EP0740970A2 - Tête de scellage pour un appareil de dilation d'un tube - Google Patents

Tête de scellage pour un appareil de dilation d'un tube Download PDFInfo

- Publication number

- EP0740970A2 EP0740970A2 EP96202318A EP96202318A EP0740970A2 EP 0740970 A2 EP0740970 A2 EP 0740970A2 EP 96202318 A EP96202318 A EP 96202318A EP 96202318 A EP96202318 A EP 96202318A EP 0740970 A2 EP0740970 A2 EP 0740970A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rod

- sleeve

- tube

- ring

- shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000012530 fluid Substances 0.000 claims abstract description 75

- 238000007789 sealing Methods 0.000 claims abstract description 57

- 239000004020 conductor Substances 0.000 claims description 2

- 238000000034 method Methods 0.000 description 16

- 230000006835 compression Effects 0.000 description 6

- 238000007906 compression Methods 0.000 description 6

- 230000006378 damage Effects 0.000 description 6

- 238000012423 maintenance Methods 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 230000013011 mating Effects 0.000 description 4

- 238000006073 displacement reaction Methods 0.000 description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 2

- 230000003252 repetitive effect Effects 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 238000013022 venting Methods 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000013536 elastomeric material Substances 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D26/00—Shaping without cutting otherwise than using rigid devices or tools or yieldable or resilient pads, i.e. applying fluid pressure or magnetic forces

- B21D26/02—Shaping without cutting otherwise than using rigid devices or tools or yieldable or resilient pads, i.e. applying fluid pressure or magnetic forces by applying fluid pressure

- B21D26/033—Deforming tubular bodies

- B21D26/045—Closing or sealing means

Definitions

- the invention is directed to means for filling a tube or similar workpiece with fluid and for pressurizing the fluid within the workpiece.

- tubes or vessels be filled with liquid and then pressurized.

- processes include: expanding tubes within a forming die cavity as described in U.S. Patents 4,567,743 and 4,829,803 to Cudini; expanding a tubular liner to form a composite lined pipe as described in U.S. Patent 3,359,624 to Cours et al; and pressure testing of fabricated pressure vessels.

- processes include the following steps: sealing of the openings of the tube or vessels workpiece; filling of the workpiece with fluid; pressurizing the fluid within the workpiece to achieve the particular desired result such as forming, expanding or pressure testing; depressurizing the fluid; draining the fluid; and removing the sealing means to release the workpiece.

- the invention provides a novel apparatus to fill a tube or like workpiece with fluid which reduces the costs of operation and maintenance, reduces the processing time required, and reduces or eliminates the risks of injury and machinery damage associated with the conventional devices described above.

- the invention provides an apparatus for filling a tube with fluid comprising:

- the invention provides an apparatus for filling a tube with fluid comprising:

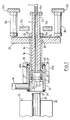

- Figure 1 shows an axial cross-sectional view of one embodiment of the invention with its shaft in a fully withdrawn position and its shroud in a fully retracted position.

- Figure 2 shows a like view with the shroud fully advanced and fluid flowing through the shroud to fill the tube as indicated by the arrow B.

- Figure 3 shows a like view with the shaft fully inserted into the interior of the tube.

- Figure 4 shows a like view with the internal sealing means sealing the interior of the tube and high pressure fluid pressurizing the fluid in the interior of the tube as indicated by the arrow A.

- Figures 5 and 6 show detailed views of the forward end of the shaft and internal sealing means corresponding to Figures 3 and 4 respectively.

- Figure 7 shows an axial cross-sectional view of a third embodiment of the invention with tube sealing means adapted to engage and seal the outer surface of the tube which projects beyond the forming die.

- the invention is applied in a tube forming process wherein a tube 20 is to be filled with liquid through an opening 21.

- the tube 20 is retained between the interior faces of a mating pair of forming die blocks 22. It will be understood that the following description is equally applicable to any process where a workpiece is to be filled and pressurized through such an opening 21.

