EP1186782B1 - Submersible pump - Google Patents

Submersible pump Download PDFInfo

- Publication number

- EP1186782B1 EP1186782B1 EP01119411A EP01119411A EP1186782B1 EP 1186782 B1 EP1186782 B1 EP 1186782B1 EP 01119411 A EP01119411 A EP 01119411A EP 01119411 A EP01119411 A EP 01119411A EP 1186782 B1 EP1186782 B1 EP 1186782B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pump

- submersible pump

- accordance

- pan

- inlet opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/70—Suction grids; Strainers; Dust separation; Cleaning

- F04D29/708—Suction grids; Strainers; Dust separation; Cleaning specially for liquid pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D13/00—Pumping installations or systems

- F04D13/02—Units comprising pumps and their driving means

- F04D13/06—Units comprising pumps and their driving means the pump being electrically driven

- F04D13/08—Units comprising pumps and their driving means the pump being electrically driven for submerged use

- F04D13/086—Units comprising pumps and their driving means the pump being electrically driven for submerged use the pump and drive motor are both submerged

Definitions

- the invention relates to a submersible pump having a pump chamber, a conveyor disposed within the same and at least one suction port, which communicates with one of the pump chamber upstream in the flow direction collecting space in the form of a trough.

- Submersible pumps of this type are from the US Pat. No. 5,205,725 known.

- the inlet openings to the pan provided there are at a distance to a footprint of the pump and at about the level of a level in which the suction port is located.

- This design is intended to prevent the usually located at the bottom of a container to be evacuated dirt is sucked from the container sump and then leads to a blockage or damage of the pump impeller, which sucks the liquid to be pumped centrally and emits radially outward into a pressure chamber, the provided with an outlet.

- centrifugal pumps such as those in the manner of a centrifugal pump from the DE U 82 10 587 are known to provide below a suction port before a filter, which is provided on its circumference with inlet openings.

- centrifugal pumps can be provided as a flat suction dipping or dewatering pumps.

- the filters tend to block when they are placed in the area of a container sump, because the inlet openings are located in the area of the base and thus in the tank bottom area.

- a submersible pump of the type mentioned which is particularly suitable for extraction at very low liquid level.

- An inadvertent intake of air and pollution should be additionally prevented if possible.

- a submersible pump of the aforementioned type is provided, wherein the trough has a circumferential side wall with an upper edge, which is at a higher level than the suction port and that at least one flow channel is provided, the at least one outside of the side wall and at a distance below the upper edge lying inlet opening leads.

- the trough surrounds a base plate which terminates the pump chamber at the bottom and is provided with the suction opening, and when the trough is filled, the guarantee is given that the suction opening projects completely into the liquid. A suction of air is thereby prevented.

- the inlet openings of the pump may be in the immediate vicinity of the bottom of a tank or the like, so that the pump according to the invention can be used effectively even at very low liquid level.

- the new submersible pump can be in development of the invention also designed so that the inlet openings for the liquid are well below the level at which the suction port is located. They can also run at the level of the bottom of the tub, which is otherwise parallel to the level of the pump, i. parallel to the installation area at the bottom of the tank.

- the size of the inlet openings of the pump is adjustable. It is then achieved an embodiment that can be switched between a Flachsaugfunktion and a conventional mode of operation as a submersible pump.

- the lateral inlet openings for the liquid to be sucked can be kept very low, for example, only a few millimeters or less than a millimeter protrude above the mounting plane. Due to the then small cross section with a correspondingly higher flow resistance, the delivery rate may indeed be lower than in the conventional mode of operation with a larger inflow cross section and lower flow resistance. Nevertheless, an extraction at extremely low water level is possible.

- an adjustable and / or removable component which may be formed, for example, as a parallel to a vertical pump central axis movable component, preferably as a housing ring. But it is also possible to adjust the size of the inlet openings by feet, which are arranged outside the pump housing in position adjustable.

- the embodiment of the invention allows the suction even at very shallow water levels with after a start-up phase high suction.

- the start-up phase can advantageously be shortened or avoided if the pan provided according to the invention is filled from the outside, for example against the direction of pump flow, before being put into operation through the pump chamber.

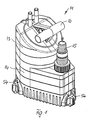

- the pump housing 12 consists essentially of an upper housing part 13, a lower housing part 14 and an outlet nozzle 15.

- the pump housing 12 may be made of plastic, but also of other materials.

- the upper housing part 13 is provided with a handle 16, which facilitates handling of the submersible pump 11. It is also possible to provide the pump with a float (not shown) to use the pump in the usual way at high water levels, which exceed the height of the pump.

- the upper housing part 13 is connected to the lower housing part 14 via screws 17. However, it is also possible to make the connection in other ways. Between the upper housing part 13 and lower housing part 14, a sealing ring 18 is provided. The slightly wider than the upper housing part 13 designed housing lower part 14 is provided with an adjacent to the upper housing part outlet nozzle 15 which is also connected via a further seal 18a to the lower housing part.

