EP0693029B1 - Pressure-sensitive recorder paper - Google Patents

Pressure-sensitive recorder paper Download PDFInfo

- Publication number

- EP0693029B1 EP0693029B1 EP94911122A EP94911122A EP0693029B1 EP 0693029 B1 EP0693029 B1 EP 0693029B1 EP 94911122 A EP94911122 A EP 94911122A EP 94911122 A EP94911122 A EP 94911122A EP 0693029 B1 EP0693029 B1 EP 0693029B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressure

- starch

- microcapsules

- recording paper

- sensitive recording

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/124—Duplicating or marking methods; Sheet materials for use therein using pressure to make a masked colour visible, e.g. to make a coloured support visible, to create an opaque or transparent pattern, or to form colour by uniting colour-forming components

- B41M5/132—Chemical colour-forming components; Additives or binders therefor

- B41M5/155—Colour-developing components, e.g. acidic compounds; Additives or binders therefor; Layers containing such colour-developing components, additives or binders

Definitions

- the present invention relates to an SC-type pressure-sensitive recording paper in which microcapsules, a color developer for the color former solution contained in the microcapsules, spacers and a binder are contained in one layer.

- DE-C-10 10 822 describes a binder-free SC paper which is produced in a coating process, the color acceptor consisting of attapulgite being added and mixed to the capsule composition suspended in water, and the paper coating composition formed being applied to a paper and dried.

- the capsule walls are made of hydrophilic colloid material.

- DE-A-16 71 544 relates to an SC paper in which, in order to avoid an unwanted color reaction of the coating composition containing the capsules, a water-soluble alkyd resin, a water-dispersible metal soap, a water-dispersible paraffin or an aqueous emulsion of a paraffin wax and natural resin or a mixture of these materials is attached.

- the color acceptor can optionally be added to the capsule mass or applied to the paper sheet either before or after application of the capsule mass.

- Gelatine and gum arabic are used to make the capsules.

- DE-A-24 46 313 relates to color formers based on fluoran compounds and their use both in pressure-sensitive and in heat-sensitive recording materials. Both CB sheets and so-called SC sheets are described as examples. Pig skin gelatin and gum arabic are given as capsule wall material. Insofar as the production of SC sheets from a composition containing the microcapsules and the color developer is described, this composition contains polyvinyl alcohol.

- a copying paper with microcapsules, the capsule walls of which are formed by polyaddition from an isocyanate and a tetra- or pentamine, is disclosed in DE-A-27 53 767.

- requirements specified in this document which are made of microcapsules in general, reference should be made in particular to the requirement for the capsules to be impermeable to the color former and the solvent used.

- the arrangement of the microcapsule layer or color acceptor layer on top of one another on one and the same paper surface is also specified in this document.

- SC paper according to DE-A-29 30 408 is known, the microcapsule walls consisting of polyurea formed by reacting a polyisocyanate with a polyamine and water and the color developer a polysilicate formed in situ during the reaction of the polyisocyanate and polyamine and / or aluminum oxide hydrate, which is formed by precipitation from silica sol and / or aluminum hydrate.

- the type of binder used is not specified.

- both color formers have already been proposed according to DE-A-28 20 462, DE-A-29 43 792, EP-A-0 011 367 and EP-A-0 120 972 also include organic color acceptors in microcapsules.

- EP-A-0 120 972 provides for avoiding undesirable discoloration, e.g. B. when folding, the incorporation of a wax-like material in a single-layer SC paper in which both the color former and the color developer are microencapsulated.

- undesirable discoloration e.g. B. when folding

- latex is also mentioned as a binder, a mixture of latex with starch or modified starch not being mentioned.

- DE-A-28 20 462 mentioned above also provides for the unencapsulated use of either color formers or color developers, but modified starches and SBR latices are not disclosed among a large number of binders, but their joint use is not disclosed.

- a pressure-sensitive recording paper of the SC type is known in which, in addition to dialdehyde starch, a water-soluble polymer is added to the color development layer as a binder.

- the color developer, also encapsulated, is organic in nature.

- DE-A-29 09 950 has already proposed a solvent for the color former, a mixture of alkylnaphthalene and to use isoparaffin and to anneal the microcapsules after their formation.

- the manufacture of SC-type pressure sensitive papers has not been addressed.

- an SC-type pressure-sensitive recording paper is known from GB-B-15 24 742.

- the color developer and / or the microcapsules are marked with a protective substance, e.g. B. encased a urea resin or a melamine-formaldehyde polymer.

- microcapsules produced are not always sufficiently leak-tight.

- additional procedural measures and the use of additional materials are to be mentioned as a disadvantage if, for. B. additionally encapsulated the color developer or microcapsules and color developer are additionally coated with a protective substance.

- Microcapsules made of polyurea have meanwhile found widespread use. Depending on the type of solvent or solvent mixture used to dissolve the color formers, the capsule walls may not be sufficiently dense. This disadvantage naturally has an effect especially when the microcapsules are to be used in SC papers.

- the invention has for its object to provide a pressure-sensitive recording paper of the SC type, in which the microcapsules have an increased tightness. Even after prolonged storage, there should be no discoloration that would impair readability.

- the cumbersome measures of a special coating of the microcapsules and / or the color developer should be dispensed with and the production in one be carried out in a single operation, ie the application of the color reaction layer from a coating slip containing both microcapsules and color developers may be possible.

- the task also includes a specific problem that arises in the manufacture of coating slips made using microcapsules with polyurea walls and with mineral color developers. The problem is that between the mineral color developers made of pigment, e.g. B.

- Another object of the invention is to achieve the desired improvement in capsule tightness without other valuable properties such as. B. decrease sufficient color intensity of the generated image or sufficient printability of the color reaction layer in offset printing.

- the invention wants to provide a pressure-sensitive recording paper of the SC type which, on the one hand, has a higher resistance to mechanical stress, for example in the case of Further processing, but on the other hand has no poorer copy performance.

