EP1595486A2 - The air purging of a liquid dispensing system of a surface cleaner - Google Patents

The air purging of a liquid dispensing system of a surface cleaner Download PDFInfo

- Publication number

- EP1595486A2 EP1595486A2 EP05252872A EP05252872A EP1595486A2 EP 1595486 A2 EP1595486 A2 EP 1595486A2 EP 05252872 A EP05252872 A EP 05252872A EP 05252872 A EP05252872 A EP 05252872A EP 1595486 A2 EP1595486 A2 EP 1595486A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- liquid

- flow path

- fluid flow

- inlet

- valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000007788 liquid Substances 0.000 title claims abstract description 225

- 238000010926 purge Methods 0.000 title claims abstract description 36

- 239000012530 fluid Substances 0.000 claims abstract description 107

- 238000004140 cleaning Methods 0.000 claims description 132

- 239000012459 cleaning agent Substances 0.000 claims description 127

- 238000011084 recovery Methods 0.000 claims description 18

- 238000005201 scrubbing Methods 0.000 claims description 18

- 238000000034 method Methods 0.000 claims description 15

- 230000004044 response Effects 0.000 claims description 12

- 238000005276 aerator Methods 0.000 claims description 11

- 238000001514 detection method Methods 0.000 claims description 11

- 238000011144 upstream manufacturing Methods 0.000 claims description 10

- 239000003570 air Substances 0.000 claims 21

- 239000012080 ambient air Substances 0.000 claims 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 14

- 238000009736 wetting Methods 0.000 description 12

- 238000010586 diagram Methods 0.000 description 10

- 239000006260 foam Substances 0.000 description 9

- 239000000463 material Substances 0.000 description 6

- 239000000243 solution Substances 0.000 description 6

- 230000037452 priming Effects 0.000 description 4

- 238000004891 communication Methods 0.000 description 3

- 238000005507 spraying Methods 0.000 description 3

- 239000004094 surface-active agent Substances 0.000 description 3

- 239000011358 absorbing material Substances 0.000 description 2

- 238000005273 aeration Methods 0.000 description 2

- 239000003945 anionic surfactant Substances 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 239000002894 chemical waste Substances 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000007599 discharging Methods 0.000 description 2

- 238000001035 drying Methods 0.000 description 2

- 239000000428 dust Substances 0.000 description 2

- 230000008030 elimination Effects 0.000 description 2

- 238000003379 elimination reaction Methods 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 238000005086 pumping Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 2

- 229920002554 vinyl polymer Polymers 0.000 description 2

- 229920000114 Corrugated plastic Polymers 0.000 description 1

- 229920001410 Microfiber Polymers 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 235000004443 Ricinus communis Nutrition 0.000 description 1

- 240000000528 Ricinus communis Species 0.000 description 1

- 239000011449 brick Substances 0.000 description 1

- -1 builders Substances 0.000 description 1

- 239000003093 cationic surfactant Substances 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 239000013256 coordination polymer Substances 0.000 description 1

- 230000009849 deactivation Effects 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 239000000645 desinfectant Substances 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 239000003292 glue Substances 0.000 description 1

- 230000006698 induction Effects 0.000 description 1

- 210000000850 labyrinthine fluid Anatomy 0.000 description 1

- 239000010808 liquid waste Substances 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000003658 microfiber Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 239000007779 soft material Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/02—Floor surfacing or polishing machines

- A47L11/03—Floor surfacing or polishing machines characterised by having provisions for supplying cleaning or polishing agents

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/29—Floor-scrubbing machines characterised by means for taking-up dirty liquid

- A47L11/30—Floor-scrubbing machines characterised by means for taking-up dirty liquid by suction

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/408—Means for supplying cleaning or surface treating agents

- A47L11/4088—Supply pumps; Spraying devices; Supply conduits

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4097—Means for exhaust-air diffusion; Exhaust-air treatment, e.g. air purification; Means for sound or vibration damping

Definitions

- the present invention is generally directed to surface cleaners having a liquid dispensing system and, more particularly, to a method and apparatus for purging air from a fluid flow path of the liquid dispensing system.

- Surface cleaners are widely used to clean floors of industrial and commercial buildings. They range in size from a small model that is controlled by an operator walking behind the machine, which may clean a path ranging from 15 inches to 36 inches wide, to a large model that is controlled by an operator riding on the machine, which may clean a path as wide as 5 feet. These surface cleaners include motorized drive wheels, rotatable scrubber brushes, a cleaning liquid dispensing system and a recovery tank to hold soiled cleaning solution that is recovered from the surface being scrubbed.

- the liquid dispensing system generally operates to dispense a cleaning liquid to the surface and/or the scrubber brushes.

- the liquid dispensing system can utilize a tank of cleaning liquid or solution.

- the liquid dispensing system can be configured to mix separate cleaning agent and water supplies to form the cleaning liquid prior to dispensing the cleaning liquid.

- the liquid dispensing system also includes a pump that is configured to drive the liquid through at least one flow restriction member.

- the flow restriction member produces a pressure drop in the flow of liquid driven by the pump.

- the flow of liquid at an inlet of the flow restriction member has a higher pressure than at an outlet of the flow restriction member.

- Exemplary flow restriction members include metering devices that control a flow rate of the liquid being pumped, a check valve that restricts the direction the liquid travels, and a nozzle through which the liquid is dispensed to the surface and/or the scrubber brushes.

- the act of removing air from the fluid flow path and the pump is known as "priming" the pump.

- Methods of priming pumps of liquid dispensing systems are known. These generally include a rerouting of the fluid flow path of the liquid such that it bypasses the flow restriction member and “releases" the flow of liquid and the air such that the air can be moved in the fluid flow path downstream of the pump.

- methods of priming the pump of liquid dispensing systems of surface cleaners require the manual opening and closing of valves to modify the fluid flow path such that it bypasses the flow restriction member, which is time consuming. Additionally, such pump priming practices can produce large amounts of liquid waste.

- the present invention is generally directed to purging air from a liquid dispensing system of a surface cleaner.

- a surface cleaner having a liquid dispensing system that includes a fluid flow path configured to receive a flow of liquid, a pump, an air purging component, and a valve actuator.

- the pump is in line with the fluid flow path and is configured to drive the flow of liquid through the fluid flow path.

- the air purging component includes an inlet in line with the fluid flow path, an outlet, an airflow path connecting the inlet and the outlet, and a valve in line with the airflow path.

- the valve includes an open position in which the airflow path is open between the inlet and the outlet and a closed position in which the airflow path is closed between the inlet and the outlet.

- the valve actuator is connected to the valve and is configured to bias the valve in the open position when air is detected in the fluid flow path.

- Another aspect of the present invention includes a method of purging air from a liquid dispensing system of a surface cleaner.

- a pump configured to drive a flow of liquid through a fluid flow path of the liquid dispensing system, is driven.

- the presence of air or liquid in the fluid flow path is detected.

- an airflow path connected the fluid flow path is opened to discharge the air from the fluid flow path.

- the airflow path is closed.

- One embodiment of the present invention is directed to a liquid or cleaning liquid dispensing system, generally designated as 100, of a surface cleaner, such as hard floor surface cleaner or a carpet cleaner.

- a surface cleaner such as hard floor surface cleaner or a carpet cleaner.

- Cleaner 110 is illustrated as a walk-behind cleaner used to clean hard floor surfaces 111, such as concrete, tile, vinyl, terrazzo, etc., over which cleaner 110 travels.

- cleaner 110 can be a ride-on or towed-behind cleaner performing a scrubbing operation as described herein.

- Cleaner 110 may include electrical motors powered through an on-board power source, such as batteries, or through an electrical cord.

- an internal combustion engine system could be used either alone, or in combination with, the electric motors.

- Cleaner 110 generally includes a recovery tank 112, a lid 114, a tank 118, and a scrub head 120.