- the pump chamber 20 is closed down to a base 21 of the submersible pump 11 through a base plate 22.

- a conveyor 24 which sucks the liquid provided with the reference numeral 55 and presses in the direction of the outlet 15.

- the conveyor 24 is in the embodiment of a driven by an electric motor 25 wheel of a centrifugal pump or a turbine.

- the centrifugal impeller shown in the embodiment is driven by the motor 25 arranged at the transition from the upper housing part 13 to the lower housing part 14.

- the power supply of the motor 25, which is expediently an electric motor, can be done from outside via cable connections, which in Fig. 1 are indicated schematically next to the handle 16.

- the motor 25 has on its base plate 22 side facing a short drive shaft 26 to which the impeller 27 of the pump is attached.

- this impeller 27 has a plurality of arcuately curved guide vanes 56, through which the liquid in a known manner in a finger-shaped in cross section from the pump chamber 20 pressure chamber 28 is transported. From there, the liquid enters the outlet nozzle 15 and is removed there.

- a substantially circular suction port 29 In the base plate 22 is a substantially circular suction port 29.

- the central axis of this intake coincides with the pump axis 39 together.

- the suction opening 29 opens into a well arranged below the base plate 22 trough.

- a filter 35 In front of the suction opening 29 is in the embodiment, a filter 35, which is used for filtering mud, dirt or the like, which may be located in the liquid to be sucked.

- the trough 30 encloses the part of the base plate 22, which substantially receives the impeller 27.

- the tub 30 consists of a tub bottom 32 and a substantially up to an upper edge 34 extending vertically upwardly extending peripheral side wall 31.

- the upper edge 34 is preferably at a higher level than the impeller 27.

- the tub volume, the down from the tub bottom 32 and is limited to the outside of the side wall 31 is provided with the reference numeral 33.

- the upper edge 34 of the side wall 31 is higher than the base plate 22 and higher than the suction port 29.

- the tub if the pump is to be used for suction at very low liquid levels - which is explained in more detail below - are filled before startup from the outside through the outlet nozzle 15 via the pump chamber 20 with liquid, so that from the beginning of operation even the full suction power is available, regardless of how high the liquid level to be extracted is.

- the submersible pump 11 has inlet openings 36, via which the sucked liquid passes into the pump interior.

- the inlet openings 36 are located depending on the embodiment at different points of the pump housing, as with reference to the other Fig. 4 to 7 will be described later.

- the inlet openings 36 are formed by a gap which between the lower edge of the housing lower part 13 - for reasons of mounting capability for the impeller is provided in two parts with a bottom attached bottom part, which surrounds the trough 30 - and a bottom surface 43 is formed, on which the submersible pump 11 is placed.

- the pump is provided in the embodiment with three height-adjustable feet 54, which can be rotatably arranged for faster adjustment for predetermined gap heights and thus can stand up with different peripheral areas on the bottom surface 43.

- the inlet openings 36 in the illustrated embodiment therefore the gap, form the inlet for at least one flow channel 37, via which the sucked liquid flows into the trough 30.

- Liquid first passes into an ascending section 38, which is delimited outwardly from the housing lower part and inwardly from the side wall 31 of the tub.

- the flow channel then continues in one of the Fig. 1 to 3 not particularly recognizable portion that leads across the top edge 34 of the side wall 31 away and then the liquid in the direction of the arrow 41 between base plate 22 and side wall 31 open into the tub volume 33.

- the base 21 of the submersible pump 11 is formed by the previously mentioned feet 54. These are each formed as independent of the pump housing component and height adjustable attached thereto.

- the feet 54 themselves are asymmetrical and rotatably mounted on a pin 50 projecting from the pump housing 12. By rotating the feet 54, the height of the underside of the submersible pump 11 can be adjusted over the bottom surface 43 due to their asymmetry. It is therefore a gap 46 adjustable in height, depending on whether the pump is set in their function "flat suction" or in their function "dive operation".

- the submersible pump 11 has a substantially flattened pear-shaped cross-section.

- a plurality of substantially vertically extending channels 37 which have been previously mentioned, are arranged at approximately regular intervals, the outwardly into associated inlet openings lead.

- the feet 54 are arranged in the manner of a tripod on the pump housing.

- the submersible pump 11 has a circumferential housing foot 42, which distributed over the circumference has a plurality of bearing surfaces and between these recesses as inlet openings for the liquid to be sucked.

- the support surfaces define the level 21 of the submersible pump 11, with which it rests on a liquid-covered bottom surface 43.

- the submersible pump 11 can also stand with the tub bottom 32 on the bottom surface 43.

- the housing foot 42 forms the lower edge of the ascending portion 38 of the flow channel 37 limiting outer wall 44.