- the invention provides for a pressure-sensitive recording paper of the SC type, in which microcapsules, a color developer for the color former solution contained in the microcapsules, spacers and a binder are contained in a layer that the binder contains modified starch and / or a Starch derivative and a synthetic latex contains and the color developer is an acidic clay.

- modified starch and / or a starch derivative considerably reduces the permeability of microcapsules to the color former solution contained in the microcapsules, especially if their walls consist of polyurea. Even with prolonged storage, there is therefore far less premature release of the color former solution and the associated unwanted color reaction with the color developer.

- the binder preferably contains a starch ester or starch ether.

- a latex based on butadiene-styrene has preferably proven to be suitable as the synthetic latex.

- Modified starch and / or starch derivative is preferably present in the layer in an amount of 5 to 25% by weight, very particularly preferably at least 8% by weight, based on the mass of the microcapsules, calculated as parts by dry weight.

- the amount of binder is preferably 5 to 20 parts by weight, in particular not more than 15 parts by weight, based on the basis weight of the layer, in each case calculated in parts by dry weight.

- the walls of the microcapsule consist of polyurea

- the invention is not limited to this and can also be applied to other capsule wall materials, e.g. for microcapsules made of melamine formaldehyde.

- the modified starches and / or starch derivatives used in the binder are not film-forming. This has the particular advantage that there is no masking, ie a coating of the color developer, so that if the color former contained in the microcapsules is released, an uninhibited reaction between the color reactants can take place. There is therefore no loss of intensity.

- acid clays activated clays, preferably clays whose main constituent is montmorillonite

- the invention is not restricted to the color formers to be used and the solvents used to dissolve them, all color donors which donate electrons and react with mineral color developers (electron acceptors) can be used.

- Undissolved starch granules or cellulose fibers are preferably used as spacers.

- inert pigments such as kaolin or calcium carbonate, can also be present in the layer or the coating slip used for its production.

- the layer is preferably applied with a mass per unit area of not less than 6 and not more than 11 g / m 2 .

- aqueous coating slip with the following composition is produced: Microcapsule 31.6 parts by weight Starch grains as spacers 12.6 parts by weight Butadiene styrene latex 11.6 parts by weight sour clay 35.4 parts by weight kaolin 8.8 parts by weight 100.0 parts by weight ⁇

- the solids content of the coating slip was 35% by weight.

- the microcapsule used is a polyurea capsule with a color former solution resulting in a black typeface.

- a coating slip was produced in which the procedure was as in the comparative example, but as a binder, a mixture of 6.1 parts by weight of a modified starch (medium-depolymerized) - Sobex 222 from SüdStar and 5.1 parts by weight of the butadiene styrene latex used in the comparative example.

- the coating slips were applied to a sized coating base paper, in the comparative example 10 g / m 2 ; in Examples 1 and 2 each 9 g / m 2 .

- aqueous coating slip with the following composition is produced: Microcapsule 33.6 parts by weight Starch grains as spacers 12.6 parts by weight Butadiene styrene latex 14.0 parts by weight sour clay 37.5 parts by weight Starch ether as in Example 2 2.3 parts by weight 100.0 parts by weight ⁇

- composition of the microcapsule dispersion corresponds to that in Example 3, but no starch is used and instead the proportion of butadiene styrene latex is increased to 16.3 parts by weight.

- Example 3 With the aid of a wire knife, the microcapsule dispersions according to Example 3 and Comparative Example 2, which had been adjusted to a solids content of 35% by weight, were applied to a sized coating base paper with the application weights shown in FIG. 1.

- test pressure device from educable, Dr.-Ing. Dürner, P formulateenberg near Kunststoff.

- the discolouration of the test strip is measured on a data color device as a difference (intensity) from the unprinted area.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Color Printing (AREA)

- Laminated Bodies (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft ein druckempfindliches Aufzeichnungspapier vom SC-Typ, bei dem in einer Schicht Mikrokapseln, ein Farbentwickler für die in den Mikrokapseln enthaltene Farbbildnerlösung, Abstandshalter und ein Bindemittel enthalten sind.The present invention relates to an SC-type pressure-sensitive recording paper in which microcapsules, a color developer for the color former solution contained in the microcapsules, spacers and a binder are contained in one layer.

Druckempfindliche Aufzeichnungspapiere vom SC-Typ (self contained) sind bekannt. Man unterscheidet dabei Aufzeichnungsbogen, bei denen Mikrokapseln und Farbakzeptoren in einer Schicht oder in übereinanderliegenden Schichten angeordnet sind.Pressure sensitive recording papers of the SC type (self contained) are known. A distinction is made between recording sheets in which microcapsules and color acceptors are arranged in one layer or in layers one on top of the other.

Die DE-C-10 10 822 beschreibt ein bindemittelfreies SC-Papier, das in einem Beschichtungsvorgang hergestellt wird, wobei der in Wasser suspendierten Kapselmasse der aus Attapulgit bestehende Farbakzeptor zugesetzt und vermengt wird und die gebildete Papierbeschichtungsmasse auf ein Papier aufgebracht und getrocknet wird. Die Kapselwände sind aus hydrophilem Kolloidmaterial gebildet.DE-C-10 10 822 describes a binder-free SC paper which is produced in a coating process, the color acceptor consisting of attapulgite being added and mixed to the capsule composition suspended in water, and the paper coating composition formed being applied to a paper and dried. The capsule walls are made of hydrophilic colloid material.

Zwar bietet die hier beschriebene bindemittelfreie Arbeitsweise den Vorteil, daß Farbbildner und Farbakzeptor ungehindert in Kontakt treten können, jedoch besteht der Nachteil, daß eine ungewollte vorzeitige Farbreaktion nicht mit ausreichender Sicherheit unterbunden wird.Although the binder-free procedure described here has the advantage that the color former and color acceptor can come into contact without hindrance, there is the disadvantage that an unwanted premature color reaction is not prevented with sufficient certainty.

