of the connecting arms allows the user to either pull or push the floor care system. This allows easy maneuvering into tight spaces and backing into corners or edges. If needed or desired in order to clean an edge or alcove, the user can disconnect the vacuum hose from the floor tool assembly and quickly attach the vac hose to a vacuum wand for trimming and cleaning these hard to reach areas.

- the wet-dry vacuum of the multi-functional cleaning and floor care system may be powered in any suitable way.

- the vacuum motor assembly may be connected to an electrical outlet (e.g., a wall outlet) via a power cord.

- the system may include a battery or the like.

- the multi-functional cleaning and floor care system may be used for a wide variety of floor care needs.

- the system may be used to apply a general-purpose cleaning solution, a stripping solution, a disinfectant, or a degreasing solution.

- the system may be used, e.g., for daily floor cleaning, stripping floors, and finishing floors.

- the system may be used in any of a number of locations and facilities, e.g., hallways, lobbies, cafeterias, gymnasiums, warehousing, shop floors, healthcare, and retail.

- a multi-functional cleaning and floor care system in accordance with the principles of the invention, may be operated in a number of different configurations and ways - determined largely by the particular cleaning- or other floor care- activity to be performed.

- a user may fill the reservoir with cleaning solution, put the liquid spreader assembly and the squeegee head assembly in the down position, open the spigot to dispense cleaning solution, turn on the vacuum motor, and start cleaning.

- extra dwell time is desired - for example, for heavy soil situations or for disinfection purposes - the user can simply raise the squeegee head assembly to the up position, and leave the liquid spreader assembly in place in the down position. In this manner, the system will disperse a thin uniform layer of solution as it leaves the spigot. Then, if desired, after a sufficient amount of dwell time, the user may simply lower the squeegee head assembly to the down position and vacuum up the solution.

- a user wants to apply and remove a floor stripper solution, the system allows them to do so in a highly productive manner.

- the user may move the four-bend handle to the front of the reservoir assembly, move the squeegee head assembly to the up position, keep the liquid spreader assembly in the down position, open the spigot, and pull the system (i.e., with the liquid spreader assembly trailing behind the spigot).

- the user may remove the liquid spreader assembly, lower the squeegee head assembly to the down position, turn on the vacuum motor, and push the system (i.e., with the squeegee head assembly and the back of the liquid reservoir now leading (i.e., the reservoir back now being at the front), and the front of the liquid reservoir now trailing behind the back. In this way, the user does not walk through the stripper solution - either in applying or removing the solution.

- system 200 is identical to system 10 (shown in Figs. 1-10 ), except that system 200 does not include the wet/dry vacuum assembly, the squeegee head assembly, and the length of vacuum hose.

- the particular multi-functional cleaning and floor care system embodiment 300 shown is identical to system 10 (shown in Figs. 1-10 ), except that system 300 does not include the liquid spreader assembly.

- the liquid spreader assembly and the squeegee head assembly may be fastened to a Kaivac No-Touch Cleaning® machine commercially available from Kaivac, Inc. of Hamilton OH.

- a bracket may be mounted to the back of a Kaivac No-Touch Cleaning® machine so as to locate the hitch at a suitable height above the floor.

- a quick disconnect fitting and spray wand may be mounted to the bracket, so that the spray line of the No-Touch Cleaning® machine may be attached to the spray wand.

- the spray wand may have a suitably sized nozzle such that the cleaning solution from the No-Touch Cleaning® machine may be dispensed at a proper location relative to the liquid spreader assembly and the squeegee head assembly (e.g., in front of both assemblies).

- the multi-functional cleaning and floor care system of the present invention may be made using any suitable material(s) and manufacturing technique(s).

- the reservoir may be made of polypropylene using injection molding

- the vacuum recovery tank may be made of polyethylene via rotational molding.

- the vacuum motor assembly may have the following specifications: 85 inches of lift; 60 cfm; 75 decibels; for the U.S., 110 Volts, 60 Hz, 10 amps; for Universal, 100-240 Volts, 50-60 Hz, 5.5 amps; and heavy duty two-stage vacuum motor.

Landscapes

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

- Nozzles For Electric Vacuum Cleaners (AREA)

Description

- This invention relates to cleaning and floor care machines, and more particularly, to multi-functional cleaning and floor care machines.

