EP1663465B1 - Mixing shaft for thorough mixing and comminuting of food products - Google Patents

Mixing shaft for thorough mixing and comminuting of food products Download PDFInfo

- Publication number

- EP1663465B1 EP1663465B1 EP04762574A EP04762574A EP1663465B1 EP 1663465 B1 EP1663465 B1 EP 1663465B1 EP 04762574 A EP04762574 A EP 04762574A EP 04762574 A EP04762574 A EP 04762574A EP 1663465 B1 EP1663465 B1 EP 1663465B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- mixing shaft

- mixing

- steel core

- coating

- elongated

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 235000013305 food Nutrition 0.000 title claims abstract description 12

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 28

- 239000010959 steel Substances 0.000 claims abstract description 28

- 239000006223 plastic coating Substances 0.000 claims abstract description 24

- 238000000034 method Methods 0.000 claims abstract description 4

- 239000011248 coating agent Substances 0.000 claims description 13

- 238000000576 coating method Methods 0.000 claims description 13

- 229920001343 polytetrafluoroethylene Polymers 0.000 claims description 6

- 239000004810 polytetrafluoroethylene Substances 0.000 claims description 6

- 229910001220 stainless steel Inorganic materials 0.000 claims description 4

- 239000010935 stainless steel Substances 0.000 claims description 4

- 238000002347 injection Methods 0.000 claims description 3

- 239000007924 injection Substances 0.000 claims description 3

- 230000001788 irregular Effects 0.000 claims description 3

- 239000002184 metal Substances 0.000 claims description 3

- 229910052751 metal Inorganic materials 0.000 claims description 3

- 239000004033 plastic Substances 0.000 claims description 3

- 229920003023 plastic Polymers 0.000 claims description 3

- 238000004519 manufacturing process Methods 0.000 claims description 2

- 238000003672 processing method Methods 0.000 claims description 2

- 238000005520 cutting process Methods 0.000 claims 1

- 230000001747 exhibiting effect Effects 0.000 claims 1

- 238000003754 machining Methods 0.000 claims 1

- 238000010438 heat treatment Methods 0.000 description 2

- 102000004169 proteins and genes Human genes 0.000 description 2

- 108090000623 proteins and genes Proteins 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- GUBGYTABKSRVRQ-QKKXKWKRSA-N Lactose Natural products OC[C@H]1O[C@@H](O[C@H]2[C@H](O)[C@@H](O)C(O)O[C@@H]2CO)[C@H](O)[C@@H](O)[C@H]1O GUBGYTABKSRVRQ-QKKXKWKRSA-N 0.000 description 1

- 239000003570 air Substances 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000003651 drinking water Substances 0.000 description 1

- 235000020188 drinking water Nutrition 0.000 description 1

- 238000013467 fragmentation Methods 0.000 description 1

- 238000006062 fragmentation reaction Methods 0.000 description 1

- 239000008101 lactose Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- -1 polytetrafluoroethylene Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 235000014059 processed cheese Nutrition 0.000 description 1

- 238000007788 roughening Methods 0.000 description 1

- 235000015067 sauces Nutrition 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 235000014347 soups Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/051—Stirrers characterised by their elements, materials or mechanical properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/051—Stirrers characterised by their elements, materials or mechanical properties

- B01F27/053—Stirrers characterised by their elements, materials or mechanical properties characterised by their materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/07—Stirrers characterised by their mounting on the shaft

- B01F27/071—Fixing of the stirrer to the shaft

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/07—Stirrers characterised by their mounting on the shaft

- B01F27/072—Stirrers characterised by their mounting on the shaft characterised by the disposition of the stirrers with respect to the rotating axis

- B01F27/0724—Stirrers characterised by their mounting on the shaft characterised by the disposition of the stirrers with respect to the rotating axis directly mounted on the rotating axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/051—Stirrers characterised by their elements, materials or mechanical properties

- B01F27/053—Stirrers characterised by their elements, materials or mechanical properties characterised by their materials

- B01F27/0531—Stirrers characterised by their elements, materials or mechanical properties characterised by their materials with particular surface characteristics, e.g. coated or rough

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/21—Mixers with rotary stirring devices in fixed receptacles; Kneaders characterised by their rotating shafts

- B01F27/211—Mixers with rotary stirring devices in fixed receptacles; Kneaders characterised by their rotating shafts characterised by the material of the shaft

Definitions

- the present invention is concerned with a mixing shaft for mixing and dividing food products in an aggregate, in particular with a plastic coating on the stainless steel core of the mixing shaft.