Die DE-A-16 71 544 betrifft ein SC-Papier, bei dem zur Vermeidung einer ungewollten Farbreaktion der die Kapseln enthaltenden Überzugsmasse ein wasserlösliches Alkydharz, eine wasserdispergierbare Metallseife, ein wasserdispergierbares Paraffin oder eine wäßrige Emulsion eines Paraffinwachses und Naturharzes oder eine Mischung dieser Materialien beigefügt wird. Wahlweise kann der Farbakzeptor der Kapselmasse zugefügt werden oder entweder vor oder nach Auftrag der Kapselmasse auf den Papierbogen aufgetragen werden. Zur Herstellung der Kapseln werden Gelatine und Gummi arabikum eingesetzt.DE-A-16 71 544 relates to an SC paper in which, in order to avoid an unwanted color reaction of the coating composition containing the capsules, a water-soluble alkyd resin, a water-dispersible metal soap, a water-dispersible paraffin or an aqueous emulsion of a paraffin wax and natural resin or a mixture of these materials is attached. The color acceptor can optionally be added to the capsule mass or applied to the paper sheet either before or after application of the capsule mass. Gelatine and gum arabic are used to make the capsules.

Die DE-A-24 46 313 betrifft Farbbildner auf Basis von Fluoranverbindungen und deren Einsatz sowohl in druckempfindlichen als auch in wärmeempfindlichen Aufzeichnungsmaterialien. Beispielhaft beschrieben sind sowohl CB-Blätter als auch sogenannte SC-Bogen. Als Kapselwandmaterial werden Schweinehautgelatine und Gummi arabikum angegeben. Soweit die Herstellung von SC-Bogen aus einer die Mikrokapseln und den Farbentwickler enthaltenden Zusammensetzung beschrieben ist, enthält diese Zusammensetzung Polyvinylalkohol.DE-A-24 46 313 relates to color formers based on fluoran compounds and their use both in pressure-sensitive and in heat-sensitive recording materials. Both CB sheets and so-called SC sheets are described as examples. Pig skin gelatin and gum arabic are given as capsule wall material. Insofar as the production of SC sheets from a composition containing the microcapsules and the color developer is described, this composition contains polyvinyl alcohol.

Ein Reaktionsdurchschreibepapier mit Mikrokapseln, deren Kapselwände durch Polyaddition aus einem Isocyanat und einem Tetra- oder Pentamin gebildet sind, ist in der DE-A-27 53 767 offenbart. Unter den in dieser Schrift angegebenen Forderungen, die ganz allgemein an Mikrokapseln gestellt werden, ist insbesondere auf die Erfordernis der Undurchlässigkeit der Kapseln für den Farbbildner und das verwendete Lösungsmittel zu verweisen. Zum Stand der Technik wird in dieser Schrift auch die Anordnung von Mikrokapselschicht bzw. Farbakzeptorschicht übereinander auf ein und derselben Papieroberfläche angegeben.A copying paper with microcapsules, the capsule walls of which are formed by polyaddition from an isocyanate and a tetra- or pentamine, is disclosed in DE-A-27 53 767. Among the requirements specified in this document, which are made of microcapsules in general, reference should be made in particular to the requirement for the capsules to be impermeable to the color former and the solvent used. In relation to the prior art, the arrangement of the microcapsule layer or color acceptor layer on top of one another on one and the same paper surface is also specified in this document.

Ein weiteres Mal ist ein SC-Papier gemäß der DE-A-29 30 408 bekannt, wobei die Mikrokapselwände aus durch Umsetzung eines Polyisocyanats mit einem Polyamin und Wasser gebildeten Polyharnstoff bestehen und der Farbentwickler ein bei der Umsetzung des Polyisocyanats und Polyamins in situ gebildetes Polysilikat und/oder Aluminiumoxidhydrat ist, das durch Ausfällung aus Kieselsol und/oder Aluminiumhydrat entstanden ist. Die Art der verwendeten Bindemittel ist nicht angegeben.Another SC paper according to DE-A-29 30 408 is known, the microcapsule walls consisting of polyurea formed by reacting a polyisocyanate with a polyamine and water and the color developer a polysilicate formed in situ during the reaction of the polyisocyanate and polyamine and / or aluminum oxide hydrate, which is formed by precipitation from silica sol and / or aluminum hydrate. The type of binder used is not specified.

Zur Vermeidung ungewollter Farbreaktionen bei SC-Papieren wurde gemäß DE-A-28 20 462, DE-A-29 43 792, EP-A-0 011 367 sowie gemaß der EP-A-0 120 972 auch bereits vorgeschlagen, sowohl Farbbildner als auch organische Farbakzeptoren in Mikrokapseln einzuschließen.In order to avoid unwanted color reactions in SC papers, both color formers have already been proposed according to DE-A-28 20 462, DE-A-29 43 792, EP-A-0 011 367 and EP-A-0 120 972 also include organic color acceptors in microcapsules.

Entsprechend der vorstehend genannten DE-A-29 43 792 ist vorgesehen, daß neben dem eingekapselten Farbbildner auch noch pulverförmiger Farbbildner in der Aufzeichnungsschicht vorliegt. Als Bindemittel werden neben wasserlöslichen natürlichen und synthetischen Bindemitteln, bei denen u. a. oxidierte Stärke und Stärkeester genannt sind, auch Latices, z. B. auf Basis Styrol-Butadien, genannt. Eine Abmischung von wasserlöslichen natürlichen Bindemitteln mit synthetischem Latex ist im Zusammenhang mit einem einschichtigen SC-Papier nicht erwähnt.According to DE-A-29 43 792 mentioned above, it is provided that in addition to the encapsulated color former there is also powdered color former in the recording layer. In addition to water-soluble natural and synthetic binders, in which u. a. oxidized starch and starch esters are also called latices, e.g. B. based on styrene-butadiene. A mixture of water-soluble natural binders with synthetic latex is not mentioned in connection with a single-layer SC paper.