- Lid 114 is attached along one side of the recovery tank 112 by hinges (not shown) so that lid 114 can be pivoted up to provide access to the interior of tank 112.

- tank 118 contains a cleaning liquid or solution that is dispensed to the surface 111 and/or brushes of the scrub head 120 by the dispensing system 100.

- the tank 118 includes a primary cleaning liquid component, preferably water, that is combined with a cleaning agent by the dispensing system 100 to form a cleaning liquid that can be applied to the hard floor surface 111 or the brushes of the scrub head 120.

- Scrub head 120 includes a scrubbing member 122, shrouds 124, and a scrubbing member drive 126.

- Scrubbing member 122 may be one or more brushes, such as bristle brushes, pad scrubbers, or other hard floor surface scrubbing elements.

- Drive 126 includes one or more electric motors to rotate the scrubbing member 122. Drive 126 may also oscillate scrubbing member 122.

- Scrub head 120 is attached to cleaner 110 such that scrub head 120 can be moved between a lowered cleaning position and a raised traveling position. Other embodiments of cleaner 110 will be discussed below that utilize alternative scrub heads 120 and that eliminate the scrub head 120 completely.

- a machine frame or mobile body 127 supports recovery tank 112 on wheels 128 and castors 129. Details of the frame are shown and described in U.S. Patent Number 5,611,105, the disclosure of which is incorporated herein by reference. Wheels 128 are preferably driven by a motor and transaxle assembly shown schematically at 130.

- One embodiment of the cleaner 110 includes a linkage 131 mounted to a rear of the frame 127 and a fluid recovery device 132 attached to the linkage 131.

- the fluid recovery device 132 includes a vacuum squeegee 134 and a vacuum 135 in communication with an inlet chamber of recovery tank 112 through a hose 136, which is illustrated in greater detail in FIG. 2.

- the bottom of the inlet chamber is provided with a drain 140 with a drain hose 142 connected to it.

- Soiled cleaning solution that is collected by squeegee 134 is sucked into recovery tank 112 by vacuum 135.

- a residue of cleaning liquid typically remains on the hard floor surface 111 until air dried.

- Alternative mechanical devices, structures, or systems may be used to convey the soiled solution from the floor surface into recovery tank 112.

- Cleaner 110 can include a battery compartment 150 in which batteries 152 reside. Batteries 152 provide power to drive motors 126, vacuum fan 154 of vacuum 135, and other electrical components of cleaner 110. Vacuum fan 154 is mounted under lid 114. A control unit 156 mounted on the rear of the body of cleaner 110 includes steering control handles 158 and operating controls and gages for cleaner 110. Additional aspects of automatic surface cleaners are disclosed in U.S. Patent Numbers 5,483,718, 5,515,568, and 5,566,422, 6,585,827, 6,662,600, 6,671,925, 6,705,332 and 6,735,811 each of which are incorporated herein by reference in their entirety.

- One embodiment of the cleaning liquid dispensing system 100 dispenses a wet foamed cleaning liquid for use by the surface cleaner 110 during surface cleaning operations.

- dispensing system 100 dispenses the cleaning liquid (formed either directly from tank 118 or through the combination of a cleaning agent with water), which is then aerated to produce a foamed cleaning liquid for use by cleaner 110 to clean a hard floor surface.

- the foamed cleaning liquid is generally a very wet foam that allows for the complete wetting of the surface. Additionally, the foamed cleaning liquid utilizes very little cleaning agent thereby reducing the amount of residue remaining on the hard floor surface, reducing chemical waste, and extending the life of the cleaning agent supply.

- FIG. 3 is a schematic diagram of cleaning liquid dispensing system 100 in accordance with various embodiments of the invention.

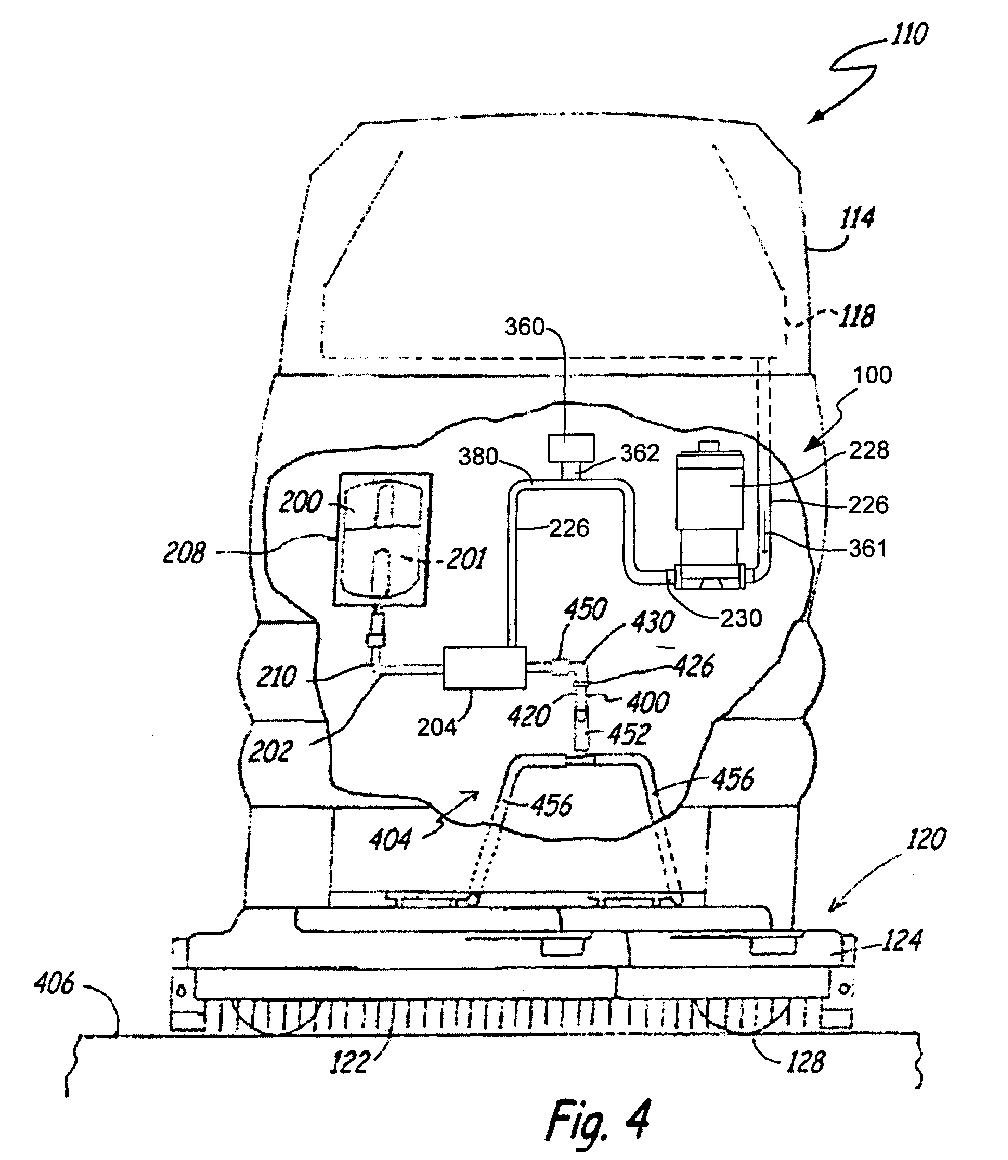

- FIG. 4 is a simplified front view of cleaner 110 that includes embodiments of the dispensing system 100.

- FIG. 5 is a side plan view of components of dispensing system 100 in accordance with embodiments of the invention.

- Embodiments of the dispensing system 100 include a cleaning agent container 200 having a supply of cleaning agent 201, a cleaning agent supply line 202, a flow control device 204, and a pressure regulator 206.