- a shaft 1 having a longitudinal axis, includes a rod 2 and a sleeve 3 outward of the rod 2.

- the rod 2 has a forwardly open longitudinal bore 4 rearwardly communicating with a fluid source via end cap 5 and high pressure conduit 6 in the particular embodiment shown.

- tube sealing means comprising inner sealing means 7 are provided, adjacent the forward end of the shaft 1, for sealing the interior of the tube 20 when the shaft 1 is inserted into the tube 20.

- Shaft reciprocating means 7 may comprise, as shown, a double acting hydraulic cylinder 8 engaging the rearward end of the shaft 1 and a stationary member 12, and acting in a direction parallel to the axis of the shaft 1.

- the cylinder 8 provides means for advancing and retracting the shaft 7 into engagement with the tube 20 by inserting and withdrawing the forward end of the shaft 1, into and out of the interior of the tube 20 through the opening 21 in the end of the tube 20.

- the inner sealing means 7 includes: a rod ring 9, connected to the forward end of the rod 2, and having a rearward radially extending face; a sleeve ring 10 connected to the forward end of the sleeve 3 and having a forward radially extending face; and an elastomeric ring 11 between the rearward face of the rod ring 9 and the forward face of the sleeve ring 10.

- Displacing means are included in the inner sealing means 7 for axially displacing the rod 2 and sleeve 3 relative to each other thereby axially compressing and decompressing, and radially expanding and contracting the elastomeric ring 11 to engage and disengage the interior of the tube 20.

- the following sequence of operations is carried out.

- the shaft 1 of the device is in a fully withdrawn position and the opening 21 of the tube 20 is aligned with the longitudinal axis of the shaft 1.

- the forward end of the shaft 1 is inserted into the interior of the tube 20 by extending the hydraulic cylinder 8.

- the elastomeric ring 11 has an outer diameter less than the diameter of the rod ring 9 and the sleeve ring 10 whereby its annular sealing surface is nested inwardly between the rod and sleeve rings in order to protect it during insertion and withdrawal.

- the edges of the tube openings 21 often have burrs remaining from cutting operations or may otherwise abrade the annular sealing surface of an exposed elastomeric ring 11 thereby reducing its serviceable life.

- the elastomeric ring 11 is inserted a distance beyond the outer edge of the tube 20 in order to engage a relatively smooth area of the interior wall of the tube 20.

- the outer dimensions of the rod ring 9 may be less than the other dimensions of the sleeve ring 10 and the forward edges of the rod ring 9 may be rounded.

- the displacing means are activated to axially displace the rod 2 and sleeve 3 relative to each other.

- the fluid control means are activated to depressurize and drain the tube 20 of water via the longitudinal bore 4 and high pressure conduit 6.

- the displacing means are then activated to decompress and radially contract the elastomeric ring 11 disengaging it from the interior of the tube 20.

- the hydraulic cylinder 8 withdraws the forward end of the shaft 1 out of engagement with the interior of the tube 20 to the fully retracted position illustrated in Figure 1.

- the displacing means for axially displacing the rod 2 and sleeve 3 relative to each other, comprises sleeve backstop means moving radially inwardly toward the axis of the shaft 1, after the shaft 1 has been inserted into the tube.

- the sleeve backstop means may comprise two oppositely radially movable blocks 13 having a semi-annular inner surface 14 through which the shaft 1 extends.

- the sleeve 3 may include an annular sleeve stop ring 15 protruding outwardly of the rearward end of the sleeve 3.

- the movable blocks 13 are initially positioned radially withdrawn from the shaft 1 in order to allow the shaft 1 to be inserted into the tube 20, as shown in Figures 1 and 2.

- the movable blocks 13 are moved radially inwardly toward the axis of the shaft 1 to engage the rearward end of the sleeve 3 and thereby to prevent rearward movement of the sleeve 3.

- the hydraulic cylinder 8 is activated to rearwardly withdraw the rod 2 to seal the interior of the tube 20.

