EP1528976B1 - Packaging, blank therefor and method for the production thereof - Google Patents

Packaging, blank therefor and method for the production thereof Download PDFInfo

- Publication number

- EP1528976B1 EP1528976B1 EP03792424.8A EP03792424A EP1528976B1 EP 1528976 B1 EP1528976 B1 EP 1528976B1 EP 03792424 A EP03792424 A EP 03792424A EP 1528976 B1 EP1528976 B1 EP 1528976B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- packaging

- marking

- lines

- blank

- fold lines

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004806 packaging method and process Methods 0.000 title claims description 61

- 238000004519 manufacturing process Methods 0.000 title claims description 18

- 238000000034 method Methods 0.000 title claims description 11

- 239000000463 material Substances 0.000 claims description 33

- 239000005022 packaging material Substances 0.000 claims description 25

- 238000007639 printing Methods 0.000 claims description 17

- 238000012545 processing Methods 0.000 claims description 10

- 239000007788 liquid Substances 0.000 claims description 7

- 230000002035 prolonged effect Effects 0.000 claims 2

- 238000004049 embossing Methods 0.000 description 26

- 239000000123 paper Substances 0.000 description 20

- 238000012856 packing Methods 0.000 description 12

- 239000003550 marker Substances 0.000 description 11

- 238000005259 measurement Methods 0.000 description 10

- 238000007789 sealing Methods 0.000 description 9

- 230000003287 optical effect Effects 0.000 description 5

- 239000012876 carrier material Substances 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 4

- 239000008267 milk Substances 0.000 description 4

- 238000007493 shaping process Methods 0.000 description 4

- 230000008901 benefit Effects 0.000 description 3

- 239000002131 composite material Substances 0.000 description 3

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 235000013336 milk Nutrition 0.000 description 3

- 210000004080 milk Anatomy 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 230000000875 corresponding effect Effects 0.000 description 2

- 238000005034 decoration Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 235000011389 fruit/vegetable juice Nutrition 0.000 description 2

- 235000021056 liquid food Nutrition 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 238000002604 ultrasonography Methods 0.000 description 2

- 108010074864 Factor XI Proteins 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000013590 bulk material Substances 0.000 description 1

- 239000011111 cardboard Substances 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 230000002596 correlated effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 235000013399 edible fruits Nutrition 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000005445 natural material Substances 0.000 description 1

- 239000011087 paperboard Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000000523 sample Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/4212—Information or decoration elements, e.g. content indicators, or for mailing

- B65D5/4216—Cards, coupons or the like formed integrally with, or printed directly on, the container or lid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B61/00—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages

- B65B61/02—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages for perforating, scoring, slitting, or applying code or date marks on material prior to packaging

- B65B61/025—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages for perforating, scoring, slitting, or applying code or date marks on material prior to packaging for applying, e.g. printing, code or date marks on material prior to packaging

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/006—Controlling; Regulating; Measuring; Improving safety

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/25—Surface scoring

- B31B50/254—Surface scoring using tools mounted on belts or chains

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B9/00—Enclosing successive articles, or quantities of material, e.g. liquids or semiliquids, in flat, folded, or tubular webs of flexible sheet material; Subdividing filled flexible tubes to form packages

- B65B9/10—Enclosing successive articles, or quantities of material, in preformed tubular webs, or in webs formed into tubes around filling nozzles, e.g. extruded tubular webs

- B65B9/20—Enclosing successive articles, or quantities of material, in preformed tubular webs, or in webs formed into tubes around filling nozzles, e.g. extruded tubular webs the webs being formed into tubes in situ around the filling nozzles

Definitions

- the invention relates to a package for a liquid and / or a bulk material, which is formed from flat packaging material, which has fold lines and a force applied to a wall panel of the packaging mark. Furthermore, the invention relates to a blank for the production of such a package and a method for producing a package, which is created from a moving web. An apparatus for carrying out the method is characterized by special reading devices.

- Packaging of the type mentioned are widely known and are often used for packaging liquid foods, such as milk or juices, which may also contain pieces of fruit pulp.

- packages, their blanks and also their manufacturing processes in which a web of packaging material is moved through various processing stations and gets fold lines, which are used for forming the web and forming the packaging. Before, during or after molding, the packaging being formed is filled and sealed.

- the known marking consists of a register or bar code and is printed with tolerances of ⁇ 1 mm.

- One wants to control printing works by reading this bar code, so that they print a decoration in register in different colors on the surface of the packaging.

- a print is often mis-positioned and may have an offset with respect to the web of the packaging material.

- the webs of the bar code and in particular their transition from black to white change, with the result that there are reading and control errors.

- composite material with paper as a carrier temperature and humidity effects significantly. Already in the paper mill during the processing of the raw material, a stretching of the web can result.

- the paper In the paper mill, the paper is optionally coated (plastic, aluminum foil, etc.), provided with fold lines and usually also with cut lines.

- the web material is often supplied on rolls and leaves the paper mill after processing also on roles, possibly even single roles.

- the filling machine is arranged separately from the paper mill and receives the individual roles, from which filled and sealed packaging are produced. In the filling machine also influences by temperature, humidity, etc. can occur. Such changes in the paper mill, between paper mill and filling machine or in the filling machine to be detected and used to control the web so that not only a decor, possibly even multi-colored, can be printed correctly on the surface in the desired manner, but that the shaping and folding on the correct location, including laying cuts when separating the filled packages.

- This older package is formed of flat packaging material having fold lines and a mark applied to a wall panel of the package formed by in-plane stamping lines from which at least two straight stamping lines intersect at least at their extension.

- the older markings are at least partially formed by printing, wherein the mentioned stamping lines are pressed into a rectangular or square area with printed ink in a certain way, so that by contrast when printing a negative printed pattern results from the fact that the printing ink to create the Marking does not come on the imprinted and thus seen from the outer of the packaging lower lying line areas.

- the disadvantages described above when printing a marking are mentioned and will be explained in addition to individual embodiments.

- the embossing lines are in the older packaging so-called compression lines, in which care is taken that the protruding from the later top of the package in the lower line portions protrusions of the press roll against a flat or average at least rectilinear counter pressure roller.

- special compression lines are expected to reduce the risk of dilamination of the compressible packaging material.

- One of the disadvantages of the negative print images proposed in the older method is that color is consumed continuously during printing.

- the negative print image can not be produced without the printing unit, so that the marking can only be used downstream of the printing unit.

- the invention is based on the idea that the lines of a marking can not necessarily be formed only by printing, but according to the invention by embossing.

- the embossing of the material for making a package has essential properties for the quality of the package.

- the package can be precisely formed, is inherently strong, firm and has a good footing Paperboard as carrier material there are packs with corner tabs, which must be put in the right place. With correct embossing, this also succeeds precisely and easily.

- the invention thus addresses the idea of applying the mark instead of printing by embossing.

- Reading a printed mark is another source of error because many optical systems are known to be sensitive and pose sources of error.

- Printed markings also allow only measurement in a linear direction.

- the French patent FR 1.413.614 discloses embossing patterns for stiffening a package from a flat packaging material.

- the invention is therefore an object of the invention to provide a package, its blank and a method for its production, so that the production of the packaging is easier, cheaper and can be achieved with greater precision.

- the marking is planar in this embodiment, at least substantially as far as possible, as is possible with the known natural substances.

- You can emboss paper, cardboard, plastics and metal foils.

- the embossing of various line shapes is achieved by known tools, for example two counter-rotating rollers, one of which has raised parts and the opposite recessed parts.

- the marking with the stamping lines has at least two straight stamping lines which either already intersect in the marking or intersect at least during their extension or mathematically (virtually).

- Such patterns allow quick and accurate reading of the mark and include important information either at the input side the relevant machine can be recorded and used for the further course of the material web; or which are detected and used on an upstream machine to control the web in a downstream machine accordingly.

- information about the elongation of the material after embossing can be measured from the paper mill to the exit from the paper mill.

- the embodiment described above in which a separate marking with separate stamping lines is applied to the material of the packaging, is preferred. While ink is consumed at a disadvantage with printing at a disadvantage, the marking can be created by embossing without comparable material consumption.

