EP1923332A1 - Package comprising windows - Google Patents

Package comprising windows Download PDFInfo

- Publication number

- EP1923332A1 EP1923332A1 EP06023604A EP06023604A EP1923332A1 EP 1923332 A1 EP1923332 A1 EP 1923332A1 EP 06023604 A EP06023604 A EP 06023604A EP 06023604 A EP06023604 A EP 06023604A EP 1923332 A1 EP1923332 A1 EP 1923332A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cover part

- top surface

- portions

- unit according

- unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/30—Containers, packaging elements or packages, specially adapted for particular articles or materials for articles particularly sensitive to damage by shock or pressure

- B65D85/32—Containers, packaging elements or packages, specially adapted for particular articles or materials for articles particularly sensitive to damage by shock or pressure for eggs

- B65D85/324—Containers with compartments made of pressed material

Definitions

- the invention relates generally to packages for fragile products, such as eggs, where the package is made of an opaque material such as moulded pulp and particularly to such packages provided with means allowing visual inspection of the contents of the package and at the same time providing large substantially planar surfaces on the package upon which information may be provided, for instance by means of labels.

- Packages for fragile products are often made by moulding of an opaque material such as pulp, which yields strong and durable packages well suited to contain and protect such fragile products.

- packages are formed as an integral unit comprising a bottom part provided with a number of compartments for accommodating the articles and a cover part connected to the bottom part by means of a flexible hinge portion.

- WO 03/086905 A1 describes a package for eggs comprising portions on the cover part of the package, the shape of which resembles the shape of corresponding portions of the eggs contained in the package. This gives a clear visual indication of the content of the package no matter from which direction the package is being viewed, also in cases where a lot of packages are stacked for instance in a retail shop.

- said egg-shaped portions on the cover part are still made of the same opaque material as the remainder of the package (and are in fact an integral part of the package) and hence a customer/consumer does not have the possibility of visual inspection of the eggs in the package without having to open the package.

- the applicant's own prior European patent application EP 1 683 740 A1 describes a package for eggs comprising both said egg shaped portions on the cover part and a centrally located window portion provided in the top surface of the cover part and extending longitudinally throughout substantially the entire length of the package.

- This window portion Is provided with a number of apertures, through which portions of the outer surface of the eggs in the package can be seen.

- the centrally located window portion the top surface of the cover part is subdivided into three sub-surfaces: the central window portion and a - substantially planar - side portion on either side of the window portion.

- two separate labels, one at either side of the window portion must be provided.

- a packaging unit where a label may be attached to the top surface of the cover part of the unit extending all the way from the front edge portion to the rear edge portion of the unit and, if desired, even over at least portions of the front and rear surfaces of the cover part of the unit.

- said means for visual inspection comprises one or more windows or apertures provided in chosen window portions of the cover part.

- window portions could potentially weaken the cover part and it is hence a further object of the present invention to provide window portions of a sufficiently strong structure to prevent or reduce said weakening effect of window portions on the cover part and still be able to keep the window portions as large as possible, in order to be able to see the largest possible portions of the articles contained in the package.

- said window portions are provided on the package in such a manner that relatively large, unbroken surface areas are left on the package despite the presence of the window portions.

- Such relatively large areas could as mentioned for instance be used for providing the package with informative text or graphics by means of labels attached to the package, although such text or graphics might also be provided directly on said areas.

- window portion refers to the whole portion of the package which comprises both at least one opening or aperture through the wall of the package as well as the whole structure used for instance to separate a number of such apertures from another and to provide strength to the window portion.

- a window portion is generally a three-dimensional structure comprising suitable apertures, although planar, i.e. two dimensional window portions could also in principle be envisaged.

- a display and distribution packaging unit (which could be used for eggs, although other applications would also be possible), which is made of an opaque material, e.g. moulded pulp and which comprises:

- window portions only extend over portions of some of the compartments in each of rows (R1, R2, ...) of compartments, although they may extend over portions of all of the compartments according to specific embodiments of the invention.

- the window portions there is thus provided one or more relatively large, unbroken surface areas on the top surface of the cover part, upon which area for instance a label can be provided, as also exemplified in the detailed description of the invention.

- the cover part with labelling means that may cover the major part of the top surface of the cover part - and, if desirable, also the front and/or rear surface of the cover part - by placement of a single label on the chosen portions of the cover part, without this single label interfering with the window portions of the cover part.

- the window portion comprises one or more apertures through the top surface of the cover part.

- the window portion can either be planar and substantially flush with the top surface or could comprise a more complex 3-dimensional structure, for instance extending from the top surface and a certain distance into the interior of the unit.

- suitable design of the structure of the window portion it is possible to add additional strength and rigidity to the unit compared with a unit comprising a planar top surface or to provide increased strength and rigidity to the window portion itself.

- the window portions comprise a number of apertures through which portions of the outer surfaces of at least two adjacent eggs are visible from outside. These apertures are separated from each other by intermediate support structures to be described in more detail in the detailed description of the invention.