- Cleaning agent container 200 is configured to contain supply of cleaning agent 201.

- the cleaning agent 201 may include one or more surfactants, builders, solvents, or other components.

- cleaning agent 201 includes an anionic surfactant, a non-anionic surfactant, a cationic surfactant, or a combination thereof.

- a particularly preferred surfactant is DeTeric CP-Na-38 manufactured by DeForest Enterprises, Inc. of Boca Raton, Florida.

- Cleaning agent is preferably in a concentrated form (e.g., more than 30% solids).

- the cleaning agent container 200 is a collapsible container that collapses as the cleaning agent contained therein is removed.

- container 200 is a collapsible bag that can be contained in a cleaning agent cartridge 208 (FIG. 2), which will be discussed in greater detail below. Additional embodiments of the container 200 include ventilated and refillable containers.

- Cleaning agent supply line 202 is coupled to the cleaning agent container 200.

- Cleaning agent supply line 202 generally corresponds to the fluid flow path formed by tubing 210 (FIG. 4) and other components of system 100 to deliver cleaning agent 201 contained in container 200 to a first input 212 of flow control device 204.

- First input 212 of flow control device 204 is configured to receive a flow of cleaning agent 214 from supply 200 through supply line 202 and other components of system 100.

- Flow control device 204 is also configured to receive a flow of primary cleaning liquid component 216 at a second input 218.

- Flow control device 204 is further configured to combine the flows of cleaning agent 214 and primary cleaning liquid component 216 and produce an output flow of cleaning liquid 220 at an output 222.

- the primary cleaning liquid component 216 is preferably water and is contained in tank 118 of cleaner 110 or provided from another source.

- the flow of primary cleaning liquid component 216 is preferably driven through a fluid flow path defined by conduit 226 by a pump 228 at a flow rate that is desired for the cleaning operation.

- the flow of primary cleaning liquid component 216 is driven at a substantially constant flow rate of approximately 0.5 gallons per minute or less.

- the flow rate can be modified depending on the application for system 100.

- Pump 228 is generally positioned in line with fluid flow path or conduit 226 and includes an outlet 230 that is maintained at a desired high pressure.

- the pressure at outlet 230 is held substantially constant at approximately 60 pounds per square inch (psi).

- Flow control device 204 preferably combines the flow of cleaning agent 214 with the flow of primary cleaning liquid component 216 at a ratio of 1 part cleaning agent to 1000 parts primary cleaning liquid component. Accordingly, the resultant cleaning liquid 220 is formed of 0.1% cleaning agent, which is substantially less than conventional hard floor surface cleaning liquids. As a result, the present invention leaves very little cleaning agent residue following application to a hard surface, produces very little chemical waste, and increases the life of the supply of cleaning agent contained in container 200.

- Flow control device 204 injects the flow of cleaning agent 214 into the flow of primary cleaning liquid component 216 using an injector 236 at a rate that is generally less than approximately 10.0 cubic centimeters per minute.

- the flow of cleaning agent 214 is preferably limited to less than approximately 2.0 cubic centimeters per minute to provide the desired 0.1% concentration level of cleaning agent in the cleaning liquid 220 relative to the flow of primary cleaning liquid 216.

- a flow rate of approximately 1.2 cubic centimeters per minute is desired when the flow rate of the primary cleaning liquid component is approximately 0.33 gallons per minute

- a flow rate of approximately 0.5 cubic centimeters per minute is desired when the flow rate of the primary cleaning liquid component is approximately 0.13 gallons per minute.

- Injector 236 preferably operates to siphon the cleaning agent flow 214 from the supply 201 using a venturi member 238.

- the flow of primary cleaning liquid 216 through venturi member 238 creates a vacuum of approximately 370 inches of water (134.6 psi), that draws the flow of cleaning agent 214 into the flow of primary cleaning liquid component 216 at the desired rate.

- One such suitable flow control device 204 is the 50580 siphon produced by Spraying Systems Company of Wheaton, Illinois.

- the vacuum produced by flow control device 204 allows the cleaning agent supply 201 contained in collapsible bag 200 of cleaning agent cartridge 208 to be completely drained regardless of its position. That is, cleaning agent cartridge 208 can be positioned below flow control device 204 without affecting the draw of the cleaning agent 201 through supply line 202.

- the diameter and length of conduit 210 forming supply line 202 be selected to prevent substantial resistance to the flow of cleaning agent 214 there through.

- the rate of the flow of cleaning agent 214 through injector 236 is adjustable using a valve 242, such as a needle seat valve, for example.

- Valve 242 is preferably configured to provide accurate adjustment to the slow output flow of cleaning agent 214.

- Valve 242 preferably includes a sharp flow-regulating needle having for example, a two degree needle tip for improved sensitivity.

- valve 242 can be used to adjust the flow rate of the of cleaning agent flow 214, problems can arise as a result of the viscosity of the cleaning agent 201, the size of the orifice of the needle seat valve 242, and the vacuum generated by injector 236.

- injector 236 generates a large vacuum, such as 370 inches of water, in response to the flow of primary cleaning liquid component 216.

- the valve 242 that is in line with injector 236 must close the flow path through which the cleaning agent flow 214 travels to such a degree that clogging of the flow path can occur, which prevents accurate cleaning agent flow rate control.

- valve 242 when valve 242 is adjusted to a large enough opening to avoid clogging of the flow path for the cleaning agent, the opening is generally too large to restrict the flow of cleaning agent 214 to the desired rate. As a result, the cleaning agent flow rate would be higher than the preferred flow rate without additional controls.

- One embodiment of the dispensing system 100 includes the pressure regulator 206, which provides the desired additional control over the flow rate of the cleaning agent flow 214.

- Pressure regulator 206 is positioned in line with the cleaning agent supply line 202 between the first input 212 of the flow control device 204 and the cleaning agent container 200.

- Pressure Regulator 206 generally operates to maintain the pressure at first input 212 of flow control device 204 at a preferred pressure to provide the desired flow rate for the flow of cleaning agent through the flow control device 204.

- the pressure in supply line 202 is decreased by pressure regulator 206, the volumetric flow rate of the cleaning agent flow 214 decreases.

- the pressure regulator 206 can be used to control the flow rate of the cleaning agent flow 214 to the desired low flow rate for the given flow control device 204 being used including a flow control device 204 that includes a valve 242 having a large enough opening to avoid clogging by the cleaning agent.

- pressure regulator 206 includes an air inlet port 244 and an airflow path 246, as shown in FIG. 5.

- the airflow path 246 extends between a cleaning agent flow path 248 and the air inlet port 244.

- the cleaning agent flow path 248 is generally defined by the cleaning agent supply line 202, such as the flow path through component 250, to which pressure regulator connects.

- Component 250 can be a check valve to prevent the undesired backflow of cleaning agent 201 and/or primary cleaning liquid component 216 from flow control device 204.

- Pressure regulator 206 can include a valve that is either located adjacent to the supply line 202, such as valve 252, or located remotely therefrom, such as valve 254.

- Valve 252 or 254 is preferably operable between an open position in which the airflow path 246 is open to allow air, indicated by arrow 256, to enter through air inlet port 244 and into the flow of cleaning agent 214, and a closed position, in which the air flow path 246 is closed.

- the valve (252 or 254) can be adjusted or pre-set to operate to maintain the pressure at the cleaning agent flow path at the desired level relative to the ambient pressure by opening when the pressure at first inlet 212 of flow control device 204 drops below a threshold minimum.

- pressure regulator 206 is a relief-check valve assembly, such as a 4-6 psi relief-check valve assembly. Such pressure regulators are available from Smart Products, Inc. of San Jose, California.

- the flow of primary cleaning liquid component 216 through venturi member 238 generates a vacuum of approximately 370 inches of water at the first input 212 of flow control device 204 when valve 252 or 254 of pressure regulator 206 is closed or pressure regulator 206 is not present.