Die vorerwähnte EP-A-0 120 972 sieht zur Vermeidung einer unerwünschten Verfärbung, z. B. beim Falten, die Einlagerung eines wachsartigen Materials bei einem einschichtigen SC-Papier vor, bei dem sowohl die Farbbildner als auch die Farbentwickler mikroverkapselt sind. Als Bindemittel wird neben Hydroxyethylzellulose, Polyvinylalkohol und modifizierter Stärke auch Latex genannt, wobei eine Abmischung von Latex mit Stärke oder modifizierter Stärke nicht erwähnt ist.The aforementioned EP-A-0 120 972 provides for avoiding undesirable discoloration, e.g. B. when folding, the incorporation of a wax-like material in a single-layer SC paper in which both the color former and the color developer are microencapsulated. In addition to hydroxyethyl cellulose, polyvinyl alcohol and modified starch, latex is also mentioned as a binder, a mixture of latex with starch or modified starch not being mentioned.

Die vorstehend erwähnte DE-A-28 20 462 sieht in ihrer allgemeinen Ausführungsform auch den unverkapselten Einsatz von entweder Farbbildnern oder Farbentwicklern vor, wobei unter einer Vielzahl von Bindemitteln auch modifizierte Stärken und SBR-Latices nicht aber deren gemeinsamer Einsatz offenbart werden.In its general embodiment, DE-A-28 20 462 mentioned above also provides for the unencapsulated use of either color formers or color developers, but modified starches and SBR latices are not disclosed among a large number of binders, but their joint use is not disclosed.

Aus dem Patents Abstracts of Japan M-1279 vom 14. Juli 1992, Vol. 16/Nr. 321 entsprechend JP 4-90376 A, ist ein druckempfindliches Aufzeichnungspapier vom SC-Typ bekannt, bei dem der Farbentwicklungsschicht neben Dialdehydstärke als Bindemittel ein wasserlösliches Polymer zugefügt wird. Der ebenfalls eingekapselte Farbentwickler ist organischer Natur.From the Patents Abstracts of Japan M-1279 of July 14, 1992, vol. 16 / no. 321 in accordance with JP 4-90376 A, a pressure-sensitive recording paper of the SC type is known in which, in addition to dialdehyde starch, a water-soluble polymer is added to the color development layer as a binder. The color developer, also encapsulated, is organic in nature.

Zur Erzielung einer besseren Lagerstabilität von Mikrokapseln enthaltenden Durchschreibepapieren, bei denen die Kapselwände aus einem durch Polyaddition eines Diisocyanats und einem Diamin gebildeten Produkt bestehen, wurde gemäß der DE-A-29 09 950 auch bereits vorgeschlagen, als Lösungsmittel für den Farbbildner ein Gemisch aus Alkylnaphthalin und Isoparaffin zu verwenden und die Mikrokapseln nach ihrer Bildung zu tempern. Die Herstellung von druckempfindlichen Papieren des SC-Typs ist nicht angesprochen.In order to achieve better storage stability of carbonless copying papers in which the capsule walls consist of a product formed by polyaddition of a diisocyanate and a diamine, DE-A-29 09 950 has already proposed a solvent for the color former, a mixture of alkylnaphthalene and to use isoparaffin and to anneal the microcapsules after their formation. The manufacture of SC-type pressure sensitive papers has not been addressed.

Ein druckempfindliches Aufzeichnungspapier vom SC-Typ ist schließlich aus der GB-B-15 24 742 bekannt. Zur Vermeidung einer vorzeitigen Farbreaktion sind der Farbentwickler und/oder die Mikrokapseln mit einer schützenden Substanz, z. B. einem Harnstoffharz oder einem Melamin-Formaldehydpolymeren umhüllt.Finally, an SC-type pressure-sensitive recording paper is known from GB-B-15 24 742. To avoid a premature color reaction, the color developer and / or the microcapsules are marked with a protective substance, e.g. B. encased a urea resin or a melamine-formaldehyde polymer.

Den bekannten Vorschlägen haften noch gewisse Nachteile an, insbesondere eine noch nicht in jedem Fall ausreichende Dichtigkeit der hergestellten Mikrokapseln. In wirtschaftlicher Hinsicht sind zusätzliche Verfahrensmaßnahmen und der Einsatz zusätzlicher Materialien als Nachteil zu nennen, wenn z. B. zusätzlich die Farbentwickler eingekapselt oder Mikrokapseln und Farbentwickler zusätzlich mit einer Schutzsubstanz umhüllt werden. Aus Polyharnstoff bestehende Mikrokapseln haben zwischenzeitlich eine weite Verbreitung gefunden. In Abhängigkeit von der Art des zur Auflösung der Farbbildner verwendeten Lösungsmittels oder des Lösungsmittelgemisches kann es jedoch auch hier zu nicht ausreichend dichten Kapselwänden kommen. Dieser Nachteil wirkt sich natürlich insbesondere dann aus, wenn die Mikrokapseln in SC-Papieren eingesetzt werden sollen.The known proposals still have certain disadvantages, in particular that the microcapsules produced are not always sufficiently leak-tight. In economic terms, additional procedural measures and the use of additional materials are to be mentioned as a disadvantage if, for. B. additionally encapsulated the color developer or microcapsules and color developer are additionally coated with a protective substance. Microcapsules made of polyurea have meanwhile found widespread use. Depending on the type of solvent or solvent mixture used to dissolve the color formers, the capsule walls may not be sufficiently dense. This disadvantage naturally has an effect especially when the microcapsules are to be used in SC papers.