- Floors can be difficult and expensive to maintain. If not cared for properly, they not only become unsightly, they can drive customers away, cause slip and fall accidents, and even become a health hazard. Unfortunately, traditional mopping can make matters worse. Mopping is slow, ineffective, and even potentially dangerous - leaving floors slippery, wet, and with very few of the soils and biopollutants removed. Grouted floors are even trickier. In fact, during mopping, grout lines actually "squeegee" soil and soap scum from mops. When the water evaporates, soils, mineral deposits, soap scum, and potentially harmful biopollutants are left to penetrate and coat the porous grout. Grout lines that started out light gray or white soon become stained and darkened.

- Traditional cleaning tools, like mops and wipes, remove very few soils, germs and other indoor pollutants. In fact, studies show they often simply spread them around. Then, workers end up crawling around on their hands and knees wiping soiled surfaces and fixtures by hand.

US6105203 discloses a floor cleaning machine for wet cleaning of a floor surface having a frame; at least one cleaning member, particularly a brush or pad, arranged rotatably on the frame, a first conduit system for feeding a first treatment solution to the floor surface in the region of the cleaning member for carrying out a first cleaning step, a first suction unit having a squeegee; a second conduit system for feeding a second treatment solution to the floor surface located behind the first suction unit as seen in the direction of normal forward movement of the machine, for carrying out a second cleaning step, a second suction unit having a squeegee, and tanks for fresh respectively used cleaning solution. Both suction units are connected to the used cleaning solution tank. Another multi-functional cleaning and floor care system is already known e.g. fromUS-A-3376597 . - The invention is defined by the subject-matter of claim 1.

- The accompanying drawings, which are a part of this specification, illustrate embodiments of the invention. And together with the general description of the invention given above, and the detailed description of the drawings given below, the accompanying drawings explain the principles of the invention.

-

Fig. 1 is a perspective view of an embodiment of the multi-functional cleaning and floor care system, in accordance with the principles of the invention; -

Fig. 2 is a perspective view of a portion of the multi-functional cleaning and floor care system ofFig. 1 ; -

Fig. 3 is a left side view of a portion of the multi-functional cleaning and floor care system ofFig. 1 ; -

Fig. 4 is another left side view of a portion of the multi-functional cleaning and floor care system ofFig. 1 , with the liquid spreader assembly and the squeegee vacuum head assembly shown in an up position; -

Fig. 5 is a bottom view of the multi-functional cleaning and floor care system ofFig. 1 ; -

Fig. 6 is a portion of the bottom view ofFig. 5 , enlarged for magnification purposes; -

Fig. 7 is a cross-sectional view of a portion of the multi-functional cleaning and floor care system ofFig. 1 , taken along line 7-7 ofFig. 6 ; -

Fig. 8 is a cross-sectional view of a portion of the multi-functional cleaning and floor care system ofFig. 1 , taken along line 8-8 ofFig. 6 ; -

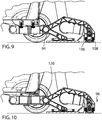

Fig. 9 is a cross-sectional view of a portion of the multi-functional cleaning and floor care system ofFig. 1 , taken along line 9-9 ofFig. 6 ; -

Fig. 10 is a cross-sectional view of a portion of the multi-functional cleaning and floor care system ofFig. 1 , taken along line 10-10 ofFig. 6 ; -

Fig. 11 is a perspective view of another embodiment of the multi-functional cleaning and floor care system, in accordance with the principles of the invention; -

Fig. 12 is a left side view of a portion of the multi-functional cleaning and floor care system ofFig.11 ; -

Fig. 13 is a perspective view of a portion of the multi-functional cleaning and floor care system ofFig.11 ; -

Fig. 14 is a perspective view of a further embodiment of the multi-functional cleaning and floor care system, in accordance with the principles of the invention; -

Fig. 15 is a left side view of a portion of the multi-functional cleaning and floor care system ofFig.14 ; and -

Fig. 16 is a perspective view of a portion of the multi-functional cleaning and floor care system ofFig.14 . - To facilitate understanding of the invention, like reference numbers are used for like elements in the various embodiments described in detail below.