- a housing ring 45 is arranged vertically adjustable, for example by rotation and guidance in a slot-like groove, and is held on the outer wall 44.

- the housing ring 45 is shown in the illustration Fig.

- the gap can, as already mentioned, have a height of only a few millimeters or optionally also below.

- the housing ring 45 for example by rotation, in the in the Fig. 4B shifted shown upper position 45 (H), so there is a relation to the gap after Fig. 4A much larger inlet opening, which corresponds to the openings in the housing foot 42.

- the housing ring 45 is sealed with respect to the outer wall 44 via a sealing ring 48, so that also in the Flachsaug ein after Fig. 4A no air flow between the outer wall 44 and the housing ring 45 which impairs the intake behavior can occur.

- a cup-shaped or annular foot insert 47 is attached to the outer wall 44 delimiting the ascending section 38 of the inflow channel and can be removed without tools, preferably with little use of force.

- This foot insert 47 for example, with a web or with projections in an annular groove of the outer wall 44 engage.

- the foot insert 47 has by the shape of its side facing the bottom surface 48 or by its relative vertical position to a housing foot on its outer periphery a small gap 46 as an inlet for liquid to be sucked on.

- the foot insert 47 is sealed by a sealing ring 49 against an air side stream between the side wall of the foot insert 47 and outer wall 44.

- the submersible pump 11 with its trough bottom 32 on the bottom surface 43 and the gap 46 between the bottom surface 43 and the lower edge of the outer wall 44 now forms the inlet opening for a Flachabsaugung.

- the pump can also rise with the lower edge of the outer wall 44 as a housing foot 42 on the bottom surface 43, wherein then recesses or openings on the circumference form the inlet openings for the Flachabsaugung.

- Fig. 6A shows a housing ring 51 are fitted from below, the openings 52 between the webs, which stand up on the bottom surface 53, which are substantially larger compared to the aforementioned gap.

- an extension of the inflow opening for example, by attaching or otherwise securing individual spacer elements, by vertical displacement, in particular turning a ring running in a slanted guide or by adjusting, in particular pivoting of permanently connected to the pump housing or its outer wall 44 spacers be achieved, which were supported instead of the housing ring 51 on the bottom surface.

- FIGS. 6A and 6B corresponds, shown.

- the spacers 53 are in Fig. 7B for the Flachsaugfunktion up and in Fig. 7A pivoted downwards for the usual submersible pump function.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

Description

Die Erfindung betrifft eine Tauchpumpe mit einer Pumpenkammer, einer innerhalb derselben angeordneten Fördereinrichtung und mindestens einer Ansaugöffnung, die mit einem der Pumpenkammer in Strömungsrichtung vorgelagerten Sammelraum in Form einer Wanne in Verbindung steht.The invention relates to a submersible pump having a pump chamber, a conveyor disposed within the same and at least one suction port, which communicates with one of the pump chamber upstream in the flow direction collecting space in the form of a trough.

Tauchpumpen dieser Art sind aus der

Pumpen dieser Bauart eignen sich nicht zur Absaugung bei sehr niedrigem Flüssigkeitspegel.Pumps of this type are not suitable for suction at very low liquid level.

Andere Pumpen, wie sie in der Art einer Kreiselpumpe aus der

Beide eben beschriebenen bekannten Bauarten unterliegen bei niedrigen Pegelständen der Gefahr, dass Luft angesaugt wird und dadurch die Leistungsfähigkeit der Pumpe beeinträchtigt ist.Both known types described above are at low water levels the risk that air is sucked in and thereby the performance of the pump is impaired.

Es ist die Aufgabe der vorliegenden Erfindung, eine Tauchpumpe der eingangs erwähnten Art zu schaffen, die insbesondere für Absaugung bei sehr niedrigem Flüssigkeitspegel geeignet ist. Ein unbeabsichtigtes Ansaugen von Luft und eine Verschmutzung soll nach Möglichkeit zusätzlich verhindert werden. Zur Lösung dieser Aufgabe wird eine Tauchpumpe der eingangs genannten Art vorgesehen, bei der die Wanne eine umlaufende Seitenwand mit einer Oberkante aufweist, die auf einem höheren Pegel als die Ansaugöffnung liegt und dass mindestens ein Strömungskanal vorgesehen ist, der zu mindestens einer außerhalb der Seitenwand und im Abstand unterhalb von deren Oberkante liegenden Eintrittsöffnung führt.It is the object of the present invention to provide a submersible pump of the type mentioned, which is particularly suitable for extraction at very low liquid level. An inadvertent intake of air and pollution should be additionally prevented if possible. To achieve this object, a submersible pump of the aforementioned type is provided, wherein the trough has a circumferential side wall with an upper edge, which is at a higher level than the suction port and that at least one flow channel is provided, the at least one outside of the side wall and at a distance below the upper edge lying inlet opening leads.

