EP0805520A2 - Card edge connector - Google Patents

Card edge connector Download PDFInfo

- Publication number

- EP0805520A2 EP0805520A2 EP97102560A EP97102560A EP0805520A2 EP 0805520 A2 EP0805520 A2 EP 0805520A2 EP 97102560 A EP97102560 A EP 97102560A EP 97102560 A EP97102560 A EP 97102560A EP 0805520 A2 EP0805520 A2 EP 0805520A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- legs

- contact strip

- insulating body

- bearing section

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/50—Fixed connections

- H01R12/51—Fixed connections for rigid printed circuits or like structures

- H01R12/52—Fixed connections for rigid printed circuits or like structures connecting to other rigid printed circuits or like structures

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/71—Coupling devices for rigid printing circuits or like structures

- H01R12/712—Coupling devices for rigid printing circuits or like structures co-operating with the surface of the printed circuit or with a coupling device exclusively provided on the surface of the printed circuit

- H01R12/714—Coupling devices for rigid printing circuits or like structures co-operating with the surface of the printed circuit or with a coupling device exclusively provided on the surface of the printed circuit with contacts abutting directly the printed circuit; Button contacts therefore provided on the printed circuit

Definitions

- the invention relates to a contact strip for printed circuit boards arranged in sandwich construction, with an insulating body and a number of contact elements arranged therein at grid spacing x, each of which has a bearing section for fixing it in the insulating body and two to be contacted with the mutually facing conductor tracks of the printed circuit boards Has contact leg.

- the invention is based on a contact strip, which is not documented in more detail, and which has an insulating body which is held in the lower of the two printed circuit boards with plug pins.

- the contact piece has a C-like shape in the broadest sense in the side view. The apex of the upper C-curvature rests under the upper circuit board, while the leg emerging from the bottom of the housing represents a soldering foot for SMT ('Surface Mounting Technique).

- SMT Surface Mounting Technique

- the object of the invention is to provide a contact strip of the type outlined in the preamble of claim 1, in which the contact elements can be introduced into the insulating body in a relatively simple manner and are held therein.

- Another object of the invention is to design the contact elements of the contact strip in such a way that, despite considerable miniaturization of the arrangement, in particular up to grid spacings of only about 0.5 mm, they ensure the necessary contact spring forces of the contact legs over long operating times.

- the present invention is characterized in that the bearing section is designed as a tongue which can be inserted into an insulating housing slot and points in the same direction as the contact legs and is arranged between them.

- the contact element For the secure reception and fixing of the contact element in the insulating body, only the insulating body slot is provided there. This can be co-generated in the injection molding production of the insulating body for the contact strip.

- a tongue is formed between the contact legs and can be inserted into the insulating body slot.

- the contact element which thus essentially has an E-shape in the side view, from the side in the longitudinal direction of the forwardly pointing bearing section into the corresponding receptacle of the insulating body.

- taped contact elements are supplied to the insulating body and all poles are simultaneously attached to the insulating body at least in a pre-fixed manner.

- a particularly advantageous further embodiment consists in that the bearing section is arranged laterally by a grid spacing x next to the plane defined by the contact legs. This configuration makes it possible to cut out the two contact legs and the tongue-like bearing section from a flat material and to deform them into the specific spatial shape.

- the contact legs which also have a tongue shape, and the bearing section start from a central one Area of the contact body and all extend in the same direction, but the bearing portion is adjacent to the plane that is defined by the contact legs lying in the same plane.

- the feature according to the invention of the arrangement of the bearing section by a grid spacing x to the side next to the contact limbs leads, in connection with a further embodiment, which is characterized by the arrangement of the contact elements in the insulating body in opposite directions from pole to pole, in that the bearing section of a contact element at one location in the insulating body anchored can be located in the plane of the contact leg of the immediately adjacent contact element.

- the contact strip can also be designed such that at least one of the two contact legs of the contact elements is designed as SMT solder pins, with which the entire contact strip would be anchored to the conductor tracks of one circuit board by soldering the solder pins, whereas the second circuit board to the opposite one resilient contact leg of the contact elements would be pressed.

- a contact strip can also be used without soldering contact legs by simply being placed between two mutually parallel printed circuit boards and being held there essentially purely by pressure.

- flanking alignment means in order to always, e.g. under the influence of vibrations, to safely avoid that the relative position of the contact elements to the conductor tracks could involuntarily change.

- the alignment means can also serve as spacers for the printed circuit boards by e.g. in the form of strips or frames, are attached to the side of the contact strip or surround it and hold the circuit boards connected to one another by clamping or fastening means at an exact distance.

- the contact elements are held with their tongues self-anchoring in the insulator body slots, for which purpose these tongues e.g. may have barbed or claw-like edge notches.

- the insulating body is preferably designed as a one-piece injection molded part.

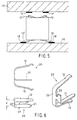

- FIGS. 1 and 5 only the outline of the insulating body 11 and the mutually opposite sides of the insulating body 11 projecting beyond the outline of contact legs 12, 13 and 12 ', 13' are shown in FIGS. 1 and 5.