- the relevant surface of the packaging need not be provided in a wall of the field untouched or left white in the case of a mark created by embossing. Visually, you can not see at first glance the mark made by embossing. If necessary, it could even go into a décor.

- the marking has at least one centrally symmetrical structure.

- Centrally symmetrical are all geometric structures that lie in one plane and cover each other after rotation through 180 ° in this plane around a fixed point.

- each track is centrally symmetric to its center.

- Each line is centrally symmetrical to each point lying on it.

- Each ray is centrally symmetric to its counter-ray.

- Two intersecting lines are centrally symmetric to their vertex.

- vertex angles are centrally symmetrical structures.

- the rhombus or the rhombus and the rhomboid also result from this as a centrally symmetric structure.

- the invention takes advantage of the characteristics of the centrosymmetric structure for the mark, as it allows a variety of important information to be read from the mark, which are useful for the control of subsequent processing stations.

- the marker in a preferred embodiment, it is expedient for the marker to have an outer rectangular frame whose sides run parallel to the longitudinal fold lines of the package in the blank, and if a parallelogram is inscribed in this outer rectangle (the frame). More specifically, it is particularly advantageous according to the invention if, in the case of a rhombus as a parallelogram, its two diagonals in the blank of the package run parallel to the longitudinal and transverse fold lines of the package. In the case of the rhombus, the diagonals are perpendicular to each other. The diagonals halve the angles of the parallelogram. In the case of such a marking, a more precise positioning of the packaging material in the production of the packaging is achieved according to the invention.

- the cross section of such a package is square or rectangular according to the section line.

- H-milk in Europe is currently usually packed in rectangular packaging, fresh milk in square packs.

- the rectangular package has two wide sidewall panels each and two narrow sidewall panels therebetween, opposite one another.

- the wide sidewall panel has the width B '

- the narrow sidewall panel has the width C'.

- the repetition length of the package blank also plays an important role, i. the length in the direction of the blanks in the machine. If you have this repetition length on the one hand and the package diagonal e on the other, then you can infer back to the pack volume, which ultimately matters.

- values can be measured and read out which provide information about the shape and the correct volume of the packing.

- the path of the pack blanks passes in such a way that the sensor beams have the opportunity to scan the mark and read out the relevant quantities. These are compared with previously read setpoints. If the difference is zero, then the packaging that is being formed has the correct angular position, the correct volume and the correct shaping.

- a second, inner rectangle is further inscribed into the outer rectangle (frame) in such a way that two sides coincide with the sides of the outer rectangle parallel to the longitudinal fold lines of the package in the blank and the two on other sides so touch the connecting corners of the rhombus that the connecting corners bisect the sides.

- the sides of the mark are not halved by the rhombus.

- a particular embodiment of packaging is that made from a web of material followed by a blank behind the other.

- each pack has a longitudinal central axis, to which in the blank two sides of the outer rectangular frame parallel. Portions of these two sides coincide with said two sides of the inscribed smaller rectangle.

- This smaller rectangle is wrapped around the rhombus so that all four sides of the smaller rectangle coincide with, or touch, the corners of the rhombus. The rhombus has thus been rewritten the smaller rectangle.

- the marking has a mathematical correlation to the packaging blank such that the distances between points on the marking describe the geometry of the fold lines.

- the distances of the transverse sides of the large rectangle have the task of describing the so-called repetition length of the blank of the packaging, ie the length of the packaging material.

- the blank has longitudinal and transverse fold lines, which can also be created by embossing, for example.

- the repetition length or the length of the packing material is the length that can be measured between two successive markings in the conveying direction of the blanks in the production at the corresponding point, since each blank carries a marking.

- the said rectangle of the mark is thus encrypted a clear measure of this repetition length.

- the height of the smaller, inscribed rectangle which means, for example, the width of a narrow sidewall field.

- the position (rotation about the longitudinal and the transverse axis) of the packaging material can be determined.

- the invention is further characterized in that the stamping lines project at least partially out of the surface of the wall panel and / or project deep into the surface of the wall panel.

- the stamping lines are raised from the surface of the wall panel. So you can feel it when you click on the wall box of the packaging as elevations. Of course, they can also be seen with suitable light and shade.

- the embossing lines in the surface of the wall field are low-lying back, so to speak, negative embossed. It can be said that in the former embodiment, where they project outwardly, they are positively marked.

- the height of the U i.

- the embossing line by which the latter protrudes from the wall field, depending on the paper thickness or thickness of another material protrudes from the wall field by a greater or lesser amount.

- the height of the embossment says something about the thickness of the material, about its thickness.

- the volume of the packaging is detectable. Furthermore, one can determine the position of the longitudinal sealing seam and make a correction in the course of the material web, if the angular adjustment of the direction should differ from the nominal value. It is also possible to sense the seam between two webs of material. Such a seam is always necessary when a feed roll is depleted with material and must be replaced by a new role. The end of the exhausted roll must then be glued or welded to the beginning of the new roll. Forming the entire package is achievable with greater precision, and the simplicity of the means clearly results in less expensive measurement and control. The production of packages of the type mentioned and also their blanks is thus significantly improved over the known solutions. If the repeat length is read out over several packages (between 5 and 15 packages), the frequency of the repeat length can be analyzed and read in as an additional parameter.

- the marking is made by introducing embossing lines in such a way that the cross section of the material is U-shaped after embossing and the thickness of the material remains essentially the same, a very advantageous signal possibility has been created.

- the embossing lines are introduced according to the invention already in the processing of the web in the paper mill.

- the printing unit is for applying a decoration in the downstream region of the machine. The marking with the aid of the stamping lines can then be introduced in advance in such a way that the information for the further processing of the material web or the subsequent blank can be observed and controlled via the marking.

- two sensors arranged at a distance from each other, be it mechanical sensors, optical or acoustic sensors.

- the two sensor beams span a window which allows detection of the optimum amount of information from the tag.

- the cutting process can be controlled, which was previously possible only after printing an additional marking.

- the angular orientation of the transported paper web can be measured.

- the filling machine can be detected in the paper mill, the seam between two roles, the empty, old, exhausted role and the new role.

- the sensors arranged stationarily at a distance from the marking scan the marking with at least one and preferably two sensor beams which run over the marking at a distance from one another and parallel to one another.

- the sensor is given, which lines are to be cut and recorded on the marking as measuring points.

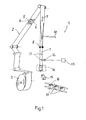

- the packaging material is pulled off in web form upwards and carries the generally designated 4 fold lines, of which one picked out for purposes of illustration, for example, the longitudinal fold lines 5 and the transverse fold lines 6 recognizes.

- the web 2 moves in the conveying direction 7 of the web according to FIG. 1 downward.

- the tube 9 is folded and provided with a downwardly wandering longitudinal sealing seam.

- This tube 9 is filled with product via the filling tube 10, for example milk or juice.

- a sensor 12 At a distance from each other markings 11 are mounted on the outside of the tube 9, which can be read by means of a sensor 12 and processed in a processing and control unit 13.

- molding and transverse sealing unit 14 In the downstream in the conveying direction 7, shown in the machine 1 below molding and transverse sealing unit 14 is essentially the final shaping of the filled packing and the transverse seal. Underneath you can see the filled and sealed packaging 15. After passing through a Endformungsaku 16 then arises in FIG. 1 shown cuboid packing 17th

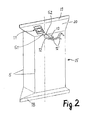

- FIG. 2 A so-called rectangular packing is in perspective in FIG. 2 shown.

- Other substantially planar wall panels could serve as a support for the marker 11.

- the bottom wall panel 20 of the package 15 is particularly well visible and also arranged in a machine Sensors readily accessible, which is why this location is preferred for the embodiment described here.

- FIG. 1 or in FIG. 2 shown square pack 15 is made of blanks, because the expert knows the machine of FIG. 1 in principle.

- reference will be made here to a blank made in FIG. 3 is shown and also allows the creation of a cuboid pack in the manner described above.

- the web 2 is made of a series of adjacent blanks of the type FIG. 3 educated. Accordingly, one must look at the FIG. 3 Under and above the blank think more blanks, so that one recognizes the position of the material web.

- the conveying direction 7 of the web and thus also of the blank is parallel to the longitudinal fold lines 5 of the blank generally designated 21.