Durch diese Ausgestaltung umgibt die Wanne eine den Pumpenraum nach unten abschließende und mit der Ansaugöffnung versehene Grundplatte vollständig und bei gefüllter Wanne ist die Gewähr dafür gegeben, dass die Ansaugöffnung vollständig in Flüssigkeit hineinragt. Ein Ansaugen von Luft wird dadurch verhindert. Dennoch können die Eintrittsöffnungen der Pumpe im unmittelbaren Bereich des Bodens eines Tanks oder dergleichen liegen, so dass die erfindungsgemäße Pumpe auch bei sehr niedrigem Flüssigkeitspegel wirksam eingesetzt werden kann.As a result of this embodiment, the trough surrounds a base plate which terminates the pump chamber at the bottom and is provided with the suction opening, and when the trough is filled, the guarantee is given that the suction opening projects completely into the liquid. A suction of air is thereby prevented. Nevertheless, the inlet openings of the pump may be in the immediate vicinity of the bottom of a tank or the like, so that the pump according to the invention can be used effectively even at very low liquid level.

Die neue Tauchpumpe lässt sich in Weiterbildung der Erfindung auch so ausgestalten, dass die Eintrittsöffnungen für die Flüssigkeit auch deutlich unterhalb des Pegels liegen, auf dem die Ansaugöffnung liegt. Sie können auch in Höhe des Bodens der Wanne verlaufen, der im übrigen parallel zur Standebene der Pumpe, d.h. parallel zum Aufstellbereich am Tankboden ist.The new submersible pump can be in development of the invention also designed so that the inlet openings for the liquid are well below the level at which the suction port is located. They can also run at the level of the bottom of the tub, which is otherwise parallel to the level of the pump, i. parallel to the installation area at the bottom of the tank.

In vorteilhafter Weiterbildung der Erfindung kann vorgesehen werden, dass die Größe der Eintrittsöffnungen der Pumpe einstellbar ist. Es wird dann eine Ausführungsform erreicht, die zwischen einer Flachsaugfunktion und einer herkömmlichen Betriebsweise als Tauchpumpe umstellbar ist. In der Flachsaugfunktion können die seitlichen Einströmöffnungen für die abzusaugende Flüssigkeit sehr niedrig gehalten werden, beispielsweise nur wenige Millimeter oder auch weniger als ein Millimeter über die Aufstellebene ragen. Durch den dann geringen Querschnitt mit entsprechend höherem Strömungswiderstand kann die Förderleistung zwar geringer sein als bei der herkömmlichen Betriebsweise mit größerem Einströmquerschnitt und geringerem Strömungswiderstand. Dennoch ist eine Absaugung bei extrem niedrigen Pegelstand möglich.In an advantageous embodiment of the invention can be provided that the size of the inlet openings of the pump is adjustable. It is then achieved an embodiment that can be switched between a Flachsaugfunktion and a conventional mode of operation as a submersible pump. In the Flachsaugfunktion the lateral inlet openings for the liquid to be sucked can be kept very low, for example, only a few millimeters or less than a millimeter protrude above the mounting plane. Due to the then small cross section with a correspondingly higher flow resistance, the delivery rate may indeed be lower than in the conventional mode of operation with a larger inflow cross section and lower flow resistance. Nevertheless, an extraction at extremely low water level is possible.

In Weiterbildung der Erfindung kann zur Querschnittsverstellung der Eintrittsöffnungen ein verstellbares und/oder abnehmbares Bauelement vorgesehen sein, das beispielsweise als ein parallel zu einer vertikalen Pumpenmittelachse bewegliches Bauelement, vorzugsweise als ein Gehäusering ausgebildet sein kann. Möglich ist es aber auch, die Größe der Einströmöffnungen durch Standfüße einzustellen, die außen am Pumpengehäuse in ihrer Lage verstellbar angeordnet sind.In a further development of the invention may be provided for the cross-sectional adjustment of the inlet openings an adjustable and / or removable component, which may be formed, for example, as a parallel to a vertical pump central axis movable component, preferably as a housing ring. But it is also possible to adjust the size of the inlet openings by feet, which are arranged outside the pump housing in position adjustable.

Die Ausgestaltung nach der Erfindung ermöglicht die Absaugung auch bei sehr flachen Pegelständen mit nach einer Anlaufphase hoher Saugkraft. Die Anlaufphase kann dabei vorteilhaft verkürzt oder vermieden werden, wenn die nach der Erfindung vorgesehene Wanne von außen beispielsweise entgegen der Pumpströmungsrichtung vor der Inbetriebnahme durch den Pumpenraum hindurch gefüllt wird. Durch den dann in der Wanne entstehenden hohen Pegelstand gegenüber dem üblicherweise vorgesehenen Kreiselpumpenlaufrad wird eine hohe Saugleistung sofort erreicht, die bei einer nicht vorgefüllten Wanne unter Umständen verzögert einsetzt, bis sich in der Wanne ausreichend Flüssigkeit angesammelt hat.The embodiment of the invention allows the suction even at very shallow water levels with after a start-up phase high suction. The start-up phase can advantageously be shortened or avoided if the pan provided according to the invention is filled from the outside, for example against the direction of pump flow, before being put into operation through the pump chamber. By then resulting in the tub high level compared to the usually provided Kreiselpumpenlaufrad a high suction power is achieved immediately, the at If the tub is not prefilled, it may be delayed until sufficient fluid has collected in the tub.

