EP2241663A1 - Washing-drying machine and method for operating the same - Google Patents

Washing-drying machine and method for operating the same Download PDFInfo

- Publication number

- EP2241663A1 EP2241663A1 EP09005345A EP09005345A EP2241663A1 EP 2241663 A1 EP2241663 A1 EP 2241663A1 EP 09005345 A EP09005345 A EP 09005345A EP 09005345 A EP09005345 A EP 09005345A EP 2241663 A1 EP2241663 A1 EP 2241663A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- water

- air

- washing

- drying

- heat exchanger

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000001035 drying Methods 0.000 title claims abstract description 123

- 238000000034 method Methods 0.000 title claims abstract description 14

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 129

- 238000005406 washing Methods 0.000 claims abstract description 47

- 239000012530 fluid Substances 0.000 claims abstract description 18

- 238000010438 heat treatment Methods 0.000 claims abstract description 13

- 238000001816 cooling Methods 0.000 claims abstract description 10

- 238000005086 pumping Methods 0.000 claims abstract description 8

- 238000004886 process control Methods 0.000 claims description 23

- 239000000498 cooling water Substances 0.000 claims description 17

- 238000004891 communication Methods 0.000 claims description 8

- 238000012544 monitoring process Methods 0.000 claims description 6

- 230000004913 activation Effects 0.000 claims description 4

- 238000011144 upstream manufacturing Methods 0.000 claims description 4

- 238000001914 filtration Methods 0.000 claims description 3

- 238000005507 spraying Methods 0.000 claims description 2

- 241000196171 Hydrodictyon reticulatum Species 0.000 description 10

- 238000010981 drying operation Methods 0.000 description 7

- 238000011084 recovery Methods 0.000 description 4

- 230000008859 change Effects 0.000 description 2

- 239000013505 freshwater Substances 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 230000003213 activating effect Effects 0.000 description 1

- 230000009849 deactivation Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000008236 heating water Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000002351 wastewater Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F25/00—Washing machines with receptacles, e.g. perforated, having a rotary movement, e.g. oscillatory movement, the receptacle serving both for washing and for centrifugally separating water from the laundry and having further drying means, e.g. using hot air

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2101/00—User input for the control of domestic laundry washing machines, washer-dryers or laundry dryers

- D06F2101/20—Operation modes, e.g. delicate laundry washing programs, service modes or refreshment cycles

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2103/00—Parameters monitored or detected for the control of domestic laundry washing machines, washer-dryers or laundry dryers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2103/00—Parameters monitored or detected for the control of domestic laundry washing machines, washer-dryers or laundry dryers

- D06F2103/02—Characteristics of laundry or load

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2105/00—Systems or parameters controlled or affected by the control systems of washing machines, washer-dryers or laundry dryers

- D06F2105/36—Condensing arrangements, e.g. control of water injection therefor

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F2105/00—Systems or parameters controlled or affected by the control systems of washing machines, washer-dryers or laundry dryers

- D06F2105/50—Starting machine operation, e.g. delayed start or re-start after power cut

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F33/00—Control of operations performed in washing machines or washer-dryers

- D06F33/50—Control of washer-dryers characterised by the purpose or target of the control

- D06F33/72—Control of the energy or water consumption

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F34/00—Details of control systems for washing machines, washer-dryers or laundry dryers

- D06F34/08—Control circuits or arrangements thereof

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/08—Liquid supply or discharge arrangements

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F58/00—Domestic laundry dryers

- D06F58/20—General details of domestic laundry dryers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F58/00—Domestic laundry dryers

- D06F58/20—General details of domestic laundry dryers

- D06F58/24—Condensing arrangements

Definitions

- the present invention relates to a washing-drying machine and to a method for operating said machine.

- a washer-dryer appliance is generally provided for performing articles washing and drying operations in a single machine.

- a washing-drying machine comprises a drum for receiving articles to be treated, which is rotatably mounted within a tub.

- a water circuit including pumping means is provided for allowing washing water to be supplied to and drained from said tub.

- An air circuit having air circulating means and heating means, is provided for carrying out drying operation by circulating hot air through the drum.

- Condensing means are further provided in said air circuit for removing moisture from drying air passing through articles to be treated thereby allowing said air to be re-circulated cyclically within the air circuit. Moisture removed from articles is either collected in a tank periodically emptied by a user or it is directly exhausted by a pipe connected to a waste water net,

- said condensing means In washing-drying machines of known type, said condensing means generally comprise a box-like structure associated to the drying air circuit and a nozzle which is connected to a water supply for spraying said water against the drying air flow.

- a drawback of such known machines consists in that droplets of water nebulized by condensing means nozzle through the moist air flow can be partly transported by the flow downwards the condensing means and, in particular, towards electrically powered heating means causing potential security risks.

- a further drawback of the above cited type of known washing-drying machines consists in that condensing efficiency is low, and, in particular, lower than that of a drying machine provided with a condenser in the form of a heat exchanger wherein drying air is dehydrated by means of a fluid flow, i.e. a flow of air or water.

- drying cycles may require a long time and a high power consuming to be carried out while drying results achieved may be poor.

- FR 2 453 930 discloses one of said known drying machines having a first heat exchanger provided in the drying air circuit upstream the condensing unit for cooling said air flow before it enters such unit. Heat recovered in the first heat exchanger is conveyed back to the drying air flow by a second heat exchanger provided in the drying air circuit between the condensing unit and electrical heating means. First and second heat exchangers are connected by a common fluid path wherein a gaseous or liquid medium circulates in a closed loop for transferring heat from a part of the drying air circuit to another.

- a drawback of a drying machine according to FR 2 453 930 consists in that its manufacture costs does not economically compensate energy savings that can be achieved with such machine.

- such machine is designed for carrying out only a drying process and it has no means for articles washing operations.

- the aim of the present invention is therefore to solve the noted drawbacks and thus providing a washing-drying machine having an improved energy efficiency.

- An object of the present invention is not only to provide a washing-drying machine having a shorter drying time compared to known machines, but also a method for operating said machine that allows to save both water and energy during washing and drying operations.

- Another object of the invention is to provide a washing-drying machine having higher safety.

- a further object of the invention is to provide a washing-drying machine wherein washing and drying operational cycles are integrated for high energy recovery.

- Another object of the invention is to provide a method for operating a washing-drying machine wherein condensing capacity of air moisture condensing means can be adjusted for achieving a desired drying efficiency and/or limiting energy consumption.

