EP0633192A2 - Packaging unit for pipette tips - Google Patents

Packaging unit for pipette tips Download PDFInfo

- Publication number

- EP0633192A2 EP0633192A2 EP94108742A EP94108742A EP0633192A2 EP 0633192 A2 EP0633192 A2 EP 0633192A2 EP 94108742 A EP94108742 A EP 94108742A EP 94108742 A EP94108742 A EP 94108742A EP 0633192 A2 EP0633192 A2 EP 0633192A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- pipette tips

- carrier

- packaging unit

- layer

- sensitive adhesive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/70—Trays provided with projections or recesses in order to assemble multiple articles, e.g. intermediate elements for stacking

Definitions

- the present invention relates to a packaging unit for pipette tips.

- sterile disposable goods such as e.g. Sleeve aprons, gloves, protective hoods, filters, cuvettes, pipette tips, syringes, weighing dishes etc.

- sleeves aprons e.g. Rubber, protective hoods, filters, cuvettes, pipette tips, syringes, weighing dishes etc.

- the pipette tips have properties such as a tight fit of the push-on sleeve on the pipette, a clean and precisely centered tip opening, a perfect surface finish and an optimal one Material transparency, which allow an accurate and thus reproducible dimensioning of liquid samples.

- pipette tips already arranged in equidistant rows and columns are offered in cardboard or plastic containers. These containers have a number of recesses or holes which are matched to the dimensions of the pipette tips and into which the pipette tips are sorted.

- the containers with pipette tips can already be sterilized, provided the nature of the container allows this. This is only the case with the elaborately made environmentally harmful plastic containers. However, this is not the case with the less complex and therefore less expensive cardboard containers.

- the pipette tips provided therein must still be transferred to the autoclavable, temperature-resistant pipette tip stand provided for sterilization.

- an adapter plate with a number of upstanding receptacles arranged in a standardized row and column spacing, which correspond to the push-on sleeves of the pipette tips can be used.

- the receiving pins of the adapter plate facing downwards are inserted into the push-on sleeves of the pipette tips from above.

- the container with the pipette tips and the adapter plate is then turned over and the container is removed from the adapter plate with the pipette tips.

- the pipette tip stand turned upside down is placed on the adapter plate with the pipette tips.

- the adapter plate with the pipette tips and the pipette tip stand is turned over again and the adapter plate is removed from the pipette tip stand with the pipette tips.

- a packaging unit for pipette tips which have a push-on sleeve with a ring edge at their rear ends, by means of a flat, plate-shaped, thin carrier which is rectangular in plan and has a layer of pressure-sensitive adhesive on its top, the pipette tips in equidistant rows and columns, with their ring edges releasably glued to the carrier.

- This configuration makes it possible to arrange the pipette tips in the standardized row and column spacing and to connect them to one another via the carrier or the layer, the carrier and the layer being able to be used simultaneously as a means of transport in the pipette tip stand.

- the handling of the packaging unit according to the invention is very simple, time-saving and, moreover, this solution is extremely inexpensive to manufacture. Furthermore, depending on the dimensions of the carrier, different numbers of pipette tips can be glued in different grids.

- the carrier with the layer can remain on the funnel-shaped push-on sleeves of the pipette tips until shortly before the pipette tips are used for pipetting as a protective cover.

- the layer expediently has a thin film with an upper film and a lower film of the pressure-sensitive adhesive.

- the carrier can be peeled off from the lower film and the film together with the upper film and the lower film can be rolled off the ring edges of the pipette tips, while the pipette tips are held in the pipette tip stand due to a slight tilting movement caused by the rolling off.

- the lower film of the pressure-sensitive adhesive can be formed from a plurality of narrow strips arranged parallel and at a distance from one another. In this way, the adhesive area of the lower film is significantly reduced, so that the carrier can be removed very easily from the lower film of the pressure-sensitive adhesive adhering to the film.

- the carrier advantageously has on its upper side a narrow all-round edge zone which is not covered by the layer of pressure-sensitive adhesive. This feature makes handling the packaging unit easier, since the adhesive layer, which is framed by the peripheral edge zone, is not touched when the carrier is picked up by hand.

- the carrier is made from corrugated cardboard.

- three-layer corrugated cardboard which consists of a bottom, top and intermediate layer, is particularly suitable for this, since it is flexible parallel to the direction of the shaft of the intermediate layer and extremely rigid perpendicular to the direction of the shaft of the intermediate layer.