- the support structures increase the rigidity and stability of the portions of the package, in which window portions are provided, thus keeping the rigidity and stability of these portions sufficiently high despite the provision of the apertures through the wall of the package. It is desirable that the apertures of each given window portion be made as large as possible in order to allow for visual inspection of the largest possible portion of the outer surfaces of the eggs and hence that the dimensions of the support structures be made as limited as possible.

- the dual objective is attained that portions of a relatively large number of the eggs contained in the package is in fact visible despite the fact that large unbroken surfaces, for instance for application of labels on the cover part of the unit, are still provided.

- the package comprises large unbroken surfaces upon which informative or decorative graphic material can be placed.

- An example of means of providing such material on the package would be by means of labels, although other means would also be possible.

- labels can be provided across the top surface of the cover part, from its front surface to its rear surface without interfering with window portions provided in the top surface of the cover part.

- the interaction between the support structures provided between the apertures in the window portions and the pillar posts provided internally of the package in the bottom part increases the vertical rigidity of the top surface of the cover part substantially, resulting in a better protection of the contents of the package and also tends to prevent sideways slip of the cover part relative to the bottom part, when the package is in the closed condition.

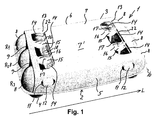

- FIG 1 there is shown a display and distribution packaging unit according to a specific embodiment of the invention generally referred to by reference numeral 1.

- This embodiment comprises three longitudinally extending rows, designated by R1, R2 and R3, respectively, each containing five compartments 4 in the bottom part 2 to accommodate eggs. It is, however, understood that other embodiments of the invention could comprise different numbers of rows and compartments without deviating from the display and distribution package according to the present invention.

- the specific embodiment of the invention shown in figure 1 comprises a bottom part 2 and a cover part 3 connected to each other by means of a hinge portion 21.

- the bottom part 2 comprises a number of compartments 4 shaped in accordance with the intended contents of the package, in the shown embodiment eggs.

- the bottom part is furthermore provided with a number of upstanding pillar posts 18 with top surfaces 18', as It appears most clearly from figure 6.

- the cover part 3 comprises egg-shaped portions 8 formed on substantially planar end faces 9 of the cover part 3.

- the cover part 3 furthermore comprises a top surface 7, which is preferably substantively planar, and front and rear surfaces 5 and 6, respectively.

- the cover part 3 is furthermore provided with window portions generally designated by 13, said window portions comprising a number of apertures 14 for visual inspection of the contents of the packaging unit. More details of the shapes and functions of the apertures 14 will be given below.

- the window portions 13 could be flush with the top surface 7 of the cover part 3 but according to a preferred embodiment, the window portion 13 is surrounded by a vertical rim portion 22 connecting the top surface 7 with support structures 15, 16, 17 of the window portion, which support structures thus in this embodiment will be located below the level of the top surface 7.

- the window portions 13 according to the embodiment of the invention shown in figures 1, 2 and 3 comprise a number of suitably shaped apertures 14 for visual inspection of the contents of the packaging unit. These apertures 14 are located on either side of said support structures 15, 16, 17, where a central portion 17 of the support structure is in alignment with and resting against the top surfaces 18' of the pillar posts 18 provided in the bottom part 2 (as shown in more detail in figure 6, where the packaging unit is shown in a open condition), when the packaging unit is in a closed condition.

- the bottom parts 17' of the central portions 17 can be provided with studs for engagement with similarly shaped holes 20 or indentations formed in the top surface 18' of the pillar posts 18.

- the inverse, i.e. studs on the top surfaces 18' and holes/indentations in the bottom part of the central portions 17, is of course also possible.

- Each of said support structures 15, 16, 17 comprises brace members 16 preferably in the form of arched members extending from the centre portions 17 to the top surface 7 of the cover part 3.

- These brace members 16 serve the important function of increasing the rigidity and overall strength of the window portion as such and thereby also of the cover part as a whole. Due to the engagement between the lower surface 17' of the recesses 17 and the corresponding recesses 20 in the upper face 18' of the pillar posts 18, the dimensions of the support structures 15, 16, 17 can be kept limited, hence making relatively large apertures 14 for inspection of the contents of the packaging unit possible.

- bracing members 16 form 3-dimensional beam structures connecting the support structures 15, 17 and the vertical rim portion 22 of the window portions 13 and comprise arched upper surfaces extending entirely up to the level of the top surface 7 of the cover part 3.

- the vertical rim portion 22 tends to increase the rigidity of the top surface of the cover part and hence to reduce depression of the top surface 7 when this surface is subjected to a downward force.

- FIGS 2 through 5 Different specific embodiments of the invention are shown in figures 2 through 5, these figures showing the top surface 7 of the cover part 3 provided with various numbers, sizes and placements of window portions 13 according to the overall concept of the invention.

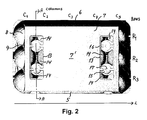

- FIG 2 there is thus shown a plane view from above of the embodiment of the invention shown in figure 1.

- This embodiment comprises two window portions 13, one substantially at either longitudinal end of the top surface 7 of the cover part 3.