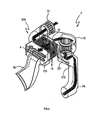

- Figure 1 shows schematically a washing-drying machine according to the invention

- Figure 2 shows a first embodiment of a condensing unit and drying air circuit of a washing-drying machine according to the invention

- Figure 3 shows a second embodiment of a condensing unit and drying air circuit of a washing-drying machine according to the invention

- a washing-drying machine 1 comprises an articles storing chamber 2 preferably in the form of a drum rotatably mounted within a tub 3.

- a water circuit 4 comprises a first conduit 4A for supplying water drained from a water net, like a public water net, to storing chamber 2 and a second conduit 4B for exhausting water from said chamber 2.

- Pumping means 5 is provided in water circuit 4 for circulating water within said circuit 4.

- Heating means 6 are provided in the storing chamber 2 for heating water during an articles washing operation.

- a first valve means 25 is mounted in the water circuit 4 for controlling water flow within the circuit 4.

- washing-drying machine 1 comprises an air circuit 7 having a first conduit 7A in fluid communication with the articles storing chamber 2 for exhausting dying air passed through articles to be dried and for conveying said air, enriched in humidity, towards a condensing unit 8, indicated with dashed lines in Figure 1 , where air moisture is removed.

- Air exiting the condensing unit 8 flows through a second conduit 7B connecting a condenser outlet port with an inlet port provided for allowing air to access the articles storing chamber 2.

- Heating means 9 are provided in conduit 7B for heating air before it enters chamber 2.

- Pumping means 10 such as a fan, is provided in the air circuit 7 for circulating drying air cyclically through the storing chamber 2. Moisture removed from drying air by the condensing unit 8 is collected in a reservoir 11.

- said condensing unit 8 generally comprises a first heat exchanger 12 of water/air type, i.e. an exchanger wherein moist drying air is condensed by water-cooled means.

- Heat exchanger 12 is therefore hydraulically connected to a water supply like a water tank of suitable capacity placed within the washer-drying machine 1 as will be diffusely described below.

- Condensing unit 8 further comprises a second heat exchanger 13 of air/air type, i.e. an exchanger wherein moist drying air is condensed by air-cooled means. Cooling air is taken from the environment surrounding the machine 1 by means of a fan 14 and it is exhausted from the second heat exchanger 13 to the same environment.

- First and second heat exchangers 12, 13 are connected in series relative to the drying air flow, such that one of them receives drying air exiting the other.

- the position order of heat exchangers 12, 13 relative to the drying air flow can be the most appropriate according to the arrangement of operational components inside the machine.

- One or more air filters 15 may be arranged in the drying air circuit 7, and preferably between the two heat exchangers 12, 13.

- FIG 2 it is disclosed a first embodiment 108 of the condensing unit 8 and drying air circuit 7 illustrated in figure 1 .

- the same reference numbers have been used for indicating features already depicted schematically in Figure 1 .

- a condensing unit 108 is formed by a first heat exchanger 112 of water/air type comprising a plurality of conduits 16 wherein cooling water is circulated for removing a first amount of moisture from drying air conveyed by air circuit 7 to pass through interstices provided among said plurality of conduits 16.

- the air circuit 7 comprises first and second conduits 7A, 7B in fluid communication with the articles storing chamber 2 ( Figure 1 ). Heating means 9 are provided in the second conduit 7B for heating the drying air flow. Condensed moisture is exhausted from the heat exchanger 112 by a water outlet port 17.

- cooling water can be supplied from a pipe 27 hydraulically connected to a water tank 28 provided inside the machine 1 and periodically refilled either by water taken by said water net through a further pipe line 29 or by water recovered during a previous washing operation through a water recovering pipe line 40 ( Figure 1 ) allowing at least a part of water used within the washing chamber 2 to be conveyed to tank 28.

- 112 cooling water may be re-circulated cyclically between the heat exchanger 12, 112 and the water tank 28 by means of pipes 27 and 30 forming with exchanger 12 and with tank 28 a hydraulic loop circuit.

- An exhausting water conduit 45 is provided for periodically discharging cooling water from tank 28 so as to allow fresh water drained by a water net through pipe line 29 to fill tank 28.

- Condensing unit 108 further comprises a second heat exchanger 113 of air/air type placed upstream relative to the first heat exchanger 112 such that drying air leaving the second heat exchanger 113 enters the first water/air heat exchanger 112. Cooling air taken from the environment surrounding the machine 1 is pumped to the heat exchanger 113 by a fan 14 while drying air flow moved within the air circuit 7 enters the heat exchanger 112. Cooling air flow and drying air flow cross each other without mixing so as to condense a second amount of moisture from drying air. Such amount of moisture is exhausted from the air/air heat exchanger 113 by a water outlet port 18. Air filtering means 15 are provided in the air circuit 7 between the heat exchangers 112, 113.

- a further water recovery may be advantageously achieved by providing a further fluid line 21 hydraulically connected to water circuit 4, the heat exchanger 12, 112 and, by means of pipe 27, to water tank 28, the latter being refilled with cooling water which is either drained from a water net at the beginning of a drying cycle or recovered in a previous washing cycle and stored within tank 28. Said cooling water being re-circulated through the water/air heat exchanger 12, 112 during the drying cycle.

- a pump 22 may be provided in fluid line 21 for leading cooling water used for condensing moisture of drying air in heat exchanger 12, 112 to the articles storing chamber 2 during washing operations following said drying cycle when water is needed for a washing or rinsing process, as it will be diffusely described hereafter. Pumps 19 and 22 may be the same, single pump, for both fluid lines 20, 21.

- a third fluid line 40 hydraulically connects the articles storing chamber 2 to the water tank 28, via conduit 4B provided for exhausting water from said chamber 2 as shown in Figure 1 or, if desired, directly, i.e. by means of a dedicated pipe without involving conduit 4B.

- the provision of conduit 40 is useful for conveying water used for one or more steps of a washing cycle to a storage means (tank 28) for a later use, in particular for being used during a drying process to cool condensing means 8. In this way, an amount of water can be used both for a washing process and for drying operations, thereby reducing the machine overall water consumption.

- a filter unit 43 may be provided in the fluid line 40 in order to remove lint and/ or foreign matter from water drained from articles storing chamber 2.

- Water recovery fluid lines 20, 21, 40 and main water circuit 4 are preferably provided with valve means 23, 24, 25, 41, 42 ( Figure 1 ) in signal communication with a process control unit 26 which is programmed for selecting, during washing operations, one of the available water supply lines 4, 20, 21 for providing water within the articles storing chamber 2 and for recovering an amount of said water by storing the latter in a storage means 28 for being used in a drying process following said washing operations.