- transverse fold lines 6 arranged perpendicular to the longitudinal fold lines 5 can be seen, between which triangular fields 22 form.

- the bottom wall panel 20 is located at the blank 21 of FIG. 3 bottom right. There one recognizes the mark 11. With 11 'above the next mark of the next, not shown blank is indicated. The distance between the two markings 11 and 11 'is the so-called repetition length G, ie the total height of the blank 21. D corresponds to the position about the transverse and the longitudinal axis.

- the wide side wall panel 24 Between the two narrow side wall panels 23 and 23 'is, separated by two longitudinal fold lines 5, the wide side wall panel 24. Its width is in FIG. 3 with B specified. The width of the respective narrow side wall panel 23 or 23 'is in FIG. 3 with C specified. A is the total height of the cut from upper cross-section line to the lower cross-section line, it is also possible to name the repeat length, which may represent a set point. The measured perpendicular to the total width of the blank 21 is designated by the dashed line of the double arrow E. A closer explanation of the blank and its lines does not appear necessary here, because the skilled person knows for the various cartons and square packs, etc., the blank forms. The person skilled in the art will even recognize markings applied to one or the other wall panel of a blank, although not in the form shown here and certainly not in the form described here.

- the marking 11 consists of the most diverse stamping lines 25. If the packaging material web is passed through a correspondingly designed embossing roller and counter-roller, then the packaging material bulges between the rollers to form the stamping lines 25. If one were to lay a cross-section through this, one would obtain per se known per se Way U shape. The thickness of the material remains substantially unchanged in front of and behind the stamping line and even inside the stamping line. Therefore, an embossing line always protrudes to one side of the material web.

- the outer side of the package is the upper side and, in a preferred embodiment, the stamping lines are positively embossed in the sense that the lines protrude from the bottom wall panel 20 of the packaging 15. With reference to FIG. 4 Thus, the embossed lines 25 oppose the viewing direction.

- the marker 11 has a particularly selected shape in the embodiment shown here. At least two straight embossed lines 25, namely all embossed lines, intersect. It turns out that in FIG. 4 shown structure is centrally symmetric.

- the marking has an outer rectangular frame 26 with two long sides 27, 27 'which extend in the conveying direction 7 of the material web, and two short sides 28, 28' lying perpendicular thereto.

- the long sides 27, 27 'of the rectangular frame 26 extend in the flattened blank 21 according to FIG FIG. 3 parallel to the longitudinal fold lines 5.

- an inner rectangle 29 is inscribed, the transverse sides 30, 30 'at a distance from the short sides 28, 28' of the outer frame 26 extend, and their longitudinal sides with the long Pages 27, 27 'of the frame 26 coincide.

- the inner rectangle 29 is traversed when the following lines are descended, the middle part of the long side 27, the transverse side 30 ', the middle part of the other long side 27' and the transverse side 30.

- a rhombus 31 is inscribed in such a way that its vertical diagonal 32 also runs parallel to the longitudinal fold lines 5 in the blank.

- the two transverse sides 30, 30 'of the inner rectangle 29 touch at their center the connecting corners 33L and 33N of the rhombus 31.

- the two transverse sides 30, 30' of the inner rectangle 29 touch the corners 33L and 33N of the rhombus 31 such that the connecting corners 33L and 33N intersect or touch the respective side 30, 30 'of the inner rectangle 29, respectively, so that in other words the center of the respective side 30, 30' is here. Therefore, the diagonal 32 of the rhombus 31 in extension is the symmetry line of the entire mark 11.

- the middle part of the marker off FIG. 4 is enlarged and schematized in FIG. 5 shown again.

- the Rhombus 31 has four connecting corners K, 33L, M and 33N.

- the vertical diagonal 32 would be the connecting line between the corners 33L and 33N.

- the transverse sides 30 'and 30 extend through these two last-mentioned corners 33L and 33N.

- the sensor beam S1 of the first sensor shown extends perpendicularly to them. At a distance and parallel to this extends the second sensor beam S2 of the second, also fixedly mounted sensor 12 (in FIG. 5 Not shown.).

- the nominal dimensions A, B, C and E are assumed as given.

- the rectangular type of packaging is selected. According to this type of packing, it is set at the sensor which one of the points on the mark 11, which he all are covered, to be grasped, in the example of the FIG. 5 and in the case of the so-called rectangular packing, the points P1 and P2 for the one sensor beam S1; and for the other sensor beam S2, the points P3 and P4.

- a ' A ⁇ X ⁇ 2

- C ' C ⁇ X ⁇ 1

- B ' B ⁇ X ⁇ 1.

- the value e is compared with the actual value e '. Ideally, the difference is zero.

- the marking 11 described represents a mathematical correlation to the packaging blank 21. This makes it possible, the geometry of the fold lines 4 - 6 of the blank 21 according to FIG. 3 to describe or determine.

- the values shown from the mark 11 one can determine the actual values of a blank, for example the values A ', B', C 'and E', and then compare them with the desired values.

- E ' is a calculated mathematical value, as stated above.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Making Paper Articles (AREA)

- Cartons (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

Description

Die Erfindung betrifft eine Verpackung für eine Flüssigkeit und/oder ein Schüttgut, die aus flachem Verpackungsmaterial gebildet ist, welches Faltlinien und eine auf ein Wandfeld der Verpackung aufgebrachte Markierung aufweist. Ferner betrifft die Erfindung einen Zuschnitt für die Herstellung einer solchen Verpackung sowie ein Verfahren zur Herstellung einer Verpackung, die aus einer bewegten Bahn erstellt wird. Eine Vorrichtung zur Durchführung des Verfahrens ist durch spezielle Leseeinrichtungen gekennzeichnet.The invention relates to a package for a liquid and / or a bulk material, which is formed from flat packaging material, which has fold lines and a force applied to a wall panel of the packaging mark. Furthermore, the invention relates to a blank for the production of such a package and a method for producing a package, which is created from a moving web. An apparatus for carrying out the method is characterized by special reading devices.

Verpackungen der eingangs genannten Art sind vielfach bekannt und werden häufig für das Verpakken flüssiger Nahrungsmittel verwendet, zum Beispiel Milch oder Säfte, die auch Fruchtfleischstücke enthalten können. Es sind Verpackungen, ihre Zuschnitte und auch ihre Herstellungsverfahren bekannt, bei denen eine Bahn aus Verpackungsmaterial durch verschiedene Bearbeitungsstationen bewegt wird und Faltlinien bekommt, die zum Ausformen der Materialbahn und Bildung der Verpakkung benutzt werden. Vor, bei oder nach dem Ausformen wird die im Entstehen begriffene Verpakkung gefüllt und verschlossen.Packaging of the type mentioned are widely known and are often used for packaging liquid foods, such as milk or juices, which may also contain pieces of fruit pulp. There are known packages, their blanks and also their manufacturing processes, in which a web of packaging material is moved through various processing stations and gets fold lines, which are used for forming the web and forming the packaging. Before, during or after molding, the packaging being formed is filled and sealed.