- Each of the window portions 13 according to this embodiment extends laterally over the top surface 7, i.e. substantially in parallel with the end faces 9 of the cover part 3, and makes at least portions of the outer surfaces of twelve of the eggs out of the total of fifteen eggs in the packaging unit visible.

- a relatively large central region 7' of the top surface 7 of the cover part 3 is still left unbroken, for the possible provision of a label, as shown in the following in figures 8 through 14.

- the three rows of compartments 4 (these compartments not being visible in figures 2 through 5) are indicated by reference characters R1, R2 and R3, respectively, and the longitudinal extension of the packaging unit is indicated by L.

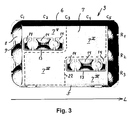

- FIG. 3 there is shown a plane view from above of a second embodiment of the invention.

- two window portions 13 are provided in the top surface 7 of the cover part 3, each window portion 13 extending longitudinally over approximately half of the entire longitudinal extension of the top surface of the cover part.

- One window portion extends transversally over portions of the compartments of the first row R1 and the adjacent second row R2, respectively, whereas the other window portion extends transversally over portions of the compartments of the second row R2 and the third row, R3, respectively.

- One single label an example being schematically indicated by the broken line 22 in figure 3, can still be provided from the front surface 5 to the rear surface 6 of the cover part 3, according to the example shown by the broken line 22 covering at least the two areas 7" and 7"' of the top surface 7 of the cover part.

- One single label may even be extended to cover substantially the whole top surface 7 except for the two window portions 13, i.e. also the areas 7 IV and 7 V in figure 3.

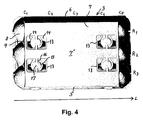

- FIG 4 there is shown a plane view from above of a third embodiment of the invention.

- This embodiment comprises a total of four relatively small window portions 13, each showing portions of the outer surfaces of four eggs, two of which are placed in a given one of the rows of compartments R1, R2, R3 and the other two placed in an adjacent row.

- Two of the four window portions are according to this specific embodiment provided adjacent to one of the end faces 9 and the other two window portions are provided adjacent to the other end face 9 of the cover part.

- the series of two apertures 14 of each of the window portions 13 extend longitudinally with a single support structure 15, 16, 17 interposed between the two apertures. Out of a total of fifteen eggs contained in the packaging unit, portions of the outer surface of twelve of these are visible through the window portions.

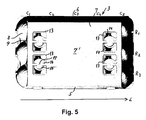

- FIG 5 there is shown a plane view from above of a fourth embodiment of the invention.

- This embodiment is substantially similar to the one shown in figure 4,except for the series of apertures 14 of the window portions 13 extending laterally at either longitudinal end of the top surface 7 of the cover part.

- twelve of the fifteen eggs in the packaging unit are partially visible through the apertures 14 of the window portions 13 in this embodiment.

- FIG 6 there is shown a perspective view of the embodiment of the invention shown in figure 1 shown in an open state and showing internal support structures and details of the window portions.

- the bottom surface of the support structures i.e. the internal surface of the support structures, when the packaging unit is in a closed condition, comprises as mentioned above stud members or protrusions 17' for engagement with similarly shaped holes 20 or indentations formed in the top surface 18' of the pillar posts 18.

- the inverse, i.e. studs or protrusions on the top surfaces 18' and holes/indentations in the bottom part of the central portions 17, is of course also possible.

- FIGS 8(a), (b) and (c) there are shown plane views from above of embodiments of the invention comprising three rows, each of six, five and three compartments, respectively. Also the above mentioned central region 7' extending throughout the top surface of the cover part from the front surface 5 to the rear surface 6 appears from the figure.

- the embodiment shown in figure 8(c) comprises only one window portion, whereas the embodiments shown in figures 8(a) and (b) comprise two window portions at either longitudinal end of the top surface 7 of the cover part.

- the three embodiments shown in figures 8(a), (b) and (c) comprise substantially rectangular window portions, but it is understood that also other shapes of the window portions, as for instance those shown in figures 9 and 11, could be used.

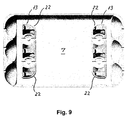

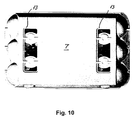

- figures 9, 10 and 11 show plane views of three alternative embodiments of the invention comprising alternatively shaped window portion 13.

- figure 9 shows window portions provided with rounded corner portions 22 corresponding to the embodiment shown in figure 1, where the rounded edge portions 22 face inwardly towards the central region of the top surface 7.

- Figure 10 shows substantially rectangular window portions 13 and figure 11 shows window portions with substantially semi-circular end portions 23 of the window portions 13. It is understood that other shapes of the window portions than those shown in figures 9, 10 and 11 could also be envisaged, at that also such shapes would fall within the scope of the present invention.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packaging Frangible Articles (AREA)

Abstract

Description

- The invention relates generally to packages for fragile products, such as eggs, where the package is made of an opaque material such as moulded pulp and particularly to such packages provided with means allowing visual inspection of the contents of the package and at the same time providing large substantially planar surfaces on the package upon which information may be provided, for instance by means of labels.