- Selection of water source and management of valve means 23, 24, 25, 41, 42, are made by unit 26 in accordance with the washing or drying program actually running in the machine 1.

- Said process control unit 26 is also in signal communication with washing/drying program input means 44, such as a program selection knob, a keyboard, push-buttons and so on, for allowing a user to input a command and/or selecting washing/drying programs to be carried out on articles stored within chamber 2.

- washing/drying program input means 44 such as a program selection knob, a keyboard, push-buttons and so on, for allowing a user to input a command and/or selecting washing/drying programs to be carried out on articles stored within chamber 2.

- FIG 3 it is shown a second embodiment 208 of a condensing unit 8 and drying air circuit 7 illustrated in Figure 1 .

- the same reference numbers have been used for indicating features already depicted in Figures 1 and 2 .

- Condensing unit 208 differs from the first embodiment depicted in Figure 2 in that the water/air heat exchanger 212 comprises a nozzle 231 hydraulically connected with a water source, such as the water tank 28 shown in figure 1 , for nebulizing water against the drying air flowing within air circuit 7.

- Water/air heat exchanger 212 is associated to portion 7A of air circuit 7, i.e. the portion receiving the moist air exiting articles drying chamber 2.

- Fans 10 and 14 for circulating drying air and cooling air of the second air/air heat exchanger 113 respectively, heating means 9, filtering means 15 and the second heat exchanger 113 have the same features as those described with reference to Figure 2 .

- water/air heat exchanger 212 is placed upstream relative to the second air/air heat exchanger 113.

- Water recovery from condensed moisture and from cooling water of water/air heat exchanger 212 is arranged as described with reference to Figures 1 and 2 and it will not be described here again.

- a desired washing program is selected by a user in a known manner, i.e. by way of input means 44 like a keyboard, a program selector knob and the like.

- Other washing parameters like washing temperature, drum rotational speed during rinsing, overall washing time and the like may be input by a user, and further parameters may be acquired by appropriate sensors included in the machine like weight sensors, fabric types and the like (not illustrated).

- control unit 26 checks whether water is present in reservoir 11 as result of moisture condensed in a previous drying cycle and further checks whether water is present within tank 28 as retained after a previous drying process or recovered in said tank 28 after a previous washing process.

- process control unit 26 selects one or more of the available water sources (reservoir 11, tank 28, main water net connected through line 4 to the machine) for supplying water to the articles storing chamber (2). If no water is stored in reservoir 11 and in tank 28, unit 26 selects the main water net as water supply source. The part of the washing cycle and the water source are chosen by the process control unit 26 based on pre-programmed data stored within control unit 26. Said data associate possible combinations of user input parameters and of parameters automatically acquired by the machine with particular programs of recovered water introduction inside the article storing chamber 2.

- process control unit 26 may establish in which part of the washing cycle and whether or not an amount of water is to be recovered in the water tank 28 instead of being exhausted through conduit 4B.

- a suitable part of a washing cycle for recovering water used for treating articles in the chamber 2 may be the last rinsing operation. In the latter case, water recovered from rinsing is clean enough to be used for cooling a condenser unit 8, 108, 208 in a drying cycle subsequent to a washing process.

- a filter unit 43 is provided in fluid line 40. In this way, dirty water may be filtered and used to cool the condenser 8, 108, 208 during a drying cycle, thereby avoiding to dirty it.

- the process control unit 26 compares data input by a user when he/she chooses a washing program with data pre-programmed within control unit 26 so as to allow the latter to decide in which part of a chosen washing program water recovering can take place.

- Water recovering is made by the process control unit 26 by activating pump 5, closing valve means 42 in conduit 4B and opening valve means 41 in conduit 40.

- valve means 41 in conduit 40 is closed and valve means 42 in conduit 4B is opened so as to exhaust water further contained in the article storage chamber 2.

- the process control unit 26 After the process control unit 26 has set the part of the washing cycle in which recovered water has to be introduced into the storing chamber 2, the water source through which this operation has to be carried out, and in which part of a chosen washing program water recovering for a later use can take place, the selected washing program is started.

- a drying process in a washing-drying machine may be carried out using a recovered amount of water already used during a previous washing cycle and stored within tank 28 as described above.

- a desired drying program is selected by a user by way of input means 44 and further parameters (for example humidity of articles in the storing chamber 2, articles weight, articles type and so on) may be acquired by appropriate sensors (not illustrated) included in the machine to instruct the process control unit 26 about articles physical condition at the beginning of a drying cycle.

- control unit 26 compares said acquired parameters with data pre-programmed therein.

- Process control unit 26 may also establish the sequence of activation of each heat exchanger 12, 112, 212 and 13, 113 and, particularly for the water/air heat exchanger 12, 112, 212, unit 26 may change cooling water source between tank 28, filled with water recovered by a previous washing process or retained therein after a preceding drying cycle, and water supplied to tank 28 by a main water net through pipe line 29.

- Such change of cooling water source may be performed by process control unit 26 after that cooling water has been continuously re-circulated between the heat exchanger 12, 112, 212 and the water tank 28 by means of pipes 27 and 30.

- cooling water progressively heats up, thereby reducing capacity of heat exchanger 12, 112, 212 to condensate moisture in drying air.

- a temperature sensor (not shown) installed within tank 28 and in signal communication with process control unit 26 may be provided for communicating to such unit 26 that cooling water has reached a pre-determined hot temperature and, consequently, that efficiency of heat exchanger 12, 112, 212 is getting low.

- tank 28 is emptied via conduit 45 and than refilled by pipe line 29 with fresh water from a main water net.

- heat exchangers 12, 112, 212 and 13, 113 may be activated in any desired sequence, and each of them may work both continuously both intermittently during the whole drying process.

- the process control unit 26 may adjust the working sequence of said heat exchangers in function of data provided by the monitoring operation.

- a drying cycle started with both heat exchangers 12, 112, 212 and 13, 113 in an active state may be continued using only one of said heat exchangers, after that temperature of cooling water inside tank 28 reaches a pre-determined value.

- process control unit 26 may deactivate water/air heat exchanger 12, 112, 212 by interrupting circulation of cooling water within water circuit 27, 30. If deactivation of the air/air heat exchanger 13, 113 is desired, process control unit 26 may turn off cooling air pumping means 14, leaving said heat exchanger 13, 113 passively passed through by drying air.

- a washing-drying machine 1 has an improved energy efficiency.