- the carrier can have a thickness of approximately one millimeter. Due to this feature, the plate-shaped carrier can also remain in a pipette tip stand which is to be closed by means of an additional sliding cover, without being a hindrance when the sliding cover is closed. Furthermore, up to this thickness of the carrier, it is still relatively easy to pull the carrier or the carrier with the layer from the pipette tips.

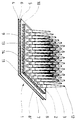

- the packaging unit shown comprises a carrier 1, a layer 2 of a pressure-sensitive adhesive and a number of pipette tips 3.

- the flat, plate-shaped carrier 1 is rectangular in plan and has a thickness of only about a millimeter.

- the carrier 1 consists of a three-layer corrugated cardboard with a flat base 4, a flat top layer 5 arranged parallel thereto and a corrugated intermediate layer 6 arranged between them.

- a layer 2 consisting of a thin film 7 with an upper film 8 and a lower film 8 'of a pressure-sensitive adhesive, is detachably attached to the carrier 1.

- the lower film 8 ' is composed of a number of narrow strips 9 arranged parallel and at a short distance from one another.

- the strips 9 are oriented perpendicular to the wave direction of the intermediate layer 6 of the carrier 1.

- the layer 2 completely covers the upper side 10 of the carrier 1 except for a consistently narrow, all-round edge zone 11 which frames the layer 2 of the pressure-sensitive adhesive.

- a total of forty-eight pipette tips 3 are arranged on the layer 2 in a grid of equidistant rows of eight pieces each and equidistant columns of six pieces each.

- widened end of each pipette tip 3 there is a likewise widened push-on sleeve 13, which ends in a flat ring edge 14.

- This narrow ring edge 14 represents the contact surface for the adhesive attachment of the pipette tips 3 to the layer 2 or the carrier 1 detachably connected thereto.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Devices For Use In Laboratory Experiments (AREA)

- Apparatus Associated With Microorganisms And Enzymes (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft eine Verpackungseinheit für Pipettenspitzen.The present invention relates to a packaging unit for pipette tips.

In modernen Labors der chemischen und der pharmazeutischen Industrie sowie den öffentlichen Forschungseinrichtungen für Medizin und Molekularbiologie wird zur Erfüllung der hohen geforderten Reinheitsstandards häufig mit steriler Einwegware, wie z.B. Ärmelschürzen, Handschuhen, Schutzhauben, Filtern, Küvetten, Pipettenspitzen, Spritzen, Wägeschalen usw., gearbeitet. Speziell bei der Verwendung von Pipettenspitzen zum Pipettieren kleinster Flüssigkeitsmengen ist man zum Einmalgebrauch übergegangen, da nur dann gewährleistet ist, daß die Pipettenspitzen Eigenschaften, wie einen dichten Sitz der Aufsteckmuffe auf der Pipette, eine saubere und exakt zentrierte Spitzenöffnung, eine einwandfreie Oberflächenbeschaffenheit sowie eine optimale Materialtransparenz, aufweisen, die eine genaue und somit reproduzierbare Dimensionierung von Flüssigkeitsproben erlauben.In modern laboratories in the chemical and pharmaceutical industries as well as public research facilities for medicine and molecular biology, sterile disposable goods such as e.g. Sleeve aprons, gloves, protective hoods, filters, cuvettes, pipette tips, syringes, weighing dishes etc., worked. Especially when using pipette tips for pipetting the smallest amounts of liquid, one has switched to single use, since this is the only way to ensure that the pipette tips have properties such as a tight fit of the push-on sleeve on the pipette, a clean and precisely centered tip opening, a perfect surface finish and an optimal one Material transparency, which allow an accurate and thus reproducible dimensioning of liquid samples.

Da bei einem Pipettiervorgang bis zu zwölf Flüssigkeitsproben gleichzeitig entnommen werden, sind zur Deckung des Laborbedarfs einmal verwendbare Pipettenspitzen in großen Stückzahlen erforderlich. Zur Rationalisierung des Pipettierens werden daher autoklavierbare, temperaturbeständige Pipettenspitzenständer mit in äquidistanten Reihen und Spalten angeordneten Pipettenspitzen vorbereitet, damit die Pipettenspitzen auf einfach Art und Weise vom Pipettiergerät aufgegriffen werden können. Diese Pipettenspitzenständer mit den Pipettenspitzen können dann im Bedarfsfall noch sterilisiert werden.Since up to twelve liquid samples are taken at the same time in a pipetting process, single-use pipette tips are required in large quantities to cover laboratory requirements. To rationalize the pipetting, autoclavable, temperature-resistant pipette tip stands with pipette tips arranged in equidistant rows and columns are therefore prepared so that the pipette tips can be picked up in a simple manner by the pipetting device. These pipette tip stands with the pipette tips can then be sterilized if necessary.