- mixing shafts are known in the art from DE 88 04 492.0 known.

- the well-known mixing shaft has a smooth, round steel core, on the surface of which a casing is applied, which has flattened areas at various points, which serve for the non-rotatable attachment of mixing elements.

- the mixing shafts are usually installed in a heating unit of a continuously producing digester, in which water-quality steam is injected through nozzles into the food products, such as processed cheese, soups, sauces.

- the mixing shafts are rotated at turns of 300 to 3,000 revolutions per minute in the food product. To ensure optimum condensation of the water vapor on the product particles and thus optimum heating ensure the product must be cut by means of the mixing shaft in order to obtain the largest possible surface.

- the mixing shafts known in the prior art consist of a stainless steel core, over which a plastic coating is applied by various methods and sealed with sealing rings.

- the structured mixing shaft according to the invention for mixing and dividing food products into an aggregate is characterized in that a steel core with a structured surface is surrounded by a coating, the coating having mixing elements integrated in the coating.

- the method for producing a coating on the surface of a steel core of a mixing shaft for mixing and dividing food products in an aggregate by means of a known processing method for applying PTFE to surfaces is characterized in that on the structured surface of the steel core at isostatic pressure ( p) and elevated temperatures (T) a coating with mixing elements is applied.

- the coating is a so-called PTFE (polytetraethylene) or a ceramic material.

- the steel core is made of stainless steel.

- the elongated cylinder portion of the mixing shaft has at one end a flange with which the mixing shaft is supported on the other working tools of the unit.

- the mixing unit has a product chamber, in the chamber wall advantageously at least one injection nozzle is arranged through which a water vapor is injected in drinking water quality.

- the plastic coating is pressed isostatically at high pressures of 300 to 350 bar, then sintered at temperatures of 360 ° C to 380 ° C and then machined. After the plastic coating has been applied to the steel core of the mixing shaft, it is advantageous to polish the surface of the plastic coating.

- mixing elements are part of the coating.

- the cylindrical portion of the mixing shaft has elongated grooves and elevations whose corners and edges are rounded, wherein the widths of the grooves and elevations are approximately equal.

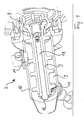

- the Fig. 1 shows a perspective schematic representation of the unit 2, in which the mixing shaft 1 according to the invention is installed.

- the mixing shaft will be described below.

- the mixing shaft 1 has at its one end another working tool 8, on which the entire shaft is supported.

- the steel core 3 has a fastening screw 16, with which the mixing shaft 1 is pressed against the working tool.

- In the walls 10 of the product unit 2 at least one injection nozzle 11 is arranged, are injected with the arbitrary means in the interior of the product unit 2.

- the mixing shaft 1 is driven with revolutions between 300 to 3,000 revolutions per minute.

- the Fig. 2 shows a perspective view of a partial sectional view of the mixing shaft according to the invention 1.

- the mixing shaft 1 consists essentially of an elongated cylindrical steel core 3, which is surrounded by a plastic coating 6.

- the steel core 3 has a bore 17 in the center, in which a bolt 18 is guided with a thread, not shown here, with which the mixing shaft 1 is pressed with a screw 16 against the working tool.

- Both the surface of the flange and the entire cylindrical portion 7 of the steel core 3, with the exception of the end faces 19, are surrounded by a single plastic coating 6.

- the surface of the plastic coating 6 itself is structured and has, in the present exemplary embodiment, radially projecting mixing elements 4 whose distances (A) are different and are distributed over the entire surface circumference of the mixing shaft 1 quasi irregular.

- the coating 6 is in the present embodiment, a so-called PTFE (polytetrafluoroethylene), which is isostatic pressed at a relatively high pressure and sintered at temperatures between 360 ° C and 380 ° C. Because of the different coefficients of expansion of plastic and steel, air gaps are generally formed at the boundary surfaces 20 between the coating and the steel core, in which product residues penetrate and can no longer be removed.

- the surface of the steel core 3 is executed structured.