- a machine 1 is possible not only saving water during a washing process by using water recovered during a previous drying process but it is also possible to adjust the drying air moisture content very finely by deactivating one of the heat exchangers 12, 13; 112, 113; 212, 113. This can be done simply turning off air/air heat exchanger 13, 113 cooling air pumping means 14, and stopping cooling water supply to water/air heat exchanger 12, 112, 212 by means of a valve means installed in the pipe line 27 connecting heat exchanger 12, 112, 212 with water tank 28.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Detail Structures Of Washing Machines And Dryers (AREA)

Abstract

- an articles storing chamber (2);

- a water circuit (4) for supplying water to the chamber (2) said water circuit being connectable to a water supply;

- an air circuit (7) for circulating drying air within said chamber (2), said air circuit (7) having pumping means (10), heating means (9) for heating said drying air and condensing means (8, 108, 208) adapted to remove moisture from said drying air comprising a first water/air heat exchanger (12, 112, 212);

Description

- The present invention relates to a washing-drying machine and to a method for operating said machine.

- A washer-dryer appliance is generally provided for performing articles washing and drying operations in a single machine. In this view a washing-drying machine comprises a drum for receiving articles to be treated, which is rotatably mounted within a tub. A water circuit including pumping means is provided for allowing washing water to be supplied to and drained from said tub. An air circuit, having air circulating means and heating means, is provided for carrying out drying operation by circulating hot air through the drum. Condensing means are further provided in said air circuit for removing moisture from drying air passing through articles to be treated thereby allowing said air to be re-circulated cyclically within the air circuit. Moisture removed from articles is either collected in a tank periodically emptied by a user or it is directly exhausted by a pipe connected to a waste water net,

- In washing-drying machines of known type, said condensing means generally comprise a box-like structure associated to the drying air circuit and a nozzle which is connected to a water supply for spraying said water against the drying air flow. A drawback of such known machines consists in that droplets of water nebulized by condensing means nozzle through the moist air flow can be partly transported by the flow downwards the condensing means and, in particular, towards electrically powered heating means causing potential security risks.

- A further drawback of the above cited type of known washing-drying machines consists in that condensing efficiency is low, and, in particular, lower than that of a drying machine provided with a condenser in the form of a heat exchanger wherein drying air is dehydrated by means of a fluid flow, i.e. a flow of air or water. In such known washing-drying machines, drying cycles may require a long time and a high power consuming to be carried out while drying results achieved may be poor.

- In order to improve efficiency of drying operations by reducing energy loss in the condenser, drying machines have been proposed in the market provided with additional heat exchangers for recovering energy by the hot drying air flow.

FR 2 453 930 - A drawback of a drying machine according to

FR 2 453 930 - The aim of the present invention is therefore to solve the noted drawbacks and thus providing a washing-drying machine having an improved energy efficiency.

- An object of the present invention is not only to provide a washing-drying machine having a shorter drying time compared to known machines, but also a method for operating said machine that allows to save both water and energy during washing and drying operations.

- Another object of the invention is to provide a washing-drying machine having higher safety.

- A further object of the invention is to provide a washing-drying machine wherein washing and drying operational cycles are integrated for high energy recovery.

- Another object of the invention is to provide a method for operating a washing-drying machine wherein condensing capacity of air moisture condensing means can be adjusted for achieving a desired drying efficiency and/or limiting energy consumption.

- Advantages, objects, and features of the invention will be set forth in part in the description and drawings which follow and in part will become apparent to those having ordinary skill in the art upon examination of the following or may be learned from practice of the invention. The objects and advantages of the invention may be realised and attained as particularly pointed out in the appended claims.

- The accompanying drawings, which are included to provide a further understanding of the invention and are incorporated in and constitute a part of this specification, illustrate possible embodiments of the invention and together with the description serve to explain the principles of the invention. Like reference numbers represents like features throughout the accompanying drawings, wherein:

-

Figure 1 shows schematically a washing-drying machine according to the invention; -

Figure 2 shows a first embodiment of a condensing unit and drying air circuit of a washing-drying machine according to the invention; -

Figure 3 shows a second embodiment of a condensing unit and drying air circuit of a washing-drying machine according to the invention; - With reference to

Figure 1 a washing-drying machine 1 according to the invention comprises anarticles storing chamber 2 preferably in the form of a drum rotatably mounted within atub 3. A water circuit 4 comprises a first conduit 4A for supplying water drained from a water net, like a public water net, to storingchamber 2 and asecond conduit 4B for exhausting water fromsaid chamber 2. Pumping means 5 is provided in water circuit 4 for circulating water within said circuit 4. Heating means 6 are provided in thestoring chamber 2 for heating water during an articles washing operation. A first valve means 25 is mounted in the water circuit 4 for controlling water flow within the circuit 4. - In order to perform an articles drying operation, washing-drying machine 1 comprises an

air circuit 7 having afirst conduit 7A in fluid communication with thearticles storing chamber 2 for exhausting dying air passed through articles to be dried and for conveying said air, enriched in humidity, towards a condensing unit 8, indicated with dashed lines inFigure 1 , where air moisture is removed. Air exiting the condensing unit 8 flows through asecond conduit 7B connecting a condenser outlet port with an inlet port provided for allowing air to access thearticles storing chamber 2. Heating means 9 are provided inconduit 7B for heating air before it enterschamber 2. Pumping means 10, such as a fan, is provided in theair circuit 7 for circulating drying air cyclically through thestoring chamber 2. Moisture removed from drying air by the condensing unit 8 is collected in a reservoir 11. - According to the invention, said condensing unit 8 generally comprises a first heat exchanger 12 of water/air type, i.e. an exchanger wherein moist drying air is condensed by water-cooled means. Heat exchanger 12 is therefore hydraulically connected to a water supply like a water tank of suitable capacity placed within the washer-drying machine 1 as will be diffusely described below.