- rod limiting means may be included for limiting the extent to which the rod 2 may be withdrawn to seal the interior of the tube 20 after the shaft 1 has been inserted into the tube 20 and the movable blocks 13 have engaged the rearward end of the sleeve 3.

- the elastomeric ring 11 is compressed to an inadequate degree leakage may occur. If the elastomeric ring 11 is overcompressed it may fail prematurely due to overstressing or fatigue of the elastomeric material.

- the degree of compression of the elastomeric ring 11 may be accurately predetermined for optimal sealing and operating life.

- the rod limiting means may comprise: a rod abutment protruding from the rod 2 rearward of the sleeve 3; and rod backstop means for moving radially inwardly to engage a rearward face of the rod abutment.

- the rod abutment comprises a rod stop member 16 threadedly and adjustably engaging the rod 2.

- the rod backstop means may comprise two semi-annular interior grooves 17 in the semi-annular inner surface 14 of the movable blocks 13, and the rod stop member 16 may comprise a ring receivable in the grooves 17.

- a rod stop member 16 may include two outwardly knurled nuts engaging a threaded portion of the rod 2 whereby rotating the nuts in opposing directions will lock them at a desired axial position upon the rod 2.

- the movable blocks 13 are moved inwardly simultaneously to engage the rearward end of the sleeve 3 and to receive the rod stop member 16 within the grooves 17.

- both the sleeve 3 and the rod 2 are limited by positive contact to accurately set the extent to which the shaft 1 is inserted into the tube 20.

- a stationary block 25 may slidably support the forward end of the shaft 1 within bearings 25b between the inner sealing means 7 and the sleeve stop ring 15.

- the movable blocks 13 are moved inwardly to engage the rearward end of the sleeve stop ring 15 when the rod 2 is withdrawn.

- the forward surface of the rod stop member 16 is housed within the groove 17 of the movable blocks 13.

- the cylinder 8 is then activated to withdraw the rod 2 to seal the interior of the tube 20.

- the extent to which the rod 2 is withdrawn is limited when the rearward surface of the rod stop member 16 abuts the rearward shoulder of the groove 17.

- a preferred second embodiment of the invention may utilize two fluid circuits namely a high flow-low pressure circuit for filling and draining the workpiece and a low flow-high pressure circuit for pressurizing and depressurizing the fluid within the workpiece.

- a second method of operating the apparatus which utilizes a high flow-low pressure circuit and a low flow-high pressure circuit.

- the high pressure circuit conducts fluid via the high pressure conduit 6, end cap 5 and longitudinal bore 4 as indicated by the arrow A.

- the low pressure circuit conducts fluid through members of relatively larger internal dimensions, namely a low pressure conduit 18 and a shroud 19, into the tube opening 21 as indicated by the arrow B.

- shaft 1 has a forwardly open longitudinal bore 4 rearwardly communicating with a high pressure fluid.

- Inner sealing means 7 are provided adjacent the forward end of the shaft 1 for sealing the interior of the tube 20 when the shaft 1 is inserted into the tube 20.

- a particular preferred embodiment of such inner sealing means 7 has been described above in relation to a first embodiment of the invention, however, it will be understood that various other tube sealing means 7 may be adapted to perform the same function.

- Shaft reciprocating means in the form of a double acting hydraulic cylinder 8, are provided for inserting and withdrawing the forward end of the shaft 1 into and out of the interior of the tube 20.

- the cylinder 8 engages the rearward end of the shaft 1 and a stationary member 12.

- the cylinder 8 acts in a direction parallel to the axis of the shaft 1.

- a forwardly open shroud 19 houses the forward end of the shaft 1 when withdrawn.

- the shroud 19 has a rearward opening slidably engaging the forward end of the shaft 1 rearward of the inner sealing means 7.

- the interior of the shroud 19 communicates with a low pressure fluid source via low pressure conduit 18.

- the shroud 19 performs three functions as illustrated, namely, as a fluid conductor in the low pressure circuit, as a safety guard in the event of failure of the elastomeric ring 11, and as a means to protect the inner sealing means 7 from abrasion or other damage during operation or maintenance of the apparatus.