Häufig werden die Pipettenspitzenständer noch in mühevoller und zeitaufwendiger Handarbeit mit unsterilen Pipettenspitzen bestückt, die in Beuteln à tausend Stück angeliefert werden.Frequently, the pipette tip stands are still laboriously and time-consuming handcrafted with unsterile pipette tips, which are delivered in bags of a thousand pieces.

Um diese Handarbeit zu vermeiden, werden bereits in äquidistanten Reihen und Spalten angeordnete Pipettenspitzen in Behältern aus Karton oder Kunststoff angeboten. Diese Behälter weisen eine Anzahl von auf die Abmessungen der Pipettenspitzen abgestimmten Vertiefungen oder Löcher auf, in welche die Pipettenspitzen einsortiert sind.In order to avoid this manual work, pipette tips already arranged in equidistant rows and columns are offered in cardboard or plastic containers. These containers have a number of recesses or holes which are matched to the dimensions of the pipette tips and into which the pipette tips are sorted.

Die Behälter mit Pipettenspitzen können bereits sterilisiert sein, sofern die Beschaffenheit des Behälters dies erlaubt. Dies ist lediglich bei den aufwendig gearbeiteten umweltbelastenden Behältern aus Kunststoff gegeben. Bei den weniger aufwendigen und dafür kostengünstigeren Behältern aus Karton ist dies jedoch nicht der Fall. Die darin bereitgestellten Pipettenspitzen müssen zum Sterilisieren noch in den dafür vorgesehenen autoklavierbaren, temperaturbeständigen Pipettenspitzenständer umgesetzt werden.The containers with pipette tips can already be sterilized, provided the nature of the container allows this. This is only the case with the elaborately made environmentally harmful plastic containers. However, this is not the case with the less complex and therefore less expensive cardboard containers. The pipette tips provided therein must still be transferred to the autoclavable, temperature-resistant pipette tip stand provided for sterilization.

Zum Umsetzen der im Behälter geordneten Pipettenspitzen kann eine Adapterplatte mit einer Anzahl von in genormtem Reihen- und Spaltenabstand angeordneten, nach oben weisenden Aufnahmezapfen, die mit den Aufsteckmuffen der Pipettenspitzen korrespondieren, verwendet werden. Dabei werden die Aufnahmezapfen der nach unten gekehrten Adapterplatte von oben kommend in die Aufsteckmuffen der Pipettenspitzen eingeführt. Daraufhin wird der Behälter mit den Pipettenspitzen sowie der Adapterplatte umgewendet und der Behälter von der Adapterplatte mit den Pipettenspitzen abgenommen. Dann wird der mit seiner Oberseite nach unten gekehrte Pipettenspitzenständer auf die Adapterplatte mit den Pipettenspitzen aufgesetzt. Schließlich wird die Adapterplatte mit den Pipettenspitzen sowie dem Pipettenspitzenständer erneut gewendet und die Adapterplatte von dem Pipettenspitzenständer mit den Pipettenspitzen abgenommen.To convert the pipette tips arranged in the container, an adapter plate with a number of upstanding receptacles arranged in a standardized row and column spacing, which correspond to the push-on sleeves of the pipette tips, can be used. The receiving pins of the adapter plate facing downwards are inserted into the push-on sleeves of the pipette tips from above. The container with the pipette tips and the adapter plate is then turned over and the container is removed from the adapter plate with the pipette tips. Then the pipette tip stand turned upside down is placed on the adapter plate with the pipette tips. Finally, the adapter plate with the pipette tips and the pipette tip stand is turned over again and the adapter plate is removed from the pipette tip stand with the pipette tips.