- Condensing unit 8 further comprises a second heat exchanger 13 of air/air type, i.e. an exchanger wherein moist drying air is condensed by air-cooled means. Cooling air is taken from the environment surrounding the machine 1 by means of a

fan 14 and it is exhausted from the second heat exchanger 13 to the same environment. First and second heat exchangers 12, 13 are connected in series relative to the drying air flow, such that one of them receives drying air exiting the other. The position order of heat exchangers 12, 13 relative to the drying air flow can be the most appropriate according to the arrangement of operational components inside the machine. One ormore air filters 15 may be arranged in the dryingair circuit 7, and preferably between the two heat exchangers 12, 13. - With reference to

Figure 2 it is disclosed afirst embodiment 108 of the condensing unit 8 and dryingair circuit 7 illustrated infigure 1 . In such embodiment, the same reference numbers have been used for indicating features already depicted schematically inFigure 1 . - A

condensing unit 108 according to the first embodiment of the inventions is formed by afirst heat exchanger 112 of water/air type comprising a plurality ofconduits 16 wherein cooling water is circulated for removing a first amount of moisture from drying air conveyed byair circuit 7 to pass through interstices provided among said plurality ofconduits 16. Theair circuit 7 comprises first andsecond conduits Figure 1 ). Heating means 9 are provided in thesecond conduit 7B for heating the drying air flow. Condensed moisture is exhausted from theheat exchanger 112 by awater outlet port 17. As shown inFigure 1 , cooling water can be supplied from apipe 27 hydraulically connected to a water tank 28 provided inside the machine 1 and periodically refilled either by water taken by said water net through afurther pipe line 29 or by water recovered during a previous washing operation through a water recovering pipe line 40 (Figure 1 ) allowing at least a part of water used within thewashing chamber 2 to be conveyed to tank 28. After being passed through theheat exchanger 12, 112 cooling water may be re-circulated cyclically between theheat exchanger 12, 112 and the water tank 28 by means ofpipes 27 and 30 forming with exchanger 12 and with tank 28 a hydraulic loop circuit. Anexhausting water conduit 45 is provided for periodically discharging cooling water from tank 28 so as to allow fresh water drained by a water net throughpipe line 29 to fill tank 28. A more detailed description of theheat exchanger 12, 112 working operation is given with reference to the method for operating a washing -drying machine according to the invention. -

Condensing unit 108 further comprises asecond heat exchanger 113 of air/air type placed upstream relative to thefirst heat exchanger 112 such that drying air leaving thesecond heat exchanger 113 enters the first water/air heat exchanger 112. Cooling air taken from the environment surrounding the machine 1 is pumped to theheat exchanger 113 by afan 14 while drying air flow moved within theair circuit 7 enters theheat exchanger 112. Cooling air flow and drying air flow cross each other without mixing so as to condense a second amount of moisture from drying air. Such amount of moisture is exhausted from the air/air heat exchanger 113 by awater outlet port 18. Air filtering means 15 are provided in theair circuit 7 between theheat exchangers - Taking now into consideration

Figure 1 again, the whole amount of moisture removed from drying air byheat exchangers Figure 2 , is collected in a reservoir 11 (not shown inFigure 2 ) and led into thearticles storing chamber 2 during a step of a washing cycle by pumping means 19 and afirst fluid line 20 fluidly connected to thewater circuit 7, as it will be diffusely described hereafter. Condensed moisture has a low hardness and it can be advantageously stored in the reservoir 11 while a drying operation is in progress and later used for a subsequent washing and/or rinsing process. Even if the amount of water recovered by dried articles may not be enough for washing or rinsing the whole washing load, it contributes to reduce water consumption of the machine 1. - A further water recovery may be advantageously achieved by providing a

further fluid line 21 hydraulically connected to water circuit 4, theheat exchanger 12, 112 and, by means ofpipe 27, to water tank 28, the latter being refilled with cooling water which is either drained from a water net at the beginning of a drying cycle or recovered in a previous washing cycle and stored within tank 28. Said cooling water being re-circulated through the water/air heat exchanger 12, 112 during the drying cycle. A pump 22 may be provided influid line 21 for leading cooling water used for condensing moisture of drying air inheat exchanger 12, 112 to thearticles storing chamber 2 during washing operations following said drying cycle when water is needed for a washing or rinsing process, as it will be diffusely described hereafter. Pumps 19 and 22 may be the same, single pump, for bothfluid lines - A

third fluid line 40 hydraulically connects thearticles storing chamber 2 to the water tank 28, viaconduit 4B provided for exhausting water from saidchamber 2 as shown inFigure 1 or, if desired, directly, i.e. by means of a dedicated pipe without involvingconduit 4B. The provision ofconduit 40 is useful for conveying water used for one or more steps of a washing cycle to a storage means (tank 28) for a later use, in particular for being used during a drying process to cool condensing means 8. In this way, an amount of water can be used both for a washing process and for drying operations, thereby reducing the machine overall water consumption. Afilter unit 43 may be provided in thefluid line 40 in order to remove lint and/ or foreign matter from water drained fromarticles storing chamber 2. - Water

recovery fluid lines Figure 1 ) in signal communication with aprocess control unit 26 which is programmed for selecting, during washing operations, one of the availablewater supply lines articles storing chamber 2 and for recovering an amount of said water by storing the latter in a storage means 28 for being used in a drying process following said washing operations. Selection of water source and management of valve means 23, 24, 25, 41, 42, are made byunit 26 in accordance with the washing or drying program actually running in the machine 1. Saidprocess control unit 26 is also in signal communication with washing/drying program input means 44, such as a program selection knob, a keyboard, push-buttons and so on, for allowing a user to input a command and/or selecting washing/drying programs to be carried out on articles stored withinchamber 2. - In

Figure 3 it is shown asecond embodiment 208 of a condensing unit 8 and dryingair circuit 7 illustrated inFigure 1 . In such embodiment, the same reference numbers have been used for indicating features already depicted inFigures 1 and2 . - Condensing

unit 208 differs from the first embodiment depicted inFigure 2 in that the water/air heat exchanger 212 comprises anozzle 231 hydraulically connected with a water source, such as the water tank 28 shown infigure 1 , for nebulizing water against the drying air flowing withinair circuit 7. Water/air heat exchanger 212 is associated toportion 7A ofair circuit 7, i.e. the portion receiving the moist air exitingarticles drying chamber 2.Fans air heat exchanger 113 respectively, heating means 9, filtering means 15 and thesecond heat exchanger 113 have the same features as those described with reference toFigure 2 . In the second embodiment ofFigure 3 , water/air heat exchanger 212 is placed upstream relative to the second air/air heat exchanger 113. Water recovery from condensed moisture and from cooling water of water/air heat exchanger 212 is arranged as described with reference toFigures 1 and2 and it will not be described here again. - There are now disclosed methods for operating a washing-drying machine according to the present invention for carrying out a washing operation and a drying process.