Ausgehend von den bekannten Nachteilen hat die Erfindung die Aufgabe, ein druckempfindliches Aufzeichnungspapier vom SC-Typ zur Verfügung zu stellen, bei dem die Mikrokapseln eine erhöhte Dichtigkeit aufweisen. Auch nach längerer Lagerung soll dabei noch keine die gute Lesbarkeit beeinträchtigende Verfärbung auftreten. Dabei soll auf die umständlichen Maßnahmen einer besonderen Umhüllung der Mikrokapseln und/oder der Farbentwickler verzichtet werden und die Herstellung in einem einzigen Arbeitsgang erfolgen, d. h. der Auftrag der Farbreaktionsschicht aus einer sowohl Mikrokapseln als auch Farbentwickler enthaltenden Streichmasse möglich sein. Die gestellte Aufgabe umfaßt auch ein spezielles Problem, das bei der Herstellung von Streichmassen auftaucht, die unter Verwendung von Mikrokapseln mit Wänden aus Polyharnstoff und mit mineralischen Farbentwicklern hergestellt werden. Das Problem besteht darin, daß zwischen den mineralischen Farbentwicklern aus Pigment, z. B. saurem Ton und freien Aminogruppen des aus Polyharnstoff bestehenden Kapselwandmaterials eine Wechselwirkung entsteht, die im Einzelfall zu einem Viskositätsschock der wäßrigen Streichmasse, zumindest aber zu einem starken Anstieg der Viskosität, führt. Durch starkes Rühren des hochviskosen Ansatzes kann es dabei zu Beschädigungen der Kapselwand bzw. zum Auftreten von Undichtigkeiten bei den Mikrokapseln kommen.Based on the known disadvantages, the invention has for its object to provide a pressure-sensitive recording paper of the SC type, in which the microcapsules have an increased tightness. Even after prolonged storage, there should be no discoloration that would impair readability. The cumbersome measures of a special coating of the microcapsules and / or the color developer should be dispensed with and the production in one be carried out in a single operation, ie the application of the color reaction layer from a coating slip containing both microcapsules and color developers may be possible. The task also includes a specific problem that arises in the manufacture of coating slips made using microcapsules with polyurea walls and with mineral color developers. The problem is that between the mineral color developers made of pigment, e.g. B. acid clay and free amino groups of the capsule wall material consisting of polyurea, an interaction occurs which leads in individual cases to a viscosity shock of the aqueous coating slip, but at least to a sharp increase in viscosity. Strong stirring of the highly viscous mixture can damage the capsule wall or cause leaks in the microcapsules.

Eine weitere Aufgabe besteht für die Erfindung darin, die gewünschte Verbesserung der Kapseldichtigkeit zu erreichen, ohne daß gleichzeitig andere wertvolle Eigenschaften, wie z. B. eine ausreichende Farbintensität des erzeugten Schriftbildes oder eine ausreichende Bedruckbarkeit der Farbreaktionsschicht im Offsetdruck abnehmen.Another object of the invention is to achieve the desired improvement in capsule tightness without other valuable properties such as. B. decrease sufficient color intensity of the generated image or sufficient printability of the color reaction layer in offset printing.

Schließlich will die Erfindung ein druckempfindliches Aufzeichnungspapier vom SC-Typ zur Verfügung stellen, das einerseits eine höhere Festigkeit gegen mechanische Beanspruchung, z.B. bei der Weiterverarbeitung, andererseits aber keine schlechtere Durchschreibeleistung besitzt.Finally, the invention wants to provide a pressure-sensitive recording paper of the SC type which, on the one hand, has a higher resistance to mechanical stress, for example in the case of Further processing, but on the other hand has no poorer copy performance.

Zur Lösung der Aufgabe sieht die Erfindung bei einem druckempfindlichen Aufzeichnungspapier vom SC-Typ, bei dem in einer Schicht Mikrokapseln, ein Farbentwickler für die in den Mikrokapseln enthaltene Farbbildnerlösung, Abstandshalter und ein Bindemittel enthalten sind vor, daß das Bindemittel modifizierte Stärke und/oder ein Stärkederivat sowie einen Syntheselatex enthält und der Farbentwickler ein saurer Ton ist.To achieve the object, the invention provides for a pressure-sensitive recording paper of the SC type, in which microcapsules, a color developer for the color former solution contained in the microcapsules, spacers and a binder are contained in a layer that the binder contains modified starch and / or a Starch derivative and a synthetic latex contains and the color developer is an acidic clay.

Wie Versuche gezeigt haben, wird durch den Zusatz von modifizierter Stärke und/oder eines Stärkederivats die Durchlässigkeit von Mikrokapseln, insbesondere, wenn deren Wände aus Polyharnstoff bestehen, für die in den Mikrokapseln enthaltene Farbbildnerlösung erheblich reduziert. Auch bei längerer Lagerung kommt es daher in weitaus geringerem Maße zu einer vorzeitigen Freisetzung der Farbbildnerlösung und der damit verbundenen ungewollten Farbreaktion mit dem Farbentwickler.As experiments have shown, the addition of modified starch and / or a starch derivative considerably reduces the permeability of microcapsules to the color former solution contained in the microcapsules, especially if their walls consist of polyurea. Even with prolonged storage, there is therefore far less premature release of the color former solution and the associated unwanted color reaction with the color developer.

Vorzugsweise enthält das Bindemittel einen Stärkeester oder Stärkeäther. Als Syntheselatex hat sich vorzugsweise ein Latex auf Basis von Butadien-Styrol als geeignet erwiesen.The binder preferably contains a starch ester or starch ether. A latex based on butadiene-styrene has preferably proven to be suitable as the synthetic latex.

Vorzugsweise liegt in der Schicht modifizierte Stärke und/oder Stärkederivat in einer Menge von 5 bis 25 Gew.%, ganz besonders bevorzugt von mindestens 8 Gew.%, bezogen auf die Masse der Mikrokapseln, gerechnet als Trockengewichtsteile, vor. Die Bindemittelmenge beträgt vorzugsweise 5 bis 20 Gew.-Teile, insbesondere nicht mehr als 15 Gew.-Teile, bezogen auf die Flächenmasse der Schicht, jeweils gerechnet in Trockengewichtsteilen. Wie sich gezeigt hat, ermöglicht die Erfindung die problemlose Herstellung der die Mikrokapseln und Farbentwickler enthaltenden Schicht aus einer Streichmasse, in der alle Komponenten enthalten sind, auch wenn das Kapselwandmaterial aus Polyharnstoff besteht und ungünstige Lösungsmittel für die Farbbildner eingesetzt werden.Modified starch and / or starch derivative is preferably present in the layer in an amount of 5 to 25% by weight, very particularly preferably at least 8% by weight, based on the mass of the microcapsules, calculated as parts by dry weight. The amount of binder is preferably 5 to 20 parts by weight, in particular not more than 15 parts by weight, based on the basis weight of the layer, in each case calculated in parts by dry weight. As has been shown, the invention enables the layer containing the microcapsules and color developers to be produced without problems from a coating slip which contains all the components, even if the capsule wall material consists of polyurea and unfavorable solvents are used for the color formers.