Bei diesem komplizierten Umsetzvorgang ist sowohl Fingerspitzengefühl als auch große Sorgfalt erforderlich, um zum gewünschten Ergebnis zu gelangen, ohne daß einzelne, schräg stehende Pipettenspitzen den Vorgang behindern. Darüber hinaus stellt diese Vorgehensweise eine erhebliche Belastung im Hinblick auf die erforderliche Reinheit der Pipettenspitzen vor dem Sterilisieren dar.With this complicated transfer process, both sensitivity and great care are required to achieve the desired result without individual, slanted pipette tips hindering the process. In addition, this procedure places a considerable burden on the required cleanliness of the pipette tips before sterilization.

Es ist Aufgabe der vorliegenden Erfindung eine Verpackungseinheit für Pipettenspitzen zu konzipieren, die eine einfache und schnelle Handhabung beim Bestücken der Pipettenspitzenständer ermöglicht.It is an object of the present invention to design a packaging unit for pipette tips that is simple and quick to handle when loading the pipette tip stand enables.

Gelöst wird diese Aufgabe bei einer Verpackungseinheit für Pipettenspitzen, die an ihren rückwärtigen Enden eine Aufsteckmuffe mit einem Ringrand aufweisen, durch einen ebenen, im Grundriß rechteckigen, plattenförmigen, dünnen Träger, der auf seiner Oberseite eine Schicht eines druckhaftenden Klebers aufweist, wobei die Pipettenspitzen in äquidistanten Reihen und Spalten, mit ihren Ringrändern auf den Träger ablösbar aufgeklebt sind. Durch diese Ausgestaltung ist es möglich, die Pipettenspitzen in den genormten Reihen- und Spaltenabständen anzuordnen und über den Träger bzw. die Schicht miteinander zu verbinden, wobei der Träger und die Schicht gleichzeitig als Transportmittel in den Pipettenspitzenständer verwendet werden können. Dabei ist die Handhabung der erfindungsgemäßen Verpackungseinheit denkbar einfach, zeitsparend und darüber hinaus ist diese Lösung in der Herstellung äußerst kostengünstig. Ferner können je nach Dimensionierung des Trägers unterschiedliche Anzahlen von Pipettenspitzen in verschiedenen Rastern aufgeklebt werden. Der Träger mit der Schicht kann bis kurz vor der Verwendung der Pipettenspitzen zum Pipettieren als schützende Abdeckung auf den trichterförmig geöffneten Aufsteckmuffen der Pipettenspitzen verbleiben.This problem is solved in a packaging unit for pipette tips, which have a push-on sleeve with a ring edge at their rear ends, by means of a flat, plate-shaped, thin carrier which is rectangular in plan and has a layer of pressure-sensitive adhesive on its top, the pipette tips in equidistant rows and columns, with their ring edges releasably glued to the carrier. This configuration makes it possible to arrange the pipette tips in the standardized row and column spacing and to connect them to one another via the carrier or the layer, the carrier and the layer being able to be used simultaneously as a means of transport in the pipette tip stand. The handling of the packaging unit according to the invention is very simple, time-saving and, moreover, this solution is extremely inexpensive to manufacture. Furthermore, depending on the dimensions of the carrier, different numbers of pipette tips can be glued in different grids. The carrier with the layer can remain on the funnel-shaped push-on sleeves of the pipette tips until shortly before the pipette tips are used for pipetting as a protective cover.

Zweckmäßig weist die Schicht eine dünne Folie mit einem oberen Film sowie einem unteren Film des druckhaftenden Klebers auf. Somit ist der Träger von dem unteren Film abziehbar und die Folie mitsamt des oberen Films sowie des unteren Films von den Ringrändern der Pipettenspitzen abrollbar, während die Pipettenspitzen aufgrund einer leichten, durch das Abrollen verursachten Kippbewegung im Pipettenspitzenständer festgehalten werden.The layer expediently has a thin film with an upper film and a lower film of the pressure-sensitive adhesive. Thus, the carrier can be peeled off from the lower film and the film together with the upper film and the lower film can be rolled off the ring edges of the pipette tips, while the pipette tips are held in the pipette tip stand due to a slight tilting movement caused by the rolling off.

Der untere Film des druckhaftenden Klebers kann aus mehreren im Abstand parallel zueinander angeordneten schmalen Streifen gebildet sein. Auf diese Weise ist die Klebefläche des unteren Films deutlich reduziert, so daß der Träger sehr leicht von dem an der Folie haftenden unteren Film des druckhaftenden Klebers abziehbar ist.The lower film of the pressure-sensitive adhesive can be formed from a plurality of narrow strips arranged parallel and at a distance from one another. In this way, the adhesive area of the lower film is significantly reduced, so that the carrier can be removed very easily from the lower film of the pressure-sensitive adhesive adhering to the film.