Es ist auch bekannt, Markierungen auf Verpackungen aufzudrucken und photoelektrisch auszulesen, um Einrichtungen bei der Herstellung der Verpackung zu steuern. Die bekannte Markierung besteht aus einem Register- bzw. Strichcode und wird mit Toleranzen von ± 1 mm aufgedruckt. Man will durch Lesen dieses Strichcodes Druckwerke steuern, damit diese auch in verschiedenen Farben ein Dekor registerhaltig auf die Oberfläche der Verpackung drucken. Es hat sich jedoch gezeigt, daß ein Aufdruck häufig fehlerhaft positioniert wird und bezüglich der Bahn des Verpackungsmaterials einen Versatz haben kann. Außerdem können sich durch Umwelteinflüsse die Stege des Strichcodes und insbesondere ihr Übergang von schwarz auf weiß verändern mit der Folge, daß sich Lese-und Steuerfehler ergeben. So hat man festgestellt, daß sich bei Verbundmaterial mit Papier als Trägermaterial Temperatur- und Feuchtigkeitseinflüsse erheblich auswirken. Schon im Papierwerk bei der Bearbeitung des Rohmaterials kann sich ein Strecken der Bahn ergeben. Im Papierwerk wird das Papier gegebenenfalls beschichtet (Kunststoff, Aluminiumfolie usw.), mit Faltlinien und meistens auch mit Schnittlinien versehen. Das Bahnmaterial wird häufig auf Rollen geliefert und verläßt das Papierwerk nach der Bearbeitung ebenfalls auf Rollen, gegebenenfalls schon Einzelrollen. Häufig ist die Abfüllmaschine separat vom Papierwerk angeordnet und erhält die Einzelrollen, aus denen gefüllte und verschlossene Verpackungen hergestellt werden. In der Füllmaschine können ebenfalls Einflüsse durch Temperatur, Feuchtigkeit usw. auftreten. Solche Veränderungen im Papierwerk, zwischen Papierwerk und Abfüllmaschine oder auch in der Abfüllmaschine sollen erfaßt und zur Steuerung der Materialbahn verwendet werden, damit nicht nur ein Dekor, gegebenenfalls auch mehrfarbig, in der gewünschten Weise richtig auf die Oberfläche aufgedruckt werden kann, sondern daß auch das Ausformen und Falten an der richtigen Stelle erfolgt, einschließlich des Legens von Schnitten beim Vereinzeln der gefüllten Packungen.It is also known to print markings on packages and photoelectrically read to control means in the manufacture of the package. The known marking consists of a register or bar code and is printed with tolerances of ± 1 mm. One wants to control printing works by reading this bar code, so that they print a decoration in register in different colors on the surface of the packaging. It has been found, however, that a print is often mis-positioned and may have an offset with respect to the web of the packaging material. In addition, by environmental influences, the webs of the bar code and in particular their transition from black to white change, with the result that there are reading and control errors. Thus, it has been found that in composite material with paper as a carrier temperature and humidity effects significantly. Already in the paper mill during the processing of the raw material, a stretching of the web can result. In the paper mill, the paper is optionally coated (plastic, aluminum foil, etc.), provided with fold lines and usually also with cut lines. The web material is often supplied on rolls and leaves the paper mill after processing also on roles, possibly even single roles. Frequently, the filling machine is arranged separately from the paper mill and receives the individual roles, from which filled and sealed packaging are produced. In the filling machine also influences by temperature, humidity, etc. can occur. Such changes in the paper mill, between paper mill and filling machine or in the filling machine to be detected and used to control the web so that not only a decor, possibly even multi-colored, can be printed correctly on the surface in the desired manner, but that the shaping and folding on the correct location, including laying cuts when separating the filled packages.

Eine aufgedruckte Markierung ist zwar weitgehend hilfreich, unterliegt bisweilen aber denselben Fehlern wie den Fehlern beim Drucken überhaupt.Although a printed mark is largely helpful, it is sometimes subject to the same errors as printing errors.

So ist in der

Zum einen werden die älteren Markierungen wenigstens teilweise durch Aufdrucken gebildet, wobei die erwähnten Prägelinien in einen rechteckigen oder quadratischen Bereich mit aufgedruckter Farbe in bestimmter Weise eingepresst werden, sodass sich durch Kontrast beim Bedrucken ein negativ gedrucktes Muster dadurch ergibt, daß die Druckfarbe zur Erstellung der Markierung nicht auf die eingedruckten und dadurch vom äußeren der Verpackung gesehen tiefer liegenden Linienbereiche kommt. Die vorstehend beschriebenen Nachteile beim Drucken einer Markierung sind aber erwähnt und werden nachfolgend zusätzlich an einzelnen Ausführungsformen erläutert.On the one hand, the older markings are at least partially formed by printing, wherein the mentioned stamping lines are pressed into a rectangular or square area with printed ink in a certain way, so that by contrast when printing a negative printed pattern results from the fact that the printing ink to create the Marking does not come on the imprinted and thus seen from the outer of the packaging lower lying line areas. However, the disadvantages described above when printing a marking are mentioned and will be explained in addition to individual embodiments.

Außerdem sind die Prägelinien bei der älteren Verpackung sogenannte Kompressionslinien, bei denen darauf geachtet ist, daß die von der späteren Oberseite der Verpackung in die tiefer liegenden Linienbereiche ragenden Vorsprünge der Presswalze einer ebenen oder im Schnitt wenigstens geradlinigen Gegendruckrolle gegenüber stehen. Daraus ergeben sich Kompressionslinien, in deren Bereichen das Verpackungsmaterial eine geringere Dicke hat als in den anderen Bereichen, die nicht komprimiert wurden. Durch die gleichmäßige Arbeitsoberfläche der Gegendruckrolle bzw. des Gegendruckwerkzeuges erwartet man geringere Kosten für das Werkzeug. Außerdem erwartet man durch die speziellen Kompressionslinien, die Gefahr der Dilaminiation des zusammenpressbaren Verpackungsmaterials zu reduzieren.In addition, the embossing lines are in the older packaging so-called compression lines, in which care is taken that the protruding from the later top of the package in the lower line portions protrusions of the press roll against a flat or average at least rectilinear counter pressure roller. This results in compression lines in the areas of the packaging material has a smaller thickness than in the other areas that were not compressed. Due to the uniform work surface of the counter-pressure roller or the counter-pressure tool, one expects lower costs for the tool. In addition, special compression lines are expected to reduce the risk of dilamination of the compressible packaging material.

Den bei dem älteren Verfahren vorgeschlagenen negativen Druckbildern haftet dabei unter anderem der Nachteil an, daß beim Druck laufend Farbe verbraucht wird. Außerdem ist ohne das Druckwerk das negative Druckbild nicht herzustellen, sodass die Markierung erst stromabseitig von dem Druckwerk verwendet werden kann.One of the disadvantages of the negative print images proposed in the older method is that color is consumed continuously during printing. In addition, the negative print image can not be produced without the printing unit, so that the marking can only be used downstream of the printing unit.

Die Erfindung geht von dem Gedanken aus, daß die Linien einer Markierung nicht unbedingt nur durch Drucken gebildet werden können, sondern erfindungsgemäß durch Prägen. Die Prägung des Materials zur Herstellung einer Packung besitzt essentielle Eigenschaften für die Qualität der Packung. Wenn die Prägung an der richtigen Stelle des Verpackungsmaterials sitzt oder eine Information über die Position der Prägung an die verarbeitende Maschine weitergegeben wird, kann die Packung präzise ausgeformt werden, ist in sich stabil, fest und hat einen richtigen Stand. Bei dem Verbundmaterial mit Papier oder Pappe als Trägermaterial gibt es Packungen mit Eckenlaschen, die an der richtigen Stelle umgelegt werden müssen. Bei korrekter Prägung gelingt auch dies präzise und leicht.The invention is based on the idea that the lines of a marking can not necessarily be formed only by printing, but according to the invention by embossing. The embossing of the material for making a package has essential properties for the quality of the package. When the embossing is in place, or information about the position of the embossing is passed to the processing machine, the package can be precisely formed, is inherently strong, firm and has a good footing Paperboard as carrier material there are packs with corner tabs, which must be put in the right place. With correct embossing, this also succeeds precisely and easily.

Die Erfindung greift also den Gedanken auf, die Markierung anstelle durch Drucken durch Prägen aufzubringen. Das Lesen einer gedruckten Markierung ist eine weitere Fehlerquelle, weil bekanntlich viele optische Systeme empfindlich sind und Fehlerquellen darstellen. Aufgedruckte Markierung erlauben auch nur die Messung in einer linearen Richtung.The invention thus addresses the idea of applying the mark instead of printing by embossing. Reading a printed mark is another source of error because many optical systems are known to be sensitive and pose sources of error. Printed markings also allow only measurement in a linear direction.

Die französische Patentschrift

Der Erfindung liegt daher die Aufgabe zugrunde, eine Verpackung, ihren Zuschnitt und ein Verfahren zu dessen Herstellung zu schaffen, so daß die Herstellung der Verpackung einfacher, preiswerter und mit größerer Präzision erreichbar ist.The invention is therefore an object of the invention to provide a package, its blank and a method for its production, so that the production of the packaging is easier, cheaper and can be achieved with greater precision.