- Packages for fragile products, such as eggs, are often made by moulding of an opaque material such as pulp, which yields strong and durable packages well suited to contain and protect such fragile products. Often such packages are formed as an integral unit comprising a bottom part provided with a number of compartments for accommodating the articles and a cover part connected to the bottom part by means of a flexible hinge portion.

- A drawback with packages entirely made of an opaque material such as pulp is that a customer gets no indication as to the contents of the package and that he can not visually inspect the contents of the package. In order to get a clearer indication of the contents of the package,

WO 03/086905 A1 - Furthermore, the applicant's own prior

European patent application EP 1 683 740 A1 describes a package for eggs comprising both said egg shaped portions on the cover part and a centrally located window portion provided in the top surface of the cover part and extending longitudinally throughout substantially the entire length of the package. This window portion Is provided with a number of apertures, through which portions of the outer surface of the eggs in the package can be seen. By the provision of the centrally located window portion, the top surface of the cover part is subdivided into three sub-surfaces: the central window portion and a - substantially planar - side portion on either side of the window portion. Hence it becomes impossible to provide a label extending from the front portion to the rear portion of the cover part without interfering with the window portion. Thus, if the portions of the cover part not taken up by the window portion are to be provided with a label in order to place informative or decorative material on the cover part, two separate labels, one at either side of the window portion, must be provided. - On the above background it is an object of the present invention to provide a display and distribution packaging unit, where the unit is provided with means for visual inspection of at least chosen portions of the articles contained in the unit. As it is desirable to have access to relatively large, preferably substantially planar, surface areas on the package upon which informative text and/or graphics can be placed, it is an object of the invention to provide said means for visual inspection in such a manner that said relatively large areas are still present despite the provision of said visual means.

- Furthermore, according to the invention there is provided a packaging unit where a label may be attached to the top surface of the cover part of the unit extending all the way from the front edge portion to the rear edge portion of the unit and, if desired, even over at least portions of the front and rear surfaces of the cover part of the unit. Various embodiments of the packaging unit according to the invention, including a number of different application of labels, will be shown and described in the detailed description of the invention.

- According to the invention, said means for visual inspection comprises one or more windows or apertures provided in chosen window portions of the cover part. Such window portions could potentially weaken the cover part and it is hence a further object of the present invention to provide window portions of a sufficiently strong structure to prevent or reduce said weakening effect of window portions on the cover part and still be able to keep the window portions as large as possible, in order to be able to see the largest possible portions of the articles contained in the package.

- According to the invention, said window portions are provided on the package in such a manner that relatively large, unbroken surface areas are left on the package despite the presence of the window portions. Such relatively large areas could as mentioned for instance be used for providing the package with informative text or graphics by means of labels attached to the package, although such text or graphics might also be provided directly on said areas.

- It is to be understood that in the present context, the term "window portion" refers to the whole portion of the package which comprises both at least one opening or aperture through the wall of the package as well as the whole structure used for instance to separate a number of such apertures from another and to provide strength to the window portion. Thus, a window portion is generally a three-dimensional structure comprising suitable apertures, although planar, i.e. two dimensional window portions could also in principle be envisaged.

- According to the invention, the above objects are attained by a display and distribution packaging unit (which could be used for eggs, although other applications would also be possible), which is made of an opaque material, e.g. moulded pulp and which comprises:

- a bottom part comprising compartments arranged longitudinally in rows (R1, R2, ...) so as to match at least partially the outer contours of the eggs or similar articles within said unit;

- a cover part comprising a top surface, front and rear surfaces and end surfaces;

- one or more window portions in the cover part for showing at least a portion of the outer surfaces of at least some of the eggs or other articles in the unit;

- Specifically said window portions only extend over portions of some of the compartments in each of rows (R1, R2, ...) of compartments, although they may extend over portions of all of the compartments according to specific embodiments of the invention.

- A number of embodiments of the above overall concept of the packaging unit according to the Invention is shown and described in the detailed description of the invention.

- Between the window portions there is thus provided one or more relatively large, unbroken surface areas on the top surface of the cover part, upon which area for instance a label can be provided, as also exemplified in the detailed description of the invention. According to the inventive concept, it furthermore becomes possible to provide the cover part with labelling means that may cover the major part of the top surface of the cover part - and, if desirable, also the front and/or rear surface of the cover part - by placement of a single label on the chosen portions of the cover part, without this single label interfering with the window portions of the cover part.

- According to the invention, the window portion comprises one or more apertures through the top surface of the cover part. The window portion can either be planar and substantially flush with the top surface or could comprise a more complex 3-dimensional structure, for instance extending from the top surface and a certain distance into the interior of the unit. By suitable design of the structure of the window portion it is possible to add additional strength and rigidity to the unit compared with a unit comprising a planar top surface or to provide increased strength and rigidity to the window portion itself. An exemplifying embodiment of window portions will be presented in the detailed description of the invention.