Vorteilhaft weist der Träger auf seiner Oberseite eine schmale rundumlaufende Randzone auf, die nicht von der Schicht des druckhaftenden Klebers bedeckt ist. Durch dieses Merkmal wird die Handhabung der Verpackungseinheit erleichtert, da beim Aufgreifen des Trägers von Hand die klebende Schicht, die von der rundumlaufenden Randzone umrahmt ist, nicht berührt wird.The carrier advantageously has on its upper side a narrow all-round edge zone which is not covered by the layer of pressure-sensitive adhesive. This feature makes handling the packaging unit easier, since the adhesive layer, which is framed by the peripheral edge zone, is not touched when the carrier is picked up by hand.

In einer besonders vorteilhaften Ausführung ist der Träger aus Wellpappe gefertigt. Speziell dreilagige Wellpape, die aus Unter-, Ober- und Zwischenlage besteht ist hierfür besonders geeignet, da sie parallel zur Wellenrichtung der Zwischenlage flexibel und senkrecht zur Wellenrichtung der Zwischenlage dagegen äußerst steif ist. Durch Verwendung des kostengünstigen und umweltfreundlichen Materials ist die Abziehbarkeit des Trägers auf einfache Art realisiert.In a particularly advantageous embodiment, the carrier is made from corrugated cardboard. In particular, three-layer corrugated cardboard, which consists of a bottom, top and intermediate layer, is particularly suitable for this, since it is flexible parallel to the direction of the shaft of the intermediate layer and extremely rigid perpendicular to the direction of the shaft of the intermediate layer. By using the inexpensive and environmentally friendly material, the strippability of the carrier is realized in a simple manner.

Der Träger kann eine Stärke von etwa einem Millimeter aufweisen. Bedingt durch dieses Merkmal kann der plattenförmige Träger auch in einem Pipettenspitzenständer verbleiben der mittels einer zusätzlichen Schiebeabdeckung verschlossen werden soll, ohne beim Verschließen der Schiebeabdeckung hinderlich zu sein. Ferner ist es bis zu dieser Stärke des Trägers noch relativ einfach, den Träger bzw. den Träger mit der Schicht von den Pipettenspitzen abzuziehen.The carrier can have a thickness of approximately one millimeter. Due to this feature, the plate-shaped carrier can also remain in a pipette tip stand which is to be closed by means of an additional sliding cover, without being a hindrance when the sliding cover is closed. Furthermore, up to this thickness of the carrier, it is still relatively easy to pull the carrier or the carrier with the layer from the pipette tips.

Die vorliegende Erfindung wird anhand der nachfolgenden Zeichnung näher erläutert.The present invention is explained in more detail with reference to the following drawing.

In der einzigen Zeichnungsfigur ist eine erfindungsgemäße Verpackungseinheit für Pipettenspitzen in perspektivischer, schematischer Darstellung gezeigt.In the single drawing figure, a packaging unit according to the invention for pipette tips is shown in a perspective, schematic representation.

Die dargestellte Verpackungseinheit umfaßt einen Träger 1, eine Schicht 2 eines druckhaftenden Klebers sowie eine Anzahl von Pipettenspitzen 3.The packaging unit shown comprises a

Der ebene, plattenförmige Träger 1 ist im Grundriß rechteckig und weist lediglich eine geringe Stärke von etwa einem Millimeter auf. Der Träger 1 besteht aus einer dreilagigen Wellpappe mit einer ebenen Unterlage 4, einer parallel dazu angeordneten ebenen Oberlage 5 sowie einer dazwischen angeordneten gewellten Zwischenlage 6.The flat, plate-

Auf dem Träger 1 ist eine Schicht 2, bestehend aus einer dünnen Folie 7 mit einem oberen Film 8 sowie einem unteren Film 8' eines druckhaftenden Klebers, ablösbar angebracht. Der untere Film 8' setzt sich aus einer Anzahl von in geringem Abstand zueinander parallel angeordneten schmalen Streifen 9 zusammen.A