Die Erfindung ist anhand von Ausführungsbeispielen in der Zeichnung dargestellt und wird im folgenden näher erläutert. Es zeigen:

- Fig. 1

- eine perspektivische Darstellung eines ersten Ausführungsbei- spiels einer erfindungsgemäßen Tauchpumpe,

- Fig. 2

- den Längsschnitt durch das Ausführungsbeispiel nach

Fig. 1 , - Fig. 3

- einen Querschnitt längs der Schnittlinie III-III, durch das in

Fig. 2 dargestellte Ausführungsbeispiel, - Fig. 4A und 4B

- jeweils einen Längsschnitt durch ein zweites Ausfüh- rungsbeispiel einer Tauchpumpe nach der Erfindung, wobei die linke und die rechte Zeichnungshälfte jeweils unterschiedliche Be- triebseinstellungen zeigt,

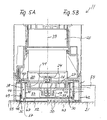

- Fig. 5A und 5B

- jeweils Längsschnitte durch ein drittes Ausführungsbeispiel ebenfalls in unterschiedlichen Betriebseinstellungen,

- Fig. 6A und 6B

- Längsschnitte durch ein viertes Ausführungsbeispiel eben- falls in unterschiedlicher Betriebseinstellung und die

- Fig. 7A und 7B

- ein weiteres Ausführungsbeispiel einer erfindungsgemä- ßen Tauchpumpe in unterschiedlichen Betriebseinstellungen.

- Fig. 1

- 1 is a perspective view of a first embodiment of a submersible pump according to the invention,

- Fig. 2

- the longitudinal section through the embodiment according to

Fig. 1 . - Fig. 3

- a cross section along the section line III-III, through the in

Fig. 2 illustrated embodiment, - FIGS. 4A and 4B

- 2 shows a longitudinal section through a second exemplary embodiment of a submersible pump according to the invention, the left and the right half of the drawing each showing different operating settings,

- Figs. 5A and 5B

- each longitudinal sections through a third embodiment also in different operating settings,

- FIGS. 6A and 6B

- Longitudinal sections through a fourth embodiment also in different operating settings and the

- Figs. 7A and 7B

- a further embodiment of an inventive submersible submersible pump in different operating settings.

Wie aus den

Das Gehäuseoberteil 13 ist mit einem Handgriff 16 versehen, der eine Handhabung der Tauchpumpe 11 erleichtert. Möglich ist es auch, die Pumpe mit einem Schwimmer (nicht dargestellt) zu versehen, um die Pumpe in der üblichen Weise bei hohen Pegelständen, welche die Höhe der Pumpe übersteigen, einzusetzen.The

Das Gehäuseoberteil 13 ist mit dem Gehäuseunterteil 14 über Schrauben 17 verbunden. Es ist jedoch auch möglich, die Verbindung auf andere Weise herzustellen. Zwischen Gehäuseoberteil 13 und Gehäuseunterteil 14 ist ein Dichtungsring 18 vorgesehen. Das etwas breiter als das Gehäuseoberteil 13 gestaltete Gehäuseunterteil 14 ist mit einem benachbart zum Gehäuseoberteil liegenden Austrittsstutzen 15 versehen, der ebenfalls über eine weitere Dichtung 18a mit dem Gehäuseunterteil verbunden ist.The

Im unteren Teil des Gehäuseoberteils 13 sowie im Gehäuseunterteil 14 befinden sich Räume, die gemeinsam die Pumpenkammer 20 bzw. den Saug- und Druckraum der Tauchpumpe 11 definieren. Die Pumpenkammer 20 wird nach unten zu einer Standfläche 21 der Tauchpumpe 11 hin durch eine Grundplatte 22 abgeschlossen.In the lower part of the

In der Pumpenkammer 20 befindet sich eine Fördereinrichtung 24, welche die mit dem Bezugszeichen 55 versehene Flüssigkeit ansaugt und in Richtung zum Austritt 15 drückt. Die Fördereinrichtung 24 ist beim Ausführungsbeispiel ein von einem Elektromotor 25 angetriebenes Rad einer Kreiselpumpe bzw. einer Turbine. Das in dem Ausführungsbeispiel dargestellte Kreiselpumpenrad ist von dem am Übergang vom Gehäuseoberteil 13 zum Gehäuseunterteil 14 angeordneten Motor 25 angetrieben. Die Energieversorgung des Motors 25, der zweckmäßig ein Elektromotor ist, kann von außen über Kabelanschlüsse erfolgen, die in