- These contact legs are under an outwardly directed spring tension, so that they engage between two circuit boards 15 and 16 arranged parallel at a distance 14 in a force-fitting or pressure-locking manner on their associated conductor tracks 17 and 18.

- the two printed circuit boards 15 and 16 which in the functional state have, for example, a clear distance of only 3 mm or less, are held in parallel in a sandwich-like manner by means not shown.

- spacers 19 are shown schematically, due to their tightly flanking the contact strip 10 as a support body, ensure that the contact strip, which is only held in a pressure-locking manner via its contact elements 12, 13, 12 ', 13' between the plates, reliably maintains its intended position with respect to the conductor tracks.

- the contact legs designated by 12 and 13 in FIG. 4 belong to a different contact element than those designated by 12 'and 13'. This is easy to understand on the basis of the illustration in FIG. 6.

- the view shows that a contact element 20 essentially has the shape of the letter E.

- the two outer legs of the E are the contact legs 12 and 13.

- a third, rectilinear leg as the bearing section 21.

- This bearing section 21 is punched out of the same flat sheet of contact metal, in particular beryllium bronze, and is only bent over, as are the contact legs 12 and 13.

- the bearing section 21 is connected to the material strip 23 via a short transition section 22 connected, from which the two legs 12 and 13 are punched out and deformed.

- the bearing section 21 comes into a plane that lies laterally next to the plane of the contact legs 12 and 13, namely by a distance x that corresponds to the grid or pole distance of the contact strip.

- the insulating body 11 is an injection molded component made of a very dimensionally stable material that has practically no shrinkage.

- the insulator has a number of thin webs 24 which are integrally connected to one another by means of core sections 25 which are smaller in outline.

- core sections 25 which are smaller in outline.

- two such core sections 25 lie close together to form a slot 26.

- This slot 26 is thus an insulating body slot into which a contact element 20 with its bearing section 21 is inserted from one of the two possible sides and then held firmly therein.

- this bearing section 21 is located laterally next to the contact sections 12, 13 of the same contact element 20. Consequently, in FIG. 4, the contact element with 20 'arranged in the same plane as the bearing section 21 of the contact element 20 and its contact leg with 12' and 13 ' designated.

- This contact element 20 ' is inserted with its bearing section, which is not visible in FIG. 4, from the other side into the adjacent insertion space.

- This comb-like intermeshing of bearing sections 21 of one contact element 20 between the contact legs 12 'and 13' of the respectively adjacent contact element 20 ' enables a very high packing density or number of poles per unit length to be achieved.

- the contact strip 10 which is shown in FIG. 5, differs from the previously described contact strip 10 essentially only with regard to its contact legs 13 or 13 ', which emerge downwards in the drawing and which are designed as SMT soldering feet aligned parallel to the conductor track 18 are. 5, the upper circuit board 15 is still shown at a distance. In the operational state, however, it is so close to the lower circuit board 16 that the contact legs 12 and 12 'of the relevant contact elements 20 and 20' bear on the conductor tracks 17 under their own spring pressure.

- the tongue-shaped bearing sections 21 are each self-anchored in the insulating body slots 26.

- the tongues 21 have edge edge formations 27 of approximately the type recognizable in FIG. 6, which can claw into the plastic material of the insulating body 10.

- an alternative is also within the scope of the invention, which in turn uses the basic E-shape in the view of a contact element 20, but in which, for example by folding, the bearing section 21 would lie in the same plane as the contact legs 12 and 13 4 shows that it would then also be possible to anchor a contact element in an insulating body slot 26 with its central bearing section. In this case could, should however, the contact elements cannot be connected to the insulating body 11 from different sides.

- contact legs 12 and 13 project freely, because only the central tongue is held on the insulating body. This ensures excellent spring properties and contact forces.

- the contact strip 10 can be made in very small dimensions, for example with grid spacing x of approximately 0.5 mm and for a printed circuit board spacing 14 of less than 3 mm.

Landscapes

- Coupling Device And Connection With Printed Circuit (AREA)

- Multi-Conductor Connections (AREA)