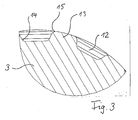

- the structure of elongated grooves 12 and elongated protrusions 13 is formed over a part of the cylindrical portion of the steel core 3.

- the depth of the grooves is about 2 mm and the widths of the grooves 12 and the elevations are between 6 mm and 10 mm.

- the grooves 12 terminate shortly before the end face of the cylindrical portion 7 of the mixing shaft 1, whereby an additional slip resistance for the plastic coating 6 is given. Further, for some embodiments, it is advantageous to roughen the entire surface, with the exception of the end faces, of the cylindrical portion of the mixing shaft 1, whereby the plastic coating can penetrate into the pores of the roughening.

Abstract

Description

Die vorliegenden Erfindung befasst sich mit einer Mischwelle zur Durchmischung und Zerteilung von Lebensmittelprodukten in einem Aggregat, insbesondere mit einem Kunststoffüberzug auf dem Edelstahlkern der Mischwelle.The present invention is concerned with a mixing shaft for mixing and dividing food products in an aggregate, in particular with a plastic coating on the stainless steel core of the mixing shaft.

Derartige Mischwellen sind im Stand der Technik aus der

Die im Stand der Technik bekannten Mischwellen bestehen aus einem Edelstahlkern, über den ein Kunststoffüberzug mit verschiedenen Methoden aufgetragen und mit Dichtringen abgedichtet wird.The mixing shafts known in the prior art consist of a stainless steel core, over which a plastic coating is applied by various methods and sealed with sealing rings.

Als nachteilig an den bisherigen Ausführungsformen der Mischwellen hat es sich erwiesen, dass gewisse Laktose-, Eiweißmoleküle und Proteine auf der Oberfläche des Kunststoffüberzugs anhaften und verbrennen und damit die Standzeit der Mischwelle und Produktqualität stark reduzieren. Ferner weisen die bisher bekannten Mischwellen bzw. deren Kunststoffüberzüge eine ungenügende Stabilität bei erhöhten Temperaturen von ca. 150 °C auf. Weiterhin ist es aus hygienischen Gründen nachteilig, dass sich infolge der unterschiedlichen thermischen Ausdehnungskoeffizienten von Kunststoffen und Metallen während des Betriebes bei erhöhten Temperaturen Zwischenräume zwischen dem Kunststoffüberzug und dem Metall der Mischwelle bilden, in die die Lebensmittelprodukte eindringen und daher schwer zu reinigen und zu entfernen sind.A disadvantage of the previous embodiments of the mixing shafts, it has been found that certain lactose, protein molecules and proteins adhere to the surface of the plastic coating and burn and thus greatly reduce the service life of the mixing shaft and product quality. Furthermore, the previously known mixing shafts or their plastic coatings an insufficient stability at elevated temperatures of about 150 ° C. Furthermore, it is disadvantageous for hygienic reasons that form due to the different thermal expansion coefficients of plastics and metals during operation at elevated temperatures interstices between the plastic coating and the metal of the mixing shaft into which penetrate the food products and are therefore difficult to clean and remove ,

Daher ist es Aufgabe der vorliegenden Erfindung, eine Mischwelle für Lebensmittelprodukte bereitzustellen, die betriebssicher ist und eine lange Standzeit aufweist und in der Anwendung hygienisch ist.Therefore, it is an object of the present invention to provide a mixing shaft for food products, which is reliable and has a long service life and is hygienic in the application.

Diese Aufgabe wird mit den kennzeichnenden Merkmalen der Hauptansprüche gelöst.This object is achieved with the characterizing features of the main claims.

Weitere erfindungswesentliche Merkmale sind den Unteransprüchen zu entnehmen.Other features essential to the invention can be found in the dependent claims.

Die erfindungsgemäße strukturierte Mischwelle zur Durchmischung und Zerteilung von Lebensmittelprodukten in einem Aggregat ist dadurch gekennzeichnet, dass ein Stahlkern mit einer strukturierten Oberfläche von einem Überzug umgeben ist, wobei der Überzug Mischelemente aufweist, die in dem Überzug integriert sind.The structured mixing shaft according to the invention for mixing and dividing food products into an aggregate is characterized in that a steel core with a structured surface is surrounded by a coating, the coating having mixing elements integrated in the coating.