- the flow of cleaning agent 208 is injected into the flow of primary cleaning liquid at a rate of much greater than 2.0 cubic centimeters per minute.

- valve 252 and/or 254 are open, the vacuum generated by flow control device 204 causes air 256 to be drawn in through air inlet port 244 and airflow path 246 of pressure regulator 206 and into the flow of cleaning agent 214. This reduces the pressure at the first inlet 212 of the flow control device 204 to a desired level and controls the flow rate of the cleaning agent flow 214 injected into the flow of primary cleaning liquid 216.

- pressure regulator 206 can be selected empirically based upon the vacuum generated by flow control device 204 and the desired flow rate for the flow of cleaning agent 214. For example, when pressure regulator 206 is a 6 psi relief-check valve, the vacuum at the first input of flow control device can be reduced from 370 inches of water to approximately 150 inches of water, thereby causing the resultant flow rate of the flow of cleaning agent that is injected into the flow of primary cleaning liquid component to drop to approximately 1.2 cubic centimeters per minute when valve 242 is property set or when a suitable metering device 260 (FIGS. 3 and 5) is installed in line with supply line 202.

- pressure regulator 206 When pressure regulator 206 is a 5 psi relief-check valve, the vacuum at the first input 212 of flow control device 204 can be reduced from 370 inches of water to approximately 110 inches of water, thereby causing the resultant flow rate of the flow of cleaning agent 214 that is injected into the flow of primary cleaning liquid component 216 to drop to approximately 0.5 cubic centimeters per minute. Accordingly, the selection or setting of pressure regulator 206 can determine the pressure drop at the inlet 212 of flow control device 204 and the resultant flow rate of the flow of cleaning agent 214 that is injected into the flow of primary cleaning liquid component 216.

- valve 252 and/or 254 of pressure regulator 206 controls the introduction of air 256 into supply line 202 and, therefore, the amount of vacuum relief and the resultant flow rate of the flow of cleaning agent 214.

- valve 252 is controllable by an operator of system 100, such as an operator of a surface cleaner 110 in which system 100 is installed.

- valve 254 can be formed as a component of a remote airflow control 262 (FIG. 5) and can be used to control the airflow 256 through airflow path 246 that extends to valve 254 through tubing 264.

- Valve 254 is preferably biased (e.g., spring-loaded) toward an open position, in which air 256 is allowed to enter tubing 264.

- Valve 254 can be closed by the operator to close the airflow path 240 regardless of the position of valve 252. Accordingly, even if valve 252 is open, valve 254 of remote airflow control 262 can close the airflow path 246 and cause the vacuum at the input 212 of flow control device 204 to increase and thereby draw the flow of cleaning agent 214 into the flow of primary cleaning liquid component 216 at a high rate. Such a surge in the flow rate of the cleaning agent may be used when an increase in the concentration of the cleaning agent 214 in the cleaning liquid 220 is desired for special cleaning operations or to drive potentially clogging debris through the flow control device 204 or metering device 260.

- Additional control of the flow rate of the flow of cleaning agent 214 can be provided by a metering device 260, shown in FIG. 3, which is positioned in line with the cleaning agent supply line 202 between the flow control device 204 and the cleaning agent container or supply 200.

- Metering device 260 can be positioned on either side of pressure regulator 206.

- Metering device 260 includes an upstream high pressure side 270 and a downstream low pressure side 272. The pressure drop across metering device 260 between high pressure side 270 and low pressure side 272 restricts the flow of fluid there through to further control the flow rate of the flow of cleaning agent 214.

- Multiple metering devices 260 can be positioned in series to provide the desired pressure drop in the fluid flow 214.

- metering device 260 includes a metering orifice or orifice plate 274, as shown in FIG. 5.

- the exemplary orifice plate 274 shown in FIG. 6 includes an orifice 276 through which the flow of cleaning agent 214 flows. Plate 274 is installed in supply line 202, such that the cleaning agent 214 is forced to flow through orifice 276. This produces the pressure drop as described above and restricts the flow 214 to the desired flow rate.

- orifice 276 of orifice plate 274 has a diameter D of 0.006 inches.

- a suitable metering orifice or orifice plate 274 is part number CP 4916-40 manufactured by Spraying Systems Co. of Wheaton, Illinois.

- Other orifice plates or metering orifice configurations are possible as well, such as by providing multiple orifices in the plate 98 or other flow restriction configurations.

- metering device 2604 includes a labyrinthine fluid flow path to provide the desired flow restriction.

- the labyrinthine path is preferably formed by one or more drip irrigators 278, as shown in FIG. 7.

- One such preferred drip irrigator suitable for use in metering device 260 is described in U.S. Patent No. 5,031,837 and available as part number R108C manufactured by Raindrip of Woodland Hills, CA.

- One or more drip irrigators 278 can are placed in series and coupled together with tubing sections 280, as shown in FIG. 7.

- a surround 282 can cover the drip irrigators 278 and tubing sections 280.

- Inlet 284 and outlet 286 couple to conduit 210 of supply line 202.

- Other suitable drip irrigators or similar flow restricting devices can also be used to form metering device 124.

- system 100 includes one or more additional supplies of cleaning agent 201, as shown in FIG. 3, that can be selectively mixed with the flow of primary cleaning liquid component 216.

- system 100 can include a second supply of cleaning agent 290, such as a surfactant as described above for first cleaning agent supply 200.

- second cleaning agent supply 290 can be another type of agent, such as a brightener, a disinfectant, or other surface treatment chemical.

- Supply of second cleaning agent 290 is preferably contained in a container, such as cartridge 208, in the same manner as the first cleaning agent supply 200.

- a second flow control device 292 which is substantially identical to flow control device 204, is provided to control the injection of a flow 294 of the second cleaning agent from supply 290.

- a valve 293, a pressure regulator 295 and/or a metering device 296 can also be included to provide additional control over the flow 294 of the second cleaning agent.

- Valves, such as valves 242 and 293, can be selectively opened and closed to control whether one or both of the first and second cleaning agent supplies 200 and 290 is added to the flow of the primary cleaning liquid component 216 to form the desired cleaning liquid 220.

- the second cleaning agent supply 290 can be fed to valve 298 of the dispensing system 100 through conduit 299, which can be a multi-way valve capable of selecting the first cleaning agent supply 200 of the second cleaning agent 290 to be passed to flow control device 204 thereby eliminating the need for the second flow control device 292 and the related components.

- the supplies of cleaning agent are contained in a removable container 200 that can be a component of a cleaning agent cartridge 208, which will be discussed in greater detail with reference to FIGS. 8-11.

- a cleaning agent cartridge 208 includes a collapsible container 200 having an interior cavity 300 and conduit 302, as shown in FIG. 8.

- Conduit 302 includes a first end 304 that is coupled to the container and is in fluid communication with the interior cavity 300 to allow the conduit 302 to receive a flow of cleaning agent from the interior cavity 300.

- the conduit 302 also includes a second end 306 that is connectable to the flow control device 204 through, for example, cleaning agent supply line 202.

- a volume of 2.8 liters, for example, of the cleaning agent 201 can preferably be contained within interior cavity 300 for dispensing to flow control device 204 through supply line 202.

- the container 200 is in the form of a collapsible bag that is completely sealed except where connected to the conduit 302. Thus, the container 200 collapses in on itself or shrinks as the cleaning agent 201 stored therein is depleted.

- the container 200 can be formed of vinyl or other suitable material.

- the container 200 can take the form of a rigid container, such as a box, that includes a vent for replacing dispensed cleaning agent 201 with air.

- Container 200 can be transparent or translucent to allow the cleaning agent 201 to be viewed.

- container 200 can be formed of a material that prevents the exposure of the cleaning agent contained therein from light.