- According to preferred embodiments of the invention, the window portions comprise a number of apertures through which portions of the outer surfaces of at least two adjacent eggs are visible from outside. These apertures are separated from each other by intermediate support structures to be described in more detail in the detailed description of the invention. The support structures increase the rigidity and stability of the portions of the package, in which window portions are provided, thus keeping the rigidity and stability of these portions sufficiently high despite the provision of the apertures through the wall of the package. It is desirable that the apertures of each given window portion be made as large as possible in order to allow for visual inspection of the largest possible portion of the outer surfaces of the eggs and hence that the dimensions of the support structures be made as limited as possible. An embodiment of support structures according to the invention by means of which this objective is attained is described in the detailed description of the invention.

- By the application of the principle of the invention, i.e. that the window portions only extend over limited surface areas of the cover part, the dual objective is attained that portions of a relatively large number of the eggs contained in the package is in fact visible despite the fact that large unbroken surfaces, for instance for application of labels on the cover part of the unit, are still provided.

- A number of important advantages are attained with the package according to the present invention. Thus, the package comprises large unbroken surfaces upon which informative or decorative graphic material can be placed. An example of means of providing such material on the package would be by means of labels, although other means would also be possible. Furthermore, it is a very important advantage of the present package that labels can be provided across the top surface of the cover part, from its front surface to its rear surface without interfering with window portions provided in the top surface of the cover part. Furthermore, the interaction between the support structures provided between the apertures in the window portions and the pillar posts provided internally of the package in the bottom part increases the vertical rigidity of the top surface of the cover part substantially, resulting in a better protection of the contents of the package and also tends to prevent sideways slip of the cover part relative to the bottom part, when the package is in the closed condition.

- The invention will be better understood by reference to the following drawings showing non-limiting embodiments of the display and distribution package according to the invention and where

- figure 1 is a perspective view of a first embodiment of the package according to the invention comprising two symmetrically placed window portions, one at either longitudinal end portion of the cover part;

- figure 2 is a plane view from above of an embodiment of the invention;

- figure 3 is a plane view from above of a second embodiment of the invention;

- figure 4 is a plane view from above of a third embodiment of the invention;

- figure 5 is a plane view from above of a fourth embodiment of the invention;

- figure 6 is a perspective view of the embodiment of the invention shown in figure 1 shown in an open state and showing Internal support structures and details of the window portions;

- figure 7 is a cross sectional view along line A - A in figure 2 showing internal support structures of the unit according to the invention;

- figures 8(a), (b) and (c) are plane views from above of embodiments comprising three rows, each of six, five and three compartments, respectively;

- figures 9, 10 and 11 show plane views of alternative embodiments of the Invention comprising alternatively shaped window portions, and

- figures 12(a), (b) and (c) are plane views from above of embodiments comprising two rows, each of six, five and three compartments, respectively.

- Referring to figure 1 there is shown a display and distribution packaging unit according to a specific embodiment of the invention generally referred to by reference numeral 1. This embodiment comprises three longitudinally extending rows, designated by R1, R2 and R3, respectively, each containing five

compartments 4 in the bottom part 2 to accommodate eggs. It is, however, understood that other embodiments of the invention could comprise different numbers of rows and compartments without deviating from the display and distribution package according to the present invention. The specific embodiment of the invention shown in figure 1 comprises a bottom part 2 and acover part 3 connected to each other by means of ahinge portion 21. The bottom part 2 comprises a number ofcompartments 4 shaped in accordance with the intended contents of the package, in the shown embodiment eggs. The bottom part is furthermore provided with a number of upstanding pillar posts 18 with top surfaces 18', as It appears most clearly from figure 6. Thecover part 3 comprises egg-shapedportions 8 formed on substantially planar end faces 9 of thecover part 3. Thecover part 3 furthermore comprises atop surface 7, which is preferably substantively planar, and front andrear surfaces - According to the embodiment of the present invention shown in the figures, the

cover part 3 is furthermore provided with window portions generally designated by 13, said window portions comprising a number ofapertures 14 for visual inspection of the contents of the packaging unit. More details of the shapes and functions of theapertures 14 will be given below. - The

window portions 13 could be flush with thetop surface 7 of thecover part 3 but according to a preferred embodiment, thewindow portion 13 is surrounded by avertical rim portion 22 connecting thetop surface 7 withsupport structures top surface 7. - The

window portions 13 according to the embodiment of the invention shown in figures 1, 2 and 3 comprise a number of suitably shapedapertures 14 for visual inspection of the contents of the packaging unit. Theseapertures 14 are located on either side of saidsupport structures central portion 17 of the support structure is in alignment with and resting against the top surfaces 18' of the pillar posts 18 provided in the bottom part 2 (as shown in more detail in figure 6, where the packaging unit is shown in a open condition), when the packaging unit is in a closed condition. In order to reduce the possibility of the cover part undergoing a horizontal displacement relative to the bottom part, the bottom parts 17' of thecentral portions 17 can be provided with studs for engagement with similarly shapedholes 20 or indentations formed in the top surface 18' of the pillar posts 18. The inverse, i.e. studs on the top surfaces 18' and holes/indentations in the bottom part of thecentral portions 17, is of course also possible. - Each of said

