EP0626442A1 - Pour point depressant treated fatty acid esters as biodegradable, combustion engine fuels - Google Patents

Pour point depressant treated fatty acid esters as biodegradable, combustion engine fuels Download PDFInfo

- Publication number

- EP0626442A1 EP0626442A1 EP94303590A EP94303590A EP0626442A1 EP 0626442 A1 EP0626442 A1 EP 0626442A1 EP 94303590 A EP94303590 A EP 94303590A EP 94303590 A EP94303590 A EP 94303590A EP 0626442 A1 EP0626442 A1 EP 0626442A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- carbon atoms

- oil

- parts

- ester

- composition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/19—Esters ester radical containing compounds; ester ethers; carbonic acid esters

- C10L1/191—Esters ester radical containing compounds; ester ethers; carbonic acid esters of di- or polyhydroxyalcohols

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/02—Liquid carbonaceous fuels essentially based on components consisting of carbon, hydrogen, and oxygen only

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/143—Organic compounds mixtures of organic macromolecular compounds with organic non-macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/16—Hydrocarbons

- C10L1/1616—Hydrocarbons fractions, e.g. lubricants, solvents, naphta, bitumen, tars, terpentine

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/16—Hydrocarbons

- C10L1/1625—Hydrocarbons macromolecular compounds

- C10L1/1633—Hydrocarbons macromolecular compounds homo- or copolymers obtained by reactions only involving carbon-to carbon unsaturated bonds

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/16—Hydrocarbons

- C10L1/1691—Hydrocarbons petroleum waxes, mineral waxes; paraffines; alkylation products; Friedel-Crafts condensation products; petroleum resins; modified waxes (oxidised)

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/1802—Organic compounds containing oxygen natural products, e.g. waxes, extracts, fatty oils

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/182—Organic compounds containing oxygen containing hydroxy groups; Salts thereof

- C10L1/1822—Organic compounds containing oxygen containing hydroxy groups; Salts thereof hydroxy group directly attached to (cyclo)aliphatic carbon atoms

- C10L1/1824—Organic compounds containing oxygen containing hydroxy groups; Salts thereof hydroxy group directly attached to (cyclo)aliphatic carbon atoms mono-hydroxy

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/182—Organic compounds containing oxygen containing hydroxy groups; Salts thereof

- C10L1/183—Organic compounds containing oxygen containing hydroxy groups; Salts thereof at least one hydroxy group bound to an aromatic carbon atom

- C10L1/1832—Organic compounds containing oxygen containing hydroxy groups; Salts thereof at least one hydroxy group bound to an aromatic carbon atom mono-hydroxy

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/188—Carboxylic acids; metal salts thereof

- C10L1/1881—Carboxylic acids; metal salts thereof carboxylic group attached to an aliphatic carbon atom

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/19—Esters ester radical containing compounds; ester ethers; carbonic acid esters

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/192—Macromolecular compounds

- C10L1/195—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

- C10L1/196—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derived from monomers containing a carbon-to-carbon unsaturated bond and a carboxyl group or salts, anhydrides or esters thereof homo- or copolymers of compounds having one or more unsaturated aliphatic radicals each having one carbon bond to carbon double bond, and at least one being terminated by a carboxyl radical or of salts, anhydrides or esters thereof

- C10L1/1963—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derived from monomers containing a carbon-to-carbon unsaturated bond and a carboxyl group or salts, anhydrides or esters thereof homo- or copolymers of compounds having one or more unsaturated aliphatic radicals each having one carbon bond to carbon double bond, and at least one being terminated by a carboxyl radical or of salts, anhydrides or esters thereof mono-carboxylic

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/192—Macromolecular compounds

- C10L1/198—Macromolecular compounds obtained otherwise than by reactions involving only carbon-to-carbon unsaturated bonds homo- or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon to carbon double bond, and at least one being terminated by an acyloxy radical of a saturated carboxylic acid, of carbonic acid

- C10L1/1985—Macromolecular compounds obtained otherwise than by reactions involving only carbon-to-carbon unsaturated bonds homo- or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon to carbon double bond, and at least one being terminated by an acyloxy radical of a saturated carboxylic acid, of carbonic acid polyethers, e.g. di- polygylcols and derivatives; ethers - esters

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/221—Organic compounds containing nitrogen compounds of uncertain formula; reaction products where mixtures of compounds are obtained

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/222—Organic compounds containing nitrogen containing at least one carbon-to-nitrogen single bond

- C10L1/2222—(cyclo)aliphatic amines; polyamines (no macromolecular substituent 30C); quaternair ammonium compounds; carbamates

- C10L1/2225—(cyclo)aliphatic amines; polyamines (no macromolecular substituent 30C); quaternair ammonium compounds; carbamates hydroxy containing

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/222—Organic compounds containing nitrogen containing at least one carbon-to-nitrogen single bond

- C10L1/223—Organic compounds containing nitrogen containing at least one carbon-to-nitrogen single bond having at least one amino group bound to an aromatic carbon atom

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/222—Organic compounds containing nitrogen containing at least one carbon-to-nitrogen single bond

- C10L1/224—Amides; Imides carboxylic acid amides, imides

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/228—Organic compounds containing nitrogen containing at least one carbon-to-nitrogen double bond, e.g. guanidines, hydrazones, semicarbazones, imines; containing at least one carbon-to-nitrogen triple bond, e.g. nitriles

- C10L1/2283—Organic compounds containing nitrogen containing at least one carbon-to-nitrogen double bond, e.g. guanidines, hydrazones, semicarbazones, imines; containing at least one carbon-to-nitrogen triple bond, e.g. nitriles containing one or more carbon to nitrogen double bonds, e.g. guanidine, hydrazone, semi-carbazone, azomethine

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/23—Organic compounds containing nitrogen containing at least one nitrogen-to-oxygen bond, e.g. nitro-compounds, nitrates, nitrites

- C10L1/231—Organic compounds containing nitrogen containing at least one nitrogen-to-oxygen bond, e.g. nitro-compounds, nitrates, nitrites nitro compounds; nitrates; nitrites

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/232—Organic compounds containing nitrogen containing nitrogen in a heterocyclic ring

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/234—Macromolecular compounds

- C10L1/236—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derivatives thereof

- C10L1/2366—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derivatives thereof homo- or copolymers derived from unsaturated compounds containing amine groups

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/22—Organic compounds containing nitrogen

- C10L1/234—Macromolecular compounds

- C10L1/238—Macromolecular compounds obtained otherwise than by reactions involving only carbon-to-carbon unsaturated bonds

- C10L1/2383—Polyamines or polyimines, or derivatives thereof (poly)amines and imines; derivatives thereof (substituted by a macromolecular group containing 30C)

Definitions

- a natural oil comprising animal fat or vegetable oils is reacted with an alcohol to obtain the transesterified esters.