- the first end 304 of the conduit 302 is preferably attached to the container 200 such that it is flush with the inside of an outlet 308.

- a seal 310 is formed between the first end 304 and the container 200 at the outlet 308 to prevent the cleaning agent 201 from escaping at that junction.

- the seal 310 includes an annular neck 312 surrounding the first end 304 and adjoining the container 200.

- a weld can be formed between the annular neck 312, the first end 304 and the container 200 to further seal the junction.

- Other methods for sealing the junction of the first end 304 and the container 200 can also be used.

- the conduit 302 can also include a flow control member 314, shown in FIG. 9, mounted to the second end 306 of the conduit 302 to terminate the flow of the cleaning agent 201 therethrough when the conduit 302 is disconnected from the flow control device 204.

- the flow control member 314 preferably includes a connector (e.g., quick-disconnect coupling) 316 that includes a shut-off valve that is actuated when disconnected from the flow control device 204 to seal the container 200 and prevent the out flow of the cleaning agent 201 therethrough.

- Other types of flow control members 314 can also be installed at second end 306 of conduit 302 to seal interior cavity 300 of container 200 such as a valve, a metering device, a clamp, a membrane, or a cap.

- the cleaning agent cartridge 208 includes a housing 318, shown in FIG. 10, that can enclose the container 200, the conduit 302, the connector 316 and the flow control member 352.

- the housing 318 provides protection and support to the container 200, which is particularly useful when the container 200 is in the form of a collapsible bag 308.

- the housing 318 is preferably made from a single piece of rigid or semirigid material, such as plastic, cardboard and/or metal that is folded to form a box, which is preferably glued shut at, for example, tab 320.

- the housing 318 is formed of corrugated plastic or cardboard.

- the housing 318 also includes openings 322 and 324 on at least one side wall 326 that are preferably defined by removable portions 328 and 330, respectively.

- the portions 328 and 330 have perforated edges 332 and 334, which facilitate their easy removal to expose openings 322 and 324.

- the housing 318 can also include apertures 336 and 338 to provide finger access to further simplify the removal of the portions 328 and 330.

- the opening 322 generally provides visual access to the container 200 and allows a user to asses the volume of the cleaning agent 201 contained therein.

- the opening 324 also provides access to the conduit 302, the connector 316 and the flow control member 352 for connection to the flow control device 204.

- the opening 324 and the removable portion 330 can also be formed on the bottom 340 through which the conduit 302 can extend for efficient dispensing of the cleaning agent 201 in the container 200, as shown in FIG. 10.

- Other openings can also be provided in the housing 318 as desired.

- the cleaning agent cartridge 208 is preferably removably receivable in a cartridge receiver 342 of the cleaner 110, shown in FIG. 11.

- the cartridge receiver 342 can be a bracket having a back plate 344, opposing side walls 346 and 348, a front wall 350, and a bottom 352.

- the back plate 344 is mountable to a wall of the cleaner 110 to position the cleaning agent cartridge 208 proximate the flow control device 204.

- the bottom 352 and the side wall 346 include an opening through which the conduit 302 can extend for connection to the flow control device 204.

- the cartridge 208 can be secured to the cartridge receiver 342 using a strap or other suitable means. Due to the limited jostling that occurs during cleaning operations, such securing devices are typically unnecessary.

- Multiple cleaning agent cartridges 234 can be provided proximate their corresponding flow control device 204 to accommodate the multiple chemical dispenser embodiment of the invention illustrated in FIG. 3.

- the cleaning agent cartridge 208 is provided and a cleaning agent container 200 is stored in the interior cavity 300 of the container 200.

- the second end 306 of the conduit 302 is coupled to the flow control device 204 and the cartridge 208 is installed in the cartridge receiver 342.

- the flow control device 204 can then receive the cleaning agent 208 through the conduit 302, which connects to the conduit 210 to form the supply line 202, and provide a controlled output flow 208 of cleaning agent, as discussed above.

- the container 200 is a collapsible bag 308, the container 200 collapses in response to the output flow of cleaning agent 208.

- the cleaning liquid dispensing system 100 includes an aerator 400.

- Aerator 400 is configured to receive the output flow of cleaning liquid 220 and aerate the cleaning liquid to produce an output flow of foamed cleaning liquid 402.

- a foamed cleaning liquid distributor 404 can receive the output flow of foamed cleaning liquid 402 and discharge the output flow 402 for wetting of a surface 406, as illustrated in FIG. 3.

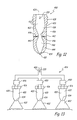

- the aerator 400 preferably includes at least one aerating nozzle 420, as shown in FIG. 4 and the simplified cross-sectional view of FIG. 12.

- Nozzle 420 includes a nozzle body 422 having an inlet 424 coupled to the output 222 of the flow control device 204 for receiving the output flow of cleaning liquid 220.

- a suitable fitting 426 (FIG. 4) can connect to nozzle 420 at threaded section 428 (FIG. 12) to couple inlet 424 to conduit 430 through which cleaning liquid flow 220 travels from output 222 of flow control device 204.

- the output flow of cleaning liquid 220 travels through a bore 432 toward an outlet 434 of nozzle 420.

- the bore 432 includes a constricted throat portion 436 having a convergent upstream end 438 and a divergent downstream end 440.

- Nozzle 420 also includes one or more gas inlets or radial ports 442 extending through a side 444 of the body 422 to throat 436. Air, represented by arrows 446, is sucked through one or more gas inlets or radial ports 442 in response to a vacuum generated within throat 436 by the output flow of cleaning liquid 220 for mixing therewith. The aeration of the cleaning liquid 220 by air induction through radial ports 442 produces the aerated or foamed cleaning liquid 402 that is discharged through outlet 434 of nozzle 420.

- aeration of cleaning liquid occurs upstream of aerator 400 due to the injection of air into the flow of cleaning agent 214 by pressure regulator 206.

- a suitable nozzle 420 is the "FoamJet" nozzle (also designated as FJP-20015-CE) produced by Spraying Systems Company of Wheaton, Illinois.

- a check valve such as check valve 450 shown in FIG. 4, is preferably upstream of outlet 434 of nozzle 420 to terminate the flow of cleaning liquid 220 through nozzle 420 when pump 228 is deactivated.

- the check valve 450 is integrated into nozzle 420.

- the foamed cleaning liquid 402 from aerator 400 when used for hard floor surfaces is preferably a very wet foam relative to that used for carpet cleaning operations. Such a wet foam is necessary to provide the desired wetting of the hard floor surface.

- a foam's "wetness” or “dryness” may be defined in relation to this volumetric expansion ratio.

- a “dry” foam has a higher expansion ratio as compared to a “wet” foam.

- High-expansion foams are “dry” due to the high ratio of air to water and are useful in carpet cleaning to facilitate quick drying of the cleaned carpet.

- a "wet” foam is not used in carpet cleaning devices since they can cause excessive wetting of the carpet, which leads to long drying times and may result in mold development.

- the ratio of volumes between the cleaning liquid (non-aerated) 220 and the foamed cleaning liquid 402 is approximately 1:8.

- 0.15 gallons of cleaning liquid is aerated to occupy 1.25 gallons.

- Other volume ratios may yield acceptable wetting results as well.

- Cleaning liquid dispensing system 100 can also include a foamed cleaning liquid distributor 404, shown schematically in FIG. 3.

- Foamed cleaning liquid distributor 404 is generally configured to direct the output flow of foamed cleaning liquid 402 for wetting of a surface 406, such as the surface 111 on which cleaner 110 travels; wetting the scrubbing member 122 of scrub head 120; or other surfaces as will be discussed below.

- foamed cleaning liquid distributor 404 includes nozzle 420, which directs the output flow of foamed cleaning liquid 402 directly to the desired surface 406, as illustrated in the schematic diagram of FIG. 13.