support structures brace members 16 preferably in the form of arched members extending from thecentre portions 17 to thetop surface 7 of thecover part 3. Thesebrace members 16 serve the important function of increasing the rigidity and overall strength of the window portion as such and thereby also of the cover part as a whole. Due to the engagement between the lower surface 17' of therecesses 17 and the correspondingrecesses 20 in the upper face 18' of the pillar posts 18, the dimensions of thesupport structures large apertures 14 for inspection of the contents of the packaging unit possible. - The shape of these bracing

members 16 is most apparent from the perspective view shown In figure 1. As it appears, the bracingmembers 16 form 3-dimensional beam structures connecting thesupport structures vertical rim portion 22 of thewindow portions 13 and comprise arched upper surfaces extending entirely up to the level of thetop surface 7 of thecover part 3. The arched shape of the bracingmembers 16, which during the moulding process of the packaging unit can be filled with pulp, strengthens the bracingmembers 16 and when the packaging unit is in a closed condition, where the pillar posts 18 rest against the support structures, the bracingmembers 16 thus effectively prevent the depression of thetop surface 7 of thecover part 3. Also thevertical rim portion 22 tends to increase the rigidity of the top surface of the cover part and hence to reduce depression of thetop surface 7 when this surface is subjected to a downward force. - Different specific embodiments of the invention are shown in figures 2 through 5, these figures showing the

top surface 7 of thecover part 3 provided with various numbers, sizes and placements ofwindow portions 13 according to the overall concept of the invention. - Referring to figure 2 there is thus shown a plane view from above of the embodiment of the invention shown in figure 1. This embodiment comprises two

window portions 13, one substantially at either longitudinal end of thetop surface 7 of thecover part 3. Each of thewindow portions 13 according to this embodiment extends laterally over thetop surface 7, i.e. substantially in parallel with the end faces 9 of thecover part 3, and makes at least portions of the outer surfaces of twelve of the eggs out of the total of fifteen eggs in the packaging unit visible. Despite the provision of these twowindow portions 13, a relatively large central region 7' of thetop surface 7 of thecover part 3 is still left unbroken, for the possible provision of a label, as shown in the following in figures 8 through 14. The three rows of compartments 4 (these compartments not being visible in figures 2 through 5) are indicated by reference characters R1, R2 and R3, respectively, and the longitudinal extension of the packaging unit is indicated by L. - Referring to figure 3 there is shown a plane view from above of a second embodiment of the invention. According to this embodiment, two

window portions 13 are provided in thetop surface 7 of thecover part 3, eachwindow portion 13 extending longitudinally over approximately half of the entire longitudinal extension of the top surface of the cover part. One window portion extends transversally over portions of the compartments of the first row R1 and the adjacent second row R2, respectively, whereas the other window portion extends transversally over portions of the compartments of the second row R2 and the third row, R3, respectively. By this placement of window portions, outer surface portions of eleven out of the fifteen eggs contained in the packaging unit are made visible from the outside of the packaging unit. One single label, an example being schematically indicated by thebroken line 22 in figure 3, can still be provided from thefront surface 5 to therear surface 6 of thecover part 3, according to the example shown by thebroken line 22 covering at least the twoareas 7" and 7"' of thetop surface 7 of the cover part. One single label may even be extended to cover substantially the wholetop surface 7 except for the twowindow portions 13, i.e. also theareas - Referring to figure 4 there is shown a plane view from above of a third embodiment of the invention. This embodiment comprises a total of four relatively

small window portions 13, each showing portions of the outer surfaces of four eggs, two of which are placed in a given one of the rows of compartments R1, R2, R3 and the other two placed in an adjacent row. Two of the four window portions are according to this specific embodiment provided adjacent to one of the end faces 9 and the other two window portions are provided adjacent to the other end face 9 of the cover part. The series of twoapertures 14 of each of thewindow portions 13 extend longitudinally with asingle support structure - Referring to figure 5 there is shown a plane view from above of a fourth embodiment of the invention. This embodiment is substantially similar to the one shown in figure 4,except for the series of

apertures 14 of thewindow portions 13 extending laterally at either longitudinal end of thetop surface 7 of the cover part. As in the embodiment shown in figure 4 also twelve of the fifteen eggs in the packaging unit are partially visible through theapertures 14 of thewindow portions 13 in this embodiment. - Referring to figure 6 there is shown a perspective view of the embodiment of the invention shown in figure 1 shown in an open state and showing internal support structures and details of the window portions. Specifically the bottom surface of the support structures, i.e. the internal surface of the support structures, when the packaging unit is in a closed condition, comprises as mentioned above stud members or protrusions 17' for engagement with similarly shaped