- FIG. 1 illustrates an application of the invention in association with a tube forming process wherein a tube 20 is retained between the interior faces of forming die blocks 22.

- a rearward external surface 23 of the die blocks 22 is adjacent an end of the tube 20.

- the gaps between the mating surface of the die blocks 22 and the mating surfaces between the tube exterior and the interior faces of the die blocks, are sufficiently narrow such that leakage of fluid under low pressure is insignificant.

- External sealing means such as a gasket ring 24 are provided about the forward end of the shroud 19 for sealing the rearward external surface 23 of the die blocks 22.

- Shroud reciprocating means engage the shroud 19 for advancing and retracting the shroud 19 forward and away from the external surface 23.

- the shaft 1 has a radially outwardly extending abutment surface inwardly of the shroud 19, namely an outward portion of the rearward face of the sleeve ring 10 which extends beyond the outer surface of the sleeve 3.

- the shroud reciprocating means comprises the stationary support 25, and spring means 26 between the stationary support 25 and the shroud 19, for biasing the shroud 19 forwardly toward the external surface 23 of the die blocks 22.

- the following sequence of operations is carried out.

- the shroud 19 is fully retracted away from the external surface 23 of the die blocks 22, and the shaft 1 is fully withdrawn out of the tube's interior.

- the outward rearward surface of the sleeve ring 10 abuts and engages the forward inner surface of the shroud 19 under the biasing action of the spring means 26.

- the cylinder 8 is activated to forwardly move the shaft 1 to an intermediate position, illustrated in Figure 2, prior to insertion of the shaft 1 into the tube 20.

- the cylinder 8 forces the rod 2 forward.

- the rod 2 has an area of enlarged diameter immediately rearward of the sleeve 3 forming a shoulder which abuts the rearward end of the sleeve 3 forcing the sleeve 3 forward.

- the engagement of the elastomeric ring 11 and the sleeve and rod rings 9 and 10 is thereby maintained.

- the gasket ring 24 at the forward end of the shroud 19 seals the external surface 23 as the shroud 19 is biased forwardly under the action of the spring means 26.

- Low pressure fluid control means communicating with a low pressure fluid source are activated to fill the tube 20 with fluid via low pressure conduit 18 and the interior of the shroud 19 as indicated by arrow B. Air from within the tube 20 is vented through means as described above.

- the fluid in the shroud 19 is under a low pressure such that the biasing force of the spring means 26 maintains the gasket ring 24 sufficiently compressed to retain an adequate fluid seal.

- An O-ring seal 27 is provided between the rearward opening of the shroud 19 and the outer surface of the shaft 1 to prevent rearward low pressure fluid leakage.

- the shaft 1 When filling of the tube 20 with low pressure fluid is substantially completed, the shaft 1 is inserted into the tube 20, as illustrated in Figure 2 and the inner sealing means 7 seals the interior of the tube 20, as illustrated in Figure 4 and as described fully above.

- high pressure fluid means communicating with a high pressure fluid source are activated to further fill and pressurize the tube 20 as indicated by arrow A, via high pressure conduit 6, end cap 5 and longitudinal bore 4.

- the high pressure fluid control means are activated to depressurize the tube 20.

- the inner sealing means 7 are disengaged from the interior of the tube 20 and the shaft 1 is partially withdrawn to the intermediate position shown in Figure 2.

- the low pressure fluid control means are activated to drain the fluid from the tube 20 in a direction opposite to arrow B, and air is allowed to reenter the tube 20 via the opened venting means.

- the cylinder 8 is activated to fully withdraw the shaft 1 to the position illustrated in Figure 1.

- the rearward surface of the sleeve ring 10 engages and retracts the shroud 19 against the action of the spring means 26 as the shaft 1 is withdrawn away from the tube 20.

- the elastomeric seal 11 and the gasket ring 24 are the components of the apparatus most susceptible to wear and damage, they are designed to be easily accessible for rapid replacement during maintenance.