Der Motor 25 besitzt an seiner der Grundplatte 22 zugewandten Seite eine kurze Antriebswelle 26, an der das Laufrad 27 der Pumpe befestigt ist. Wie die

In der Grundplatte 22 befindet sich eine im wesentlichen kreisrunde Ansaugöffnung 29. Die Mittelachse dieser Ansaugöffnung fällt mit der Pumpenachse 39 zusammen. Die Ansaugöffnung 29 mündet in eine unterhalb der Grundplatte 22 angeordnete Wanne. Vor der Ansaugöffnung 29 befindet sich beim Ausführungsbeispiel ein Filter 35, der zur Filtrierung von Schlamm, Schmutzpartikel oder dergleichen dient, die sich in der anzusaugenden Flüssigkeit befinden können.In the

Wie in den

Die Tauchpumpe 11 besitzt Eintrittsöffnungen 36, über die die angesaugte Flüssigkeit in das Pumpeninnere gelangt. Die Eintrittsöffnungen 36 befinden sich je nach Ausführungsform an verschiedenen Stellen des Pumpengehäuses, wie anhand der weiteren

Die Eintrittsöffnungen 36, beim gezeigten Ausführungsbeispiel daher der Spalt, bilden den Eingang für mindestens einen Strömungskanal 37, über den die angesaugte Flüssigkeit in die Wanne 30 fließt. Flüssigkeit gelangt dabei zunächst in einen aufsteigenden Abschnitt 38, der nach außen vom Gehäuseunterteil und nach innen von der Seitenwand 31 der Wanne begrenzt ist. Der Strömungskanal setzt sich dann fort in einem in den

Die Standfläche 21 der Tauchpumpe 11 wird durch die vorher schon erwähnten Standfüße 54 gebildet. Diese sind jeweils als vom Pumpengehäuse unabhängiges Bauteil ausgebildet und höhenverstellbar daran befestigt. Die Standfüße 54 selbst sind asymmetrisch ausgebildet und an einem vom Pumpengehäuse 12 vorstehenden Zapfen 50 drehbar gelagert. Durch Verdrehen der Standfüße 54 kann infolge deren Asymmetrie die Höhe der Unterseite der Tauchpumpe 11 über der Bodenfläche 43 eingestellt werden. Es ist daher ein Spalt 46 mit unterschiedlicher Höhe einstellbar, je nachdem, ob die Pumpe in ihrer Funktion "Flachsaugen" oder in ihrer Funktion "Tauchbetrieb" eingestellt ist.The

Aus

Bei den in den

Bei der in den

Wird der Gehäusering 45, beispielsweise durch Drehung, in die in der

Bei der in der

Wird, wie in

Bei der Anordnung nach

Anstelle des aufgesteckten Gehäuserings 51 kann eine Erweiterung der Einströmöffnung beispielsweise auch durch Aufstecken oder sonstiges Befestigen von einzelnen Abstandselementen, durch vertikales Verschieben, insbesondere Drehen eines in einer Schrägführung laufenden Rings oder durch Verstellen, insbesondere Verschwenken von dauerhaft mit dem Pumpengehäuse bzw. dessen Außenwand 44 verbundenen Distanzelementen erzielt werden, welche sich anstelle des Gehäuserings 51 an der Bodenfläche abstützten.Instead of the plugged housing ring 51, an extension of the inflow opening, for example, by attaching or otherwise securing individual spacer elements, by vertical displacement, in particular turning a ring running in a slanted guide or by adjusting, in particular pivoting of permanently connected to the pump housing or its

In

Allen Ausführungsformen gemeinsam ist das Merkmal, dass die den Pumpenraum 20 nach unten in Richtung zu einer Standebene anschließende Grundplatte 22, welche die Ansaugöffnung 29 enthält, von einer nach oben offenen Wanne seitlich umgeben ist. Der Wannenboden liegt zwischen Grundplatte und Standebene und die Seitenwand der Wanne erstreckt sich bis zu einer Oberkante, die höher liegt als die Ausgangsöffnung, nach oben von der Standebene weg. Diese Ausgestaltung führt zu den eingangs erwähnten Vorteilen der Erfindung.Common to all embodiments is the feature that the base of the

Claims (12)

- Submersible pump (11) comprising a pump chamber (20), a feed device (24) arranged in said pump chamber, and at least one suction opening (29) communicating with a collecting space configured as a pan (30) located upstream of the pump chamber (20) when viewed in the direction of flow, characterized in that the pan (30) has an all-round lateral wall (31) with an upper edge (34) located at a higher level than the suction opening (29), and that at least one flow channel (37) is provided, said channel leading to at least one inlet opening (36) located outside the lateral wall (31) and at a distance below said wall's upper edge (34).