- With reference to

Fig. 1 , the particular multi-functional cleaning and floorcare system embodiment 10 shown comprises a freshliquid reservoir assembly 12, a wet/dry vacuum assembly 14, a four-bend handle 16, aliquid spreader assembly 18, asqueegee head assembly 20, and a length ofvacuum hose 22 fluidly connecting the squeegee head assembly to the wet/dry vacuum assembly. - The fresh

liquid reservoir assembly 12 has areservoir 24 and awheeled chassis 26 integral with the reservoir. The reservoir has a circumferential sidewall 28, a bottom wall 30, and an upper end 32 - with the circumferential sidewall including afront wall 34, aback wall 36, a left sidewall 38, and aright sidewall 40. The reservoir defines an interior space, and the reservoir upper end defines an opening - with the reservoir capable of holding a fresh cleaning liquid (e.g., water or another cleaning liquid or solution). The chassis includes the structure that supports the wheels. The reservoir assembly has four wheels - two swivel casters at the front (as at 42), and two fixed-axle wheels at the back (as at 44). At the front, the chassis includes a reinforced post or leg at the front lower-left corner, and a reinforced post or leg at the front lower-right corner. Each of these legs includes a cylindrical bore for receiving the post of the corresponding caster. At the back, the chassis includes a wheel frame at the back lower-left corner, and a wheel frame at the back lower-right corner. If desired, the reservoir and integral wheeled chassis also may be referred to as a trolley-bucket. - The

reservoir assembly 12 further has a spigot 46 (Fig. 6 ) fluidly connected to the reservoir interior space, with the spigot having a valve that is adjustable between a fully open position and a fully closed position. Anextension arm 48 is connected to the spigot and includes an upwardly extending section. A user may operate the spigot between a fully open position and a fully closed position by rotating the extension arm. In this fashion, when the reservoir contains a fresh cleaning liquid (e.g., water or another cleaning liquid or solution), a user may turn or rotate the extension arm, thereby adjusting the spigot valve and regulating the flow of the fresh cleaning liquid from the reservoir through the spigot. - The wet/

dry vacuum assembly 14 has avacuum recovery tank 50 and avacuum motor assembly 52 fluidly connected to the vacuum recovery tank. The vacuum motor assembly is positioned on top of the vacuum recovery tank, and is releasably fastened to the vacuum recovery tank with latches. The vacuum recovery tank has a top wall 54, a bottom wall 56, a front wall 58, a back wall 60, a left sidewall 62, and a right sidewall 64. Asuction inlet 66 is located toward the top of the front wall; and a discharge outlet 68 is located at the bottom of the front wall. Four swivel caster wheels (as at 70,Fig. 2 ) extend downward from the bottom wall. - The wet/

dry vacuum assembly 14 is removably positioned on top of thereservoir 24, and the four-bend handle 16 is removably connected to the reservoir. A strap assembly (as at 72) on each side of thevacuum recovery tank 50 releasably connects the wet/dry vacuum assembly to the four-bend handle. The wet/dry vacuum assembly is transportable on the reservoir. In addition, each of the reservoir assembly and the wet/dry vacuum assembly is operable both when the wet/dry vacuum assembly is positioned on top of the reservoir, and when the wet/dry vacuum assembly is separated from the reservoir. - The

reservoir assembly 12 is further shown and described in commonly-ownedU.S. Patent Application No. 12/660,935 U.S. Patent Application No. 13/477,040 dry vacuum assembly 14, are further shown and described in commonly-ownedU.S. Patent Application No. 13/477,040 . - With reference to

Fig. 2 , theliquid spreader assembly 18 and thesqueegee head assembly 20 are releasably connected to the freshliquid reservoir assembly 12 via ahitch assembly 74. The hitch assembly is connected to the reservoir bottom wall 30 at the back of the reservoir, and extends rearward from the reservoir assembly. - As best seen in