- the rod ring 9 is internally threaded upon the forward end of the rod 2 and the elastomeric ring 11 and sleeve ring 10 slip over the rod 2.

- the elastomeric ring 11 is easily replaced by simply removing the rod ring 9.

- a sliding key 28 is provided engaging the rod 2 and sleeve 3 in order to prevent rotational displacement of the sleeve 3 relative to the rod 2 during removal of the rod ring 9. Such rotational displacement may induce torsional stresses in the elastomeric ring 11 reducing its serviceable life.

- the gasket ring 24 has an L-shaped cross section in order to flexibly engage a mating gasket groove in the forward end of the shroud 19, likewise for rapid replacement.

- the apparatus may be rapidly adapted to accommodate a range of tube opening 21 sizes by simply changing the rod ring 9, elastomeric ring and sleeve ring 10 to the desired size.

- the area of the exterior face 23 enveloped by the shroud 19 and gasket ring 24 may be increased by simply installing shrouds 19 of larger size to accommodate tubes 20 having larger openings 21.

- a second embodiment of the invention is illustrated wherein the tube sealing means are adapted to engage and seal the outer surface of the tube 20.

- the tube 20 projects beyond the die face 23 providing an outer surface available for sealing.

- the tube sealing means comprise outer sealing means adjacent the forward end of the shaft la for sealing the exterior of the tube 20.

- the sleeve ring 9a is forward of the rod ring 7a.

- the rod ring 7a is connected to the forward end of the rod 2a and has a forward radially extending face.

- the sleeve ring 9a is connected to the forward end of the sleeve 3a and has a rearward radially extending face.

- the elastomeric ring 11a is positioned between the forward face of the rod ring 7a and the rearward face of the sleeve ring 9a.

- displacing means are provided to axially displace the rod 2a and sleeve 3a thereby radially expanding and contracting the elastomeric ring 11a to engage and disengage the exterior of the tube 20.

- the shroud 19 and the low pressure - high flow circuit operates identically as described above and therefore will not be described in detail in association with the third embodiment.

- the stationary support 25a illustrated in Figure 7 differs slightly from the stationary support 25 in the other drawings in that the shroud is housed in and protected by the stationary support 25a when fully retracted.

- the displacing means shown in Figure 7 differ significantly from that of the first and second embodiments.

- the displacing means comprise rod backstop means, comprising two oppositely radially movable blocks 13a, which move inwardly toward the longitudinal axis after the shaft la has been advanced into engagement with the exterior of the tube 20.

- the rod backstop blocks 13a engage the rearward end of the rod 2a to prevent rearward movement of the rod 2a as the shaft reciprocating means rearwardly withdraws the sleeve 3a to seal the exterior of the tube 20.

- the rearward end of the rod 2a includes an annular rod stop ring 16a protruding outwardly of the rod 2a to engage the rod backstop blocks 13a.

- the sleeve limiting means comprises a sleeve backstop ring 15a protruding from the rod 2a rearward of the sleeve 3a and forward of the rod stop ring 16a.

- the sleeve backstop ring 15a is threaded upon the rod 2a in order to adjust its position thereby determining the degree of compression.

- the shroud 19 and shaft 1a are fully retracted.

- the forward end of the sleeve 3a within the shroud 19 is of enlarged diameter forming a shoulder 28a which abuts and engages the forward inner surface of the shroud 19 under the biasing action of the springs 26.

- the shaft reciprocating means comprise two double acting hydraulic cylinders 8a and 8b each engaging a beam 29.

- the beam 29 is centrally connected to the rearward end of the sleeve 3a by fasteners 30.

- the cylinders 8a and 8b are mounted on stationary members 12a and 12b, and act in a direction parallel to the longitudinal axis of the apparatus.

- the cylinders 8a and 8b are activated to move the shaft 1 forwardly to an intermediate position prior to engagement of the outer tube sealing means.