Da Versuche gezeigt haben, daß besonders gute Ergebnisse erzielt werden konnten, wenn die Wände der Mikrokapsel aus Polyharnstoff bestehen, wird eine solche Ausführungsform bevorzugt. Die Erfindung ist jedoch nicht darauf beschränkt und kann auch bei anderen Kapselwandmaterialien angewendet werden, z.B. bei Mikrokapseln aus Melamin-Formaldehyd.Since tests have shown that particularly good results could be achieved if the walls of the microcapsule consist of polyurea, such an embodiment is preferred. However, the invention is not limited to this and can also be applied to other capsule wall materials, e.g. for microcapsules made of melamine formaldehyde.

Gemäß einer weiteren Ausführungsform sind die im Bindemittel eingesetzten modifizierten Stärken und/oder Stärkederivate nicht filmbildend. Dadurch entsteht der besondere Vorteil, daß es nicht zu einer Maskierung, d. h. einer Umhüllung des Farbentwicklers kommt, so daß bei gewollter Freisetzung des in den Mikrokapseln enthaltenen Farbbildners eine ungehemmte Reaktion zwischen den Farbreaktanten erfolgen kann. Ein Intensitätsverlust tritt somit nicht ein.According to a further embodiment, the modified starches and / or starch derivatives used in the binder are not film-forming. This has the particular advantage that there is no masking, ie a coating of the color developer, so that if the color former contained in the microcapsules is released, an uninhibited reaction between the color reactants can take place. There is therefore no loss of intensity.

Erfindungsgemäß werden saure Tone, aktivierte Tone, vorzugsweise solche Tone, deren Hauptbestandteil der Montmorillonit ist, als Farbentwickler eingesetzt. Bei den einzusetzenden Farbbildnern und den zu ihrer Lösung angewendeten Lösungsmitteln ist die Erfindung nicht beschränkt, eingesetzt werden können alle Elektronen abgebenden und mit mineralischen Farbentwicklern (Elektronenakzeptoren) reagierenden Farbbildner.According to the invention, acid clays, activated clays, preferably clays whose main constituent is montmorillonite, are used as color developers. The invention is not restricted to the color formers to be used and the solvents used to dissolve them, all color donors which donate electrons and react with mineral color developers (electron acceptors) can be used.

Als Abstandshalter werden vorzugsweise ungelöste Stärkekörnchen oder Cellulosefasern verwendet.Undissolved starch granules or cellulose fibers are preferably used as spacers.

In der Schicht bzw. der zu ihrer Herstellung verwendeten Streichmasse können außer den farbreaktiven Tonen auch noch Inertpigmente, wie Kaolin oder Calciumcarbonat, vorliegen.In addition to the color-reactive clays, inert pigments, such as kaolin or calcium carbonate, can also be present in the layer or the coating slip used for its production.

Vorzugsweise wird die Schicht mit einer Flächenmasse von nicht weniger als 6 und nicht mehr als 11 g/m2 aufgetragen.The layer is preferably applied with a mass per unit area of not less than 6 and not more than 11 g / m 2 .

Die nachfolgenden Beispiele dienen der Erläuterung der Erfindung.The following examples serve to explain the invention.

Es wird eine wäßrige Streichmasse mit der nachfolgenden Zusammensetzung hergestellt:

Der Feststoffgehalt der Streichmasse betrug 35 Gew.%. Bei der eingesetzten Mikrokapsel handelt es sich um eine Polyharnstoffkapsel mit einer ein schwarzes Schriftbild ergebenden Farbbildnerlösung.The solids content of the coating slip was 35% by weight. The microcapsule used is a polyurea capsule with a color former solution resulting in a black typeface.

Es wurde eine Streichmasse hergestellt, bei der wie im Vergleichsbeispiel verfahren wurde, jedoch wurde als Bindemittel eine Abmischung aus 6,1 Gew.-Teilen einer modifizierten Stärke (mitteldepolymerisiert) - Sobex 222 der Firma Südstärke und 5,1 Gew.-Teilen des auch im Vergleichsbeispiel eingesetzten Butadien-Styrollatex eingesetzt.A coating slip was produced in which the procedure was as in the comparative example, but as a binder, a mixture of 6.1 parts by weight of a modified starch (medium-depolymerized) - Sobex 222 from SüdStar and 5.1 parts by weight of the butadiene styrene latex used in the comparative example.

Es wurde wie in Beispiel 1 verfahren, jedoch gelangte als Stärkederivat ein Carboxymethylstärkeether - Quicksolan CMS der Firma Avebe zum Einsatz.The procedure was as in Example 1, but a carboxymethyl starch ether - Quicksolan CMS from Avebe was used as the starch derivative.

Mit Hilfe eines Drahtrakels wurden die hergestellten Streichmassen auf ein geleimtes Streichrohpapier aufgetragen, im Vergleichsbeispiel 10 g/m2; in den Beispielen 1 und 2 je 9 g/m2.With the help of a wire doctor, the coating slips were applied to a sized coating base paper, in the comparative example 10 g / m 2 ; in Examples 1 and 2 each 9 g / m 2 .