Figs. 5-6 , thehitch assembly 74 has a pair ofparallel brackets crossbar 80 mounted at the exterior surface of the reservoir bottom wall 30.Bracket 78 is positioned between the left rear wheel and thespigot 46, andBracket 76 is positioned between the right rear wheel and the spigot. As seen inFig. 6 , the bottom wall of each bracket has a pair of longitudinal slots (as at 82), so that each bracket may be adjusted forward and aft as desired. Thecrossbar 80 is circular in cross-section, and is held in position by the brackets. - The

liquid spreader assembly 18 has aframe 84, aspreader pad 86 releasably attached to a bottom surface of the frame, a pair of connectingarms strap 92. These items may be made of any suitable materials. The pad may be releasably attached to the frame using any suitable material(s) or method(s). For example, the frame bottom surface may have one or more strips of hook-type fasteners (of the hook-and-loop variety) that engage an upper surface of the pad. The pad may be any suitable pad, with one example being a microfiber pad. One end of each connecting arm is attached to an upper surface of the frame; and the other end is releasably and rotatably attached to the hitch crossbar. As best seen inFig. 9 , theend 94 includes an integral resilient generally C-shaped member that releasably snap-fits onto and around the crossbar. As best seen inFigs. 2-4 , the strap has male and female snap members along its length. The lower portion of the strap is affixed to connecting arm 83; and female snaps at different locations along an upper portion of the strap may be releasably connected to a male snap (not shown) at a rear wall member to the left of the extension arm, at the back of thereservoir 24. - Depending on the particular upper portion female snap selected, a user may put the

liquid spreader assembly 18 in a down position or in an up position (Fig. 4 ). When the liquid spreader assembly is in the down position, thespreader pad 86 is in a floor contacting relationship with a floor surface. When the liquid spreader assembly is in the up position, the spreader pad is in a non-contacting relationship with the floor surface (Fig. 4 ). A user may install or remove the liquid spreader assembly quickly and easily, without the use of any tools. To install the assembly, the user aligns the open portion of the C-shaped member of each connectingarm crossbar 80, exerts a pushing force on the arms thereby snap-fitting the C-shaped members onto the crossbar, and fastens the upper portion of thestrap 92 to thereservoir 24. To remove the assembly, the user may unfasten the upper portion of the strap, and then exert a pulling force on the arms to release the arms from the crossbar. - The

squeegee head assembly 20 has aframe assembly 96, a pair of connectingarms 98, 100, and astrap 102. These items may be made of any suitable materials. The frame assembly has a frame 104, squeegee blades (as at 106 and 108), and wheels (as at 110 along the length of the frame. The frame has a front, a back, a top, a first end, a second end, and a crown. A first row of squeegee blades (aligned end-to-end) depends from the front; and a second row of squeegee blades (aligned end-to-end) depends from the back. A tube segment of circular cross-section extends from the crown and serves to define a suction outlet for the assembly. The tube segment also serves as a connector, by which a user can releasably connect (e.g., via a friction fit) the assembly to an end portion of a length of vacuum hose - with the other end of the length of vacuum hose being releasably connectable to the suction inlet of the vacuum recovery tank. - In addition, the

squeegee head assembly 20 has aplow member system 10 in a direction such that the squeegee head assembly trails behind the spigot, and a portion of a power cord is located to the left or right of the reservoir assembly but within the path of a laterally extending portion of the squeegee head assembly, the plow facilitates smooth movement of the power cord portion - either up and over the squeegee head assembly, or laterally away from the squeegee head assembly. - One end of each connecting arm is attached to an upper surface of the squeegee head assembly frame (as at 118); and the other end is releasably and rotatably attached to the hitch crossbar (as at 120). As best seen in

Fig. 10 , theend 120 includes an integral resilient generally C-shaped member that releasably snap-fits onto and around the crossbar. As best seen inFigs. 1-4 , the strap has male and female snap members along its length. The lower portion of the strap is affixed to connectingarm 100; and female snaps at different locations along upper portions of the strap may be releasably connected to a male snap (not shown) at a rear wall member to the right of the extension arm, at the back of thereservoir 24. - Depending on the particular upper portion female snap selected, a user may put the squeegee head assembly in a down position or in an up position (