- These natural oils include triglycerides of the formula wherein R1, R2 and R3 are aliphatic hydrocarbyl groups containing from about 6 to about 24 carbon atoms.

- the term "hydrocarbyl group” as used herein and throughout this specification and claims denotes a radical having a carbon atom directly attached to the remainder of the molecule.

- the aliphatic hydrocarbyl groups include the following:

- Example A-9 The procedure of Example A-9 is essentially followed except that beef tallow oil is utilized instead of cottonseed oil.

- the product obtained is the transesterified ethyl ester of beef tallow oil.

- Example A-10 The procedure of Example A-10 is essentially followed except that menhaden oil is utilized instead of corn oil.

- the product obtained is the transesterified n-butyl ester of menhaden oil.

- low molecular weight groups include methoxy, ethoxy, n-propyloxy, isopropyloxy, n-butyloxy, sec-butyloxy, iso-butyloxy, n-pentyloxy, neo-pentyloxy, n-hexyloxy, cyclohexyloxy, xyxlopentyloxy, 2-methyl-butyl-1-oxy, 2,3-dimethyl-butyl-1-oxy, etc.

- alkoxy groups of suitable size comprise the preferred high and low molecular weight ester groups.

- Polar substituents may be present in such ester groups. Examples of polar substituents are chloro, bromo, ether, nitro, etc.

- the ratio is from about 2.5:1 to about 5:1. More than one high molecular weight alcohol or low molecular weight alcohol may be used in the process; so also may be used commercial alcohol mixtures such as the so-called Oxoalcohols which comprise, for example mixtures of alcohols having from 8 to about 24 carbon atoms.

- a particularly useful class of alcohols are the commercial alcohols or alcohol mixtures comprising decylalcohol, dodecyl alcohol, tridecyl alcohol, tetradecyl alcohol, pentadecyl alcohol, hexadecyl alcohol, heptadecyl alcohol and octadecyl alcohol.

- Other alcohols useful in the process are illustrated by those which, upon esterification, yield the ester groups exemplified above.

- Example (B-10) The following example is similar to Example (B-10) but employs different alcohols and different levels in a different order of addition.

- Component (B) may be at least one hydrocarbon-soluble acrylate polymer of the formula wherein R5 is hydrogen or a lower alkyl group containing from 1 to about 4 carbon atoms, R6 is a mixture of alkyl, cycloalkyl or aromatic groups containing from about 4 to about 24 carbon atoms, and x is an integer providing a weight average molecular weight (Mw) to the acrylate polymer of about 5000 to about 1,000,000.

- R5 is hydrogen or a lower alkyl group containing from 1 to about 4 carbon atoms

- R6 is a mixture of alkyl, cycloalkyl or aromatic groups containing from about 4 to about 24 carbon atoms

- x is an integer providing a weight average molecular weight (Mw) to the acrylate polymer of about 5000 to about 1,000,000.

- alkyl groups R6 which may be included in the polymers of the present invention include, for example, n-butyl, octyl, decyl, dodecyl, tridecyl, octadecyl, hexadecyl, octadecyl.

- the mixture of alkyl groups can be varied so long as the resulting polymer is hydrocarbon-soluble.

- the reaction is held at 100°C for 16 hours after which the temperature is increased to 120°C to remove toluene and added is 216 parts of Sunyl® 80. Volatiles are removed by vacuum distillation at 20 millimeters mercury at 140°C. The contents are filtered to give the desired product.

- Component (B) may also be a nitrogen-containing polyacrylate prepared by reacting an acrylate ester of the formula wherein R9 is hydrogen or an alkyl group containing from 1 to about 4 carbon atoms and R10 is an alkyl, cycloalkyl or aromatic group containing from 4 to about 24 carbon atoms with a nitrogen containing compound. For each mole of the acrylate ester from 0.001 - 1.0 moles of the nitrogen containing compound is employed. The reaction is carried out at a temperature of from 50°C up to about 250°C.

- the components (a'), (b'), (c'), (d') and (e') might be present in weight ratios of (a'):(b'):(c'):(d'):(e') in the ranges of about (1):(.01-1):(0.5-6):(0.5-22):(1-40) and most preferably (1):(0.2):(3):(11):(20); all ratios are in parts by weight.

- the additive (C) may be selected from

- the carboxylic dispersant composition is characterized by the presence within its molecular structure of (i) at least one polar group selected from acyl, acyloxy or hydrocarbyl-imidoyl groups, and (ii) at least one group in which a nitrogen or oxygen atom is attached directly to said group (i), and said nitrogen or oxygen atom also is attached to a hydrocarbyl group.

- the structures of the polar group (i), as defined by the International Union of Pure and Applied Chemistry, are as follows (R27 representing a hydrocarbon or similar group): Acyl: Acyloxy: Hydrocarbylimidoyl:

- the carboxylic dispersants can be prepared by the reaction of a hydrocarbon-substituted succinic acid-producing compound (herein sometimes referred to as the "succinic acylating agent") with at least about one-half equivalent, per equivalent of acid-producing compound, of an organic hydroxy compound, or an amine containing at least one hydrogen attached to a nitrogen group, or a mixture of said hydroxy compound and amine.

- a hydrocarbon-substituted succinic acid-producing compound herein sometimes referred to as the "succinic acylating agent”

- the carboxylic dispersants (C-4) obtained in this manner are usually complex mixtures whose precise composition is not readily identifiable.

- the nitrogen- containing carboxylic dispersants are sometimes referred to herein as "acylated amines”.

- a convenient route for the preparation of the nitrogen-containing carboxylic dispersants (C-3) comprises the reaction of a hydrocarbon-substituted succinic acid-producing compound ("carboxylic acid acylating agent") with an amine containing at least one hydrogen attached to a nitrogen atom (i.e., H-N ⁇ ).

- the hydrocarbon-substituted succinic acid-producing compounds include the succinic acids, anhydrides, halides and esters.

- the number of carbon atoms in the hydrocarbon substituent on the succinic acid-producing compound may vary over a wide range provided that the nitrogen-containing composition (C-3) is soluble in the lubricating compositions of the present invention.