Abstract

Bei einer Kontaktleiste für in Sandwich-Bauweise angeordnete Leiterplatten mit einem Isolierkörper und einer Anzahl von im Rasterabstand x darin angeordneten Kontaktelementen, von denen jedes einen Lagerabschnitt zu seiner Fixierung im Isolierkörper sowie zwei mit den zueinander weisenden Leiterbahnen der Leiterplatten zu kontaktierende Kontaktschenkel aufweist, ist der Lagerabschnitt als in einen Isoliergehäuseschlitz einsetzbare, in dieselbe Richtung wie die Kontaktschenkel weisende sowie zwischen ihnen angeordnete Zunge ausgebildet. Bei einer bevorzugten Ausführung ist der Lagerabschnitt um einen Rasterabstand x seitlich neben der von den Kontaktschenkeln definierten Ebene angeordnet. Wenn dabei die Kontaktelemente von Pol zu Pol gegensinnig im Isolierkörper angeordnet werden, liegen der Lagerabschnitt eines Kontaktelements in derselben Ebene wie die Kontakschenkel des benachbarten Kontaktelements, wodurch sich eine hohe Kontaktdichte bzw. Polzahl erreichen läßt. <IMAGE>In the case of a contact strip for printed circuit boards arranged in sandwich construction with an insulating body and a number of contact elements arranged therein at grid spacing x, each of which has a bearing section for fixing it in the insulating body and two contact legs to be contacted with the mutually facing conductor tracks of the printed circuit boards Bearing section designed as insertable into an insulating housing slot, pointing in the same direction as the contact legs and arranged between them. In a preferred embodiment, the bearing section is arranged laterally by a grid spacing x next to the plane defined by the contact legs. If the contact elements are arranged from pole to pole in opposite directions in the insulating body, the bearing section of a contact element lies in the same plane as the contact limbs of the adjacent contact element, as a result of which a high contact density or number of poles can be achieved. <IMAGE>

Description

Die Erfindung bezieht sich auf eine Kontaktleiste für in Sandwich-Bauweise angeordnete Leiterplatten, mit einem Isolierkörper und einer Anzahl von im Rasterabstand x darin angeordneten Kontaktelementen, von denen jedes einen Lagerabschnitt zu seiner Fixierung im Isolierkörper sowie zwei mit den zueinander weisenden Leiterbahnen der Leiterplatten zu kontaktierende Kontaktschenkel aufweist.The invention relates to a contact strip for printed circuit boards arranged in sandwich construction, with an insulating body and a number of contact elements arranged therein at grid spacing x, each of which has a bearing section for fixing it in the insulating body and two to be contacted with the mutually facing conductor tracks of the printed circuit boards Has contact leg.

Die Erfindung geht aus von einer nicht näher dokumentierten Kontaktleiste, die einen Isolierkörper aufweist, der mit Steckzapfen in der unteren der beiden Leiterplatten gehalten ist. Das Kontaktstück weist in der Seitenansicht eine im weitesten Sinne C-artige Formgebung auf. Der Scheitel der oberen C-Wölbung legt sich federnd unter die obere Leiterplatte, während der unten aus dem Gehäuse tretende Schenkel ein Lötfüßchen für SMT ('Surface Mounting Technique) darstellt. Zwischen den, im Sinne der vorliegenden Erfindung "Kontaktschenkel" genannten Kontaktabschnitten ist ein nicht näher definierter weiterer Abschnitt vorhanden, der auch der Fixierung des Kontaktelements im Isolierkörper dient und in der Terminologie der vorliegenden Anmeldung "Lagerabschnitt" genannt wird.The invention is based on a contact strip, which is not documented in more detail, and which has an insulating body which is held in the lower of the two printed circuit boards with plug pins. The contact piece has a C-like shape in the broadest sense in the side view. The apex of the upper C-curvature rests under the upper circuit board, while the leg emerging from the bottom of the housing represents a soldering foot for SMT ('Surface Mounting Technique). Between the contact sections called "contact legs" in the sense of the present invention, there is a further section, not defined in more detail, which also serves to fix the contact element in the insulating body and is called "bearing section" in the terminology of the present application.

In welcher Art und Weise die Kontaktelemente in den Isolierkörper eingebracht werden ist ebenso wenig bekannt wie die konkreten Maßnahmen, die die Fixierung des Kontaktelementes im Isolierkörper gewährleisten.The manner in which the contact elements are introduced into the insulating body is as little known as the specific measures which ensure that the contact element is fixed in the insulating body.

Aufgabe der Erfindung ist es, eine Kontaktleiste der im Oberbegriff des Anspruchs 1 näher umrissenen Art anzugeben, bei der die Kontaktelemente auf relativ einfache Art und Weise sicher in den Isolierkörper eingebracht werden können und darin festgehalten sind. Ein weiteres Ziel der Erfindung besteht darin, die Kontaktelemente der Kontaktleiste so auszubilden, daß sie trotz erheblicher Miniaturisierung der Anordnung, insbesondere bis zu Rasterabständen von nur ca. 0,5 mm die erforderlichen Andruckfederkräfte der Kontaktschenkel über lange Betriebszeiten sichergestellt.The object of the invention is to provide a contact strip of the type outlined in the preamble of claim 1, in which the contact elements can be introduced into the insulating body in a relatively simple manner and are held therein. Another object of the invention is to design the contact elements of the contact strip in such a way that, despite considerable miniaturization of the arrangement, in particular up to grid spacings of only about 0.5 mm, they ensure the necessary contact spring forces of the contact legs over long operating times.

Gekennzeichnet ist die vorliegende Erfindung dadurch, daß der Lagerabschnitt als in einen Isoliergehäuseschlitz einsteckbare, in dieselbe Richtung wie die Kontaktschenkel weisende sowie zwischen ihnen angeordnete Zunge ausgebildet ist.The present invention is characterized in that the bearing section is designed as a tongue which can be inserted into an insulating housing slot and points in the same direction as the contact legs and is arranged between them.