holes 20 or indentations formed in the top surface 18' of the pillar posts 18. As mentioned, the inverse, i.e. studs or protrusions on the top surfaces 18' and holes/indentations in the bottom part of thecentral portions 17, is of course also possible. This engagement between stud members 17' and corresponding holes orindentations 20 on the end faces 18' of the pillar posts 19 is also apparent from the cross sectional view shown in figure 7, taken along line A - A in figure 2, showing internal support structures of the unit according to the invention. The engagement between thesupport structure top surface 7 of thecover part 3, hence offering increased protection of the contents of the packaging unit and also to prevent sideways slip of the cover part relative to the bottom part, when the package is in the closed condition. Specifically the prevention of sideways slip is according to the invention brought about by the engagement between the holes orindentations 20 in the pillar posts 18 and the corresponding stud members or protrusions 17' on the support structure. This function is readily apparent from figure 7. - Referring to figures 8(a), (b) and (c) there are shown plane views from above of embodiments of the invention comprising three rows, each of six, five and three compartments, respectively. Also the above mentioned central region 7' extending throughout the top surface of the cover part from the

front surface 5 to therear surface 6 appears from the figure. The embodiment shown in figure 8(c) comprises only one window portion, whereas the embodiments shown in figures 8(a) and (b) comprise two window portions at either longitudinal end of thetop surface 7 of the cover part. The three embodiments shown in figures 8(a), (b) and (c) comprise substantially rectangular window portions, but it is understood that also other shapes of the window portions, as for instance those shown in figures 9 and 11, could be used. - Finally, figures 9, 10 and 11 show plane views of three alternative embodiments of the invention comprising alternatively shaped

window portion 13. Thus, figure 9 shows window portions provided with roundedcorner portions 22 corresponding to the embodiment shown in figure 1, where therounded edge portions 22 face inwardly towards the central region of thetop surface 7. Figure 10 shows substantiallyrectangular window portions 13 and figure 11 shows window portions with substantiallysemi-circular end portions 23 of thewindow portions 13. It is understood that other shapes of the window portions than those shown in figures 9, 10 and 11 could also be envisaged, at that also such shapes would fall within the scope of the present invention. - Although specific embodiments of the invention comprising three rows of five eggs each have been described above and shown in the figures 1 through 5, it is understood that the invention is not limited to these specific embodiments. Thus, different numbers of rows comprising a different number of eggs in each row also form a part of the present invention. Thus, typical configurations would be 3 rows, comprising either 9, 15 or 18 eggs in each unit or 2 rows comprising 6, 10 or 12 eggs in each unit as shown in figure 12.

whereby a single label extending between the front and rear surface can be applied to said central region.

Claims (14)

- A display and distribution packaging unit for eggs or similar fragile articles, said unit being made of an opaque material, e.g. moulded pulp and comprising:- a bottom part (2) comprising compartments (4) arranged longitudinally (L) in rows (R1, R2, ...) so as to match at least partially the outer contours of the eggs or similar articles within said unit;- a cover part (3) comprising a top surface (7), front and rear surfaces (5, 6) and end surfaces (9);- one or more window portions (13) in said cover part (3) for showing at least a portion of the outer surfaces of at least some of the eggs or other articles in the unit;characterised in that the top surface (7) of the cover part comprises a central region (7'; 7", 7"') that extends from said front surface (5) to said rear surface (6) of the cover part (3);

whereby for instance a single label extending between the front and rear surface (5, 6) can be applied to said central region (7'; 7", 7"'), without interfering with said one or more window portions in the top surface (7) of the cover part (3). - A unit according to claim 1, where the top surface (7) of the cover part (3) comprises two window portions (13), one at either longitudinal end of the top surface of the cover part, each of said window portions (13) extending over portions of compartments in all rows (R1, R2 ....).

- A unit according to claim 1, where the top surface (7) of the cover part (3) comprises two window portions (13) extending longitudinally over a subset of columns (C1, C2 ....) of the unit.

- A unit according to claim 3, where said window portions (13) are offset from each other in a direction perpendicular to the longitudinal direction (L) of the package, whereby one window portion (13) provides for visual inspection of the contents of the package in a first subset of rows (R1, R2) and the other window portion provides for visual inspection of the contents of the package in a second subset of rows (R2, R3).

- A unit according to claim 1, where the top surface of the cover part comprises four window portions (13), two at either longitudinal end of the top surface of the cover part.

- A unit according to claim 1, characterised in that said one or more window portions (13) is/are surrounded by a vertical rim portion (22).

- A unit according to claim 1, characterised in that said one or more window portion(s) comprise(s) a number of apertures (14) for visual inspection of the contents of the unit.

- A claim corresponding to claim 7, comprising brace members (16) between adjacent apertures (14).

- A unit according to claim 8, characterised in that said brace members (16) are arched.

- A unit according to claim 8, characterised in that said brace members (16) are connected to centre portions (15) resting against the top surfaces (18') of pillar posts (18) provided between compartments in the bottom part (2), when the unit is in the closed condition.

- A unit according to claim 10, characterised in that said centre portions (15) on the bottom part hereof are provided with retainment means (17') for interaction with corresponding means (20) in the top surface (18') of the pillar posts (18), whereby the tendency of sideways slip between the cover part (3) and the bottom part (2) is reduced or eliminated, when the package is in the closed condition.

- A unit according to any of the preceding claims, characterised in that said central portion (7') of the top surface (7) of the cover part (3) is provided with a label.

- A unit according to claim 12, characterised in that said label extends over the front surface (5) or the rear surface (6) or over both of these surfaces (5, 6).