Fig. 4 ). When the squeegee head assembly is in the down position, the first and second rows of squeegee blades are in a floor contacting relationship with a floor surface. When the squeegee head assembly is in the up position, the first and second rows are in a non-contacting relationship with the floor surface (Fig. 4 ). A user may install or remove the squeegee head assembly quickly and easily, without the use of any tools. To install the assembly, the user aligns the open portion of the C-shaped member of each connecting arm with the crossbar, exerts a pushing force on the arms thereby snap-fitting the C-shaped members onto the crossbar, and fastens an upper portion of the strap to the reservoir. To remove the assembly, the user may unfasten an upper portion of the strap, and then exert a pulling force on the arms to release the arms from the crossbar. - In use, the user may open the reservoir spigot and turn on the wet-dry vacuum. Then the user may pull or push the multi-functional cleaning and floor care system (e.g., in a serpentine pattern) over the floor surface to be cleaned. As the user pulls or pushes the system along, cleaning solution is dispensed, spread, and vacuumed in one easy step.

- The modular design of the multi-functional cleaning and floor care system allows for quick and easy part replacement and changing from one cleaning mode to another. The design makes this process as simple as snapping on and snapping off. The modular design also allows the user to shift quickly and easily between a spread-only mode, a vacuum-only mode, and a spread-and-vacuum mode.

- The connecting arms are designed so that, if a user catches part of the liquid spreader assembly or squeegee head assembly on an obstacle (e.g., a corner of wall or heavy table), the connecting arms may detach (i.e., snap off) from the hitch - thereby preventing the liquid spreader assembly and the squeegee head assembly from breaking. Also, the connecting arms are designed to have some degree of twist; in this fashion, if either end of the squeegee head assembly frame brushes up against an obstacle, the squeegee head assembly can flex to get around the obstacle.

- The connecting arms are free to rotate around the hitch. This allows the arms to be rotated and stored in the upward-most position. In the upward position, the user can easily have access to the spreader pad (e.g., a microfiber pad) for replacement. The rigid design of the connecting arms allows the user to either pull or push the floor care system. This allows easy maneuvering into tight spaces and backing into corners or edges. If needed or desired in order to clean an edge or alcove, the user can disconnect the vacuum hose from the floor tool assembly and quickly attach the vac hose to a vacuum wand for trimming and cleaning these hard to reach areas.

- The wet-dry vacuum of the multi-functional cleaning and floor care system may be powered in any suitable way. For example, the vacuum motor assembly may be connected to an electrical outlet (e.g., a wall outlet) via a power cord. Alternatively, the system may include a battery or the like.

- In use, the multi-functional cleaning and floor care system may be used for a wide variety of floor care needs. For example, the system may be used to apply a general-purpose cleaning solution, a stripping solution, a disinfectant, or a degreasing solution. The system may be used, e.g., for daily floor cleaning, stripping floors, and finishing floors. Also, the system may be used in any of a number of locations and facilities, e.g., hallways, lobbies, cafeterias, gymnasiums, warehousing, shop floors, healthcare, and retail.

- In use, a multi-functional cleaning and floor care system, in accordance with the principles of the invention, may be operated in a number of different configurations and ways - determined largely by the particular cleaning- or other floor care- activity to be performed.

- For example, for general or routine cleaning, a user may fill the reservoir with cleaning solution, put the liquid spreader assembly and the squeegee head assembly in the down position, open the spigot to dispense cleaning solution, turn on the vacuum motor, and start cleaning. If extra dwell time is desired - for example, for heavy soil situations or for disinfection purposes - the user can simply raise the squeegee head assembly to the up position, and leave the liquid spreader assembly in place in the down position. In this manner, the system will disperse a thin uniform layer of solution as it leaves the spigot. Then, if desired, after a sufficient amount of dwell time, the user may simply lower the squeegee head assembly to the down position and vacuum up the solution.

- If a user wants to apply and remove a floor stripper solution, the system allows them to do so in a highly productive manner. For example, to apply the solution, the user may move the four-bend handle to the front of the reservoir assembly, move the squeegee head assembly to the up position, keep the liquid spreader assembly in the down position, open the spigot, and pull the system (i.e., with the liquid spreader assembly trailing behind the spigot). To vacuum up the stripper solution, the user may remove the liquid spreader assembly, lower the squeegee head assembly to the down position, turn on the vacuum motor, and push the system (i.e., with the squeegee head assembly and the back of the liquid reservoir now leading (i.e., the reservoir back now being at the front), and the front of the liquid reservoir now trailing behind the back. In this way, the user does not walk through the stripper solution - either in applying or removing the solution.