Diese Aufgabe wird durch eine Verpackung nach Anspruch 1, durch einen Zuschnitt nach Anspruch 7 sowie durch ein Verfahren nach Anspruch 13 gelöst.This object is achieved by a package according to

Die Markierung ist bei dieser Ausführungsform eben, wenigstens im wesentlichen so weit eben, wie dies bei den bekannten Naturstoffen möglich ist. Prägen kann man Papier, Karton, Kunststoffe und Metallfolien. Das Prägen verschiedenster Linienformen wird durch bekannte Werkzeuge erreicht, zum Beispiel zwei gegeneinanderlaufende Rollen, deren eine erhabene Teile und die gegenüberliegende vertiefte Teile hat. Es hat sich erfindungsgemäß als zweckmäßig erwiesen, daß die Markierung mit den Prägelinien wenigstens zwei gerade Prägelinien hat, die sich entweder in der Markierung bereits schneiden oder sich mindestens bei ihrer Verlängerung oder mathematisch (virtuell) schneiden. Solche Muster erlauben ein schnelles und präzises Lesen der Markierung und beinhalten wichtige Informationen, die entweder an der Eingangsseite der betreffenden Maschine aufgenommen und für den weiteren Verlauf der Materialbahn verwendet werden können; oder die an einer vorgeschalteten Maschine festgestellt und verwendet werden, um die Materialbahn in einer nachgeschalteten Maschine entsprechend zu steuern. So können zum Beispiel aus dem Papierwerk Informationen bezüglich der Längung des Materials nach dem Prägen bis zum Ausgang aus dem Papierwerk gemessen werden.The marking is planar in this embodiment, at least substantially as far as possible, as is possible with the known natural substances. You can emboss paper, cardboard, plastics and metal foils. The embossing of various line shapes is achieved by known tools, for example two counter-rotating rollers, one of which has raised parts and the opposite recessed parts. It has proved to be expedient according to the invention that the marking with the stamping lines has at least two straight stamping lines which either already intersect in the marking or intersect at least during their extension or mathematically (virtually). Such patterns allow quick and accurate reading of the mark and include important information either at the input side the relevant machine can be recorded and used for the further course of the material web; or which are detected and used on an upstream machine to control the web in a downstream machine accordingly. Thus, for example, information about the elongation of the material after embossing can be measured from the paper mill to the exit from the paper mill.

Erfindungsgemäß ist zwar auch daran gedacht worden, die für das Falten und Ausformen der Pakkung erforderlichen Faltlinien teilweise zugleich als Markierung zu verwenden. Bevorzugt erläutert ist aber die vorstehend beschriebene Ausführungsform, bei welcher eine gesonderte Markierung mit gesonderten Prägelinien auf das Material der Verpackung aufgebracht wird. Während beim Druck mit Nachteil auch laufend Farbe verbraucht wird, kann die Markierung durch Prägen ohne vergleichbaren Materialverbrauch erstellt werden. Die betreffende Oberfläche der Verpackung braucht im Falle einer durch Prägung entstandenen Markierung nicht in einem vom Dekor unberührt oder weiß belassenen Wandfeld vorgesehen zu werden. Optisch sieht man auf den ersten Blick die durch Prägung hergestellte Markierung nicht. Sie könnte gegebenenfalls sogar in ein Dekor reichen.Although according to the invention has also been thought to use the folding lines required for folding and forming the package partially as a marker at the same time. However, the embodiment described above, in which a separate marking with separate stamping lines is applied to the material of the packaging, is preferred. While ink is consumed at a disadvantage with printing at a disadvantage, the marking can be created by embossing without comparable material consumption. The relevant surface of the packaging need not be provided in a wall of the field untouched or left white in the case of a mark created by embossing. Visually, you can not see at first glance the mark made by embossing. If necessary, it could even go into a décor.

Es hat sich erfindungsgemäß als besonders günstig erwiesen, wenn die Markierung wenigstens ein zentralsymmetrisches Gebilde aufweist. Zentralsymmetrisch sind alle geometrischen Gebilde, die in einer Ebene liegen und sich nach der Drehung um 180° in dieser Ebene um einen festen Punkt zueinander decken. So ist zum Beispiel jede Strecke zentralsymmetrisch zu ihrem Mittelpunkt. Jede Gerade ist zentralsymmetrisch zu jedem auf ihr liegenden Punkt. Jeder Strahl ist zentralsymmetrisch zu seinem Gegenstrahl. Zwei sich schneidende Geraden sind zentralsymmetrisch zu ihrem Scheitelpunkt. Auch Scheitelwinkel sind zentralsymmetrische Gebilde. Die Raute oder der Rhombus und das Rhomboid ergeben sich daraus ebenfalls als zentralsymmetrische Gebilde. Die Erfindung macht sich die Eigenschaften des zentralsymmetrischen Gebildes für die Markierung zunutze, weil dadurch eine Vielzahl wichtiger Informationen von der Markierung abgelesen bzw. abgeleitet werden kann, welche für die Steuerung der nachfolgenden Bearbeitungsstationen nützlich sind.It has proved to be particularly favorable according to the invention if the marking has at least one centrally symmetrical structure. Centrally symmetrical are all geometric structures that lie in one plane and cover each other after rotation through 180 ° in this plane around a fixed point. For example, each track is centrally symmetric to its center. Each line is centrally symmetrical to each point lying on it. Each ray is centrally symmetric to its counter-ray. Two intersecting lines are centrally symmetric to their vertex. Also vertex angles are centrally symmetrical structures. The rhombus or the rhombus and the rhomboid also result from this as a centrally symmetric structure. The invention takes advantage of the characteristics of the centrosymmetric structure for the mark, as it allows a variety of important information to be read from the mark, which are useful for the control of subsequent processing stations.

So ist es erfindungsgemäß bei einer bevorzugten Ausführungsform zweckmäßig, wenn die Markierung einen äußeren rechteckigen Rahmen aufweist, dessen Seiten im Zuschnitt parallel zu den Längsfaltlinien der Verpackung verlaufen, und wenn in dieses äußere Rechteck (den Rahmen) ein Parallelogramm einbeschrieben ist. Spezieller ist es dabei erfindungsgemäß besonders vorteilhaft, wenn im Falle eines Rhombus als Parallelogramm seine zwei Diagonalen im Zuschnitt der Verpakkung parallel zu den Längs- und Querfaltlinien der Verpackung verlaufen. Im Falle des Rhombus stehen die Diagonalen senkrecht aufeinander. Dabei halbieren die Diagonalen die Winkel des Parallelogramms. Bei einer derart angelegten Markierung wird erfindungsgemäß eine genauere Positionierung des Verpackungsmaterials bei der Herstellung der Verpackung erreicht.Thus, according to the invention, in a preferred embodiment, it is expedient for the marker to have an outer rectangular frame whose sides run parallel to the longitudinal fold lines of the package in the blank, and if a parallelogram is inscribed in this outer rectangle (the frame). More specifically, it is particularly advantageous according to the invention if, in the case of a rhombus as a parallelogram, its two diagonals in the blank of the package run parallel to the longitudinal and transverse fold lines of the package. In the case of the rhombus, the diagonals are perpendicular to each other. The diagonals halve the angles of the parallelogram. In the case of such a marking, a more precise positioning of the packaging material in the production of the packaging is achieved according to the invention.

Bekanntlich ist:

- ein Quadrat ein gleichseitiges, rechtwinkliges Parallelogramm;

- ein Rechteck ein ungleichseitiges, rechtwinkliges Parallelogramm,

- ein Rhombus ein gleichseitiges, schiefwinkliges Parallelogramm und

- ein Rhomboid ein ungleichseitiges, schiefwinkliges Parallelogramm.

- Verwendet man ein solches Parallelogramm als zentralsymmetrisches Gebilde in der Markierung, dann beschreibt dieses Parallelogramm die Packungsart. Zum Beispiel beschreibt der Rhombus eine quadratische Packung, der Rhomboid eine rechteckige Packung.

- a square is an equilateral, right-angled parallelogram;

- a rectangle a non-equilateral, right-angled parallelogram,

- a rhombus an equilateral, oblique parallelogram and

- a rhomboid is a non-equilateral oblique parallelogram.

- If such a parallelogram is used as a centrally symmetric structure in the marking, then this parallelogram describes the type of packing. For example, the rhombus describes a square pack, the rhomboid a rectangular pack.