- Another source of the substantially hydrocarbon group comprises saturated aliphatic hydrocarbons such as highly refined high molecular weight white oils or synthetic alkanes such as are obtained by hydrogenation of high molecular weight olefin polymers illustrated above or high molecular weight olefinic substances.

- olefin polymers having molecular weights (Mn) of about 700-10,000 are preferred.

- Higher molecular weight olefin polymers having molecular weights (Mn) from about 10,000 to about 100,000 or higher have been found to impart also viscosity index improving properties to the final products of this invention.

- the use of such higher molecular weight olefin polymers often is desirable.

- the substituent is derived from a polyolefin characterized by an Mn value of about 700 to about 10,000, and an Mw/Mn value of 1.0 to about 4.0.

- an equivalent weight of chlorinated polyalkene is the weight corresponding to the Mn value divided by the average number of chloro groups per molecule of chlorinated polyalkene while the equivalent weight of a maleic reactant is its molecular weight.

- the ratio of chlorinated polyalkene to maleic reactant will normally be such as to provide about one equivalent of maleic reactant for each mole of chlorinated polyalkene up to about one equivalent of maleic reactant for each equivalent of chlorinated polyalkene with the understanding that it is normally desirable to provide an excess of maleic reactant; for example, an excess of about 5% to about 25% by weight. Unreacted excess maleic reactant may be stripped from the reaction product, usually under vacuum, or reacted during a further stage of the process as explained below.

- Chlorine may be introduced continuously or intermittently during the one-step process.

- the rate of introduction of the chlorine is not critical although, for maximum utilization of the chlorine, the rate should be about the same as the rate of consumption of chlorine in the course of the reaction.

- the introduction rate of chlorine exceeds the rate of consumption, chlorine is evolved from the reaction mixture. It is often advantageous to use a closed system, including superatmospheric pressure, in order to prevent loss of chlorine so as to maximize chlorine utilization.

- the upper limit of the useful temperature in the one-step process is determined primarily by the decomposition point of the components in the reaction mixture including the reactants and the desired products.

- the decomposition point is that temperature at which there is sufficient decomposition of any reactant or product such as to interfere with the production of the desired products.

- the amines may also contain non-hydrocarbon substituents or groups as long as these groups do not significantly interfere with the reaction of the amines with the acylating reagents of this invention.

- non-hydrocarbon substituents or groups include lower alkoxy, lower alkyl mercapto, nitro, interrupting groups such as -O- and -S- (e.g., as in such groups as -CH2CH2-X-CH2CH2- where X is -O- or -S-).

- the amines ordinarily contain less than about 40 carbon atoms in total and usually not more than about 20 carbon atoms in total.

- Aliphatic monoamines include mono-aliphatic and dialiphatic substituted amines wherein the aliphatic groups can be saturated or unsaturated and straight or branched chain. Thus, they are primary or secondary aliphatic amines. Such amines include, for example, mono- and dialkyl-substituted amines, mono- and di-alkenyl-substituted amines, and amines having one N-alkenyl substituent and one N-alkyl substituent and the like. The total number of carbon atoms in these aliphatic monoamines will, as mentioned before, normally not exceed about 40 and usually not exceed about 20 carbon atoms.

- Such monoamines include ethylamine, diethylamine, n-butylamine, di-n-butylamine, allylamine, isobutylamine, cocoamine, stearylamine, laurylamine, methyllaurylamine, oleyl-amine, N-methyl-octylamine, dodecylamine, octadecylamine, and the like.

- Cycloaliphatic monoamines are those monoamines wherein there is one cycloaliphatic substituent attached directly to the amino nitrogen through a carbon atom in the cyclic ring structure.

- Examples of cycloaliphatic monoamines include cyclohexylamines, cyclopentylamines, cyclohexenylamines, cyclopentenylamines, N-ethyl-cyclohexylamine, dicyclohexylamines, and the like.

- aliphatic-substituted, cycloaliphatic-substituted, and heterocyclic-substituted aromatic monoamines are para-ethoxyaniline, para-dodecylaniline, cyclohexyl-substituted naphthylamine, and thienyl-substituted aniline.

- substantially neutral or acidic dispersants are preferred, and a typical method of producing mixed oxygen- and nitrogen-bridged dispersants of this type (which are especially preferred) is to react the acylating agent with the hydroxy reagent first and subsequently react the intermediate thus obtained with a suitable nitrogen-containing reagent in an amount to afford a substantially neutral or acid product.

- Example (C-3)-1 The procedure of Example (C-3)-1 is repeated using 55.0 grams (1.5 equivalents) of triethylene tetramine as the amine reactant. The resulting product has a nitrogen content of 2.9%.

- a mixture is prepared by the addition of 57 parts (1.38 equivalents) of a commercial mixture of ethylene polyamine having from about 3 to 10 nitrogen atoms per molecule to 1067 parts of mineral oil and 893 parts (1.38 equivalents) of the substituted succinic acylating agent at 140-145°C.

- the reaction mixture is heated to 155°C in 3 hours and stripped by blowing with nitrogen.

- the reaction mixture if filtered to yield the filtrate as an oil solution of the desired product.

- the fuel compositions of the present invention contain a major amount of a normally liquid fuel comprising

- Synthetic ester base oils that comprise the reaction of a monocarboxylic acid of the formula R19COOH or a dicarboxylic acid of the formula with an alcohol of the formula R21(OH) n wherein R19 is a hydrocarbyl group containing from about 4 to about 24 carbon atoms, R20 is hydrogen or a hydrocarbyl group containing from about 4 to about 50 carbon atoms, R21 is a hydrocarbyl group containing from 1 to about 24 carbon atoms, m is an integer of from 0 to about 6 and n is an integer of from 1 to about 6.

- Alcohols that may be employed are methyl alcohol, ethyl alcohol, butyl alcohol, the isomeric pentyl alcohols, the isomeric hexyl alcohols, dodecyl alcohol, 2-ethylhexyl alcohol, ethylene glycol, diethylene glycol, propylene glycol, neopentyl glycol, pentaerythritol, dipentaerythritol, trimethololpropane, bis-trimethololpropane, etc.

- a non-exhaustive list of companies that produce synthetic esters and their trade names are BASF as Glissofluid, Ciba-Geigy as Reolube, JCI as Emkarote, Oleofina as Radialube and the Emery Group of Henkel Corporation as Emery 2964, 2911, 2960, 2976, 2935, 2971, 2930 and 2957.