- the cylinders 8a and 8b force the sleeve 3a forward.

- the sleeve 3a has a forward inner shoulder 31 which abuts the rearward end of the rod ring 7a forcing the rod 2a forward.

- the elastomeric ring 11a is therefore not subjected to any tensile or compressive force as a result.

- the shaft 1 When filling of the tube 20 with low pressure fluid is substantially completed, the shaft 1 is fully advanced such that the outer tube sealing means is positioned about the rearward end of the tube 20.

- the rod stop ring 16a is as a result advanced forward of the rod backstop blocks 13a.

- the rod backstop blocks 13a are moved radially inwardly to engage the rearward face of the rod stop ring 16a and to prevent to the rod 2a from moving rearwardly.

- the cylinders 8a and 8b are activated to retract the sleeve 3a rearwardly.

- the elastomeric ring 11a is compressed between the rearward face of the sleeve ring 9a and the forward face of the rod ring 7a such that the elastomeric ring 11a radially expands sealing the exterior surface of the tube.

- the retraction of the sleeve 3a is limited when the rearward end of the sleeve 3a abuts the forward face of the sleeve backstop ring 15a which is positioned upon the stationary rod 2a.

- the gap 32 between the rearward end of the sleeve 3a and sleeve backstop ring 15a therefore determines the degree of compression of the elastomeric ring 11a.

- the high pressure fluid means are then activated to further fill and pressurize the tube 20 as described above. Upon completion of the pressurization process the above sequence of operations is reversed in a manner which need not be fully described in light of the above detailed description.

- the elastomeric ring 11a is of larger inner dimension than the sleeve and rod rings 9a and 7a and is nested inwardly between the rod and sleeve rings 7a and 9a to protect it during operation from cutting or abrading on the tube's rearward end.

- the inner dimensions of the sleeve ring 9a are preferably greater than the inner dimensions of the rod ring 7a, and the inner forward edges of the sleeve ring 9a are rounded.

Landscapes

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Pipe Accessories (AREA)

- Joints With Sleeves (AREA)

- Heating, Cooling, Or Curing Plastics Or The Like In General (AREA)

- Coating With Molten Metal (AREA)

- Sealing Devices (AREA)

- Percussion Or Vibration Massage (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP92303228A EP0564732B1 (fr) | 1992-04-10 | 1992-04-10 | Tête de scellage pour un appareil de dilation d'un tube |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92303228.8 Division | 1992-04-10 | ||

| EP92303228A Division EP0564732B1 (fr) | 1992-04-10 | 1992-04-10 | Tête de scellage pour un appareil de dilation d'un tube |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0740970A2 true EP0740970A2 (fr) | 1996-11-06 |

| EP0740970A3 EP0740970A3 (fr) | 1998-01-14 |

| EP0740970B1 EP0740970B1 (fr) | 2000-06-07 |

Family

ID=8211325

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92303228A Expired - Lifetime EP0564732B1 (fr) | 1992-04-10 | 1992-04-10 | Tête de scellage pour un appareil de dilation d'un tube |

| EP96202318A Expired - Lifetime EP0740970B1 (fr) | 1992-04-10 | 1992-04-10 | Tête de scellage pour un appareil de dilation d'un tube |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92303228A Expired - Lifetime EP0564732B1 (fr) | 1992-04-10 | 1992-04-10 | Tête de scellage pour un appareil de dilation d'un tube |

Country Status (7)

| Country | Link |

|---|---|

| EP (2) | EP0564732B1 (fr) |

| AT (2) | ATE193665T1 (fr) |

| DE (2) | DE69218176T2 (fr) |

| DK (2) | DK0740970T3 (fr) |

| ES (2) | ES2099210T3 (fr) |

| GR (2) | GR3023466T3 (fr) |

| PT (1) | PT740970E (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU2006220389B2 (en) * | 2000-09-18 | 2009-05-28 | Rothmans, Benson & Hedges Inc. | Low sidestream smoke cigarette with combustible paper |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5445002A (en) * | 1993-08-16 | 1995-08-29 | Ti Corporate Services Limited | Fill and pressurization apparatus |