Schneidet man eine quaderförmige Packung senkrecht zu ihrer Längsmittelachse, im allgemeinen also längs einer horizontalen Ebene, dann ist der Querschnitt einer solchen Packung gemäß der Schnittlinie quadratisch oder rechteckig. H-Milch wird in Europa derzeit in aller Regel in rechteckigen Verpackungen verpackt, Frischmilch in quadratischen Packungen. Die rechteckige Verpackung weist jeweils zwei breite Seitenwandfelder und dazwischen zwei schmale Seitenwandfelder, einander gegenüberliegend, auf. Die Packungsdiagonale ist bekanntlich ein wichtiger Faktor für die Bestimmung des Packungsvolumens. Aus der Breite der Seitenwandfelder kann die Packungsdiagonale e berechnet werden. Im Fall der quadratischen Packung sind beiden Seitenwandfelder gleich breit, haben zum Beispiel eine Breite von B'. Dann gilt,

Im Fall einer rechteckigen Verpackung hat das breite Seitenwandfeld beispielsweise die Breite B', und das schmale Seitenwandfeld hat die Breite C'. In diesem Fall gilt für die Packungsdiagonale:

Bekanntlich spielt auch die Wiederholungslänge des Packungszuschnitts eine wichtige Rolle, d.h. die Länge in Laufrichtung der Zuschnitte in der Maschine. Hat man diese Wiederholungslänge einerseits und die Packungsdiagonale e andererseits, dann kann man auf das Packungsvolumen zurückschließen, auf das es letztlich ankommt.As is known, the repetition length of the package blank also plays an important role, i. the length in the direction of the blanks in the machine. If you have this repetition length on the one hand and the package diagonal e on the other, then you can infer back to the pack volume, which ultimately matters.

Aus der Markierung mit dem in der beschriebenen Weise einbeschriebenen Parallelogramm, zum Beispiel Rhomboid, können Werte gemessen und ausgelesen werden, die über die Ausformung und das richtige Volumen der Packung Auskunft geben. An mindestens einem ortsfesten Sensor läuft die Bahn der Packungszuschnitte derart vorbei, daß die Sensorstrahlen Gelegenheit haben, die Markierung abzutasten und die betreffenden Größen auszulesen. Diese werden mit zuvor eingelesenen Sollwerten verglichen. Ist die Differenz null, dann hat die in Entstehung begriffene Packung die richtige Winkellage, das richtige Volumen und die korrekte Ausformung.From the marking with the parallelogram inscribed in the manner described, for example rhomboid, values can be measured and read out which provide information about the shape and the correct volume of the packing. At at least one stationary sensor, the path of the pack blanks passes in such a way that the sensor beams have the opportunity to scan the mark and read out the relevant quantities. These are compared with previously read setpoints. If the difference is zero, then the packaging that is being formed has the correct angular position, the correct volume and the correct shaping.

Unbeachtlich der Ausgestaltung der betreffenden Markierung ist erfindungsgemäß auch daran gedacht worden, zwei separate Markierungen an unterschiedlichen Stellen der Oberfläche der Verpakkung anzubringen. Dadurch können zum Beispiel unterschiedliche Durchmesser eines Tubus gemessen werden und dadurch die Überlappungsnaht eingestellt werden. Andererseits weiß man ferner, daß drei Seiten der Verpackungen durch die Herstellung vorgegeben sind. Die dritte Seite, durch welche die Längsnaht führt, ist davon abhängig, wie genau der Maschinenführer die Überlappung einstellt (durch eine zu kleine oder zu große Überlappung entsteht eine trapezförmige Verpakkung). Durch eine zweite Markierung kann die Position der Überlappung genau bestimmt und automatisch eingestellt werden.Irrespective of the design of the mark in question, it has also been thought according to the invention to apply two separate markings at different points on the surface of the package. As a result, for example, different diameters of a tube can be measured and thereby the overlap seam can be adjusted. On the other hand, it is further known that three sides of the packaging are predetermined by the production. The third side, through which the longitudinal seam passes, depends on how precisely the operator sets the overlap (a too small or too large overlap creates a trapezoidal packaging). A second marking allows the position of the overlap to be precisely determined and adjusted automatically.

Es ist auch vorteilhaft, wenn erfindungsgemäß ferner ein zweites, inneres Rechteck derart in das äußere Rechteck (den Rahmen) einbeschrieben ist, daß zwei Seiten mit den Seiten des äußeren Rechtecks, die im Zuschnitt parallel zu den Längsfaltlinien der Verpackung verlaufen, zusammenfallen und die beiden anderen Seiten so die Verbindungsecken des Rhombus berühren, daß die Verbindungsecken die Seiten halbieren. Im Falle einer quaderförmigen Verpackung werden die Seiten der Markierung durch den Rhombus nicht halbiert. Eine besondere Ausführungsform von Verpakkung ist diejenige, die aus einer Materialbahn hergestellt wird, bei welcher ein Zuschnitt hinter dem anderen folgt. Außerdem hat jede Packung eine Längsmittelachse, zu welcher im Zuschnitt zwei Seiten des äußeren Rechteckenrahmens parallel verlaufen. Teile dieser zwei Seiten fallen mit den besagten zwei Seiten des einbeschriebenen, kleineren Rechtecks zusammen. Dieses kleinere Rechteck ist so um den Rhombus herumgelegt, daß alle vier Seiten des kleineren Rechtecks mit den Ecken des Rhombus zusammenfallen, bzw. diese berühren. Dem Rhombus ist also das kleinere Rechteck umschrieben worden.It is also advantageous if, according to the invention, a second, inner rectangle is further inscribed into the outer rectangle (frame) in such a way that two sides coincide with the sides of the outer rectangle parallel to the longitudinal fold lines of the package in the blank and the two on other sides so touch the connecting corners of the rhombus that the connecting corners bisect the sides. In the case of a cuboid packaging, the sides of the mark are not halved by the rhombus. A particular embodiment of packaging is that made from a web of material followed by a blank behind the other. In addition, each pack has a longitudinal central axis, to which in the blank two sides of the outer rectangular frame parallel. Portions of these two sides coincide with said two sides of the inscribed smaller rectangle. This smaller rectangle is wrapped around the rhombus so that all four sides of the smaller rectangle coincide with, or touch, the corners of the rhombus. The rhombus has thus been rewritten the smaller rectangle.

Besonders vorteilhaft ist es, wenn erfindungsgemäß die Markierung eine mathematische Korrelation zum Verpackungszuschnitt derart hat, daß die Abstände zwischen Punkten auf der Markierung die Geometrie der Faltlinien beschreiben. So haben zum Beispiel die Abstände der Querseiten des großen Rechtecks die Aufgabe, die sogenannte Wiederholungslänge des Zuschnitts der Verpackung, d.h. die Packungsmateriallänge, zu beschreiben. Der Zuschnitt hat Längs- und Querfaltlinien, die man zum Beispiel ebenfalls durch Prägen erstellen kann. Die Wiederholungslänge bzw. die Länge des Packungsmaterials ist diejenige Länge, die zwischen zwei in Förderrichtung der Zuschnitte bei der Herstellung aufeinanderfolgenden Markierungen an der entsprechenden Stelle derselben gemessen werden kann, denn jeder Zuschnitt trägt eine Markierung. Das besagte Rechteck der Markierung gibt also verschlüsselt ein klares Maß für diese Wiederholungslänge. Das Gleiche gilt auch für die Höhe des kleineren, einbeschriebenen Rechtecks, welches zum Beispiel die Breite eines schmalen Seitenwandfeldes bedeutet. Ebenso kann man aus anderen Abständen die gesamte Querlänge eines Zuschnitts quer zu den Längsfaltlinien, die Breite eines breiten Wandfeldes der Verpackung oder auch die Diagonale des Zuschnitts ablesen. Weiterhin kann die Lage (Verdrehung um die Längs- und die Querachse) des Verpackungsmaterials bestimmt werden.It is particularly advantageous if, according to the invention, the marking has a mathematical correlation to the packaging blank such that the distances between points on the marking describe the geometry of the fold lines. For example, the distances of the transverse sides of the large rectangle have the task of describing the so-called repetition length of the blank of the packaging, ie the length of the packaging material. The blank has longitudinal and transverse fold lines, which can also be created by embossing, for example. The repetition length or the length of the packing material is the length that can be measured between two successive markings in the conveying direction of the blanks in the production at the corresponding point, since each blank carries a marking. The said rectangle of the mark is thus encrypted a clear measure of this repetition length. The same applies to the height of the smaller, inscribed rectangle, which means, for example, the width of a narrow sidewall field. Likewise, one can read from other distances the entire transverse length of a blank across the longitudinal fold lines, the width of a wide wall field of the package or the diagonal of the blank. Furthermore, the position (rotation about the longitudinal and the transverse axis) of the packaging material can be determined.