Eine Messung ergab unmittelbar nach Herstellung der Papiere folgende Helligkeitswerte in %:

- Vergleichsbeispiel 1:

- 82

- Beispiel 1:

- 84

- Beispiel 2:

- 82

- Comparative Example 1:

- 82

- Example 1:

- 84

- Example 2:

- 82

Eine nach 18-tägiger Alterung im Klimakasten bei 70 oC und 75 % RF durchgeführte Messung ergab folgenden Helligkeitsabfall:

- Vergleichsbeispiel 1:

- 50 % Punkte

- Beispiel 1:

- 25 % Punkte

- Beispiel 2:

- 30 % Punkte

- Comparative Example 1:

- 50% points

- Example 1:

- 25% points

- Example 2:

- 30% points

Es wird eine wässrige Streichmasse mit der nachfolgenden Zusammensetzung hergestellt:

Die Zusammensetzung der Mikrokapseldispersion entspricht der in Beispiel 3, wobei jedoch keine Stärke zum Einsatz kommt und statt dessen der Anteil des Butadien-Styrollatex auf 16,3 Gew.-Teile angehoben wird.The composition of the microcapsule dispersion corresponds to that in Example 3, but no starch is used and instead the proportion of butadiene styrene latex is increased to 16.3 parts by weight.

Mit Hilfe eines Drahtrakels wurden die auf einen Feststoffgehalt von 35 Gew.-% eingestellten Mikrokapseldispersionen nach Beispiel 3 und Vergleichsbeispiel 2 auf ein geleimtes Streichrohpapier mit den aus Figur 1 zu entnehmenden Auftragsgewichten aufgetragen.With the aid of a wire knife, the microcapsule dispersions according to Example 3 and Comparative Example 2, which had been adjusted to a solids content of 35% by weight, were applied to a sized coating base paper with the application weights shown in FIG. 1.

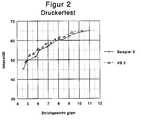

Die in Figur 1 dargestellten Ergebnisse des Rollentestes zeigen für die nach Beispiel 3 hergestellten erfindungsgemäßen Aufzeichnungspapiere eine geringere Empfindlichkeit gegen mechanische Beanspruchung, während aus Figur 2 zu entnehmen ist, daß die Durchschreibefähigkeit des erfindungsgemäßen Aufzeichnungspapiers im Vergleich zu dem keine modifizierte Stärke enthaltenden Aufzeichnungspapier nach Vergleichsbeispiel 2 sich nicht verschlechtert hat.The results of the roll test shown in FIG. 1 show the inventive recording papers produced according to Example 3 a lower sensitivity to mechanical stress, while it can be seen from FIG. 2 that the write-through capacity of the recording paper according to the invention has not deteriorated in comparison with the recording paper according to Comparative Example 2 containing no modified starch.

Diese Prüfung wird mit dem Probeandruckgerät der Firma Prüfbau, Dr.-Ing. Dürner, Peißenberg bei München, durchgeführt. Ein 4,5 cm breiter und 24 cm langer Teststreifen des zu untersuchenden Papiers, der mit einem Schutzpapier von 40 g/qm abgedeckt und auf einem Schlitten fixiert ist, wird zwischen zwei Rollen mit einer Geschwindigkeit von 2 m/sek. durchgeführt, die mit definiertem Druck gegeneinander angepreßt werden, wobei die auf dem Schutzpapier angreifende Rolle eine 4 cm breite Aluminiumrolle ist. Nach einer Dunkellagerung von 24 h wird auf einem Datacolorgerät die Verfärbung des Teststreifens als Differenz (Intensität) zur unbedruckten Fläche gemessen.This test is carried out with the test pressure device from Prüfbau, Dr.-Ing. Dürner, Peißenberg near Munich. A 4.5 cm wide and 24 cm long test strip of the paper to be examined, which is covered with a protective paper of 40 g / m2 and fixed on a slide, is placed between two rolls at a speed of 2 m / sec. carried out, which are pressed against each other with a defined pressure, the roller acting on the protective paper being a 4 cm wide aluminum roller. After 24 hours of dark storage, the discolouration of the test strip is measured on a data color device as a difference (intensity) from the unprinted area.

Bei diesem von der Anmelderin entwickelten Untersuchungsverfahren wird ein mit einem 40 g/qm Schutzpapier abgedeckter Prüfling auf einem Nadeldrucker in einer Größe von 4 x 3,5 cm vollflächig bedruckt. Es kommt dabei zu einer vollflächigen Zerstörung der Kapseln. Die Messung erfolgt wie vorstehend zum Rollentest angegeben.In this test method developed by the applicant, a test piece covered with 40 g /

Claims (9)

- Pressure-sensitive recording paper of the SC type, in which there are contained in one layer:- microcapsules,- spacers,- an acidic clay as colour developer for the colour-forming solution contained in the microcapsules, and- a binder that contains modified starch and/or a starch derivative and also a synthetic latex.

- Pressure-sensitive recording paper according to claim 1, characterised in that the starch derivative is a starch ester.

- Pressure-sensitive recording paper according to claim 1, characterised in that the starch derivative is a starch ether.

- Pressure-sensitive recording paper according to any one of claims 1 to 3, characterised in that the synthetic latex consists of a butadiene/styrene polymerisate.

- Pressure-sensitive recording paper according to any one of claims 1 to 4, characterised in that the layer contains modified starch and/or starch derivatives in an amount of from 5 to 25 % by weight, based on the mass of the microcapsules, calculated as dry weight proportions.

- Pressure-sensitive recording paper according to claim 5, characterised in that the layer contains modified starch and/or starch derivatives in an amount of at least 8 % by weight, based on the mass of the microcapsules, calculated as dry weight proportions.

- Pressure-sensitive recording paper according to any one of claims 1 to 6, characterised in that the binder is present in an amount of from 5 to 20 % by weight, based on the mass per unit area of the layer.

- Pressure-sensitive recording paper according to claim 7, characterised in that the binder is present in an amount of up to 15 % by weight, based on the mass per unit area of the layer.