- Synthetic lubricating oils include hydrocarbon oils and halosubstituted hydrocarbon oils such as polymerized and interpolymerized olefins (e.g., polybutylenes, polypropylenes, propyleneisobutylene copolymers, chlorinated polybutylenes, etc.); poly(1-hexenes), poly(l-octenes), poly(1-decenes), etc.

- hydrocarbon oils and halosubstituted hydrocarbon oils such as polymerized and interpolymerized olefins (e.g., polybutylenes, polypropylenes, propyleneisobutylene copolymers, chlorinated polybutylenes, etc.); poly(1-hexenes), poly(l-octenes), poly(1-decenes), etc.

- alkylbenzenes e.g., dodecylbenzenes, tetradecylbenzenes, dinonylbenzenes, di-(2-ethylhexyl)benzenes, etc.

- polyphenyls e.g., biphenyls, terphenyls, alkylated polyphenyls, etc.

- Unrefined, refined and rerefined oils can also be used in the present invention.

- Unrefined oils are those obtained directly from a natural or synthetic source without further purification treatment.

- a shale oil obtained directly from retorting operations a petroleum oil obtained directly from primary distillation or ester oil obtained directly from an esterification process and used without further treatment would be an unrefined oil.

- Refined oils are similar to the unrefined oils except they have been further treated in one or more purification steps to improve one or more properties. Many such purification techniques are known to those skilled in the art such as solvent extraction, secondary distillation, acid or base extraction, filtration, percolation, etc.

- Vegetable oils having utility as a fuel in this invention are those vegetable oils obtained without genetic modification, i.e., their monounsaturation content (as oleic acid) is below 60 percent.

- Vegetable oils having utility are canola oil, peanut oil, palm oil, corn oil, soybean oil, sunflower oil, cottonseed oil, safflower oil and coconut oil.

- these fuel compositions contain an amount of the (A), (B) composition or (A), (B), (C) composition sufficient to improve one or more properties of the fuel such as rust-inhibition, dispersancy, etc., usually this amount is about 0.005 to about 0.5% by volume, preferably about 0.01 to about 0.1% by volume, based on the volume of such fuel compositions.

- the fuel additive compositions of this invention can be added directly to the fuel, or they can be diluted with a substantially inert, normally liquid organic diluent such as naphtha, benzene, toluene, xylene or a normally liquid fuel as described above, to form an additive concentrate.

- a substantially inert, normally liquid organic diluent such as naphtha, benzene, toluene, xylene or a normally liquid fuel as described above

- These concentrates generally contain from about 20% to about 90% by weight of the composition of this invention and may contain, in addition, one or more other conventional additives known inthe art or described hereinabove.

- the (A) : (B) weight ratio is generally from 90:10 to 99.5:0.5, preferably from 95:5 to 99.5:0.5 and most preferably from 98:2 to 99.5:0.5.

- composition comprises components (A) and (B) or (A), (B) and (C) with (D) the following states the ranges of these components in parts by weight: Component Generally Preferred Most Preferred (A) 10-90 20-90 20-50 (B) 0.1-20 0.1-10 0.5-5 (C) zero or 0.001-1.0 zero or 0.01-0.5 zero or 0.01-0.1 (D) 10-90 20-90 20-50

Landscapes

- Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Emergency Medicine (AREA)

- Lubricants (AREA)

- Liquid Carbonaceous Fuels (AREA)

- Fats And Perfumes (AREA)

Abstract

- (A) esters from the transesterification of at least one animal fat or vegetable oil triglyceride of the formula

- (B) a pour point depressant.

Description

- The present invention relates to natural oils such as animal oils and vegetable oils that are transesterified and contain at least one pour point depressant. In addition to pour point depressants, the transesterified natural oil may also contain additional additives as well as a normally liquid fuel.

- Successful use of esters of transesterified natural oils as environmentally friendly, that is biodegradable, base fluids in industrial applications and also as a fuel additive when mixed with normally liquid fuels, is contingent upon improving their low temperature viscometries. For example, a methyl ester obtained from the transesterification of rapeseed oil, has utility as an environmentally friendly diesel fuel. However, this methyl ester has a pour point of -12°C and solidifies at 13.6°C which results in clogged filters and engine failure. In order to take advantage of the biodegradability of transesterified esters of natural oils, it becomes necessary to lower the pour point.

- U.S. Patent No. 2,243,198 (Dietrich, May 27, 1941) relates to non-viscous normally liquid hydrocarbon oils and more particularly to the production of fuel oils having improved flow characteristics under low temperature conditions. The flow characteristics of fuel oil is improved by the addition of a hydrogenated castor oil derivative to a non-viscous normally liquid hydrocarbon oil. Hydrogenated castor oil derivative is defined as the product obtained by reacting hydrogenated castor oil either with its own hydroxyl group or with another organic compound selected from the classes of alcohols, aldehydes, acids, isocyanates and isothiocyanates.

-

- (a) R is (1) an alkyl radical having from 1 to 12 carbon atoms, (2) alkoxy alkyl wherein the alkoxy portion has from 1 to 4 carbon atoms and the alkyl portion is ethyl or propyl, (3) cyclopentyl or cyclohexyl and (4) hydroxy ethyl and hydroxy propyl;

- (b) n = 11-22;

- (c) a = 2n+1, 2n-1, 2n-3, 2n-5, or 2n-7; and

- (d) x is 0 or 1.

- U.S. Patent No. 4,575,382 (Sweeney et al, March 11, 1986) relates to a vegetable oil containing middle distillate fuel characterized by an improved thermal stability. The vegetable oils which may be used include soybean oil, peanut oil and sunflower seed oil.

- U.S. Patent 4,695,411 (Stern et al, September 22, 1987) relates to a process for manufacturing a major portion of ethyl esters usable as gas oil substitute motor fuel by transesterification of an animal or vegetable oil optionally containing free acids.

- U.S. Patent 5,160,506 (Schur et al, November 3, 1992) relates to a liquid fuel mixture, comprising a C₃ and/or at least a C₄-alkane, at least one oil component and optionally at least one additive, a process for its preparation and its use for two-stroke engines.

- A composition is disclosed which comprises

- (A) esters from the transesterification of at least one animal fat or vegetable oil triglyceride of the formula

- (B) a pour point depressant.

- In addition to components (A) and (B), the composition may also contain an additive (C) and/or (D) a normally liquid fuel.

- Various preferred features and embodiments of the invention are described below by way of non-limiting illustration.