Dabei sind die Streifen 9 senkrecht zur Wellenrichtung der Zwischenlage 6 des Trägers 1 orientiert. Die Schicht 2 bedeckt die Oberseite 10 des Trägers 1 bis auf eine gleichbleibend schmale, ringsumlaufende Randzone 11, welche die Schicht 2 des druckhaftenden Klebers einrahmt, vollständig.The

Auf der Schicht 2 sind insgesamt achtundvierzig Pipettenspitzen 3 in einem Raster von äquidistanten Reihen zu jeweils acht Stück und äquidistanten Spalten zu jeweils sechs Stück angeordnet. Dabei weisen die kegelartigen Pipettenspitzen 3 mit ihrer konisch zulaufenden, kreisförmigen Spitzenöffnung 12 senkrecht nach oben, relativ zur Ebene des Trägers 1. Am rückwärtigen, aufgeweiteten Ende jeder Pipettenspitze 3 schließt sich eine ebenfalls aufgeweitete Aufsteckmuffe 13 an, welche in einem ebenen Ringrand 14 endet. Dieser schmale Ringrand 14 stellt die Kontaktfläche für die klebende Befestigung der Pipettenspitzen 3 auf der Schicht 2 bzw. dem ablösbar damit verbundenen Träger 1 dar.A total of forty-eight

- 11

- Trägercarrier

- 22nd

- Schichtlayer

- 33rd

- PipettenspitzenPipette tips

- 44th

- Unterlagedocument

- 55

- OberlageTop layer

- 66

- ZwischenlageLiner

- 77

- Foliefoil

- 8,8'8.8 '

- FilmMovie

- 99

- StreifenStripes

- 1010th

- Oberseite von 1Top of 1

- 1111

- RandzoneEdge zone

- 1212th

- SpitzenöffnungTip opening

- 1313

- AufsteckmuffeSlip-on sleeve

- 1414

- RingrandRing edge

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE9310258U | 1993-07-09 | ||

| DE9310258U DE9310258U1 (en) | 1993-07-09 | 1993-07-09 | Packaging unit for pipette tips |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0633192A2 true EP0633192A2 (en) | 1995-01-11 |

| EP0633192A3 EP0633192A3 (en) | 1995-08-09 |

Family

ID=6895401

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94108742A Withdrawn EP0633192A3 (en) | 1993-07-09 | 1994-06-08 | Packaging unit for pipette tips. |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5445270A (en) |

| EP (1) | EP0633192A3 (en) |

| JP (1) | JPH07165258A (en) |

| DE (1) | DE9310258U1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006014882A1 (en) * | 2004-07-29 | 2006-02-09 | Cook Vascular Incorporated | Micropipette holder |

| CN104150101A (en) * | 2013-04-12 | 2014-11-19 | 埃佩多夫股份公司 | Device for providing pipette tips |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE9310258U1 (en) * | 1993-07-09 | 1993-08-26 | Carl Roth GmbH & Co, 76185 Karlsruhe | Packaging unit for pipette tips |

| US5779984A (en) * | 1996-12-04 | 1998-07-14 | Rainin Intstrumental Co., Inc. | Pipette tip rack and refill pack containing large maximized volume freely nestable pipette tips |

| WO1998045041A1 (en) * | 1997-04-05 | 1998-10-15 | Bernd Steinbrenner | Device for picking up and distributing laboratory objects with at least in part a hollow cylindrical contour |

| US6328933B1 (en) | 2000-03-16 | 2001-12-11 | Corning Incorporated | Double density pipette tip storage rack |

| DE10056912A1 (en) * | 2000-11-16 | 2002-05-23 | Bernd Steinbrenner | Filling support with e.g. pipette tips or reaction vessels involves positioning storage stack of objects, maintaining uppermost layer and removing support |

| US9895526B2 (en) * | 2006-03-08 | 2018-02-20 | Ivaxis, Llc | Anti-contamination cover for fluid connections |

| US7780794B2 (en) | 2006-07-21 | 2010-08-24 | Ivera Medical Corporation | Medical implement cleaning device |

| US8647326B2 (en) * | 2007-01-16 | 2014-02-11 | Catheter Connections, Inc. | System for cleaning luer connectors |

| US8419713B1 (en) | 2012-08-01 | 2013-04-16 | The University Of Utah Research Foundation | Carrier assembly with caps for medical connectors |