Das Verfahren zur Herstellung eines Überzugs auf der Oberfläche eines Stahlkerns einer Mischwelle zur Durchmischung und Zerteilung von Lebensmittelprodukten in einem Aggregat mit Hilfe eines an sich bekannten Verarbeitungsverfahrens zur Aufbringung von PTFE auf Oberflächen ist dadurch gekennzeichnet, dass auf die strukturierte Oberfläche des Stahlkerns bei isostatischem Druck (p) und erhöhten Temperaturen (T) ein Überzug mit Mischelementen aufgebracht wird.The method for producing a coating on the surface of a steel core of a mixing shaft for mixing and dividing food products in an aggregate by means of a known processing method for applying PTFE to surfaces is characterized in that on the structured surface of the steel core at isostatic pressure ( p) and elevated temperatures (T) a coating with mixing elements is applied.

Vorteilhaft ist es dabei, dass der Überzug ein sogenannter PTFE (Polytetraethylen) oder ein Keramikmaterial ist. Ferner ist es vorteilhaft, dass der Stahlkern aus Edelstahl ist.It is advantageous in this case that the coating is a so-called PTFE (polytetraethylene) or a ceramic material. Furthermore, it is advantageous that the steel core is made of stainless steel.

Vorteilhaft ist es ferner, dass der längliche Zylinderabschnitt der Mischwelle an einem Ende einen Flansch aufweist, mit dem sich die Mischwelle an den weiteren Arbeitswerkzeugen des Aggregats abstützt.It is also advantageous that the elongated cylinder portion of the mixing shaft has at one end a flange with which the mixing shaft is supported on the other working tools of the unit.

Vorteilhaft ist es auch, dass auf dem zylindrischen Abschnitt der Mischwelle Mischelemente, vorzugsweise rund, in bestimmten Abständen (A) angeordnet sind, wobei die Abstände (A) unregelmäßig sind.It is also advantageous that on the cylindrical portion of the mixing shaft mixing elements, preferably round, at certain intervals (A) are arranged, wherein the distances (A) are irregular.

Das Mischaggregat weist eine Produktkammer auf, in dessen Kammerwand vorteilhaft mindestens eine Injektionsdüse angeordnet ist, durch die ein Wasserdampf in Trinkwasserqualität injiziert wird.The mixing unit has a product chamber, in the chamber wall advantageously at least one injection nozzle is arranged through which a water vapor is injected in drinking water quality.

Vorteilhaft ist es ferner, dass der Kunststoffüberzug isostatisch bei hohen Drücken von 300 bis 350 bar aufgepresst, dann bei Temperaturen von 360°C bis 380°C gesintert und anschließend spanend bearbeitet wird. Nachdem der Kunststoffüberzug auf den Stahlkern der Mischwelle aufgebracht wurde, ist es vorteilhaft, die Oberfläche des Kunststoffüberzugs zu polieren.It is also advantageous that the plastic coating is pressed isostatically at high pressures of 300 to 350 bar, then sintered at temperatures of 360 ° C to 380 ° C and then machined. After the plastic coating has been applied to the steel core of the mixing shaft, it is advantageous to polish the surface of the plastic coating.

Vorteilhaft ist es weiterhin, dass die Mischelemente Bestandteil des Überzugs sind.It is also advantageous that the mixing elements are part of the coating.

Vorteilhaft ist es auch, dass der zylindrische Abschnitt der Mischwelle längliche Nuten und Erhebungen aufweist, deren Ecken und Kanten abgerundet sind, wobei die Breiten der Nuten und Erhebungen etwa gleich groß sind.It is also advantageous that the cylindrical portion of the mixing shaft has elongated grooves and elevations whose corners and edges are rounded, wherein the widths of the grooves and elevations are approximately equal.

Im nun Folgenden wird die Erfindung anhand von Zeichnungen im Detail näher erläutert. Es zeigt

- Fig. 1:

- eine perspektivische Darstellung des Mischaggregats (2) einer Anlage zur Durchmischung und Zerteilung von Lebensmittelprodukten;

- Fig. 2:

- eine perspektivische Darstellung der erfindungsgemäßen Mischwelle (1) mit ihrem Stahlkern (3) und dem Kunststoffüberzug (6);

- Fig. 3:

- einen Ausschnitt aus der Oberfläche des Stahlkerns (3).