- In practicing this invention, a natural oil comprising animal fat or vegetable oils is reacted with an alcohol to obtain the transesterified esters. These natural oils include triglycerides of the formula

wherein R¹, R² and R³ are aliphatic hydrocarbyl groups containing from about 6 to about 24 carbon atoms. The term "hydrocarbyl group" as used herein and throughout this specification and claims denotes a radical having a carbon atom directly attached to the remainder of the molecule. The aliphatic hydrocarbyl groups include the following: - (1) Aliphatic hydrocarbon groups; that is, alkyl groups such as heptyl, nonyl, undecyl, tridecyl, heptadecyl; alkenyl groups containing a single double bond such as heptenyl, nonenyl, undecenyl, tridecenyl, heptadecenyl, heneicosenyl; alkenyl groups containing 2 or 3 double bonds such as 8,11-heptadecadienyl and 8,11,14-heptadecatrienyl. All isomers of these are included, but straight chain groups are preferred.

- (2) Substituted aliphatic hydrocarbon groups; that is groups containing non-hydrocarbon substituents which, in the context of this invention, do not alter the predominantly hydrocarbon character of the group. Those skilled in the art will be aware of suitable substituents; examples are hydroxy, carbalkoxy, (especially lower carbalkoxy) and alkoxy (especially lower alkoxy), the term, "lower" denoting groups containing not more than 7 carbon atoms.

- (3) Hetero groups; that is, groups which, while having predominantly aliphatic hydrocarbon character within the context of this invention, contain atoms other than carbon present in a chain or ring otherwise composed of aliphatic carbon atoms. Suitable hetero atoms will be apparent to those skilled in the art and include, for example, oxygen, nitrogen and sulfur.

- Animal fats having utility include beef tallow oil and menhaden oil. Useful vegetable oils include sunflower oil, cottonseed oil, safflower oil, corn oil, soybean oil, rapeseed oil, meadowfoam oil or any of the previously mentioned vegetable oils that are genetically modified such that the monounsaturated content is greater than the normal value. For example, a synthetic triglyceride prepared by reacting one mole of glycerol with three moles of oleic has an oleic acid content of 100% and consequently a monounsaturated content of 100%. Normal sunflower oil has an oleic acid content of 25-30%. By genetically modifying the seeds of sunflowers, a sunflower oil can be obtained wherein the oleic acid content is from about 60% up to about 90%.

- It is preferred that the monounsaturated character be derived from an oleyl radical, i.e.,

is the residue of oleic acid. The preferred triglyceride oils are high oleic (at least 60 percent) acid triglyceride oils. Typical high oleic vegetable oils employed within the instant invention include high oleic safflower oil, high oleic corn oil, high oleic rapeseed oil, high oleic sunflower oil, high oleic soybean oil, high oleic cottonseed oil and high oleic palm olein. A preferred high oleic vegetable oil is high oleic sunflower oil obtained from Helianthus sp. This product is available from SVO Enterprises, Eastlake, Ohio as Sunyl® high oleic sunflower oil. Sunyl 80 is a high oleic triglyceride wherein the acid moieties comprise 80 percent oleic acid. Another preferred high oleic vegetable oil is high oleic rapeseed oil obtained from Brassica compestris or Brassica napus, also available from SVO Enterprises as RSR high oleic rapeseed oil. RS80 signifies a rapeseed oil wherein the acid moieties comprise 80 percent oleic acid. - Alcohols utilized in forming the transesterified esters are of the formula R⁴OH wherein R⁴ is an aliphatic group that contains from 1 to about 24 carbon atoms. The R⁴ may be straight chained or branched chain, saturated or unsaturated. An illustrative but non exhaustive list of alcohols are: methyl alcohol, ethyl alcohol, n-propyl alcohol, isopropyl alcohol and the isomeric butyl, pentyl, hexyl, heptyl, octyl, nonyl dodecyl, pentadecyl and octadecyl alcohols. Preferably the alcohol is methyl alcohol.

- The transesterification generally occurs by mixing at least 3 moles of R⁴OH per 1 mole of triglyceride. A catalyst, when employed, comprises alkali or alkaline earth metal alkoxides containing from 1 up to 6 carbon atoms. Preferred catalysts are sodium or potassium methoxide, calcium or magnesium methoxide, the ethoxides of sodium, potassium, calcium or magnesium and the isomeric propoxides of sodium, potassium, calcium or magnesium. The most preferred catalyst is sodium methoxide.

- The transesterification conveniently occurs at a temperature of from ambient up to the decomposition temperature of any reactant or product. Usually the upper temperature limit is not more than 150°C and preferably not more than 120°C. In the transesterification mixed esters are obtained according to the following reaction:

Transesterification is an equilibrium reaction. To shift the equilibrium to the right it is usually necessary to use either a large excess of alcohol, or else remove glycerol as it is formed. When using an excess of alcohol, once the transesterification reaction is complete the excess alcohol is removed by distillation. - The following non-limiting examples are illustrative of the preparation of the transesterified product of the present invention. Unless otherwise indicated, all parts and percentages are by weight.

- Charged to a 12 liter 4 neck flask is 7056 parts (8 moles) high oleic rapeseed oil, 1280 parts (40 moles) absolute methyl alcohol and 70.5 parts (1.30 moles) sodium methoxide. The contents are heated to a reflux temperature of 73°C and held at this temperature for 3 hours and 76 parts (0.65 moles) of 85% phosphoric acid is added dropwise in 0.4 hours to neutralize the catalyst. Excess methyl alcohol is then removed by heating to 100°C with nitrogen blowing at 0.2 cubic feet per hour and later to a vacuum of 30 millimeters of mercury. The contents are filtered to give 6952 parts of the transesterified methyl ester of high oleic rapeseed oil.

- The procedure of Example A-1 is essentially followed except that the high oleic rapeseed oil is replaced with high oleic sunflower oil to give the transesterified methyl ester of high oleic sunflower oil.

- Charged to a 5 liter 4 neck flask is 759 parts (12.5 moles) isopropyl alcohol. While at room temperature, 5.75 parts (0.25 moles) elemental sodium is slowly added. When all the sodium is reacted, added is 2205 (25 moles) high oleic sunflower oil. The contents are heated to 85°C and held for 4 hours followed by neutralization of the catalyst with 9.67 parts (0.083 moles) of 85% phosphoric acid. The contents are stripped to 120°C at 27 millimeters of mercury to give 2350 parts of the transesterified isopropyl ester of high oleic sunflower oil.