- Pressure-sensitive recording paper according to any one of claims 1 to 6, characterised in that the walls of the microcapsules consist of polyurea.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI9430071T SI0693029T1 (en) | 1993-04-08 | 1994-03-08 | Pressure-sensitive recorder paper |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4311463 | 1993-04-08 | ||

| DE4311463A DE4311463C3 (en) | 1993-04-08 | 1993-04-08 | Pressure sensitive recording paper |

| PCT/EP1994/000703 WO1994023953A1 (en) | 1993-04-08 | 1994-03-08 | Pressure-sensitive recorder paper |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0693029A1 EP0693029A1 (en) | 1996-01-24 |

| EP0693029B1 true EP0693029B1 (en) | 1997-07-02 |

Family

ID=6484982

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94911122A Expired - Lifetime EP0693029B1 (en) | 1993-04-08 | 1994-03-08 | Pressure-sensitive recorder paper |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0693029B1 (en) |

| CZ (1) | CZ257795A3 (en) |

| DE (2) | DE4311463C3 (en) |

| ES (1) | ES2104369T3 (en) |

| WO (1) | WO1994023953A1 (en) |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6026039B2 (en) * | 1977-09-05 | 1985-06-21 | 三菱製紙株式会社 | Self-coloring pressure-sensitive recording paper |

| JPS5561495A (en) * | 1978-11-02 | 1980-05-09 | Mitsubishi Paper Mills Ltd | Self-color-developing pressure-sensitive recording sheet |

| JPS5964387A (en) * | 1982-10-06 | 1984-04-12 | Mitsubishi Paper Mills Ltd | Simple layer type self-color developable pressure sensitive recording material |

-

1993

- 1993-04-08 DE DE4311463A patent/DE4311463C3/en not_active Expired - Fee Related

-

1994

- 1994-03-08 WO PCT/EP1994/000703 patent/WO1994023953A1/en not_active Application Discontinuation

- 1994-03-08 CZ CZ952577A patent/CZ257795A3/en unknown

- 1994-03-08 DE DE59403255T patent/DE59403255D1/en not_active Expired - Fee Related

- 1994-03-08 ES ES94911122T patent/ES2104369T3/en not_active Expired - Lifetime

- 1994-03-08 EP EP94911122A patent/EP0693029B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE4311463C3 (en) | 1999-07-15 |

| EP0693029A1 (en) | 1996-01-24 |

| WO1994023953A1 (en) | 1994-10-27 |

| DE4311463A1 (en) | 1994-10-13 |

| CZ257795A3 (en) | 1996-06-12 |

| DE59403255D1 (en) | 1997-08-07 |

| ES2104369T3 (en) | 1997-10-01 |

| DE4311463C2 (en) | 1996-09-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3346601C2 (en) | Microcapsules, process for their production and their use in pressure-sensitive carbonless copying papers | |

| DE3019591C2 (en) | ||

| DE2847855A1 (en) | HEAT SENSITIVE RECORDING MATERIAL AND METHOD FOR THE PRODUCTION THEREOF | |

| DE3242262C2 (en) | ||

| DE2515426A1 (en) | METHOD OF MANUFACTURING MICROCAPSULES FROM A COMPLEX HYDROPHILIC COLLOID MATERIAL | |

| DE1955542C3 (en) | Pressure sensitive sheet material | |

| DE2729143B2 (en) | Application of the curtain coating process to the manufacture of pressure sensitive copier papers of the microcapsule type | |

| DE2237288B2 (en) | Thermal copy material | |

| DE2422899C3 (en) | Basically substituted furan compounds, process for their preparation and their use as color formers for a pressure- or heat-sensitive recording material | |

| DE2447103C2 (en) | Pressure sensitive recording web | |

| DE69321765T3 (en) | Pressure-sensitive recording material | |

| DE2147585C3 (en) | Pressure sensitive recording material and color developer coating therefor | |

| DE1671544B2 (en) | PRESSURE SENSITIVE RECORDING MATERIAL | |

| DE2447117C2 (en) | Pressure sensitive recording sheet | |

| DE2820462C3 (en) | Self-recording pressure-sensitive paper | |

| DE2919521C2 (en) | Recording material for use in a pressure-sensitive copier system | |

| DE2438250A1 (en) | PROCEDURES FOR DESENSITIZATION | |

| DE2854318C2 (en) | ||

| DE3706491C2 (en) | ||

| DE2513526A1 (en) | METHOD OF PRESSURE MEASUREMENT | |

| DE2909950A1 (en) | MICROCAPSULES | |

| DE2630582C3 (en) | Desensitizing compound | |

| DE3604343A1 (en) | COUNTERPRINT SENSITIVE PAPER | |

| CH643782A5 (en) | PRESSURE SENSITIVE TRANSFER SHEET. | |

| DE2502142A1 (en) | PRESSURE SENSITIVE RECORDING MATERIAL |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19950627 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE ES FR GB IT |

|

| AX | Request for extension of the european patent |

Free format text: SI PAYMENT 950627 |

|

| RAX | Requested extension states of the european patent have changed |

Free format text: SI PAYMENT 950627 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19960417 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| ITF | It: translation for a ep patent filed |

Owner name: STUDIO INGG. FISCHETTI & WEBER |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: STORA PUBLICATION PAPER AKTIENGESELLSCHAFT |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| AX | Request for extension of the european patent |

Free format text: SI PAYMENT 950627 |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 59403255 Country of ref document: DE Date of ref document: 19970807 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2104369 Country of ref document: ES Kind code of ref document: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19971001 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: ARJO WIGGINS APPLETON PLC Effective date: 19980316 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: STORA CARBONLESS PAPER GMBH |

|

| PLBO | Opposition rejected |

Free format text: ORIGINAL CODE: EPIDOS REJO |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: MITSUBISHI HITEC PAPER BIELEFELD GMBH |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAE | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOS REFNO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: ARJO WIGGINS APPLETON PLC Effective date: 19980316 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 20030710 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20090317 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090324 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20090318 Year of fee payment: 16 Ref country code: DE Payment date: 20090216 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20090325 Year of fee payment: 16 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100308 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20101130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100308 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100308 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100309 |