- Additional embodiments and configurations of the multi-functional cleaning and floor care system of the present invention are described in further detail below. And as noted above, to facilitate understanding of the invention, like reference numbers are used for like elements across the various embodiments.

- With reference to

Figs. 11-13 , the particular multi-functional cleaning and floorcare system embodiment 200 shown is identical to system 10 (shown inFigs. 1-10 ), except thatsystem 200 does not include the wet/dry vacuum assembly, the squeegee head assembly, and the length of vacuum hose. - With reference to

Figs. 14-16 , the particular multi-functional cleaning and floorcare system embodiment 300 shown is identical to system 10 (shown inFigs. 1-10 ), except thatsystem 300 does not include the liquid spreader assembly. - In an alternate embodiment (not shown), the liquid spreader assembly and the squeegee head assembly may be fastened to a Kaivac No-Touch Cleaning® machine commercially available from Kaivac, Inc. of Hamilton OH. As needed, a bracket may be mounted to the back of a Kaivac No-Touch Cleaning® machine so as to locate the hitch at a suitable height above the floor. A quick disconnect fitting and spray wand may be mounted to the bracket, so that the spray line of the No-Touch Cleaning® machine may be attached to the spray wand. The spray wand may have a suitably sized nozzle such that the cleaning solution from the No-Touch Cleaning® machine may be dispensed at a proper location relative to the liquid spreader assembly and the squeegee head assembly (e.g., in front of both assemblies).

- The multi-functional cleaning and floor care system of the present invention may be made using any suitable material(s) and manufacturing technique(s). For example, if desired, the reservoir may be made of polypropylene using injection molding, and the vacuum recovery tank may be made of polyethylene via rotational molding. Also, if desired, the vacuum motor assembly may have the following specifications: 85 inches of lift; 60 cfm; 75 decibels; for the U.S., 110 Volts, 60 Hz, 10 amps; for Universal, 100-240 Volts, 50-60 Hz, 5.5 amps; and heavy duty two-stage vacuum motor.

- While the present invention has been illustrated by a description of embodiments, and while the illustrative embodiments have been described in considerable detail, additional advantages and modifications readily will appear to those skilled in the art upon a reading of this patent document.

Claims (9)

- A multi-functional cleaning and floor care system, comprising a reservoir (24) defining an interior space operable to hold a fresh cleaning liquid, a wet vacuum assembly (14) including a vacuum recovery tank (50), and a vacuum motor assembly (52) fluidly connected to the vacuum recovery tank (50), a wheeled chassis (26) configured to support at least one of the fresh liquid reservoir (24) and the vacuum recovery tank (50), a spigot (46) fluidly connected to the reservoir interior space, the spigot (46) adjustable between a fully open position and a fully closed position, whereby when the reservoir (24) contains a fresh cleaning liquid, a user may regulate the flow of the fresh cleaning liquid from the reservoir (24) through the spigot (46) by adjusting the spigot (46), a liquid spreader assembly (18) connected to at least one of the fresh liquid reservoir (24), the wet vacuum assembly (14) and the wheeled chassis (26), the liquid spreader assembly (18) including a frame and a spreader pad, and a squeegee head assembly (20) connected to at least one of the fresh liquid reservoir (24), the wet vacuum assembly (14), and the wheeled chassis (26), the squeegee head assembly (20) fluidly connectable to the vacuum recovery tank (50), the liquid spreader assembly operable to spread on a floor surface at least a portion of the fresh cleaning liquid from the reservoir and the squeegee head assembly (20) operable to vacuum at least a portion of the liquid on the floor surface into the vacuum recovery tank (50), wherein the multi-functional cleaning and floor care system is operable in a spread-only mode, a vacuum-only mode, and in a spread-and-vacuum mode.

- The multi-functional cleaning and floor care system of claim 1 wherein the liquid spreader assembly (18) is connected to the reservoir (24).

- The multi-functional cleaning and floor care system of claim 1 wherein the liquid spreader assembly (18) is releasably connected to the reservoir (24).

- The multi-functional cleaning and floor care system of claim 1 wherein the liquid spreader assembly (18) is connectable and disconnectable by a user without the use of a tool.