- A unit according to any of the preceding claims, characterised in that said cover part (4) furthermore comprises egg-shaped portions (8) provided on either one or both end surfaces (9) of the cover part (3).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP06023604A EP1923332A1 (en) | 2006-11-14 | 2006-11-14 | Package comprising windows |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP06023604A EP1923332A1 (en) | 2006-11-14 | 2006-11-14 | Package comprising windows |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1923332A1 true EP1923332A1 (en) | 2008-05-21 |

Family

ID=37907035

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06023604A Withdrawn EP1923332A1 (en) | 2006-11-14 | 2006-11-14 | Package comprising windows |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1923332A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013038337A3 (en) * | 2011-09-13 | 2013-06-20 | Brødrene Hartmann A/S | A display and distribution package for eggs |

| WO2013164664A1 (en) * | 2012-05-03 | 2013-11-07 | Brødrene Hartmann A/S | Egg package |

| US9682811B2 (en) | 2012-08-21 | 2017-06-20 | Brødrene Hartmann A/S | Package for eggs and method for manufacturing said package |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3489270A (en) * | 1967-09-15 | 1970-01-13 | Diamond Int Corp | Plastic container |

| US3865299A (en) * | 1974-02-12 | 1975-02-11 | Keyes Fibre Co | Egg carton with flexible window well |

| GB2131399A (en) * | 1981-09-29 | 1984-06-20 | Diamond Int Corp | Moulded egg cartons |

| DE9013925U1 (en) * | 1989-10-06 | 1990-12-06 | Thermopac S.A., Freiburg/Fribourg | Composite packaging for eggs, fruits and fragile items |

-

2006

- 2006-11-14 EP EP06023604A patent/EP1923332A1/en not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3489270A (en) * | 1967-09-15 | 1970-01-13 | Diamond Int Corp | Plastic container |

| US3865299A (en) * | 1974-02-12 | 1975-02-11 | Keyes Fibre Co | Egg carton with flexible window well |

| GB2131399A (en) * | 1981-09-29 | 1984-06-20 | Diamond Int Corp | Moulded egg cartons |

| DE9013925U1 (en) * | 1989-10-06 | 1990-12-06 | Thermopac S.A., Freiburg/Fribourg | Composite packaging for eggs, fruits and fragile items |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013038337A3 (en) * | 2011-09-13 | 2013-06-20 | Brødrene Hartmann A/S | A display and distribution package for eggs |

| EP2755901B1 (en) | 2011-09-13 | 2018-02-21 | Brødrene Hartmann A/S | A display and distribution package for eggs |

| US10000332B2 (en) | 2011-09-13 | 2018-06-19 | Brødrene Hartmann A/S | Display and distribution package for eggs |

| WO2013164664A1 (en) * | 2012-05-03 | 2013-11-07 | Brødrene Hartmann A/S | Egg package |

| US9650204B2 (en) | 2012-05-03 | 2017-05-16 | Brødrene Hartmann A/S | Egg package |

| EP3251973A2 (en) | 2012-05-03 | 2017-12-06 | Brødrene Hartmann A/S | Egg package |

| EP3251973B1 (en) * | 2012-05-03 | 2020-07-08 | Brødrene Hartmann A/S | A method for manufacturing an egg package |

| US9682811B2 (en) | 2012-08-21 | 2017-06-20 | Brødrene Hartmann A/S | Package for eggs and method for manufacturing said package |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2751894C (en) | Package for holding and displaying shaving razors | |

| US5979662A (en) | Packaging assembly, and related method, for shipping and displaying a plurality of products | |

| US5370220A (en) | Article display and dispensing container with vertical troughs | |

| EP1683740A1 (en) | Package comprising windows | |

| CA2567668A1 (en) | Display pack and related packaging assembly | |

| US20230413975A1 (en) | Shaving razor package assembly | |

| EP1923332A1 (en) | Package comprising windows | |

| EP3288425B1 (en) | Package | |

| RU2294877C2 (en) | Package for food products such as eggs | |

| EP1373100B1 (en) | Display package for articles such as eggs | |

| US20220024666A1 (en) | Packaging system for distribution, storing, and displaying fragile items | |

| CA2356915A1 (en) | Product packaging arrangement for shipping and display | |

| US8646608B2 (en) | Packaging and display device | |

| EP1931579B1 (en) | Package with a support structure for confectionery products | |

| EP1310439A1 (en) | Package for goods such as eggs | |

| KR19980060587U (en) | Box with multiple containers | |

| CA2321485C (en) | Shelf ready inner package shipping container | |

| JP2001097388A (en) | Packing box with indication tag | |

| IT9020902U1 (en) | STRUCTURE OF PACKAGING FOR EGGS ESPECIALLY FOR PACKAGING TRADE LI | |

| WO2000034151A1 (en) | Lids for egg boxes | |

| ITMI20010315A1 (en) | CONTAINER FOR THE DISPLAY OF PACKAGED PRODUCTS AND RELATED TEST SAMPLES |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20081121 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20100212 |