- The procedure of Example A-3 is essentially followed except that the catalyst is made by reacting 690 parts (15 moles) absolute ethyl alcohol with 6.9 parts (0.3 moles) sodium metal. The product obtained is the transesterified ethyl ester of high oleic sunflower oil.

- The procedure of Example A-3 is essentially followed except that the catalyst is made by reacting 910 parts (15 moles) n-propyl alcohol with 6.9 parts (0.3 moles) sodium metal. The product obtained is the transesterified n-propyl ester of high oleic sunflower oil.

- The procedure of Example A-3 is essentially followed except that the catalyst is made by reacting 1114.5 parts (15 moles) n-butyl alcohol with 6.9 parts (0.3 moles) sodium metal. The product obtained is the transesterified n-butyl ester of high oleic sunflower oil.

- The procedure of Example A-3 is essentially followed except that the catalyst is made by reacting 1300 (12.5 moles) n-hexyl alcohol with 5.75 parts (0.25 moles) sodium metal. The product obtained is the transesterified n-hexyl ester of high oleic sunflower oil.

- Utilizing the catalyst as prepared in Example A-3, safflower oil is transesterified with isopropyl alcohol to obtain transesterified isopropyl esters of safflower oil.

- Utilizing the catalyst as prepared in Example A-4, cottonseed oil is transesterified with ethyl alcohol to obtain transesterified ethyl esters of cottonseed oil.

- Utilizing the catalyst as prepared in Example A-6, corn oil is transesterified with n-butyl alcohol to obtain transesterified n-butyl esters of corn oil.

- The procedure of Example A-9 is essentially followed except that beef tallow oil is utilized instead of cottonseed oil. The product obtained is the transesterified ethyl ester of beef tallow oil.

- The procedure of Example A-10 is essentially followed except that menhaden oil is utilized instead of corn oil. The product obtained is the transesterified n-butyl ester of menhaden oil.

- The procedure of Example A-1 is essentially followed except that rapeseed oil is utilized instead of high oleic rapeseed oil. The product obtained is the transesterified methyl ester of rapeseed oil.

- The procedure of Example A-1 is essentially followed except that soybean oil is utilized instead of high oleic rapeseed oil. The product obtained is the transesterified methyl ester of soybean oil.

- A drawback of using transesterified esters is in the difficulty with congelation of the transesterified esters at low temperatures (less than -10°C). This difficulty arises from a natural stiffening at low temperatures of the transesterified esters analogous to the stiffening of honey or molasses at a reduced temperature. To maintain the "pour" or "flow" of the transesterified esters, a pour point depressant is added to the oil.

- Preferred, pour point depressants (PPD) having utility in this invention are carboxy containing interpolymers in which many of the carboxy groups are esterified and the remaining carboxy groups, if any, are neutralized by reaction with amino compounds; acrylate polymers, nitrogen containing acrylate polymers and methylene linked aromatic compounds.

- This PPD is an ester of a carboxy-containing interpolymer, said interpolymer having a reduced specific viscosity of from about 0.05 to about 2, said ester being substantially free of titratable acidity, i.e., at least 90% esterification, and being characterized by the presence within its polymeric structure of pendant polar groups: (A) a relatively high molecular weight carboxylic ester group having at least 8 aliphatic carbon atoms in the ester radical, (B) a relatively low molecular weight carboxylic ester group having no more than 7 aliphatic carbon atoms in the ester radical, and optionally (C) a carbonyl-polyamino group derived from a polyamino compound having one primary or secondary amino group, wherein the molar ratio of (A):(B) is (1-20):1, preferably (1-10):1 and wherein the molar ratio of (A) : (B) : (C) is

(50-100):(5-50):(0.1-15) - An essential element of this ester is that the ester is a mixed ester, i.e., one in which there is the combined presence of both a high molecular weight ester group and a low molecular weight ester group, particularly in the ratio as stated above. Such combined presence is critical to the viscosity properties of the mixed ester, both from the standpoint of its viscosity modifying characteristics and from the standpoint of its thickening effect upon lubricating compositions in which it is used as an additive.

- In reference to the size of the ester groups, it is pointed out that an ester radical is represented by the formula

-C(O) (OR)

and that the number of carbon atoms in an ester radical is the combined total of the carbon atoms of the carbonyl group and the carbon atoms of the ester group i.e., the (OR) group. - An optional element of this ester is the presence of a polyamino group derived from a particular amino compound, i.e., one in which there is one primary or secondary amino group and at least one mono-functional amino group. Such polyamino groups, when present in this mixed ester in the proportion stated above enhances the dispersability of such esters in lubricant compositions and additive concentrates for lubricant compositions.

- Still another essential element of the mixed ester is the extent of esterification in relation to the extent of neutralization of the unesterified carboxy groups of the carboxy-containing interpolymer through the conversion thereof to the optional polyamino-containing groups. For convenience, the relative proportions of the high molecular weight ester group to the low molecular weight ester group and to the polyamino group are expressed in terms of molar ratios of

(50-100):(5-50):(0.1-15), respectively. The preferred ratio is (70-85):(15-30):(3-4). It should be noted that the linkage described as the carbonyl-polyamino group may be imide, amide, or amidine and inasmuch as any such linkage is contemplated within the present invention, the term "carbonyl polyamino" is thought to be a convenient, generic expression useful for the purpose of defining the inventive concept. In a particularly advantageous embodiment of the invention such linkage is imide or predominantly imide. - Still another important element of the mixed ester is the molecular weight of the carboxy-containing interpolymer. For convenience, the molecular weight is expressed in terms of the "reduced specific viscosity" of the interpolymer which is a widely recognized means of expressing the molecular size of a polymeric substance. As used herein, the reduced specific viscosity (abbreviated as RSV) is the value obtained in accordance with the formula

wherein the relative viscosity is determined by measuring, by means of a dilution viscometer, the viscosity of a solution of one gram of the interpolymer in 10 ml. of acetone and the viscosity of acetone at 30°± 0.02°C. For purpose of computation by the above formula, the concentration is adjusted to 0.4 gram of the interpolymer per 100 ml. of acetone. A more detailed discussion of the reduced specific viscosity, also known as the specific viscosity, as well as its relationship to the average molecular weight of an interpolymer, appears in Paul J. Flory, Principles of Polymer Chemistry, (1953 Edition) pages 308 et seq. - While interpolymers having reduced specific viscosity of from about 0.05 to about 2 are contemplated in the mixed ester, the preferred interpolymers are those having a reduced specific viscosity of from about 0.1 to about 1. In most instances, interpolymers having a reduced specific viscosity of from about 0.1 to about 0.8 are particularly preferred.