- Fig. 1:

- a perspective view of the mixing unit (2) of a plant for mixing and fragmentation of food products;

- Fig. 2:

- a perspective view of the mixing shaft (1) according to the invention with its steel core (3) and the plastic coating (6);

- 3:

- a section of the surface of the steel core (3).

Die

Die

Claims (14)

- Mixing shaft (1) for thorough mixing and cuting of food products in an assembly (2) with a steel core (3) exhibiting a coated plastic (6) wherein on an elongated cylindrical section (7) mixing elements (4) are disposed in a predetermined distance (A), characterized in that the mixing elements (4) are components of the coating (6) and the steel core (3) exhibits a structure surface (5) formed on the elongated cylindrical section (7) of the steel core (3) of mixing shaft by elongated grooves (12) and elongated projections (13).

- Mixing shaft (1) according to claim 1 characterized in that the coating (6) is a PTFE.

- Mixing shaft (1) according to claim 1 characterized in that the steel core (3) is made of stainless steel.

- Mixing shaft (1) according to claim 1 characterized in that a flange (8) is arranged at one end of the elongated section (7).

- Mixing shaft (1) according to claim 1 characterized in that the distances (A) are furnished irregular.

- Mixing shaft (1) according to one of the preceding claims characterized in that the elongated cylindrical section (7) is disposed in an elongated product chamber (9).

- Mixing shaft (1) according to claim 6 characterized in that at least one injection nozzle (11) is disposed at the product chamber wall (10).

- Mixing shaft (1) according to one of the preceding claims characterized in that the plastic coating (6) is pressed on isostatically at high pressure, then is sintered at high temperatures and in the following worked by metal cutting and machining away.

- Mixing shaft (1) according to one of the preceding claims characterized in that the surface of the plastic coating (6) is polished.

- Mixing shaft (1) according to one of the preceding claims characterized in that the plastic coating (6) is pressed on with an isostatic pressure of about 300 bar to 350 bar onto the steel core (3) of the mixing shaft (1).

- Mixing shaft (1) according to one of the preceding claims 8 to 10 characterized in that the plastic coating (6) is sintered at temperatures from about 360 degrees centigrade to 380 degrees centigrade after the isostatic pressure application.

- Mixing shaft (1) according to one of the preceding claims characterized in that the corners (14) and edges (15) of the elongated grooves (12) and elongated projections (13) are formed rounded.

- Mixing shaft (1) according to one of the preceding claims characterized in that the width of the grooves (12) and the projections (13) are approximately of equal size.

- Method for the production of a coating (6) on a surface of a steel core (3) of a mixing shaft (1) for thorough mixing and cuting of food products in an aggregate (2) with the aid of a processing method of PTFE under pressure characterized in that a coating (6) with mixing elements (4) is applied onto the structured surface of the steel core (3) at isostatic pressure (p) and at increased temperatures (T).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL04762574T PL1663465T3 (en) | 2003-08-02 | 2004-08-02 | Mixing shaft for thorough mixing and comminuting of food products |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10335552A DE10335552B4 (en) | 2003-08-02 | 2003-08-02 | Mixing shaft for mixing and dividing food products and method for producing a coating for such a mixing shaft |

| PCT/DE2004/001729 WO2005014152A2 (en) | 2003-08-02 | 2004-08-02 | Mixing shaft for thorough mixing and comminuting of food products |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1663465A2 EP1663465A2 (en) | 2006-06-07 |

| EP1663465B1 true EP1663465B1 (en) | 2008-02-27 |

Family

ID=34129481

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04762574A Active EP1663465B1 (en) | 2003-08-02 | 2004-08-02 | Mixing shaft for thorough mixing and comminuting of food products |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8833688B2 (en) |

| EP (1) | EP1663465B1 (en) |

| AT (1) | ATE387257T1 (en) |

| DE (2) | DE10335552B4 (en) |

| PL (1) | PL1663465T3 (en) |

| WO (1) | WO2005014152A2 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ZA200705709B (en) | 2005-01-28 | 2009-01-28 | Unilever Plc | Edible dispersions comprising oil and structuring agent |

| DE102010023793A1 (en) | 2010-06-15 | 2011-12-15 | J. F. Knauer Industrie-Elektronik Gmbh | Apparatus and method for mixing conditioning agent, in particular flocculant, in sludge |