Die Erfindung ist weiterhin dadurch gekennzeichnet, daß die Prägelinien wenigstens teilweise aus der Oberfläche des Wandfeldes erhaben vorstehen und/oder in die Oberfläche des Wandfeldes tiefliegend zurückstehen. Bei der bevorzugten, ersten Ausführungsform stehen die Prägelinien aus der Oberfläche des Wandfeldes erhaben vor. Man kann sie also beim Greifen auf das Wandfeld der Verpackung als Erhöhungen fühlen. Bei geeignetem Licht und Schatten sind sie selbstverständlich auch zu sehen. In der gleichen oder in einer anderen Markierung oder bei einer anderen Charge bei der Herstellung von anderen Verpackungen ist es zweckmäßig, wenn bei eine; anderen Ausführungsform die Prägelinien in die Oberfläche des Wandfeldes tiefliegend zurückstehen, also sozusagen negativ geprägt sind. Man kann sagen, daß sie in der erstgenannten Ausführungsform, wo sie erhaben nach außen vorstehen, positiv geprägt sind. Der Fachmann weiß, daß die Höhe des U, d.h. der Prägelinie, um welche letztere aus dem Wandfeld vorsteht, je nach Papierdicke oder Dicke eines anderweitigen Materials um einen mehr oder weniger großen Betrag aus dem Wandfeld heraussteht. Die Höhe der Prägung sagt also etwas über die Stärke des Materials, über dessen Dicke aus. Erfindungsgemäß ist also eine Messung in Z-Richtung ebenso möglich, wie die auch bei anderen Markierungen möglichen Messungen in der X-Y-Ebene. Es versteht sich, daß durch die positive Prägung nach oben und/oder die negative nach unten zusätzliche Informationen in die Markierung eingebracht bzw. aus dieser ausgelesen werden können.The invention is further characterized in that the stamping lines project at least partially out of the surface of the wall panel and / or project deep into the surface of the wall panel. In the preferred, first embodiment, the stamping lines are raised from the surface of the wall panel. So you can feel it when you click on the wall box of the packaging as elevations. Of course, they can also be seen with suitable light and shade. In the same or a different marking or batch in the manufacture of other packages, it is expedient if one; Another embodiment, the embossing lines in the surface of the wall field are low-lying back, so to speak, negative embossed. It can be said that in the former embodiment, where they project outwardly, they are positively marked. The person skilled in the art knows that the height of the U, i. the embossing line, by which the latter protrudes from the wall field, depending on the paper thickness or thickness of another material protrudes from the wall field by a greater or lesser amount. The height of the embossment says something about the thickness of the material, about its thickness. Thus, according to the invention, a measurement in the Z direction is just as possible as the measurements which are also possible with other markings in the XY plane. It is understood that additional information can be introduced or read out of the marking by the positive embossing upward and / or the negative downward.

Bei Verwendung der neuen Markierung kann man im Falle von Abweichungen den Hub der Füllmaschine verändern und an die tatsächlich vorhandenen Prägelinien anpassen. Ferner ist das Volumen der Verpackung erfaßbar. Weiterhin kann man die Position der Längssiegelnaht feststellen und eine Korrektur beim Verlaufen der Materialbahn vornehmen, wenn die Winkeleinstellung der Laufrichtung vom Sollwert abweichen sollte. Es ist auch möglich, die Verbindungsnaht zwischen zwei Materialbahnen abzufühlen. Eine solche Verbindungsnaht ist immer notwendig, wenn eine Zuführrolle mit Material erschöpft ist und durch eine neue Rolle ersetzt werden muß. Das Ende der erschöpften Rolle muß dann an den Anfang der neuen Rolle angeklebt bzw. angeschweißt werden. Die Formung der gesamten Packung ist mit größerer Präzision erreichbar, und durch die Einfachheit der Mittel ergibt sich ersichtlich eine preiswertere Messung und Steuerung. Die Herstellung von Packungen der eingangs genannten Art und auch deren Zuschnitte ist damit gegenüber den bekannten Lösungen erheblich verbessert. Wird die Wiederholungslänge über mehrere Verpackungen (zwischen 5 und 15 Verpackungen) ausgelesen, kann die Frequenz der Wiederholungslänge analysiert und als zusätzlicher Parameter eingelesen werden.When using the new marking, in case of deviations, it is possible to change the stroke of the filling machine and adapt it to the actually existing stamping lines. Furthermore, the volume of the packaging is detectable. Furthermore, one can determine the position of the longitudinal sealing seam and make a correction in the course of the material web, if the angular adjustment of the direction should differ from the nominal value. It is also possible to sense the seam between two webs of material. Such a seam is always necessary when a feed roll is depleted with material and must be replaced by a new role. The end of the exhausted roll must then be glued or welded to the beginning of the new roll. Forming the entire package is achievable with greater precision, and the simplicity of the means clearly results in less expensive measurement and control. The production of packages of the type mentioned and also their blanks is thus significantly improved over the known solutions. If the repeat length is read out over several packages (between 5 and 15 packages), the frequency of the repeat length can be analyzed and read in as an additional parameter.

Wenn man gemäß dem erfindungsgemäßen Verfahren die Markierung durch Einbringen von Prägelinien derart erstellt, daß der Querschnitt des Materials nach dem Prägen U-förmig ist und dabei die Dicke des Materials im wesentlichen gleich bleibt, hat man eine sehr vorteilhafte Signalmöglichkeit geschaffen. Detektoren, die auf unterschiedlichen physikalischen Eigenschaften die Markierung abtasten, stellen - im Querschnitt gesehen - die Prägelinien dadurch fest, daß die Prägelinie an der betreffenden Oberfläche, aus welcher sie erhaben heraussteht, konvex ist; und auf der gegenüberliegenden Seite konkav ist. Deshalb kann man zusätzliche Informationen in einer schon recht einfachen Markierung unterbringen, wenn man gegebenenfalls sowohl positive als auch negative Prägung des betreffenden Feldes der Materialbahn vornimmt.If, according to the method of the invention, the marking is made by introducing embossing lines in such a way that the cross section of the material is U-shaped after embossing and the thickness of the material remains essentially the same, a very advantageous signal possibility has been created. Detectors that scan the marking on different physical properties, seen in cross section, the embossing lines determined by the fact that the embossed line at the surface from which it protrudes raised, is convex; and concave on the opposite side. Therefore, one can accommodate additional information in an already quite simple marking, if appropriate, makes both positive and negative imprinting of the relevant field of the web.

Dabei kann es besonders vorteilhaft sein, daß die Prägelinien erfindungsgemäß schon bei der Bearbeitung der Materialbahn im Papierwerk eingebracht werden. Man kann die Prägelinien entweder zusammen mit dem Einbringen der Faltlinien für die Ausformung der Verpackung vorsehen, gleichzeitig oder auch danach. Da man Faltlinien ohnehin vorsehen muß und diese zum Beispiel auch durch Prägen erstellen kann, springt die Einfachheit des erfindungsgemäßen Verfahrens zur Erstellung einer Markierung durch Prägen ins Auge. Bei vielen Ausführungsformen befindet sich das Druckwerk zum Aufbringen eines Dekors im abstromseitigen Bereich der Maschine. Die Markierung mit Hilfe der Prägelinien kann man dann vorher so einbringen, daß die Informationen für die weitere Bearbeitung der Materialbahn bzw. des späteren Zuschnitts über die Markierung beobachtet und gesteuert werden kann.It may be particularly advantageous that the embossing lines are introduced according to the invention already in the processing of the web in the paper mill. You can provide the stamping lines either together with the introduction of the fold lines for the formation of the packaging, simultaneously or afterwards. Since you have to provide fold lines anyway and this can create, for example, by embossing, jumps the simplicity of the method for creating a mark by embossing into the eye. In many embodiments, the printing unit is for applying a decoration in the downstream region of the machine. The marking with the aid of the stamping lines can then be introduced in advance in such a way that the information for the further processing of the material web or the subsequent blank can be observed and controlled via the marking.