- From the standpoint of utility, as well as for commercial and economical reasons, esters in which the high molecular weight ester group has from 8 to 24 aliphatic carbon atoms, the low molecular weight ester group has from 3 to 5 carbon atoms, and the carbonyl amino group is derived from a primary-aminoalkyl-substituted tertiary amine, particularly heterocyclic amines, are preferred. Specific examples of the high molecular weight carboxylic ester group, i.e., the (OR) group of the ester radical (i.e., -(O) (OR)) include heptyloxy, isooctyloxy, decyloxy, dodecyloxy, tridecyloxy, tetradecyloxy, pentadecyloxy, octadecyloxy, eicosyloxy, tricosyloxy, tetracosyloxy, etc. Specific examples of low molecular weight groups include methoxy, ethoxy, n-propyloxy, isopropyloxy, n-butyloxy, sec-butyloxy, iso-butyloxy, n-pentyloxy, neo-pentyloxy, n-hexyloxy, cyclohexyloxy, xyxlopentyloxy, 2-methyl-butyl-1-oxy, 2,3-dimethyl-butyl-1-oxy, etc. In most instances, alkoxy groups of suitable size comprise the preferred high and low molecular weight ester groups. Polar substituents may be present in such ester groups. Examples of polar substituents are chloro, bromo, ether, nitro, etc.

- Examples of the carbonyl polyamino group include those derived from polyamino compounds having one primary or secondary amino group and at least one mono-functional amino group such as tertiary-amino or heterocyclic amino group. Such compounds may thus be tertiary-amino substituted primary or secondary amines or other substituted primary or secondary amines in which the substituent is derived from pyrroles, pyrrolidones, caprolactams, oxazolidones, oxazoles, thiazoles, pyrazoles, pyrazolines, imidazoles, imidazolines, thiazines, oxazines, diazines, oxycarbamyl, thiocarbamyl, uracils, hydantoins, thiohydantoins, guanidines, ureas, sulfonamides, phosphoramides, phenothiaznes, amidines, etc. Examples of such polyamino compounds include dimethylamino-ethylamine, dibutylamino-ethylamine, 3-dimethylamino-1-propylamine, 4-methylethylamino-1-butylamine, pyridyl-ethylamine, N-morpholino-ethylamine, tetrahydropyridyl-ethylamine, bis(dimethylamino)propyl-amine, bis-(diethylamino)ethylamine, N,N-dimethyl-p-phenylene diamine, piperidyl-ethylamine, 1-aminoethyl pyrazole, 1-(methylamino)pyrazoline, 1-methyl-4-amino-octyl pyrazole, 1-aminobutyl imidazole, 4-aminoethyl thiazole, 2-aminoethyl pyridine, ortho-aminoethyl-N,N- dimethylbenzenesulfamide, N-aminoethyl phenothiazine, N-aminoethylacetamidine, 1-aminophenyl-2-aminoethyl pyridine, N-methyl-N-aminoethyl-S-ethyldithiocarbamate, etc. Preferred polyamino compounds include the N-aminoalkyl-substituted morpholines such as aminopropyl morpholine. For the most part, the polyamino compounds are those which contain only one primary-amino or secondary-amino group and, preferably at least one tertiary-amino group. The tertiary amino group is preferably a heterocyclic amino group. In some instances polyamino compounds may contain up to about 6 amino groups although, in most instances, they contain one primary amino group and either one or two tertiary amino groups. The polyamino compounds may be aromatic or aliphatic amines and are preferably heterocyclic amines such as amino-alkyl-substituted morpholines, piperazines, pyridines, benzopyrroles, quinolines, pyrroles, etc. They are usually amines having from 4 to about 30 carbon atoms, preferably from 4 to about 12 carbon atoms. Polar substituents may likewise be present in the polyamines.

- The carboxy-containing interpolymers include principally interpolymers of alpha, beta-unsaturated acids or anhydrides such as maleic anhydride or itaconic anhydride with olefins (aromatic or aliphatic) such as ethylene, propylene, isobutene or styrene, or substituted styrene wherein the substituent is a hydrocarbyl group containing from 1 up to about 18 carbon atoms. The styrene-maleic anhydride interpolymers are especially useful. They are obtained by polymerizing equal molar amounts of styrene and maleic anhydride, with or without one or more additional interpolymerizable comonomers. In lieu of styrene, an aliphatic olefin may be used, such as ethylene, propylene or isobutene. In lieu of maleic anhydride, acrylic acid or methacrylic acid or ester thereof may be used. Such interpolymers are know in the art and need not be described in detail here. Where an interpolymerizable comonomer is contemplated, it should be present in a relatively minor proportion, i.e., less that about 0.3 mole, usually less than about 0.15 mole, per mole of either the olefin (e.g. styrene) or the alpha, beta-unsaturated acid or anhydride (e.g. maleic anhydride). Various methods of interpolymerizing styrene and maleic anhydride are known in the art and need not be discussed in detail here. For purpose of illustration, the interpolymerizable comonomers include the vinyl monomers such as vinyl acetate, acrylonitrile, methylacrylate, methylmethacrylate, acrylic acid, vinyl methyl either, vinyl ethyl ether, vinyl chloride, isobutene or the like.

- The nitrogen-containing esters of the mixed ester are most conveniently prepared by first 100 percent esterifying the carboxy-containing interpolymer with a relatively high molecular weight alcohol and a relatively low molecular weight alcohol. When the optional (C) is employed, the high molecular weight alcohol and low molecular weight alcohol are utilized to convert at least about 50% and no more than about 98% of the carboxy radicals of the interpolymer to ester radicals and then neutralizing the remaining carboxy radicals with a polyamino compound such as described above. To incorporate the appropriate amounts of the two alcohol groups into the interpolymer, the ratio of the high molecular weight alcohol to the low molecular weight alcohol used in the process should be within the range of from about 2:1 to about 9:1 on a molar basis. In most instances the ratio is from about 2.5:1 to about 5:1. More than one high molecular weight alcohol or low molecular weight alcohol may be used in the process; so also may be used commercial alcohol mixtures such as the so-called Oxoalcohols which comprise, for example mixtures of alcohols having from 8 to about 24 carbon atoms. A particularly useful class of alcohols are the commercial alcohols or alcohol mixtures comprising decylalcohol, dodecyl alcohol, tridecyl alcohol, tetradecyl alcohol, pentadecyl alcohol, hexadecyl alcohol, heptadecyl alcohol and octadecyl alcohol. Other alcohols useful in the process are illustrated by those which, upon esterification, yield the ester groups exemplified above.