- One or more nozzles 420 can be coupled to the output flow of cleaning liquid 220 by conduit 430 to cover a wide section of surface 406 that extends across a width of cleaner 110.

- Outlet 434 of each nozzle 420 is preferably slotted to provide wide dispersion of the foamed cleaning liquid output flow 402.

- check valves 450 can be placed upstream of outlet 434 of nozzle 420 to prevent passage of cleaning liquid 220 through conduit 430 when pump 228 (FIGS. 3 and 4) is deactivated.

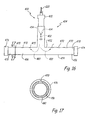

- foamed cleaning liquid distributor 404 receives the output flow of foamed cleaning liquid 402 from outlet 434 of nozzle 420 and discharges the output flow of foamed cleaning liquid 402 for wetting of the desired surface 406, such as surface 111, as shown in FIG. 14.

- foamed cleaning liquid distributor 404 includes distributing conduit 452 having a first end 454 coupled to outlet 434 of nozzle 420 that receives the foamed cleaning liquid flow 402 and discharges the flow 402 to the desired surface 406, as shown in FIGS. 1, 4 and 14.

- Distributing conduit 452 can include one or more sections or branches 456 that receive foamed cleaning liquid flow 402 from a second end 458 of conduit 452 and operate to spread out the discharging of the foamed cleaning liquid flow 402 directly to surface 406, such as surface 111 across the width of cleaner 110, as shown in FIG. 14.

- Check valves 460 can be provided in each branch 456 of distributing conduit 452, or in line with the branch 462 of distributing conduit 452 receiving the cleaning liquid flow 402 from outlet 434 of nozzle.

- Branches 456 can also be configured to discharge the foamed cleaning liquid flow 402 onto scrubbing member 122 of scrub head 120, as shown in FIGS. 1 and 4, which in turn wets surface 111.

- distributing conduit 452 can discharge foamed cleaning liquid flow 402 into an annular trough 464 in the hub 466 of the rotating scrubbing members 122.

- a series of holes 468 in the bottom of trough 464 pass the foamed cleaning liquid 402 down to the central region of the scrubbing member 122.

- the foamed cleaning liquid 402 is centrifuged out under the scrubbing member 122 in contact with the hard floor surface 111.

- Distributing conduit 452 includes one or more substantially horizontal sections or branches 456 that include a plurality of apertures 470 in a top side 472 that is opposite a floor-facing side 474.

- Sections 456 of distributing conduit 452 are preferably formed of rigid plastic tubing that is mounted to cleaner 110 in a desired location.

- Each section 456 includes an end cap 476 closing an end 478.

- foamed cleaning liquid flow 402 travels into closed sections 456. Once sections 456 fill with foamed cleaning liquid 402, the foamed cleaning liquid 402 is discharged through apertures 470.

- the discharged foamed cleaning liquid 402 flows over the exterior surface 480 of sections 456 and drops to the surface immediately below, such as surface 111.

- the apertures 470 positioned closest to ends 478 have a larger diameter than those farther from ends 478 to compensate for pressure drops in sections 456.

- This design of foamed cleaning liquid distributor 404 prevents undesirable dripping of foamed cleaning liquid 402 to the surface following deactivation of pump 228 of dispensing system 100 by containing the foamed cleaning liquid 402 within sections 456 of distributing conduit 452.

- foamed cleaning liquid distributor 404 includes a wand member 490, shown in FIG. 18, that allows a user to direct the foamed cleaning liquid to a surface 492 that is remote from cleaner 110.

- Wand member 490 generally includes a rigid tubing section 494 supporting nozzle 420 of aerator 400 at a dispensing end 496. Accordingly, wand member 490 can operate in the manner described above with reference to FIG. 13.

- a length of flexible tubing 430 connects a receiving end 498 to output 222 of flow control device 204. During operation a user can extend the tubing 430 from cleaner 110 and apply the foamed cleaning liquid 402 to remote hard surface 492, such as a wall or an object, for cleaning.

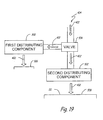

- FIG. 19 is a schematic diagram of a foamed cleaning liquid distributor 404 that includes first and second distributing components 500 and 502, respectively.

- the discharging of foamed cleaning liquid 402 through either first or second distributing component 500 or 502 is controlled by a valve 504.

- First and second distributing components 500 and 502 can comprise any of the embodiments of foamed cleaning liquid distributor 404 described above.

- first distributing component 500 can take the form of wand member 490 (FIG. 18) and second distributing component 502 can take the form of distributing conduit 452 shown in FIG. 14.

- foamed cleaning liquid 402 can be easily applied to different types of surfaces, such as surfaces 506 and 508.

- surface cleaner 110 can be configured to include a motorized scrub head 120 that includes a scrubbing member 122 that is configured for rotating engagement with hard or carpeted floor surfaces 111, over which the mobile body 127 of cleaner 110 travels.

- FIGS. 20 and 21 show simplified front and side views of a front or leading portion of a cleaner 110 that includes a scrub head 120 in accordance with another embodiment of the invention.

- Scrub head 120 includes a scrubbing member 122 formed of a plurality of discs 510 mounted to a shaft 512 that is rotated by a motor (not shown).

- the discs 510 are preferably concentrically aligned with the axis of rotation 514 of the shaft 512 and can be positioned to engage surface 111.

- Discs 510 can be mounted to shaft 512 using glue or other suitable means.

- Discs 510 are preferably formed of a liquid absorbing material, such as material composed of approximately 70% polyester and 30% polyamide, or microfiber. Such liquid absorbing material is known to hold many times its weight in viscous liquid. Additionally, such material collects dirt, dust, mildew and other materials without a need for a large volume of foamed cleaning liquid 402, thereby eliminating a need for fluid recovery device 132 (FIG. 1). Large particles of dirt and dust that do not adhere to the discs 510 can be captured by a debris collector 516 positioned immediately behind scrub head 120. Another advantage to the vertically oriented discs 510 is that they can clean grooves that may be encountered in tile, brick, cement, and rock floors.

- foamed cleaning liquid distributor 404 can discharge the foamed cleaning liquid 402 to a leading side 518 of scrub head 120 as indicated by arrow 520, on discs 510 as indicated by arrow 522, or even through the scrubbing member 122.

- FIG. 22 is a simplified side elevation view of another embodiment of surface cleaner 110 that does not include a motorize scrub head 120.

- a scrubber-less cleaner 110 can be used on delicate floor surfaces that would be susceptible to abrasive damage from contact with rotating scrubbing members 122.

- Cleaner 110 relies upon the cleaning power of the foamed cleaning liquid 402 that is applied to hard floor surface 111 by system 100, as illustrated by arrow 530, to clean the surface 111.

- the wetting of the floor with the foamed cleaning liquid 402 traps dirt particles with the bubbles of the foam, which are then carried into the recovery tank 112 by the fluid recovery system 132.

- the scrubber-less cleaner 110 uses far less power than those including motorized scrub heads 120 thereby allowing for the removal of some of the batteries 152 used to power cleaner 110.

- Scrubber-less cleaner 110 can also be formed much lighter and smaller due to the elimination of scrub head 120 and batteries 152, or the solution and recovery tanks 118 and 112 can be formed larger to accommodate longer operational runtimes for cleaner 110.

- the elimination of some of the components of cleaner 110 allows scrubber-less cleaner 110 to be manufactured quicker and cheaper that those incorporating scrub heads 120.

- cleaner 110 can include a non-motorized wetting component 540, shown in FIGS. 23 and 24, which are front and side views of a leading portion of cleaner 110, respectively.

- Wetting component 540 generally includes a plurality of liquid dispersing members 542 each having a first end 544 that is connected adjacent to a bottom side 546 of mobile body 127 of cleaner 110. A second end 548 of each liquid dispersing member 542 is positioned to engage hard floor surface 111.