- The multi-functional cleaning and floor care system of claim 1 wherein the liquid spreader assembly (18) is moveable to an up position and a down position by a user without the use of a tool.

- The multi-functional cleaning and floor care system of claim 1 wherein the squeegee head assembly (20) is connected to the reservoir (24).

- The multi-functional cleaning and floor care system of claim 1 wherein the squeegee head assembly (20) is releasably connected to the reservoir (24).

- The multi-functional cleaning and floor care system of claim 1 wherein the squeegee head assembly (20) is connectable and disconnectable by a user without the use of a tool.

- The multi-functional cleaning and floor care system of claim 1 wherein the squeegee head assembly (20) is moveable to an up position and a down position by a user without the use of a tool.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201161513662P | 2011-07-31 | 2011-07-31 | |

| US201161548221P | 2011-10-18 | 2011-10-18 | |

| PCT/US2012/049087 WO2013019823A1 (en) | 2011-07-31 | 2012-07-31 | Multi-functional cleaning and floor care system |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2736397A1 EP2736397A1 (en) | 2014-06-04 |

| EP2736397B1 true EP2736397B1 (en) | 2020-07-29 |

| EP2736397B8 EP2736397B8 (en) | 2020-09-09 |

Family

ID=50625238

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12766341.7A Active EP2736397B8 (en) | 2011-07-31 | 2012-07-31 | Multi-functional cleaning and floor care system |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2736397B8 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112915234A (en) * | 2021-01-12 | 2021-06-08 | 刘贵芳 | Sterilization equipment for department of respiration |

| CN112915233A (en) * | 2021-01-12 | 2021-06-08 | 刘贵芳 | Sterilization device for department of respiration |

-

2012

- 2012-07-31 EP EP12766341.7A patent/EP2736397B8/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2736397A1 (en) | 2014-06-04 |

| EP2736397B8 (en) | 2020-09-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20210030237A1 (en) | Multi-Functional Cleaning and Floor Care System | |

| US6206980B1 (en) | Multi-functional cleaning machine | |

| EP1715783B1 (en) | Apparatus for floor cleaning and treatment | |

| EP2706898B1 (en) | Modular multi-functional cleaning and floor care system | |

| US7533435B2 (en) | Floor treatment apparatus | |

| AU2023203855B2 (en) | Floor treatment apparatus | |

| US7272869B1 (en) | Ergonomic multi-functional cleaning machine | |

| US10188250B2 (en) | Floor cleaning tool having a mechanically operated pump | |

| US6895633B2 (en) | Squeegee with clog reduction structure | |

| WO2016054457A1 (en) | Floor care system with interchangeable ac and dc vacuum motor assemblies | |

| EP2736397B1 (en) | Multi-functional cleaning and floor care system | |

| US5343591A (en) | Washing apparatus for walls and other non-horizontal surfaces | |

| EP3206546B1 (en) | Floor scrubbing machine | |

| WO2011057228A1 (en) | Squeegee assembly | |

| US20240148214A1 (en) | Accessory tool assembly for use with extraction cleaners | |

| HK40055917A (en) | Floor treatment apparatus | |

| HK40055917B (en) | Floor treatment apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140219 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KYDE, ROBERT, W. Inventor name: ROBINSON, ROBERT, S. Inventor name: LLOYD, DAVID, W. Inventor name: HARRELL, JOSHUA, L. Inventor name: RICHTER, JOHN, T. |

|

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20170118 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20191022 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAL | Information related to payment of fee for publishing/printing deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR3 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| INTC | Intention to grant announced (deleted) | ||

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAR | Information related to intention to grant a patent recorded |

Free format text: ORIGINAL CODE: EPIDOSNIGR71 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| INTG | Intention to grant announced |

Effective date: 20200619 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PK Free format text: BERICHTIGUNG B8 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1294822 Country of ref document: AT Kind code of ref document: T Effective date: 20200815 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: KAIVAC, INC. |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012071482 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1294822 Country of ref document: AT Kind code of ref document: T Effective date: 20200729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201029 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201030 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201029 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201130 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201129 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012071482 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 |

|

| 26N | No opposition filed |

Effective date: 20210430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200729 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20250814 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250813 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250825 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250814 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250828 Year of fee payment: 14 |