- Submersible pump in accordance with Claim 1, characterized in that the upper edge (34) of the lateral wall (31) is on a higher level than an impeller (27) of the feed device.

- Submersible pump in accordance with Claim 1, characterized in that the inlet opening (36) is on a lower level than the suction opening (29).

- Submersible pump in accordance with Claim 1 or 3, characterized in that the inlet opening (36) is configured at the height of the level of a pan bottom (32).

- Submersible pump in accordance with one of the previous Claims, characterized in that several inlet openings (35) are arranged around the pan bottom (32), in particular at regular intervals.

- Submersible pump in accordance with one of the previous Claims, characterized in that the size of the inlet opening (36) is adjustable.

- Submersible pump in accordance with Claim 6, characterized in that the height of the inlet opening (36) can be adjusted above a standing plane (21) of the submersible pump (11).

- Submersible pump in accordance with Claim 7, characterized in that the height adjustment is achieved by means of at least one adjustable and/or removable component.

- Submersible pump in accordance with Claim 8, characterized in that a component, preferably a housing ring (45), is provided so as to be movable relative to the pump housing (12), in particular parallel to a vertical central axis (39) of the pump.

- Submersible pump in accordance with Claim 8, characterized in that support feet (54) are provided as the component.

- Submersible pump in accordance with one of the previous Claims, characterized in that the fluid can be filled from the outside into the pump chamber (20) and the pan (30).

- Submersible pump in accordance with one of the previous Claims, characterized in that a pan (30) is provided,(a) said pan having a pan bottom located between a base plate (22) and the standing plane (21) of the submersible pump (11),(b) having a lateral wall (31) forming, with a radially outward spaced wall ring of the pump housing (12), the flow channel (37),- said flow channel having an inlet opening in the area of the standing plane (21),- leading from the standing plane (21) in the upward direction, and- leading over and beyond the upper edge (34) of the lateral wall (31) and then, between the lateral wall (31) of the pan (30) and the pump chamber (20), in the downward direction into the pan,(c) where the upper edge (34) of the lateral wall is at a higher level than the base plate (22).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10044966 | 2000-09-11 | ||

| DE10044966A DE10044966B4 (en) | 2000-09-11 | 2000-09-11 | submersible pump |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1186782A1 EP1186782A1 (en) | 2002-03-13 |

| EP1186782B1 true EP1186782B1 (en) | 2008-12-31 |

Family

ID=7655867

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01119411A Expired - Lifetime EP1186782B1 (en) | 2000-09-11 | 2001-08-11 | Submersible pump |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1186782B1 (en) |

| AT (1) | ATE419466T1 (en) |

| DE (2) | DE10044966B4 (en) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB0215559D0 (en) * | 2002-07-05 | 2002-08-14 | Mitchell Harry | Improvements in and relating to pumps |

| DE102005031420B4 (en) * | 2005-07-04 | 2010-07-08 | Al-Ko Kober Ag | Combined immersion / flat suction rotary pump with concentric impeller inlet opening |

| FR2922609B1 (en) * | 2007-10-18 | 2010-02-19 | Exel Ind | SUBMERSIBLE PUMP |

| FR2924769B1 (en) * | 2007-12-07 | 2010-01-08 | Gatech | HYDRAULIC PUMP COMPRISING A PRE FILTER BODY HAVING TWO ROTATING ORIENTABLE PARTS. |

| EP2698544A1 (en) | 2012-08-15 | 2014-02-19 | Dipra | Submerged pump, resting on a ground, with adjustable suction height |

| PL2740940T3 (en) | 2012-12-04 | 2020-07-13 | Einhell Germany Ag | Immersion pump |

| CN103062120B (en) * | 2013-02-07 | 2015-04-29 | 江苏科技大学 | Sea water pump with elastic body impeller |

| CN104454649A (en) * | 2014-10-24 | 2015-03-25 | 成都安迪生测量有限公司 | Large-work-flow LNG immersed pump |

| CN107044427A (en) * | 2017-05-23 | 2017-08-15 | 苏州优德通力科技有限公司 | A kind of amphibious pump of block-resistant type ultra low water level land diving |

| DE202018103708U1 (en) | 2018-06-28 | 2018-08-09 | T.I.P. Technische Industrie-Produkte Gmbh | submersible pump |

| EP3875767A1 (en) * | 2020-03-02 | 2021-09-08 | Husqvarna Ab | Foot for a pump |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1020237B (en) * | 1954-07-10 | 1957-11-28 | Friedrich Achenbach Dr Ing | Suction basket, especially for emptying fuel containers, tankers and the like. like |

| DE8210587U1 (en) * | 1982-04-15 | 1982-08-05 | Licentia Patent-Verwaltungs-Gmbh, 6000 Frankfurt | CENTRIFUGAL PUMP, IN PARTICULAR FLAT SUCTION DIVE OR DRAINAGE PUMP |