| US5709116A (en) * | 1996-02-29 | 1998-01-20 | General Electric Company | Hydraulic crimper and bolt assembly |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2299434A (en) * | 1941-05-05 | 1942-10-20 | Svirsky Bennett | Plumber's pipe testing device |

| US2837810A (en) * | 1955-06-17 | 1958-06-10 | Flexonics Corp | Method of producing fittings |

| US3359624A (en) * | 1965-11-29 | 1967-12-26 | Gray Tool Co | Pipe lining method |

| US3963054A (en) * | 1974-08-01 | 1976-06-15 | Martin Carlyle J | Seal assemblies for water-well casings |

| US3998245A (en) * | 1974-08-01 | 1976-12-21 | Martin Carlyle J | Seal assemblies for water well casings |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2709633C3 (de) * | 1976-03-26 | 1981-04-23 | Combustion Engineering, Inc., 06095 Windsor, Conn. | Vorrichtung zum Befestigen einer Muffe in einer Rohrleitung |

-

1992

- 1992-04-10 DK DK96202318T patent/DK0740970T3/da active

- 1992-04-10 ES ES92303228T patent/ES2099210T3/es not_active Expired - Lifetime

- 1992-04-10 DK DK92303228.8T patent/DK0564732T3/da active

- 1992-04-10 ES ES96202318T patent/ES2146833T3/es not_active Expired - Lifetime

- 1992-04-10 PT PT96202318T patent/PT740970E/pt unknown

- 1992-04-10 EP EP92303228A patent/EP0564732B1/fr not_active Expired - Lifetime

- 1992-04-10 AT AT96202318T patent/ATE193665T1/de not_active IP Right Cessation

- 1992-04-10 DE DE69218176T patent/DE69218176T2/de not_active Expired - Fee Related

- 1992-04-10 DE DE69231165T patent/DE69231165T2/de not_active Expired - Fee Related

- 1992-04-10 AT AT92303228T patent/ATE149890T1/de not_active IP Right Cessation

- 1992-04-10 EP EP96202318A patent/EP0740970B1/fr not_active Expired - Lifetime

-

1997

- 1997-05-16 GR GR970401115T patent/GR3023466T3/el unknown

-

2000

- 2000-08-17 GR GR20000401913T patent/GR3034228T3/el not_active IP Right Cessation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2299434A (en) * | 1941-05-05 | 1942-10-20 | Svirsky Bennett | Plumber's pipe testing device |

| US2837810A (en) * | 1955-06-17 | 1958-06-10 | Flexonics Corp | Method of producing fittings |

| US3359624A (en) * | 1965-11-29 | 1967-12-26 | Gray Tool Co | Pipe lining method |

| US3963054A (en) * | 1974-08-01 | 1976-06-15 | Martin Carlyle J | Seal assemblies for water-well casings |

| US3998245A (en) * | 1974-08-01 | 1976-12-21 | Martin Carlyle J | Seal assemblies for water well casings |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU2006220389B2 (en) * | 2000-09-18 | 2009-05-28 | Rothmans, Benson & Hedges Inc. | Low sidestream smoke cigarette with combustible paper |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0740970A3 (fr) | 1998-01-14 |

| DK0564732T3 (da) | 1997-09-22 |

| DE69218176D1 (de) | 1997-04-17 |

| GR3023466T3 (en) | 1997-08-29 |

| PT740970E (pt) | 2000-09-29 |

| DE69231165T2 (de) | 2000-11-16 |

| ES2099210T3 (es) | 1997-05-16 |

| DK0740970T3 (da) | 2000-10-09 |

| EP0564732B1 (fr) | 1997-03-12 |

| ATE149890T1 (de) | 1997-03-15 |

| ATE193665T1 (de) | 2000-06-15 |

| EP0564732A1 (fr) | 1993-10-13 |

| ES2146833T3 (es) | 2000-08-16 |

| DE69218176T2 (de) | 1997-06-19 |

| GR3034228T3 (en) | 2000-12-29 |

| DE69231165D1 (de) | 2000-07-13 |

| EP0740970B1 (fr) | 2000-06-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5235836A (en) | Seal head for tube expansion apparatus | |