Zur sicheren Aufnahme und Fixierung des Kontaktelements im Isolierkörper ist lediglich dort der Isolierkörperschlitz vorgesehen. Dieser läßt sich bei der spritzgießtechnischen Herstellung des Isolierkörpers für die Kontaktleiste miterzeugen. An dem im wesentlichen U- bzw. C-förmigen Kontaktelement ist zwischen den Kontaktschenkeln eine Zunge ausgebildet, die in den Isolierkörperschlitz einsteckbar ist. Dadurch ist es im Rahmen einer automatisierten Fertigung möglich, das Kontaktelement, das somit in der Seitenansicht im wesentlichen eine E-Form aufweist, von der Seite her in Längsrichtung des nach vorn weisenden Lagerabschnitts in die entsprechende Aufnahme des Isolierkörpers einzustecken. Üblicherweise wird dies geschehen, indem gegurtete Kontaktelemente dem Isolierkörper zugeführt und alle Pole gleichzeitig zumindest vorfixiert am Isolierkörper angebracht werden.For the secure reception and fixing of the contact element in the insulating body, only the insulating body slot is provided there. This can be co-generated in the injection molding production of the insulating body for the contact strip. On the essentially U-shaped or C-shaped contact element, a tongue is formed between the contact legs and can be inserted into the insulating body slot. As a result, in the context of automated production, it is possible to insert the contact element, which thus essentially has an E-shape in the side view, from the side in the longitudinal direction of the forwardly pointing bearing section into the corresponding receptacle of the insulating body. Usually this will be done by taped contact elements are supplied to the insulating body and all poles are simultaneously attached to the insulating body at least in a pre-fixed manner.

Eine besonders vorteilhafte weitere Ausgestaltung besteht darin, daß der Lagerabschnitt um einen Rasterabstand x seitlich neben der von den Kontaktschenkeln definierten Ebene angeordnet ist. Durch diese Ausgestaltung ist es möglich, die beiden Kontaktschenkel und den zungenartigen Lagerabschnitt aus einem flachen Material freizuschneiden und in die konkrete Raumform hinein zu verformen.A particularly advantageous further embodiment consists in that the bearing section is arranged laterally by a grid spacing x next to the plane defined by the contact legs. This configuration makes it possible to cut out the two contact legs and the tongue-like bearing section from a flat material and to deform them into the specific spatial shape.

Bei dieser Ausführungsform, bei der das Kontaktelement in der Seitenansicht im wesentlichen wiederum eine E-Form aufweist, deren äußere Schenkel von den Kontaktschenkeln und deren zentraler Schenkel von der Zunge ausgebildet sind, gehen die, ebenfalls Zungenform aufweisenden, Kontaktschenkel und der Lagerabschnitt von einem zentralen Bereich des Kontaktkörpers aus und erstrecken sich alle in dieselbe Richtung, wobei der Lagerabschnitt jedoch neben derjenigen Ebene liegt, die von den der in derselben Ebene liegenden Kontaktschenkeln definiert wird.In this embodiment, in which the side view of the contact element essentially again has an E-shape, the outer legs of which are formed by the contact legs and the central leg of which is formed by the tongue, the contact legs, which also have a tongue shape, and the bearing section start from a central one Area of the contact body and all extend in the same direction, but the bearing portion is adjacent to the plane that is defined by the contact legs lying in the same plane.

Das erfindungsgemäße Merkmal der Anordnung des Lagerabschnitts um einen Rasterabstand x seitlich neben den Kontaktschenkeln führt in Verbindung mit einer weiteren Ausgestaltung, die gekennzeichnet ist durch von Pol zu Pol gegenläufige Anordnung der Kontaktelemente im Isolierkörper, dazu, daß der Lagerabschnitt eines Kontaktelements an einer Stelle im Isolierkörper verankert werden kann, die sich in der Ebene der Kontaktschenkel des unmittelbar benachbarten Kontaktelements befindet. Durch die Nebeneinanderanordnung von Lagerabschnitt und Kontaktschenkel an demselben Kontaktelement einerseits und durch die von Pol zu Pol wechselweise Bestückung des Isolierkörpers aus einander gegenüberliegenden seitlichen Richtungen wird ein sehr enger Kontaktabstand bzw. eine hohe Polzahl/laufende Verbinderlänge erzielt.The feature according to the invention of the arrangement of the bearing section by a grid spacing x to the side next to the contact limbs leads, in connection with a further embodiment, which is characterized by the arrangement of the contact elements in the insulating body in opposite directions from pole to pole, in that the bearing section of a contact element at one location in the insulating body anchored can be located in the plane of the contact leg of the immediately adjacent contact element. The side-by-side arrangement of the bearing section and contact leg on the same contact element on the one hand, and the fact that the insulator is alternately fitted from pole to pole from opposite lateral directions, a very close contact distance or a high number of poles / running connector length is achieved.