- Liquid dispersing members 542 are preferably formed of a soft material that conforms to surface 111.

- Foamed cleaning liquid 402 is discharged by foamed cleaning liquid distributor 404 of dispensing system 100 either on members 542 as indicated by arrow 550, or to a leading side of members 542 as indicated by arrow 552, as shown in FIG. 24.

- Liquid dispersing members 542 evenly distribute the foamed cleaning liquid 402 on surface 111 as cleaner 110 moves across surface 111.

- Cleaner 110 may include a scrub head 120 downstream of liquid dispersing members 542 to scrub surface 111 with evenly distributed foamed cleaning liquid 402 thereon, or cleaner 110 can be scrubber-less and a portion of the foamed cleaning liquid 402 can be removed from surface 111 by fluid recovery system 132.

- flow restriction members 560 Inline with the fluid flow path 226 are one or more flow restriction members 560 (FIG. 3) such as, for example, check valves 450, nozzles 400, metering devices (e.g., orifice plates), and other components that restrict the flow of liquid through the fluid flow path that is defined by the conduit 226 (FIGS. 3 and 4).

- Such flow restriction members produce a pressure drop from the inlet to the outlet of the flow restriction member in the flow of liquid traveling therethrough, as discussed above.

- the pumping of liquid through such flow restriction members with the pump 228 can cause air to enter the fluid flow path 226 when the pump is not operating.

- the ability of the pump 228 to drive the liquid through the fluid flow path 226 becomes more difficult. As a result, the pump 228 will likely operate poorly until the air is purged from the fluid flow path 226.

- FIGS. 25 and 26 are simplified diagrams of a portion of the liquid dispensing system that includes the air purging component 360 and FIG. 27 is a flowchart illustrating a method of purging air from the liquid dispensing system 100, in accordance with embodiments of the invention.

- the liquid dispensing system 100 includes a pump 228 that is configured to drive a flow of liquid (either a cleaning liquid contained in tank 118 or water 216) through the fluid flow path 226 in a downstream direction.

- a flow of liquid either a cleaning liquid contained in tank 118 or water 216

- the downstream direction is indicated by arrow 361 in FIGS. 3, 4, 25 and 26.

- the air purging component includes an inlet 362 in line with the fluid flow path 226, an outlet 364, an airflow path 366 connecting the inlet 362 and the outlet 364, and a valve 368 in line with the airflow path 366.

- the valve 368 includes an open position, shown in FIG. 25, in which the airflow path 366 is open between the inlet 362 and the outlet 364 as indicated by the arrow 370. When in the open position, air 372 from the fluid flow path 226 can be discharged through the outlet 364.

- the valve 368 also includes a closed position, shown in FIG. 26, in which the airflow path 366 is closed between the inlet 362 and the outlet 364, as indicated by the arrow 370. When in the closed position, the valve 368 prevents air or liquid from passing through the outlet 364 from the fluid flow path 226.

- Actuation of the valve 368 is preferably performed automatically in response to the detection of air or liquid in the fluid flow path 226.

- the liquid dispensing system includes a valve actuator 374 that biases the valve 368 in the open position (FIG. 25) when air is detected in the fluid flow path 226.

- the valve actuator 374 biases the valve 368 in the closed position (FIG. 26) when liquid is detected in the fluid flow path.

- the detection of the presence of air in the fluid flow path 226 is the equivalent of detecting the absence of liquid in the fluid flow path 226, and the detecting of the absence of air in the fluid flow path 226 is the equivalent to detecting a presence of liquid in the fluid flow path 226.

- the detection of the presence or absence of air or liquid in the fluid flow path 226 can be performed in many different ways including, for example, through the detection of the presence or absence of air or liquid in the airflow path 366, which is in line with the fluid flow path 226.

- the valve 368 of the air purging component 360 is preferably automatically moved to the open position when air is detected in the fluid flow path 226 and closed when liquid is detected in the fluid flow path 226.

- the liquid dispensing system includes a sensor 376 that is configured to detect the presence or absence of liquid or air in the fluid flow path 226.

- the sensor 376 can be an electronic device that communicates the presence or absence of air or liquid to a controller of the valve actuator 374, which controls the valve actuator 374 to open or close the valve 368 in response to the communication from the sensor 376.

- the senor 376 is a passive device.

- the sensor 376 can includes a float type sensor having a float member that is raised to a threshold level when liquid is sufficiently present (air absent) in the fluid flow path 226, and falls below the threshold level when air is present (liquid absent) in the fluid flow path 226. The detection of the absence or presence of air or liquid can then be communicated mechanically and/or electronically to the valve actuator 374, which responds by adjusting the valve 368 accordingly.

- such a passive sensor 376 can be a component of the valve actuator 374 and used to control the actuation of the valve 368 through the connection of the rising and falling float member to the valve 368 through a suitable mechanical linkage.

- One exemplary air purging component 360 that includes such a passive control of the valve 368 is the Amtrol Model 700-30, in which a float member, contained in the airflow passage 366, controls the opening and closing of the valve 368 in response to the absence and presence of liquid in the airflow passage 366. Air in the airflow passage 366 is discharged through the outlet 364 until the airflow passage 366 fills with liquid to a threshold level.

- One embodiment of the air purging component 360 includes a non-return stage 378, which prevents air from returning to the fluid flow path 226 through the outlet 364 when the valve 368 is open.

- a non-return stage is included in the exemplary air purging component 360 mentioned above.

- the fluid flow path 226 includes a section of conduit 380 that is elevated relative to the outlet 230 or the inlet of the pump 228.

- the inlet 362 of the air purging component 360 is preferably coupled to the elevated conduit section 380 of the fluid flow path 226.

- the fluid flow path 226 is preferably configured such that air is routed to the elevated section of conduit 380 where it can be removed by the air purging component 380.

- the inlet 362 of the air purging component 360 is coupled to the fluid flow path 226, such as to the elevated conduit section 380, downstream of the pump 228 relative to the downstream direction 361 in which the pump is configured to drive the flow of liquid, as shown in FIGS. 3 and 4.

- This is a preferred location for the air purging component 360, since air is most likely to enter the fluid flow path from the downstream side of the pump 228 where the flow restriction members, such as nozzle 400 and check valve 450, are located.

- the inlet 362 of the air purging component 360 is coupled to the fluid flow path 226, such as to the elevated conduit section 380, upstream of the pump 228 relative to the downstream direction 361 in which the pump is configured to drive the flow of liquid.

- FIG. 27 is a flowchart illustrating a method of purging air from the liquid dispensing system 100 of the cleaner 110.

- the pump 228 is provided that is configured to drive a flow of liquid (either a cleaning liquid contained in tank 118 or water 216) through the fluid flow path 226 in a downstream direction 361, as shown in FIGS. 3 and 4.

- the pump is driven at step 392.

- the presence of air or liquid is detected in the fluid flow path 226.

- the airflow path 366 is opened, at step 396, in response to the detection of air in the fluid flow path 226 to discharge air contained in the fluid flow path 226 through the outlet 364.

- the airflow path 366 is closed in response to the detection of liquid in the fluid flow path 266.

Landscapes

- Cleaning By Liquid Or Steam (AREA)

- Cleaning In General (AREA)

Abstract

Description

Claims (21)

- A surface cleaner including a liquid dispensing system comprising:a fluid flow path configured to receive a flow of liquid;a pump in line with the fluid flow path and configured to drive the flow of liquid through the fluid flow path;an air purging component including an inlet in line with the fluid flow path, an outlet, an airflow path connecting the inlet and the outlet, and a valve in line with the airflow path and having an open position in which the airflow path is open between the inlet and the outlet and a closed position in which the airflow path is closed between the inlet and the outlet; anda valve actuator connected to the valve and configured to bias the valve in the open position when air is detected in the fluid flow path.