| KR101040927B1 (en) | 2011-03-30 | 2011-06-16 | (주)플록마스터 | Mixing apparatus for sludge spallation |

| CN103363813B (en) * | 2013-06-20 | 2014-11-12 | 宁波长振铜业有限公司 | Smelting device with automatic smashing and stirring devices |

| CA2937568C (en) | 2014-03-17 | 2022-01-11 | Sani-Tech West, Inc. | Magnetic mixing system and method |

| US11103245B2 (en) * | 2018-12-31 | 2021-08-31 | Cilag Gmbh International | Knife for surgical stapler and associated method of manufacture with MIM and hip |

| DE102019125593A1 (en) * | 2019-09-24 | 2021-03-25 | Thomas Molé | Modular mixing tool |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2852238A (en) * | 1957-08-19 | 1958-09-16 | Toms River Cincinnati Chemical | Agitator for lined pressure vessel |

| DE1944828U (en) * | 1966-07-01 | 1966-08-25 | Ver Leichtmetallwerke Gmbh | MIXING DRUM. |

| US3622129A (en) * | 1969-05-14 | 1971-11-23 | Bellco Glass Inc | Magnetic stirrer apparatus |

| DE8021396U1 (en) * | 1980-08-09 | 1980-12-04 | Bohlender, Hermann, 6970 Lauda | STIRRING SHAFT FOR STIRRERS FOR LABORATORY TREATMENT OF AGGRESSIVE MEDIA |

| DE3332403A1 (en) * | 1983-09-08 | 1985-03-28 | Robert 5446 Engeln Wolff | Stirrer as an attachment for do-it-yourself machines, e.g. drilling machines, for mixing liquids, suspensions or the like |

| US4651935A (en) * | 1984-10-19 | 1987-03-24 | Morehouse Industries, Inc. | Horizontal media mill |

| DE3723558A1 (en) * | 1987-07-16 | 1989-01-26 | Netzsch Erich Holding | MILL, ESPECIALLY AGITATOR MILL |

| DE8804492U1 (en) * | 1988-04-05 | 1988-07-07 | Polytetra Draack + Meyer Gmbh, 4050 Moenchengladbach, De | |

| DE9116859U1 (en) * | 1991-02-15 | 1994-04-07 | Stephan & Soehne | Device for the production of processed cheese |

| DE4208100C2 (en) * | 1992-03-13 | 1994-05-26 | Mtu Muenchen Gmbh | Blank for the production of fiber-reinforced coatings or metal components |

| DE4328160C2 (en) * | 1992-10-23 | 1994-10-20 | Reifenhaeuser Masch | Worm shaft of a screw extruder and method for producing such a worm shaft |

| CH688849A5 (en) * | 1993-02-25 | 1998-04-30 | Buehler Ag | Agitator mill. |

| DE19530026A1 (en) * | 1995-08-16 | 1997-02-20 | Werner & Pfleiderer | Screw set element for screw machines |

| DE19544871C2 (en) * | 1995-12-01 | 1998-02-26 | Hoechst Ag | Process for the preparation and processing of fluorine-containing organic compounds |

| US6531559B1 (en) * | 1998-08-06 | 2003-03-11 | Eidgenössische Technische Hochschule Zürich | Melt-processible poly (tetrafluoroethylene) |

| ATE271922T1 (en) * | 1999-06-01 | 2004-08-15 | Elan Pharma Int Ltd | SMALL MILL AND METHOD THEREOF |

| US6999432B2 (en) | 2000-07-13 | 2006-02-14 | Microsoft Corporation | Channel and quality of service adaptation for multimedia over wireless networks |

| WO2002009458A2 (en) | 2000-07-24 | 2002-01-31 | Bluesocket, Inc. | Method and system for enabling seamless roaming in a wireless network |

-

2003

- 2003-08-02 DE DE10335552A patent/DE10335552B4/en not_active Expired - Fee Related