Bei der Serienherstellung würde man einem Isolierkörper jeweils von den beiden einander gegenüberliegenden Seiten die Kontaktelemente gegurtet zuführen, wobei jeweils nur jede zweite Isolier-Kammer von den Kontaktelementen des einen Gurtes bestückt wird, die jeweils dazwischen liegenden von den Kontaktelemente des von der anderen Seite herangeführten Gurtes.In series production, one would feed an insulating body with the contact elements strapped from each of the two opposite sides, only every second insulating chamber being equipped with the contact elements of the one belt, the intermediate between the contact elements of the belt coming from the other side .

Die Kontaktleiste kann so ferner so ausgebildet sein, daß zumindest einer der beiden Kontaktschenkel der Kontaktelemente als SMT-Lötbeinchen ausgebildet ist, womit die gesamte Kontaktleiste durch Verlöten der Lötbeinchen auf den Leiterbahnen der einen Leiterplatte an dieser verankert wäre, wohingegen die zweite Leiterplatte an die gegenüberliegenden federnden Kontaktschenkel der Kontaktelemente angedrückt würde.The contact strip can also be designed such that at least one of the two contact legs of the contact elements is designed as SMT solder pins, with which the entire contact strip would be anchored to the conductor tracks of one circuit board by soldering the solder pins, whereas the second circuit board to the opposite one resilient contact leg of the contact elements would be pressed.

Eine Kontaktleiste läßt sich allerdings auch ohne Lötanschluß von Kontaktschenkeln verwenden, indem sie einfach zwischen zwei zueinander parallelen Leiterplatten gesetzt wird und dort im wesentlichen rein druckschlüssig gehalten ist.However, a contact strip can also be used without soldering contact legs by simply being placed between two mutually parallel printed circuit boards and being held there essentially purely by pressure.

In einem solchen Fall ist es sinnvoll, die Kontaktleiste durch flankierende Ausrichtmittel zu den Leiterbahnen auszurichten, um stets, z.B. unter Einfluß von Erschütterungen, sicher zu vermeiden, daß sich die Relativlage der Kontaktelemente zu den Leiterbahnen unwillentlich verändern könnte.In such a case, it makes sense to align the contact strip with the conductor tracks using flanking alignment means in order to always, e.g. under the influence of vibrations, to safely avoid that the relative position of the contact elements to the conductor tracks could involuntarily change.

Die Ausrichtmittel können zugleich als Abstandshalter für die Leiterplatten dienen, indem sie, z.B. in Form von Leisten oder Rähmchen, seitlich neben der Kontaktleiste angebracht sind bzw. diese umgeben und die durch Spann- oder Befestigungsmittel miteinander verbundenen Leiterplatten auf exakte Distanz halten.The alignment means can also serve as spacers for the printed circuit boards by e.g. in the form of strips or frames, are attached to the side of the contact strip or surround it and hold the circuit boards connected to one another by clamping or fastening means at an exact distance.

Die Kontaktelemente sind, was im Bereich der Verbindertechnik grundsätzlich bekannt ist, mit ihren Zungen selbstverankernd in den Isolierkörperschlitzen gehalten, wozu diese Zungen z.B. widerhaken- oder krallenartige Randausklinkungen aufweisen können.As is generally known in the field of connector technology, the contact elements are held with their tongues self-anchoring in the insulator body slots, for which purpose these tongues e.g. may have barbed or claw-like edge notches.

Der Isolierkörper ist vorzugsweise als einstückiges Spritzgießteil ausgebildet.The insulating body is preferably designed as a one-piece injection molded part.

Die Erfindung wird nachfolgend anhand von in den beiliegenden Zeichnungen dargestellten Ausführungsbeispielen noch näher erläutert. Es zeigen:

- Fig. 1

- eine schematische Stirnansicht einer Anordnung von zwei Leiterplatten und einer dazwischen angeordneten Kontaktleiste,

- Fig. 2

- auf Seitenansicht der Kontaktleiste mit Blick in Richtung des Pfeiles II in Fig. 1,

- Fig. 3

- eine Unteransicht unter die Kontaktleiste,

- Fig. 4

- einen Querschnitt durch die Kontaktleiste der Fig. 3 entsprechend der Schnittangabe IV-IV,

- Fig. 5

- eine der Fig. 1 entsprechende schematische Darstellung einer Kontaktleiste, deren Kontaktelemente an einer Seite als SMT-Lötbeinchen ausgebildet sind und

- Fig. 6

- ein bevorzugtes Kontaktelement im Schaubild, in der Seitenansicht und in der Aufsicht.

- Fig. 1

- 1 shows a schematic end view of an arrangement of two printed circuit boards and a contact strip arranged between them,

- Fig. 2

- side view of the contact strip with a view in the direction of arrow II in Fig. 1,

- Fig. 3

- a bottom view under the contact bar,

- Fig. 4

- 3 shows a cross section through the contact strip of FIG. 3 in accordance with section IV-IV,

- Fig. 5

- 1 a schematic representation of a contact strip corresponding to FIG. 1, the contact elements of which are formed on one side as SMT solder pins and

- Fig. 6

- a preferred contact element in the diagram, in side view and in top view.