Die Beobachtung erfolgt erfindungsgemäß bei der Durchführung des Herstellungsverfahrens der Packung mit Leseeinrichtungen. Hier stehen verschiedene physikalische Prinzipien zur Verfügung, und erfolgreiche Betriebsversuche haben bereits gezeigt, daß man die Prägelinien mechanisch durch einen Fühler oder optisch oder akustisch durch einen entsprechenden Meßgeber abfühlen, erfassen und registrieren kann. Besonders vorteilhaft hat man eine Ausführung mit akustischem Meßgeber ausgestaltet. Dabei läßt man die Materialbahn zwischen einem Ultraschallwandler und einem im Abstand von diesem angeordneten Aufnahmegerät hindurchlaufen. Die Materialbahn wird also von einem Ultraschallstrahl durchdrungen und dämpft diesen. Daraus lassen sich sehr schnell sehr genaue Ergebnisse erzielen. Möglich ist es auch, an der Oberfläche der Materialbahn reflektierte Ultraschallstrahlen zu messen. Eine solche Ultraschallmessung gelingt mit oder ohne optische Meßgeber. Man erkennt, daß sehr vorteilhaft bisher bekannte Fehlerquellen, die sich insbesondere in Verbindung mit optischen Messungen ergeben, eliminiert werden können.The observation is carried out according to the invention in carrying out the manufacturing process of the pack with reading devices. Various physical principles are available here, and successful operational trials have already shown that one can mechanically sense, detect and register the embossed lines by a probe or optically or acoustically by a corresponding transducer. Particularly advantageous one has designed a version with acoustic transmitter. In this case, the material web is passed between an ultrasound transducer and a recording device arranged at a distance from it. The material web is thus penetrated by an ultrasonic beam and dampens it. This can be very quickly achieve very accurate results. It is also possible to measure reflected ultrasound beams on the surface of the material web. Such an ultrasonic measurement succeeds with or without optical measuring sensors. It can be seen that very advantageously previously known sources of error, which arise in particular in conjunction with optical measurements, can be eliminated.

Bei allen Meßverfahren, die sozusagen einen Strahl auf die Markierung senden und den Einfluß der Markierung zur Messung ausnutzen, ist es zweckmäßig, wenn der betreffende Strahl (ein optischer, ein akustischer, oder auch eine mechanische Bewegungsbahn) alle Linien der Markierung trifft. Betrachtet man die Ausführungsform mit dem oben beschriebenen, in die beiden Rechtecke einbeschriebenen Rhombus, dann gelingt das Treffen aller Linien einer Markierung mit einem Strahl in dem besonderen Grenzfall, daß der abtastende Strahl in der Symmetrielinie der Markierung liegt. Dieser Strahl verläuft also parallel zur Längsmittellinie des Zuschnitts, parallel zu den langen Seitenwänden des großen Rechtecks und mittig so durch dieses, daß er auch durch die Verbindungsecken des Rhombus läuft.In all measuring methods that send a beam onto the marking and exploit the influence of the marking for the measurement, it is expedient if the relevant beam (an optical, an acoustic, or also a mechanical trajectory) strikes all lines of the marking. Considering the embodiment with the above-described, described in the two rectangles rhombus, then succeeds the meeting of all lines of a marker with a beam in the particular limit case that the scanning beam is in the line of symmetry of the marker. This beam thus runs parallel to the longitudinal center line of the blank, parallel to the long side walls of the large rectangle and centrally through it so that it also passes through the connecting corners of the rhombus.

Verläßt man diesen Grenzfall, ist es zweckmäßig, als Leseeinrichtung gemäß der Erfindung zwei im Abstand voneinander angeordnete Sensoren zu verwenden, seien es mechanische Fühler, optische oder akustische Sensoren. Bei deren Tätigkeit spannen die zwei Sensorstrahlen ein Fenster auf, welches das Detektieren der optimalen Menge an Informationen von der Markierung gestattet.If one leaves this limiting case, it is expedient to use as a reading device according to the invention two sensors arranged at a distance from each other, be it mechanical sensors, optical or acoustic sensors. In their operation, the two sensor beams span a window which allows detection of the optimum amount of information from the tag.

Auf diese Weise kann man sehr effektiv nicht nur in der Abfüllmaschine, sondern auch im Fall des Verbundmaterial mit Papier als Trägermaterial und Herstellung von Verpackungen kontinuierlich aus dem Schlauch im Papierwerk die Markierung erstellen, lesen und zur Steuerung der nachfolgenden Schritte verwenden. Zum Beispiel kann im Papierwerk der Schneidvorgang gesteuert werden, was früher erst nach Aufdrucken einer zusätzlichen Markierung möglich war. Es kann die winkelmäßige Ausrichtung der transportierten Papierbahn gemessen werden. Wie bei der Abfüllmaschine kann auch im Papierwerk die Verbindungsnaht zwischen zwei Rollen, der leeren, alten, erschöpften Rolle und der neuen Rolle erfaßt werden.In this way, it is very effective not only in the filling machine, but also in the case of the composite material with paper as a carrier material and production of packaging continuously from the tube in the paper mill create the marker, read and use to control the subsequent steps. For example, in the paper mill, the cutting process can be controlled, which was previously possible only after printing an additional marking. The angular orientation of the transported paper web can be measured. As with the filling machine can be detected in the paper mill, the seam between two roles, the empty, old, exhausted role and the new role.

Damit die aus der Markierung gemessenen und ausgelesenen Werte mit vorgegebenen Sollwerten verglichen werden können und letztlich der Istwert deckungsgleich auf den Sollwert eingestellt wird, gibt es die vorstehend erwähnte mathematische Korrelation zwischen der Markierung einerseits und dem Verpackungszuschnitt andererseits. Dabei werden Abstände zwischen Punkten auf der Markierung gemessen, die durch Schneiden von Linien der Markierung einerseits und Schneiden von Sensorstrahlen mit bestimmten Linien der Markierung andererseits entstehen oder bestimmt werden. Der Hauptwert, der hierbei verglichen wird (Soll und Ist) ist der Wert e der Packungsdiagonalen. Für die mathematische Korrelation ist wichtig, daß jedes Maß mit einem Faktor multipliziert wird, den man zum Beispiel Verhältnisfaktor nennen könnte. Jedes Maß wird mit einem solchen Faktor Xi multipliziert. Auf diese Weise kann man die Geometrie der Verpackung mit der geprägten Markierung in Übereinstimmung bringen. Bei entsprechend gewähltem Faktor erreicht man eine Verkleinerung der tatsächlichen Zuschnittswerte. Hierdurch ergibt sich der Vorteil, daß die Messung, welche ja an der Markierung stattfindet, eine größere Genauigkeit bekommt, denn durch die miniaturisierten Abmaße können Varianzen in der Lesegeschwindigkeit ausgeschlossen werden. Die Messung kann dadurch genauer werden.So that the values measured and read out from the marking can be compared with predetermined desired values and finally the actual value is congruently set to the desired value, there is the abovementioned mathematical correlation between the marking on the one hand and the packaging blank on the other hand. Distances between points on the marking are measured, which are created or determined by cutting lines of the marking on the one hand and cutting sensor beams with certain lines of the marking on the other hand. The main value that is compared here (target and actual) is the value e of the package diagonals. For the mathematical correlation, it is important that each measure is multiplied by a factor that could be called the ratio factor, for example. Each measure is multiplied by such a factor Xi. In this way, one can bring the geometry of the packaging with the embossed mark in accordance. If the factor has been selected, a reduction of the actual cutting values is achieved. This has the advantage that the measurement, which indeed takes place at the mark, gets a greater accuracy, because by the miniaturized dimensions variances in the reading speed can be excluded. The measurement can be more accurate.