| DE3718325C2 (en) * | 1987-03-16 | 1989-01-19 | Lutz Fa Karl | DRUM PUMP |

| US4934914A (en) * | 1987-07-30 | 1990-06-19 | Ebara Corporation | Portable motor pump |

| US5055000A (en) * | 1989-08-11 | 1991-10-08 | Wayne/Scott Fetzer Company | Enclosed pump motor and housing thereof |

| JPH03175195A (en) * | 1989-09-26 | 1991-07-30 | Ebara Corp | Submerged pump |

| US5181841A (en) * | 1990-08-10 | 1993-01-26 | Wayne/Scott Fetzer Company | Sewage pump |

| US5205725A (en) * | 1991-07-16 | 1993-04-27 | Wayne/Scott Fetzer Company | Top suction sump pump having bottom suction impeller |

| EP0717195B1 (en) * | 1992-04-14 | 2000-11-08 | Ebara Corporation | Pump casing made of sheet metal |

-

2000

- 2000-09-11 DE DE10044966A patent/DE10044966B4/en not_active Expired - Fee Related

-

2001

- 2001-08-11 DE DE50114610T patent/DE50114610D1/en not_active Expired - Lifetime

- 2001-08-11 EP EP01119411A patent/EP1186782B1/en not_active Expired - Lifetime

- 2001-08-11 AT AT01119411T patent/ATE419466T1/en active

Also Published As

| Publication number | Publication date |

|---|---|

| ATE419466T1 (en) | 2009-01-15 |

| DE10044966A1 (en) | 2002-03-21 |

| DE50114610D1 (en) | 2009-02-12 |

| EP1186782A1 (en) | 2002-03-13 |

| DE10044966B4 (en) | 2004-07-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69005510T2 (en) | Pump to separate gas from a liquid to be pumped. | |

| DE102005031420B4 (en) | Combined immersion / flat suction rotary pump with concentric impeller inlet opening | |

| DE19781894B4 (en) | Self-priming centrifugal pump | |

| DE4102323C2 (en) | Fuel pump | |

| DE10327574B4 (en) | Impeller for a fuel pump | |

| DE2423707C3 (en) | Pump unit for the fuel supply system of a gas turbine engine | |

| EP1186782B1 (en) | Submersible pump | |

| DE2130474B2 (en) | centrifugal pump | |

| DE8613923U1 (en) | Evaporative humidifier | |

| DE10334762B4 (en) | Centrifuge for separating particulate matter from a fluid | |

| WO2009022019A1 (en) | Pump rotor and pump comprising a pump rotor of said type | |

| DE4428633A1 (en) | Fuel pump for supplying fuel to a vehicle engine | |

| DE69900972T2 (en) | drain pump | |

| DE4338931C2 (en) | Non-clogging centrifugal pump | |

| DE29514402U1 (en) | Device for improving the suction behavior of flow pumps | |

| DE3519816C2 (en) | Impeller for pumps | |

| DE69106779T2 (en) | Single-stage centrifugal pump with a peripheral-axial diffuser. | |

| DE4039712A1 (en) | CIRCUMFERENTIAL RIVER LIQUID PUMP | |

| DE69119765T2 (en) | PUMP WITH SPIRAL SHOVELS | |

| DE19804907C1 (en) | Rotary fluid pump | |

| DE2903277A1 (en) | SCREW PUMP, ESPECIALLY FOR CONVEYING WASTE WATER AND THE LIKE | |

| DE4239071A1 (en) | Submersible pump unit | |

| DE19834012C2 (en) | Centrifugal pump with mechanical seal | |

| DE2409576C2 (en) | Vertical centrifugal submersible pump | |

| EP0995906A1 (en) | Motor-driven double pump of the centrifugal type |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20020816 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: GARDENA MANUFACTURING GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: SUBMERSIBLE PUMP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50114610 Country of ref document: DE Date of ref document: 20090212 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090411 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090601 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20090612 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081231 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081231 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20091001 |

|

| BERE | Be: lapsed |

Owner name: GARDENA MANUFACTURING G.M.B.H. Effective date: 20090831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090831 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090811 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090831 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090811 |

|

| EUG | Se: european patent has lapsed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090811 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100812 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: HUSQVARNA AB, SE Effective date: 20140407 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: SD Effective date: 20140512 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 50114610 Country of ref document: DE Owner name: HUSQVARNA AB, SE Free format text: FORMER OWNER: GARDENA MANUFACTURING GMBH, 89079 ULM, DE Effective date: 20140627 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081231 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: PC Ref document number: 419466 Country of ref document: AT Kind code of ref document: T Owner name: HUSQVARNA AB, SE Effective date: 20140916 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20170623 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20170717 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20170609 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180716 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20180901 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 419466 Country of ref document: AT Kind code of ref document: T Effective date: 20180811 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180811 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180831 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50114610 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200303 |