Von der insgesamt mit 10 bezeichneten Kontaktleiste sind in den Fig. 1 und 5 jeweils nur der Umriß des Isolierkörpers 11 sowie die aneinander gegenüberliegenden Seiten des Isolierkörpers 11 über den Umriß hervorstehende Kontaktschenkel 12, 13 bzw. 12', 13' dargestellt. Diese Kontaktschenkel stehen unter nach auswärts gerichteter Federspannung, so daß sie sich zwischen zwei im Abstand 14 parallel angeordnete Leiterplatten 15 und 16 kraft- bzw. druckschlüssig an deren zugeordnete Leiterbahnen 17 und 18 anlegen.1 and 5, only the outline of the

Die beiden Leiterplatten 15 und 16, die im Funktionszustand beispielsweise einen lichten Abstand von nur 3 mm oder darunter aufweisen, sind mit nicht dargestellten Mitteln sandwichartig parallel gehalten. In Fig. 1 sind schematisch noch Abstandshalter 19 dargestellt, die aufgrund ihrer die Kontaktleiste 10 als Stützkörper dicht flankierenden Zuordnung dafür sorgen, daß die lediglich druckschlüssig über ihre Kontaktelemente 12, 13, 12', 13' zwischen den Platten eingespannt gehaltene Kontaktleiste ihre bestimmungsgemäße Lage zu den Leiterbahnen zuverlässig beibehält.The two printed

Die in Fig. 4 mit 12 und 13 bezeichneten Kontaktschenkel gehören zu einem anderen Kontaktelement als die mit 12' und 13' bezeichneten. Dies ist leicht nachvollziehbar anhand der Darstellung der Fig. 6. Danach nämlich besitzt in der Ansicht ein Kontaktelement 20 im wesentlichen die Form des Buchstabens E. Die beiden äußeren Schenkel des E sind die Kontaktschenkel 12 und 13. Zwischen diesen beiden Schenkeln 12 und 13 befindet sich ein dritter, gleichgerichteter Schenkel als Lagerabschnitt 21. Dieser Lagerabschnitt 21 ist aus dem gleichen flächigen Blech aus Kontaktmetall, insbesondere Berylliumbronce, ausgestanzt und lediglich umgebogen, ebenso die Kontaktschenkel 12 und 13. Der Lagerabschnitt 21 ist über einen kurzen Übergangsabschnitt 22 mit dem Materialstreifen 23 verbunden, aus dem die beiden Schenkel 12 und 13 ausgestanzt und verformt sind.The contact legs designated by 12 and 13 in FIG. 4 belong to a different contact element than those designated by 12 'and 13'. This is easy to understand on the basis of the illustration in FIG. 6. After that, the view shows that a

Somit gelangt der Lagerabschnitt 21 in eine Ebene, die seitlich neben der Ebene der Kontaktschenkel 12 und 13 liegt, und zwar um einen Abstand x, der dem Raster- oder Polabstand der Kontaktleiste entspricht.Thus, the

Der Isolierkörper 11 ist ein Spritzgießbauteil aus einem sehr formbeständigen Werkstoff, der praktisch keine Schwindung aufweist. Der Isolierkörper besitzt eine Anzahl von dünnen Stegen 24, die über im Umriß kleinere Kernabschnitte 25 stoffschlüssig miteinander verbunden sind. Beim Ausführungsbeispiel liegen zwei solcher Kernabschnitte 25 unter Bildung eines Schlitzes 26 dicht beieinander. Dieser Schlitz 26 ist also ein Isolierkörperschlitz, in den ein Kontaktelement 20 mit seinem Lagerabschnitt 21 von einer der beiden möglichen Seiten her eingeschoben und sodann fest darin gehalten wird.The

Wie ausgeführt, liegt dieser Lagerabschnitt 21 seitlich neben den Kontaktabschnitten 12, 13 desselben Kontaktelements 20. Folgerichtig ist in Fig. 4 zur Unterscheidung das in derselben Ebene wie der Lagerabschnitt 21 des Kontaktelementes 20 angeordnete Kontaktelement mit 20' und dessen Kontaktschenkel mit 12' und 13' bezeichnet. Dieses Kontaktelement 20' wird mit seinem in Fig. 4 nicht sichtbaren Lagerabschnitt von der anderen Seite her in den benachbarten Einschubraum eingeschoben. Durch dieses kammartige Ineinandergreifen von Lagerabschnitten 21 jeweils eines Kontaktelements 20 zwischen die Kontaktschenkel 12' und 13' des jeweils benachbarten Kontaktelements 20' läßt sich eine sehr hohe Packungsdichte bzw. Polzahl pro Längeneinheit erzielen.As stated, this