| US4875615A (en) | Vapor plug for temporarily sealing or plugging a pipeline | |

| EP0122099B1 (fr) | Jonction et étanchement pour éléments de tuyaux | |

| US6154944A (en) | Method for expansion forming of tubing | |

| EP0047727A1 (fr) | Procédé d'ancrage de la roche et dispositif comprennant un boulon d'ancrage expansible et son dispositif de mise en place | |

| EP2378177A1 (fr) | Ensemble de raccordement hydraulique à commande de décharge de pression | |

| EP0146316A2 (fr) | Procédé pour réunir des tubes | |

| US20160169385A1 (en) | Energized screw gland | |

| JPS63246629A (ja) | 管の継手の気密性試験装置 | |

| US6502822B1 (en) | Apparatus and method for creating a seal on an inner wall of a tube for hydroforming | |

| US5445002A (en) | Fill and pressurization apparatus | |

| EP0564732B1 (fr) | Tête de scellage pour un appareil de dilation d'un tube | |

| US3267568A (en) | Apparatus for hydraulically removing and replacing interference fitted parts and the like | |

| US6532785B1 (en) | Method and apparatus for prefilling and hydroforming parts | |

| US5540075A (en) | Method and apparatus for shock release of thin foil materials | |

| US3606347A (en) | Wireline wipers | |

| GB1584508A (en) | Work reducing and pressure applying apparatus | |

| NZ203168A (en) | Apparatus for pressing tubular parts onto tubes,sleeves or pipes | |

| EP0175531A2 (fr) | Dispositif d'étanchéité | |

| US4444527A (en) | Collar forming machine for submerged pipelines | |

| EP0619416B1 (fr) | Procédé d'excavation de blocs de pierre et dispositif de mise en oeuvre du procédé | |

| CA2285115C (fr) | Appareil de remplissage et de pressurisation | |

| JPH05215243A (ja) | 超高圧用シール装置 | |

| RU2219052C2 (ru) | Пресс штемпель для измельчения изношенных автомобильных шин | |

| EP0080282A1 (fr) | Dispositif de transfert de pression |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19960906 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 564732 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU MC NL PT SE |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: MASON, MURRAY R. Inventor name: KRASNICKI, FRANK S. C/O STAN KRASNICKI Inventor name: KLAGES, GERRALD A. |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 19990113 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 564732 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU MC NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 193665 Country of ref document: AT Date of ref document: 20000615 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 69231165 Country of ref document: DE Date of ref document: 20000713 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: RITSCHER & SEIFERT |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2146833 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20000621 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010430 |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: TI CORPORATE SERVICES LIMITED TRANSFER- VARI-FORM |

|

| BECA | Be: change of holder's address |

Free format text: 20010822 *VARI-FORM INC.:LOTHIAN AVENUE 233, STRATHROY ONTARIO |

|

| BECH | Be: change of holder |

Free format text: 20010822 *VARI-FORM INC. |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| NLS | Nl: assignments of ep-patents |

Owner name: VARI-FORM INC.;TI AUTOMOTIVE (NEWCO) LIMITED |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: PC4A Free format text: VARI-FORM INC. CA Effective date: 20011031 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20060321 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20060322 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20060426 Year of fee payment: 15 Ref country code: CH Payment date: 20060426 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20060428 Year of fee payment: 15 Ref country code: DK Payment date: 20060428 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060430 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20060503 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20060516 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20060517 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20071010 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| BERE | Be: lapsed |

Owner name: *VARI-FORM INC. Effective date: 20070430 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20071101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071010 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070430 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070411 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080428 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071102 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080417 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070410 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090429 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070410 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091222 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101103 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110426 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20120409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20120409 |