- The surface cleaner of claim 1, wherein the valve actuator is configured to bias the valve in the closed position when liquid is detected in the fluid flow path.

- The surface cleaner of claim 1, including a sensor configured to detect air in the fluid flow path, wherein the valve actuator biases the valve in the open position in response to the detection of air in the fluid flow path by the sensor.

- The surface cleaner of claim 1, wherein the air purging component includes a non-return stage in line with the airflow path, which prevents air from entering the fluid flow path through the outlet of the air purging component.

- The surface cleaner of claim 1, wherein the inlet of the air purging component is coupled to the fluid flow path downstream of the pump relative to a downstream direction in which the pump is configured to drive the flow of liquid.

- The surface cleaner of claim 1, wherein the inlet of the air purging component is coupled to the fluid flow path upstream of the pump relative to a downstream direction in which the pump is configured to drive the flow of liquid.

- The surface cleaner of claim 1, wherein:the fluid flow path includes a section of conduit that is elevated relative to the pump; andthe inlet of the air purging component is coupled to the section of conduit.

- The surface cleaner of claim 1 including a flow restriction member having an upstream inlet and a downstream outlet relative to a downstream direction in which the pump is configured to drive the flow of liquid, wherein a pressure drop occurs across the flow restriction member when a flow of liquid travels through the flow restriction member.

- The surface cleaner of claim 1 including:a rotatable scrubbing member configured to scrub a surface; anda vacuumized fluid recovery device configured to remove fluid from the surface.

- The surface cleaner of claim 1 including a cleaning agent dispensing system comprising:a cleaning agent container attached to the mobile body;a cleaning agent flow path connected to the cleaning agent container and configured to receive a flow of cleaning agent from an interior cavity of the cleaning agent container; anda flow control device having a first input connected to the cleaning agent flow path, a second input connected to the fluid flow path, and an output in line with the first and second inputs.

- The surface cleaner of claim 10 including an aerator having an inlet in line with the output of the flow control device, and outlet, and a gas inlet, the aerator configured to receive an output flow of cleaning liquid at the inlet, inject gas into the output flow of cleaning liquid through the gas inlet, and produce an output flow of foamed cleaning liquid through the outlet.

- A surface cleaner comprising:a liquid dispensing system comprising:a fluid flow path configured to receive a flow of liquid;a pump in line with the fluid flow path and configured to drive the flow of liquid through the fluid flow path;an air purging component including an inlet in line with the fluid flow path, an outlet, an airflow path connecting the inlet and the outlet, and a valve in line with the airflow path and having an open position in which the airflow path is open between the inlet and the outlet and a closed position in which the airflow path is closed between the inlet and the outlet;a valve actuator connected to the valve and configured to bias the valve in the open position when air is detected in the fluid flow path;a rotatable scrubbing member configured to scrub a surface; anda vacuumized fluid recovery device configured to remove fluid from the surface.

- The surface cleaner of claim 12, wherein the valve actuator is configured to bias the valve in the closed position when liquid is detected in the fluid flow path.

- The surface cleaner of claim 12, including a sensor configured to detect absence of liquid in the fluid flow path, wherein the valve actuator biases the valve in the open position in response to the detection of air in the fluid flow path by the sensor.

- The surface cleaner of claim 12, wherein the inlet of the air purging component is coupled to the fluid flow path downstream of the pump relative to a downstream direction in which the pump is configured to drive the flow of liquid.

- The surface cleaner of claim 12, wherein:the fluid flow path includes a section of conduit that is elevated relative to the pump; andthe inlet of the air purging component is coupled to the section of conduit.

- The surface cleaner of claim 12 including a flow restriction member having an upstream inlet and a downstream outlet relative to a downstream direction in which the pump is configured to drive the flow of liquid, wherein a pressure drop occurs across the flow restriction member when a flow of liquid travels through the flow restriction member.

- A method of purging air from a liquid dispensing system of a surface cleaner comprising steps of:providing a pump configured to drive a flow of liquid through a fluid flow path of the liquid dispensing system;driving a pump;detecting one of the presence of air and liquid in the fluid flow path;opening an airflow path connected to the fluid flow path through which the air is discharged from the fluid flow path in response to a detection of air in the fluid flow path in the detecting step; andclosing the airflow path in response to a detection of liquid in the fluid flow path in the detecting step.

- The method of claim 18 including preventing air from entering the fluid flow path through the airflow path when the airflow path is opened.

- The method of claim 18 wherein:the surface cleaner includes an air purging component including an inlet in line with the fluid flow path, an outlet, the airflow path connecting the inlet and the outlet open to ambient air, and a valve in line with the airflow path and having an open position in which the airflow path is open between the inlet and the outlet and a closed position in which the airflow path is closed between the inlet and the outlet;the automatically opening step includes biasing the valve to the open position; andthe automatically closing step includes biasing the valve to the closed position.

- The method of claim 18 including providing a flow restriction member in line with the fluid flow path, the flow restriction member having an upstream inlet and a downstream outlet relative to a downstream direction in which the pump is configured to drive the flow of liquid, wherein a pressure drop occurs across the flow restriction member when the pump drives a flow of liquid through the flow restriction member.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US56976104P | 2004-05-10 | 2004-05-10 | |

| US569761P | 2004-05-10 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1595486A2 true EP1595486A2 (en) | 2005-11-16 |

| EP1595486A3 EP1595486A3 (en) | 2008-02-06 |

Family

ID=34941231

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05252872A Withdrawn EP1595486A3 (en) | 2004-05-10 | 2005-05-10 | The air purging of a liquid dispensing system of a surface cleaner |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1595486A3 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114652229A (en) * | 2022-05-05 | 2022-06-24 | 北京顺造科技有限公司 | Wet surface cleaning apparatus and method of operating the same |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5287590A (en) * | 1992-09-02 | 1994-02-22 | Yonkers Robert A | Wet vacuum/extractor with vacuum priming system |

| US6286180B1 (en) * | 1995-11-06 | 2001-09-11 | Bissell Homecare, Inc. | Upright water extraction cleaning machine pump priming |

| US5920955A (en) * | 1996-07-12 | 1999-07-13 | Shop Vac Corporation | Self-evacuating vacuum cleaner |

-

2005

- 2005-05-10 EP EP05252872A patent/EP1595486A3/en not_active Withdrawn

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114652229A (en) * | 2022-05-05 | 2022-06-24 | 北京顺造科技有限公司 | Wet surface cleaning apparatus and method of operating the same |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1595486A3 (en) | 2008-02-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20040221407A1 (en) | Cleaning liquid dispensing system | |

| US20040040102A1 (en) | Foamed cleaning liquid dispensing system | |

| US6671925B2 (en) | Chemical dispenser for a hard floor surface cleaner | |

| US7051399B2 (en) | Cleaner cartridge | |

| US20050217062A1 (en) | Air purging of a liquid dispensing system of a surface cleaner | |

| CN212066635U (en) | Boom assemblies and surface cleaning equipment | |

| AU2002319714A1 (en) | Cleaner cartridge | |

| US6735811B2 (en) | Cleaning liquid dispensing system for a hard floor surface cleaner | |

| US6705332B2 (en) | Hard floor surface cleaner utilizing an aerated cleaning liquid | |

| US4938421A (en) | Cleaning liquid mixer for a water line, particularly for a surface cleaner | |

| US7240394B2 (en) | Cleaning machine for cleaning a surface | |

| EP1230889A2 (en) | Tank mounting of carpet extractor | |

| US7954200B2 (en) | Constant head device for a cleaning machine | |

| EP1595486A2 (en) | The air purging of a liquid dispensing system of a surface cleaner | |

| CA2013834A1 (en) | Cleaning liquid mixer for a water line, particularly for a surface cleaner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20080714 |

|

| AKX | Designation fees paid |

Designated state(s): DE FR GB IT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Effective date: 20090729 |