Die Kontaktleiste 10, die in Fig. 5 dargestellt ist, unterscheidet sich von der bisher beschriebenen Kontaktleiste 10 im wesentlichen nur hinsichtlich seiner in der Zeichnung nach unten austretenden Kontaktschenkel 13 bzw. 13', die als flächenparallel zur Leiterbahn 18 ausgerichtete SMT-Lötfüßchen ausgebildet sind. In dieser Fig. 5 ist die obere Leiterplatte 15 noch mit Abstand dargestellt. Im betriebsgemäßen Zustand ist sie der unteren Leiterplatte 16 jedoch soweit angenähert, daß sich die Kontaktschenkel 12 und 12' der diesbezüglichen Kontaktelemente 20 und 20' unter Eigenfederdruck an den Leiterbahnen 17 anlegen.The

Die zungenförmigen Lagerabschnitte 21 sind jeweils selbstverankernd in den Isolierkörperschlitzen 26 gehalten. Dazu weisen die Zungen 21 Randkantenausformungen 27 etwa der in Fig. 6 erkennbaren Art auf, die sich in den Kunststoffwerkstoff des Isolierkörpers 10 einkrallen können.The tongue-shaped

Wichtig für die Erfindung ist die E-Konfiguration eines Kontaktelements 20. Für den Fall der im einzelnen beschriebenen Nebeneinander-Anordnung von Kontaktschenkeln 12, 13 einerseits und Lagerabschnitt 21 andererseits ist es für die Erfindung des weiteren wichtig, daß die Kontaktelemente von Pol zu Pol in gegenläufiger Anordnung dem Isolierkörper 11 zugeordnet sind und ihm entsprechend zugeführt werden.Important for the invention is the E-configuration of a

Im Rahmen der Erfindung liegt jedoch durchaus auch eine Alternative, die zwar wiederum die grundsätzliche E-Form in der Ansicht auf ein Kontaktorgan 20 benutzt, bei der jedoch, z.B. durch Umfaltung, der Lagerabschnitt 21 in derselben Ebene liegen würde wie die Kontaktschenkel 12 und 13. Ein Blick auf Fig. 4 zeigt, daß es auch dann möglich wäre, ein Kontaktelement in einem Isolierkörperschlitz 26 mit seinem zentralen Lagerabschnitt zu verankern. In diesem Falle könnten, müßten jedoch nicht, die Kontaktelemente abwechselnd von verschiedenen Seiten mit dem Isolierkörper 11 verbunden sein.However, an alternative is also within the scope of the invention, which in turn uses the basic E-shape in the view of a

Wesentlich ist auch, daß die Kontaktschenkel 12 und 13 weit frei vorragen, weil ja nur die zentrale Zunge am Isolierkörper gehalten ist. Dadurch werden hervorragende Federeigenschaften und Kontaktkräfte gewährleistet.It is also essential that the

Die Kontaktleiste 10 kann in sehr kleinen Dimensionen ausgeführt werden, beispielsweise mit Rasterabständen x von ca. 0,5 mm und für einen Leiterplattenabstand 14 von unter 3 mm.The

Claims (10)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19617121A DE19617121C1 (en) | 1996-04-29 | 1996-04-29 | Terminal strip for circuit board assembly |

| DE19617121 | 1996-04-29 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0805520A2 true EP0805520A2 (en) | 1997-11-05 |

| EP0805520A3 EP0805520A3 (en) | 1999-01-13 |

| EP0805520B1 EP0805520B1 (en) | 2006-10-18 |

Family

ID=7792796

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97102560A Expired - Lifetime EP0805520B1 (en) | 1996-04-29 | 1997-02-18 | Card edge connector |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5951303A (en) |

| EP (1) | EP0805520B1 (en) |

| JP (1) | JP3742937B2 (en) |

| DE (2) | DE19617121C1 (en) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0903810A3 (en) * | 1997-09-18 | 2000-03-29 | The Whitaker Corporation | Connector for adjacent circuit-bearing substrates |

| US6758702B2 (en) | 2000-02-24 | 2004-07-06 | Fci Americas Technology, Inc. | Electrical connector with compression contacts |

| US6488513B1 (en) | 2001-12-13 | 2002-12-03 | Intercon Systems, Inc. | Interposer assembly for soldered electrical connections |

| SG104969A1 (en) * | 2002-05-24 | 2004-07-30 | Fci Asia Technology Pte Ltd | An electrical connector |

| JP4427274B2 (en) * | 2003-05-28 | 2010-03-03 | 佐鳥エス・テック株式会社 | Power tool switch |

| US6921270B2 (en) | 2003-06-11 | 2005-07-26 | Cinch Connectors, Inc. | Electrical connector |

| US7455556B2 (en) * | 2003-06-11 | 2008-11-25 | Cinch Connectors, Inc. | Electrical contact |

| US7625216B2 (en) * | 2003-06-11 | 2009-12-01 | Cinch Connectors, Inc. | Electrical connector |

| US7435105B2 (en) * | 2004-03-29 | 2008-10-14 | Finisar Corporation | Electrical connector for use in an optical transceiver module |

| JP6821522B2 (en) * | 2017-06-27 | 2021-01-27 | モレックス エルエルシー | socket |

| CN211605463U (en) * | 2020-01-07 | 2020-09-29 | 番禺得意精密电子工业有限公司 | Electrical connector |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4699593A (en) * | 1986-01-14 | 1987-10-13 | Amp Incorporated | Connector having contact modules for a substrate such as an IC chip carrier |