- When a washing cycle has to be carried out, a desired washing program is selected by a user in a known manner, i.e. by way of input means 44 like a keyboard, a program selector knob and the like. Other washing parameters, like washing temperature, drum rotational speed during rinsing, overall washing time and the like may be input by a user, and further parameters may be acquired by appropriate sensors included in the machine like weight sensors, fabric types and the like (not illustrated). After the machine has been set for carrying out a washing process, control

unit 26 checks whether water is present in reservoir 11 as result of moisture condensed in a previous drying cycle and further checks whether water is present within tank 28 as retained after a previous drying process or recovered in said tank 28 after a previous washing process. If water presence is detected within reservoir 11 and/or within tank 28,process control unit 26 selects one or more of the available water sources (reservoir 11, tank 28, main water net connected through line 4 to the machine) for supplying water to the articles storing chamber (2). If no water is stored in reservoir 11 and in tank 28,unit 26 selects the main water net as water supply source. The part of the washing cycle and the water source are chosen by theprocess control unit 26 based on pre-programmed data stored withincontrol unit 26. Said data associate possible combinations of user input parameters and of parameters automatically acquired by the machine with particular programs of recovered water introduction inside thearticle storing chamber 2. - Furthermore, according to the selected washing program and to the washing parameters set by a user and parameters acquired by the machine itself,

process control unit 26 may establish in which part of the washing cycle and whether or not an amount of water is to be recovered in the water tank 28 instead of being exhausted throughconduit 4B. For example, a suitable part of a washing cycle for recovering water used for treating articles in thechamber 2 may be the last rinsing operation. In the latter case, water recovered from rinsing is clean enough to be used for cooling acondenser unit filter unit 43 is provided influid line 40. In this way, dirty water may be filtered and used to cool thecondenser - Operationally, the

process control unit 26 compares data input by a user when he/she chooses a washing program with data pre-programmed withincontrol unit 26 so as to allow the latter to decide in which part of a chosen washing program water recovering can take place. Water recovering is made by theprocess control unit 26 by activatingpump 5, closing valve means 42 inconduit 4B and opening valve means 41 inconduit 40. When water tank 28 is completely filled, valve means 41 inconduit 40 is closed and valve means 42 inconduit 4B is opened so as to exhaust water further contained in thearticle storage chamber 2. - After the

process control unit 26 has set the part of the washing cycle in which recovered water has to be introduced into the storingchamber 2, the water source through which this operation has to be carried out, and in which part of a chosen washing program water recovering for a later use can take place, the selected washing program is started. - A drying process in a washing-drying machine according to the present invention may be carried out using a recovered amount of water already used during a previous washing cycle and stored within tank 28 as described above. Similarly to what has been already described with reference to the washing process, a desired drying program is selected by a user by way of input means 44 and further parameters (for example humidity of articles in the storing

chamber 2, articles weight, articles type and so on) may be acquired by appropriate sensors (not illustrated) included in the machine to instruct theprocess control unit 26 about articles physical condition at the beginning of a drying cycle. After the machine has been set to carry out the desired drying process, controlunit 26 compares said acquired parameters with data pre-programmed therein. The result of the comparison is the activation of one or both theheat exchangers article storing chamber 2 by means ofair circuit 7. This allows the drying process to adapt drying efficiency of the machine according to the actual drying condition of articles to be treated.Process control unit 26 may also establish the sequence of activation of eachheat exchanger air heat exchanger unit 26 may change cooling water source between tank 28, filled with water recovered by a previous washing process or retained therein after a preceding drying cycle, and water supplied to tank 28 by a main water net throughpipe line 29. - Such change of cooling water source may be performed by

process control unit 26 after that cooling water has been continuously re-circulated between theheat exchanger pipes 27 and 30. In fact, during a drying process, cooling water progressively heats up, thereby reducing capacity ofheat exchanger process control unit 26 may be provided for communicating tosuch unit 26 that cooling water has reached a pre-determined hot temperature and, consequently, that efficiency ofheat exchanger conduit 45 and than refilled bypipe line 29 with fresh water from a main water net. - Thanks to data pre-programmed in the

process control unit 26heat exchangers chamber 2 during a drying cycle and by monitoring working parameters of eachheat exchangers process control unit 26 may adjust the working sequence of said heat exchangers in function of data provided by the monitoring operation. As a mere example, a drying cycle started with bothheat exchangers process control unit 26 may deactivate water/air heat exchanger water circuit 27, 30. If deactivation of the air/air heat exchanger 13, 113 is desired,process control unit 26 may turn off cooling air pumping means 14, leaving saidheat exchanger 13, 113 passively passed through by drying air. - Conclusively it can be stated that a washing-drying machine 1 according to the invention has an improved energy efficiency. In particular with such a machine 1 is possible not only saving water during a washing process by using water recovered during a previous drying process but it is also possible to adjust the drying air moisture content very finely by deactivating one of the heat exchangers 12, 13; 112, 113; 212, 113. This can be done simply turning off air/

air heat exchanger 13, 113 cooling air pumping means 14, and stopping cooling water supply to water/air heat exchanger pipe line 27 connectingheat exchanger

Claims (15)

- A washing-drying machine comprising:a. an articles storing chamber (2);b. a water circuit (4) for supplying water to the chamber (2) said water circuit being connectable to a water supply;c. an air circuit (7) for circulating drying air within said chamber (2), said air circuit (7) having pumping means (10), heating means (9) for heating said drying air and condensing means (8, 108, 208) adapted to remove moisture from said drying air comprising a first water/air heat exchanger (12, 112, 212);

characterized in that said water/air heat exchanger (12, 112, 212) is fluidly connected to said water circuit (4) through a first fluid line (21) such that at least a portion of water provided for cooling heat exchanger (12, 112, 212) can be supplied within said articles storing chamber (2) for washing operations, and/or said articles storing chamber (2) is hydraulically connected to the water/air heat exchanger (12, 112, 212) through a pipe line (40, 27) such that at least a portion of water provided for washing operations can be supplied to cool said heat exchanger (12, 112,212). - A washing-drying machine according to claim 1 wherein said water/air heat exchanger (12, 112, 212) is in fluid communication with a water tank (28) by means of a water re-circulating circuit (27, 30).

- A washing-drying machine according to any preceding claim comprising a reservoir (11) for collecting said moisture wherein the reservoir (11) is fluidly connected to said water circuit (4) through a second fluid line (20) for supplying said moisture to the articles storing chamber (2) for washing operations.

- A washing-drying machine according to any preceding claim wherein valve means (25, 23) are provided in said water circuit (4) and in said first fluid line (21) in signal communication with a process control unit (26) programmed for selecting a water source for supplying water to the articles storing chamber (2).

- A washing-drying machine according to claim 3 and 4 wherein said process control unit (26) is in signal communication with further valve means (24, 41) provided respectively in said second fluid line (20) and in said pipe line (40).