| US8328767B2 (en) | 2007-01-16 | 2012-12-11 | Catheter Connections, Inc. | Disinfecting caps for medical male luer connectors |

| US9259284B2 (en) | 2007-02-12 | 2016-02-16 | 3M Innovative Properties Company | Female Luer connector disinfecting cap |

| FI20085988A0 (en) | 2008-10-20 | 2008-10-20 | Thermo Fisher Scientific Oy | Packed lace |

| BRPI1011707A2 (en) * | 2009-06-01 | 2019-09-24 | Ivera Medical Corp | "Friction-based medical instrument cleaning device" |

| WO2011066565A1 (en) | 2009-11-30 | 2011-06-03 | Catheter Connections, Inc. | Disinfecting caps having an extendable feature and related systems and methods |

| US20120216359A1 (en) * | 2011-02-18 | 2012-08-30 | Ivera Medical Corporation | Medical Implement Cleaning System |

| US8832894B2 (en) | 2011-07-19 | 2014-09-16 | Ivera Medical Corporation | Cleaning device for male end of intraveneous set |

| CA2875153A1 (en) | 2012-06-04 | 2013-12-12 | Ivera Medical Corporation | Male medical implement cleaning device |

| US9907617B2 (en) | 2013-03-15 | 2018-03-06 | 3M Innovative Properties Company | Medical implement cleaning device |

| JP2015098342A (en) * | 2013-11-19 | 2015-05-28 | 株式会社エンプラス | Closed vessel and closed vessel set |

| US11628288B1 (en) | 2014-07-14 | 2023-04-18 | Merit Medical Systems, Inc. | Disinfecting cap for needleless injection sites |

| WO2016085815A1 (en) | 2014-11-24 | 2016-06-02 | Catheter Connections, Inc. | Disinfecting cap for medical connectors |

| WO2017087400A1 (en) | 2015-11-16 | 2017-05-26 | Catheter Connections, Inc. | Disinfecting cap for male luers |

| WO2018140284A1 (en) | 2017-01-27 | 2018-08-02 | Merit Medical Systems, Inc. | Disinfecting luer cap and method of use |

| US11058858B2 (en) | 2017-10-04 | 2021-07-13 | Merit Medical Systems, Inc. | Disinfecting cap for valved connectors and method of use |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63194735A (en) * | 1987-02-06 | 1988-08-11 | Inoue Seisakusho:Kk | Tip set for micropipette |

| DE3924103A1 (en) * | 1989-07-20 | 1991-01-31 | Gert Schiedel | Dropping pipette tips into autoclavable container from grid - releasably held in folding cardboard box |

| DE9310258U1 (en) * | 1993-07-09 | 1993-08-26 | Carl Roth GmbH & Co, 76185 Karlsruhe | Packaging unit for pipette tips |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3047144A (en) * | 1960-10-10 | 1962-07-31 | Joseph A Wissel | Ad-token card |

| US3853217A (en) * | 1972-08-09 | 1974-12-10 | Medical Laboratory Automation | Pipette tip package |

| US4015708A (en) * | 1975-11-21 | 1977-04-05 | Gould Inc. | Button cell storage and merchandising package |

| DE8010525U1 (en) * | 1980-04-17 | 1981-10-08 | Landgold Milch GmbH, 7118 Künzelsau | Packaging and presentation unit for can, cup or bottle-shaped containers |

| JPS59158596A (en) * | 1983-02-28 | 1984-09-08 | 奥井 徳次郎 | Method of containing small-sized electronic part |

| SE454348B (en) * | 1983-06-14 | 1988-04-25 | Moelnlycke Ab | PACKAGING FOR MENSTRUATION PROTECTION |

| DE3711256A1 (en) * | 1987-04-03 | 1988-10-13 | Lohmann Therapie Syst Lts | REMOVAL AID AND THEIR USE |

| US5011779A (en) * | 1988-01-21 | 1991-04-30 | Long Island Jewish Medical Center | Apparatus for rapid deposition of test samples on an absorbent support |

| DE9106583U1 (en) * | 1991-05-29 | 1991-08-14 | Robert Thoma GmbH Rotho - Kunststoffwerke, 7800 Freiburg | Packaging unit with adhesive hooks or similar arranged therein. |

| DE9203388U1 (en) * | 1992-03-13 | 1992-05-21 | Gizeh-Werk Gmbh, 5275 Bergneustadt | Sales packaging for cigarette papers booklets or similar. |

| US5299687A (en) * | 1992-12-22 | 1994-04-05 | Sage Products, Inc. | Cannula adaptor delivery system |

| US5350059A (en) * | 1993-02-02 | 1994-09-27 | Minnesota Mining And Manufacturing Company | Dental dispensing system |