| GB2251138A (en) * | 1990-12-17 | 1992-06-24 | Amp Inc | Planar circuit connector |

| US5358411A (en) * | 1993-08-09 | 1994-10-25 | The Whitaker Corporation | Duplex plated epsilon compliant beam contact and interposer |

| US5484295A (en) * | 1994-04-01 | 1996-01-16 | Teledyne Electronic Technologies | Low profile compression electrical connector |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5125846A (en) * | 1991-07-25 | 1992-06-30 | Molex Incorporated | Input-output electrical connector |

| US5199884A (en) * | 1991-12-02 | 1993-04-06 | Amp Incorporated | Blind mating miniature connector |

| KR950033507A (en) * | 1994-02-08 | 1995-12-26 | 오가 노리오 | IC measurement test apparatus and IC measurement test method using the same |

-

1996

- 1996-04-29 DE DE19617121A patent/DE19617121C1/en not_active Expired - Fee Related

-

1997

- 1997-02-18 EP EP97102560A patent/EP0805520B1/en not_active Expired - Lifetime

- 1997-02-18 DE DE59712749T patent/DE59712749D1/en not_active Expired - Fee Related

- 1997-04-10 JP JP12616297A patent/JP3742937B2/en not_active Expired - Fee Related

- 1997-04-28 US US08/847,846 patent/US5951303A/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4699593A (en) * | 1986-01-14 | 1987-10-13 | Amp Incorporated | Connector having contact modules for a substrate such as an IC chip carrier |

| GB2251138A (en) * | 1990-12-17 | 1992-06-24 | Amp Inc | Planar circuit connector |

| US5358411A (en) * | 1993-08-09 | 1994-10-25 | The Whitaker Corporation | Duplex plated epsilon compliant beam contact and interposer |

| US5484295A (en) * | 1994-04-01 | 1996-01-16 | Teledyne Electronic Technologies | Low profile compression electrical connector |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59712749D1 (en) | 2006-11-30 |

| JP3742937B2 (en) | 2006-02-08 |

| DE19617121C1 (en) | 1997-07-24 |

| JPH1050432A (en) | 1998-02-20 |

| US5951303A (en) | 1999-09-14 |

| EP0805520B1 (en) | 2006-10-18 |

| EP0805520A3 (en) | 1999-01-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69419406T2 (en) | ELECTRICAL CONNECTOR FOR CONNECTING AN ELECTRONIC MEMORY CARD | |

| DE3522708C2 (en) | ||

| DE1790342A1 (en) | SPRING CONTACT PART | |

| DE10006530A1 (en) | Antenna spring | |

| DE2234961C3 (en) | Process for the production of connectors for circuit boards | |

| DE2204924A1 (en) | Electrical connector assembly | |

| DE2460704A1 (en) | ELECTRIC CONTACT | |

| DE4243076A1 (en) | Kotaktiereinrichtung for a chip card | |

| DE3590369C2 (en) | ||

| EP0805520B1 (en) | Card edge connector | |

| DE19755715A1 (en) | Smart card reader | |

| DE2659645C2 (en) | ||

| EP0129068A1 (en) | Miniaturised electromagnetic relay, and method for its manufacture | |

| DE3447135A1 (en) | Screwless connecting and joining terminal for electrical leads | |

| DE69119857T2 (en) | Connector device | |

| DE3444844A1 (en) | IC SOCKET | |

| DE69506750T2 (en) | Level circuit board | |

| DE19706636C2 (en) | Electrical connection device for consumers arranged in a row, in particular solenoid valves | |

| DE3855949T2 (en) | Housing for integrated circuits | |

| DE29607758U1 (en) | Contact strip for printed circuit boards | |

| DE19833248C2 (en) | Device for guiding and grounding circuit boards | |

| DE19611422C2 (en) | Connector for the electrical connection of two printed circuit boards | |

| DE29720511U1 (en) | Installation housing for printed circuit boards and electronic components | |

| DE19630859C2 (en) | Terminal block, especially initiator-actuator terminal | |

| DE10306618B4 (en) | Planar contact structure with contact tongues for a variable plug-in position |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FI FR GB IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FI FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19981222 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: LUMBERG CONNECT GMBH & CO. KG |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: H01R 12/22 20060101ALI20060531BHEP Ipc: H01R 12/04 20060101AFI20060531BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FI FR GB IT NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20061018 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 59712749 Country of ref document: DE Date of ref document: 20061130 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20061221 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070719 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20080213 Year of fee payment: 12 Ref country code: SE Payment date: 20080213 Year of fee payment: 12 Ref country code: NL Payment date: 20080229 Year of fee payment: 12 Ref country code: IT Payment date: 20080228 Year of fee payment: 12 Ref country code: GB Payment date: 20080204 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080226 Year of fee payment: 12 Ref country code: DE Payment date: 20080423 Year of fee payment: 12 |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090218 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090218 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20090901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090218 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090302 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090218 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090219 |