- A washing-drying machine according to any preceding claim wherein said condensing means (8, 108, 208) further comprises a second air/air heat exchanger (13, 113) connected in series with said first water/air heat exchanger (12, 112, 212).

- A washing-drying machine according to any preceding claim wherein said first water/air heat exchanger (12, 112, 212) comprises a nozzle (231) hydraulically connected to a water supply (28) for spraying water against a drying air flow.

- A washing-drying machine according to claims 6 and 7 wherein said first water/air heat exchanger (12, 112, 212) is placed upstream relative to the second air/air heat exchanger (13, 113).

- A washing-drying machine according to any claim 1 to 6 wherein said first water/air heat exchanger (12, 112, 212) comprises a plurality of conduits (16) for circulating cooling water drained from a water supply (28), said conduits (16) being arranged within the air circuit (7) for being invested by a drying air flow.

- A washing-drying machine according to claims 6 and 9 wherein said first water/air heat exchanger (12, 112, 212) is placed downstream relative to the second air/air heat exchanger (13, 113).

- A washing-drying machine according to any preceding claim wherein said articles storing chamber (2) is rotatably mounted within a tub (3).

- A washing-drying machine according to any preceding claim wherein air filtering means (15) are arranged in said air circuit (7).

- A method for operating a washing-drying machine according to claims 1 to 12 for washing articles, said machine comprising an articles storing chamber (2), a process control unit (26), and a condensing unit (8, 108, 208) provided with a water/air heat exchanger (12, 112, 212), said method being characterized by operating said process control unit (26) such that a first amount of water is transferred from said heat exchanger (12, 112, 212) to said chamber (2) and by operating said process control unit (26) to establish whether or not a second amount of water is to be transferred from the chamber (2) to the heat exchanger (12, 112, 212) in addition to or in place of said first amount of water.

- A method according to claim 13 wherein said first amount of water is drained from a water storage means (28) and/or from a reservoir (11) which is provided in said washing-drying machine for collecting condensate produced by the heat exchanger (12, 112, 212) during a drying process.

- A method for operating a washing-drying machine for drying articles, said machine comprising an articles storing chamber (2), drying program input means (44), sensor means for acquiring articles physical condition at the beginning of a drying cycle, a condensing means (8, 108, 208) which includes a first water/air heat exchanger (12, 112, 212) and a second air/air heat exchanger (13, 113) provided for condensing moisture from a drying airflow passing through chamber (2), said method being characterized by the following steps:a) Acquiring a drying program input by a user through said input means (44);b) Operating the process control unit (26) for establishing the activation sequence of each of said first and second heat exchangers (12, 112, 212; 13, 113) in response to user input of step a) and/or data acquired by said sensor means;c) Starting the drying process;d) Monitoring drying status of said articles and monitoring working parameters of each heat exchangers (12, 112, 212; 13, 113);e) Operating the process control unit (26) for adjusting said activation sequence of said heat exchangers (12, 112, 212; 13, 113) in function of data provided by the monitoring operation;

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09005345A EP2241663B1 (en) | 2009-04-15 | 2009-04-15 | Washing-drying machine and method for operating the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09005345A EP2241663B1 (en) | 2009-04-15 | 2009-04-15 | Washing-drying machine and method for operating the same |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2241663A1 true EP2241663A1 (en) | 2010-10-20 |

| EP2241663B1 EP2241663B1 (en) | 2013-03-20 |

Family

ID=41105228

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09005345A Not-in-force EP2241663B1 (en) | 2009-04-15 | 2009-04-15 | Washing-drying machine and method for operating the same |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2241663B1 (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITRN20110054A1 (en) * | 2011-08-05 | 2013-02-06 | Indesit Co Spa | APPLIANCE |

| EP2775028A3 (en) * | 2013-03-05 | 2015-02-25 | Samsung Electronics Co., Ltd | Laundry treating apparatus |

| WO2017137323A1 (en) * | 2016-02-08 | 2017-08-17 | Arcelik Anonim Sirketi | A laundry washing and drying machine comprising an air-cooled condenser |

| EP2716809A3 (en) * | 2012-10-08 | 2018-01-03 | Whirlpool EMEA S.p.A | Electrical household appliance for washing and drying linen |

| WO2018104333A1 (en) * | 2016-12-06 | 2018-06-14 | J.P.Industries S.P.A. | Machine for the drying of dishes or the like and method for the drying of dishes or the like with said machine. |

| EP3933088A1 (en) * | 2020-07-03 | 2022-01-05 | LG Electronics Inc. | Laundry treating apparatus |

| KR20220004528A (en) * | 2020-07-03 | 2022-01-11 | 엘지전자 주식회사 | Laundry treating apparatus |

| KR20220005337A (en) * | 2020-07-06 | 2022-01-13 | 엘지전자 주식회사 | Laundry treating apparatus |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2453930A1 (en) | 1979-04-12 | 1980-11-07 | Bauknecht Gmbh G | Clothes tumble drier - has an additional heat exchanger to reduce energy consumption |

| EP0250870A2 (en) * | 1986-06-26 | 1988-01-07 | INDUSTRIE ZANUSSI S.p.A. | Combined machine for washing and drying laundry |

| EP0252323A2 (en) * | 1986-07-11 | 1988-01-13 | INDUSTRIE ZANUSSI S.p.A. | Combined laundry washing and drying machine |

| DE4009102A1 (en) | 1990-03-21 | 1991-09-26 | Licentia Gmbh | Program-controlled washing dryer - condensates damp hot air coming out of drum by cooling and transports dehumidified air back to drum |

| GB2287961A (en) | 1994-04-01 | 1995-10-04 | Zanussi Elettrodomestici | Clothes washing machine with improved water recovery tank |

| EP1302586A1 (en) | 2001-10-10 | 2003-04-16 | Electrolux Home Products Corporation N.V. | Combined clothes washing and drying machine |

| EP1584729A1 (en) | 2004-04-09 | 2005-10-12 | Lg Electronics Inc. | Washing-drying machine |

| DE102007016077A1 (en) | 2007-04-03 | 2008-10-09 | BSH Bosch und Siemens Hausgeräte GmbH | Condensation dryer operating method for drying process of article in laundry, involves measuring parameter as temperature of refrigerant in direction behind condensor, where parameter is measured as compressor power consumption |