-

2004

- 2004-08-02 WO PCT/DE2004/001729 patent/WO2005014152A2/en active IP Right Grant

- 2004-08-02 AT AT04762574T patent/ATE387257T1/en not_active IP Right Cessation

- 2004-08-02 PL PL04762574T patent/PL1663465T3/en unknown

- 2004-08-02 DE DE502004006334T patent/DE502004006334D1/en active Active

- 2004-08-02 EP EP04762574A patent/EP1663465B1/en active Active

- 2004-08-02 US US10/567,133 patent/US8833688B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US20070125894A1 (en) | 2007-06-07 |

| DE10335552A1 (en) | 2005-03-17 |

| DE10335552B4 (en) | 2005-07-28 |

| DE502004006334D1 (en) | 2008-04-10 |

| EP1663465A2 (en) | 2006-06-07 |

| WO2005014152A3 (en) | 2005-04-21 |

| ATE387257T1 (en) | 2008-03-15 |

| US8833688B2 (en) | 2014-09-16 |

| PL1663465T3 (en) | 2008-10-31 |

| WO2005014152A2 (en) | 2005-02-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2234669B2 (en) | Nozzle assembly | |

| EP0615085B1 (en) | Method for making a shaft seal | |

| DE60202873T2 (en) | METHOD FOR PRODUCING A STATOR FOR AN ECCENTRIC SCISSOR PUMP AND STATOR THEREFOR | |

| EP1663465B1 (en) | Mixing shaft for thorough mixing and comminuting of food products | |

| DE2460185A1 (en) | PROCESS FOR THE PRODUCTION OF SEALING ELEMENTS WITH HYDRODYNAMIC EFFECT | |

| AT511880B1 (en) | WEAR-OPTIMIZED MANUFACTURE OF TAPPY SPRAY HOLES | |

| WO2014166677A1 (en) | Mechanical connecting element, pertaining connecting system and pertaining surface treatment method | |

| EP0165417B1 (en) | Piston ring | |

| DE19730008C1 (en) | Sheathing for metallic engine component | |

| EP1517766B1 (en) | Method for the hydro-erosive rounding of an edge of a part and use thereof | |

| EP1887264A1 (en) | Method for manufacturing a tribiological component | |

| DE2750224C2 (en) | ||

| DE202018107062U1 (en) | Radial shaft sealing device | |

| EP0157204B1 (en) | Clamping element | |

| CH669557A5 (en) | ||

| DE3448025C3 (en) | Process for the manufacture of rotors for screw compressors | |

| EP3293432B1 (en) | Component with tube section having enamelled collar | |

| DE884437C (en) | Gasket made of steel with surface hardened, sealing cutting edges and method for producing such gaskets | |

| DE102009040510A1 (en) | Rotor for e.g. vane-type pump, that produces vacuum in low pressure chamber of brake booster, has raised surface provided radially outside of coupling front surface of coupling element, where raised surface surrounds coupling element | |

| DE202007015873U1 (en) | injection molding | |

| WO2005054522A1 (en) | Method for the selective hardening of sealing surfaces | |

| DE202006012531U1 (en) | Rotating passage, e.g. for jet blasting tool using fluid at high pressure, has fixed concentric sleeve at the end of the hollow shaft against the inflow and seal at the shaft holder with flat surfaces at the sealing and support rings | |

| DE10239379A1 (en) | Method for machining a workpiece for a high-pressure fuel accumulator and workpiece for applying the method | |

| DE20312001U1 (en) | Industrial food mixer has mixer shaft and blades with polytetra-fluorethylene or ceramic mantle | |

| EP1920901B1 (en) | Device for holding templates |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20060228 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004006334 Country of ref document: DE Date of ref document: 20080410 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080607 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080527 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080721 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20081128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080831 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20080802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080527 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080802 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080828 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20110729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080901 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004006334 Country of ref document: DE Representative=s name: REICHERT & LINDNER PARTNERSCHAFT PATENTANWAELT, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004006334 Country of ref document: DE Representative=s name: REICHERT & LINDNER PARTNERSCHAFT PATENTANWAELT, DE Effective date: 20141217 Ref country code: DE Ref legal event code: R081 Ref document number: 502004006334 Country of ref document: DE Owner name: STEPHAN MACHINERY GMBH, DE Free format text: FORMER OWNER: STEPHAN MACHINERY GMBH & CO., 31789 HAMELN, DE Effective date: 20141217 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 502004006334 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: B01F0015000000 Ipc: B01F0035000000 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20220822 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20220729 Year of fee payment: 19 Ref country code: DE Payment date: 20220831 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20220725 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004006334 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20230901 |