-

1993

- 1993-07-09 DE DE9310258U patent/DE9310258U1/en not_active Expired - Lifetime

-

1994

- 1994-06-08 EP EP94108742A patent/EP0633192A3/en not_active Withdrawn

- 1994-07-07 JP JP6155882A patent/JPH07165258A/en active Pending

- 1994-07-07 US US08/271,677 patent/US5445270A/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63194735A (en) * | 1987-02-06 | 1988-08-11 | Inoue Seisakusho:Kk | Tip set for micropipette |

| DE3924103A1 (en) * | 1989-07-20 | 1991-01-31 | Gert Schiedel | Dropping pipette tips into autoclavable container from grid - releasably held in folding cardboard box |

| DE9310258U1 (en) * | 1993-07-09 | 1993-08-26 | Carl Roth GmbH & Co, 76185 Karlsruhe | Packaging unit for pipette tips |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 012 no. 479 (C-552) ,14.Dezember 1988 & JP-A-63 194735 (INOUE SEISAKUSHO:KK) 11.August 1988, * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006014882A1 (en) * | 2004-07-29 | 2006-02-09 | Cook Vascular Incorporated | Micropipette holder |

| US7770730B2 (en) | 2004-07-29 | 2010-08-10 | Cook Vascular Incorporated | Micropipette holder |

| CN104150101A (en) * | 2013-04-12 | 2014-11-19 | 埃佩多夫股份公司 | Device for providing pipette tips |

| CN104150101B (en) * | 2013-04-12 | 2018-02-13 | 埃佩多夫股份公司 | For providing the device of suction pipe head |

Also Published As

| Publication number | Publication date |

|---|---|

| DE9310258U1 (en) | 1993-08-26 |

| US5445270A (en) | 1995-08-29 |

| EP0633192A3 (en) | 1995-08-09 |

| JPH07165258A (en) | 1995-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0633192A2 (en) | Packaging unit for pipette tips | |

| DE69021672T2 (en) | Cuvette matrix and its tray. | |

| DE10300702B4 (en) | Recharging system and method for holding a plurality of stacks of pipette tip assemblies | |

| DE69808272T2 (en) | REACTION CONTAINER APPARATUS | |

| EP0744994B1 (en) | Microtitration plate | |

| DE2716323C2 (en) | Device for inhalation of medicaments | |

| DE2545237C3 (en) | Device for ejecting a ferrule from a pipette | |

| DE2628344C3 (en) | Dish for tissue culture groups | |

| EP2671056B1 (en) | Weighing compartment with integrated balance | |

| EP2660602A1 (en) | Test kit for lab diagnostics | |

| DE29817223U1 (en) | Device for taking up a cell culture | |

| DE2340106A1 (en) | PACKAGING PIPETTE TIPS | |

| EP0608401B1 (en) | Incubator | |

| WO2008000312A1 (en) | Microtiter plate with stirring elements | |

| DE69718425T2 (en) | Variety cuvette pack, method and device for introducing cuvettes into a measuring device | |

| DE19952139C1 (en) | Transparent object carrier for optical microscope has adhered transparent plastics foil providing line grid used as coordinate refernece grid for examination of microscope object | |

| DE69006251T2 (en) | Universal containment against evaporation. | |

| DE3529455A1 (en) | Test tube for medical laboratories | |

| DE4321062C2 (en) | Method and device for treating biological objects that are in a liquid | |

| DE3903974C2 (en) | ||

| DE10302895B4 (en) | Cover for the openings of reaction vessels formed in microtiter plates | |

| DE29607444U1 (en) | Device for high-purity packaging and use of laboratory disposables | |

| DE4215932C1 (en) | METHOD FOR EQUIPPING SAMPLE TUBES WITH DISKS WITH BIOLOGICALLY ACTIVE SUBSTANCES BONDED TO IT IN AN AUTOMATIC PIPETTING DEVICE | |

| DE3934088C2 (en) | ||

| EP1281373B1 (en) | System for displaying dental instruments and/or for mixing dental substances |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19951130 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19961206 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19970415 |