-

2009

- 2009-04-15 EP EP09005345A patent/EP2241663B1/en not_active Not-in-force

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2453930A1 (en) | 1979-04-12 | 1980-11-07 | Bauknecht Gmbh G | Clothes tumble drier - has an additional heat exchanger to reduce energy consumption |

| EP0250870A2 (en) * | 1986-06-26 | 1988-01-07 | INDUSTRIE ZANUSSI S.p.A. | Combined machine for washing and drying laundry |

| EP0252323A2 (en) * | 1986-07-11 | 1988-01-13 | INDUSTRIE ZANUSSI S.p.A. | Combined laundry washing and drying machine |

| DE4009102A1 (en) | 1990-03-21 | 1991-09-26 | Licentia Gmbh | Program-controlled washing dryer - condensates damp hot air coming out of drum by cooling and transports dehumidified air back to drum |

| GB2287961A (en) | 1994-04-01 | 1995-10-04 | Zanussi Elettrodomestici | Clothes washing machine with improved water recovery tank |

| EP1302586A1 (en) | 2001-10-10 | 2003-04-16 | Electrolux Home Products Corporation N.V. | Combined clothes washing and drying machine |

| EP1584729A1 (en) | 2004-04-09 | 2005-10-12 | Lg Electronics Inc. | Washing-drying machine |

| DE102007016077A1 (en) | 2007-04-03 | 2008-10-09 | BSH Bosch und Siemens Hausgeräte GmbH | Condensation dryer operating method for drying process of article in laundry, involves measuring parameter as temperature of refrigerant in direction behind condensor, where parameter is measured as compressor power consumption |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITRN20110054A1 (en) * | 2011-08-05 | 2013-02-06 | Indesit Co Spa | APPLIANCE |

| EP2573246A1 (en) * | 2011-08-05 | 2013-03-27 | Indesit Company S.p.A. | Electrical household appliance |

| RU2599369C2 (en) * | 2011-08-05 | 2016-10-10 | Индезит Компани С.П.А. | Domestic electrical appliance |

| EP2716809A3 (en) * | 2012-10-08 | 2018-01-03 | Whirlpool EMEA S.p.A | Electrical household appliance for washing and drying linen |

| EP2775028A3 (en) * | 2013-03-05 | 2015-02-25 | Samsung Electronics Co., Ltd | Laundry treating apparatus |

| WO2017137323A1 (en) * | 2016-02-08 | 2017-08-17 | Arcelik Anonim Sirketi | A laundry washing and drying machine comprising an air-cooled condenser |

| WO2018104333A1 (en) * | 2016-12-06 | 2018-06-14 | J.P.Industries S.P.A. | Machine for the drying of dishes or the like and method for the drying of dishes or the like with said machine. |

| CN110072426A (en) * | 2016-12-06 | 2019-07-30 | Jp产业股份公司 | Machine for drying dishware etc. and the method with the machine drying dishware etc. |

| EP3933088A1 (en) * | 2020-07-03 | 2022-01-05 | LG Electronics Inc. | Laundry treating apparatus |

| KR20220004528A (en) * | 2020-07-03 | 2022-01-11 | 엘지전자 주식회사 | Laundry treating apparatus |

| US11692292B2 (en) | 2020-07-03 | 2023-07-04 | Lg Electronics Inc. | Laundry treating apparatus |

| JP2023531774A (en) * | 2020-07-03 | 2023-07-25 | エルジー エレクトロニクス インコーポレイティド | clothing processing equipment |

| US12043938B2 (en) | 2020-07-03 | 2024-07-23 | Lg Electronics Inc. | Laundry treating apparatus |

| KR20220005337A (en) * | 2020-07-06 | 2022-01-13 | 엘지전자 주식회사 | Laundry treating apparatus |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2241663B1 (en) | 2013-03-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2241663B1 (en) | Washing-drying machine and method for operating the same | |

| EP2107148B1 (en) | Laundry treating machine | |

| EP2039819B1 (en) | Washer-drier machine | |

| KR101265616B1 (en) | laundry dryer and method for controlling the same | |

| EP3064629B1 (en) | Pulsator-type heat pump combined washer-dryer and drying method | |

| RU2439229C2 (en) | Device for treatment of linen with steam | |

| KR101199396B1 (en) | drying device | |

| EP2246470B1 (en) | Washer-drier machine | |

| EP1967640B1 (en) | Fabric processing apparatus and method | |

| EP2628844A1 (en) | Laundry treatment apparatus with heat exchanger cleaning | |

| EP2065510B1 (en) | Machine for treating laundry, particularly a washer-drier machine with recirculation circuit | |

| KR101430459B1 (en) | Apparatus for processing clothes | |

| JP4631740B2 (en) | Washing and drying machine | |

| KR100964692B1 (en) | Clothing processing device and control method | |

| KR20080107788A (en) | Clothing processing device and control method | |

| EP2604739B1 (en) | Washing machine with recirculation pump | |

| KR101191206B1 (en) | dryer | |

| KR101199394B1 (en) | drying device | |

| RU2584513C2 (en) | Method and device for washing clothes | |

| EP2019162A1 (en) | Washer-drier machine | |

| KR101157612B1 (en) | Steam washing method for washing machine | |

| CN209307705U (en) | a clothes dryer | |

| KR101199393B1 (en) | drying device and control method thereof | |

| CN120026485A (en) | Clothes treating device including controller | |

| CN113605068A (en) | Control method of clothes treatment equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ELECTROLUX HOME PRODUCTS CORPORATION N.V. |

|

| 17P | Request for examination filed |

Effective date: 20110420 |

|

| 17Q | First examination report despatched |

Effective date: 20110510 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ELECTROLUX HOME PRODUCTS CORPORATION N.V. |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: D06F 58/24 20060101ALI20120730BHEP Ipc: D06F 58/28 20060101ALI20120730BHEP Ipc: D06F 58/20 20060101ALI20120730BHEP Ipc: D06F 25/00 20060101AFI20120730BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 602166 Country of ref document: AT Kind code of ref document: T Effective date: 20130415 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602009014033 Country of ref document: DE Effective date: 20130516 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130620 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130701 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130620 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 602166 Country of ref document: AT Kind code of ref document: T Effective date: 20130320 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130621 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20130320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130722 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130430 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| 26N | No opposition filed |

Effective date: 20140102 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602009014033 Country of ref document: DE Effective date: 20140102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090415 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130415 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 602009014033 Country of ref document: DE Representative=s name: KILBURN & STRODE LLP, NL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20220421 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20230421 Year of fee payment: 15 Ref country code: DE Payment date: 20230427 Year of fee payment: 15 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230625 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20230418 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230430 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602009014033 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20240415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240415 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240415 |