- The extent of esterification, as indicated previously, may range from about 50% to about 98% conversion of the carboxy radicals of the interpolymer to ester radicals. In a preferred embodiment, the degree of esterification ranges from about 75% to about 95%.

- The esterification can be accomplished simply be heating the carboxy-containing interpolymer and the alcohol or alcohols under conditions typical for effecting esterification. Such conditions usually include, for example, a temperature of at least about 80°C, preferably from about 150°C to about 350°C, provided that the temperature be below the decomposition point of the reaction mixture, and the removal of water of esterification as the reaction proceeds. Such conditions may optionally include the use of an excess of the alcohol reactant so as to facilitate esterification, the use of a solvent or diluent such as mineral oil, toluene, benzene, xylene or the like and a esterification catalyst such as toluene sulfonic acid, sulfuric acid, aluminum chloride, boron trifluoride-triethylamine, hydrochloric acid, ammonium sulfate, phosphoric acid, sodium methoxide or the like. These conditions and variations thereof are well know in the art.

- A particularly desirable method of effecting esterification involves first reacting the carboxy-containing interpolymer with the relatively high molecular weight alcohol and then reacting the partially esterified interpolymer with the relatively low molecular weight alcohol. A variation of this technique involves initiating the esterification with the relatively high molecular weight alcohol and before such esterification is complete, the relatively low molecular weight alcohol is introduced into the reaction mass so as to achieve a mixed esterification. In either event it has been discovered that a two-step esterification process whereby the carboxy-containing interpolymer is first esterified with the relatively high molecular weight alcohol so as to convert from about 50% to about 75% of the carboxy radicals to ester radicals and then with the relatively low molecular weight alcohol to achieve the finally desired degree of esterification results in products which have unusually beneficial viscosity properties.

- The esterified interpolymer may optionally be treated with a polyamino compound in an amount so as to neutralize substantially all of the unesterified carboxy radicals of the interpolymer. The neutralization is preferably carried out at a temperature of at least about 80°C, often from about 120°C to about 300°C, provided that the temperature does not exceed the decomposition point of the reaction mass. In most instances the neutralization temperature is between about 150°C and 250°C. A slight excess of the stoichiometric amount of the amino compound is often desirable, so as to insure substantial completion of neutralization, i.e., no more than about 2% of the carboxy radicals initially present in the interpolymer remained unneutralized.

- The following non-limiting examples are illustrative of the preparation of the mixed ester of the present invention. Unless otherwise indicated all parts and percentages are by weight.

- A styrene-maleic interpolymer is obtained by preparing a solution of styrene (16.3 parts by weight) and maleic anhydride (12.9 parts) in a benzene-toluene solution (270 parts; weight ratio of benzene:toluene being 66.5:33.5) and contacting the solution at 86°C. in nitrogen atmosphere for 8 hours with a catalyst solution prepared by dissolving 70% benzoyl peroxide (0.42 part) in a similar benzene-toluene mixture (2.7 parts). The resulting product is a thick slurry of the interpolymer in the solvent mixture. To the slurry there is added mineral oil (141 parts) while the solvent mixture is being distilled off at 150°C. and then at 150°C./200 mm. Hg. To 209 parts of the stripped mineral oil-interpolymer slurry (the interpolymer having a reduced specific viscosity of 0.72) there are added toluene (25.2 parts), n-butyl alcohol (4.8 parts), a commercial alcohol consisting essentially of primary alcohols having from 12 to 18 carbon atoms (56.6 parts) and a commercial alcohol consisting of primary alcohols having from 8 to 10 carbon atoms (10 parts) and to the resulting mixture there is added 96% sulfuric acid (2.3 parts). The mixture is then heated at 150°-160°C. for 20 hours whereupon water is distilled off. An additional amount of sulfuric acid (0.18 part) together with an additional amount of n-butyl alcohol (3 parts) is added and the esterification is continued until 95% of the carboxy radicals of the polymer has been esterified. To the esterified interpolymer, there is then added aminopropyl morpholine (3.71 parts; 10% in excess of the stoichiometric amount required to neutralize the remaining free carboxy radicals) and the resulting mixture is heated to 150°-160°C./10 mm. Hg to distill off toluene and any other volatile components. The stripped product is mixed with an additional amount of mineral oil (12 parts) filtered. The filtrate is a mineral oil solution of the nitrogen-containing mixed ester having a nitrogen content of 0.16-0.17%.

- The procedure of Example (B-1) is followed except that the esterification is carried out in two steps, the first step being the esterification of the styrene-maleic interpolymer with the commercial alcohols having from 8 to 18 carbon atoms and the second step being the further esterification of the interpolymer with n-butyl alcohol.

- The procedure of Example (B-1) is followed except that the esterification is carried out by first esterifying the styrene-maleic interpolymer with the commercial alcohol having from 8 to 18 carbon atoms until 70% of the carboxyl radicals of the interpolymer have been converted to ester radicals and thereupon continuing the esterification with any yet-unreacted commercial alcohols and n-butyl alcohol until 95% of the carbonyl radicals of the interpolymer have been converted to ester radicals.

- The procedure of Example (B-1) is followed except that the interpolymer is prepared by polymerizing a solution consisting of styrene (416 parts), maleic anhydride (392 parts), benzene (2153 parts) and toluene (5025 parts) in the presence of benzoyl peroxide (1.2 parts) at 65°-106°C. (The resulting interpolymer has a reduced specific viscosity of 0.45).

- The procedure of Example (B-1) is followed except that the styrene-maleic anhydride is obtained by polymerizing a mixture of styrene (416 parts), maleic anhydride (392 parts), benzene (6101 parts) and toluene (2310 parts) in the presence of benzoyl peroxide (1.2 parts) at 78°-92°C. (The resulting interpolymer has a reduced specific viscosity of 0.91).

- The procedure of Example (B-1) is followed except that the styrene-maleic anhydride is prepared by the following procedure: Maleic anhydride (392 parts) is dissolved in benzene (6870 parts). To this mixture there is added styrene (416 parts) at 76°C. whereupon benzoyl peroxide (1.2 parts) is added. The polymerization mixture is maintained at 80-82°C. for about 5 hours. (The resulting interpolymer has a reduced specific viscosity of 1.24.)

- The procedure of Example (B-1) is followed except that acetone (1340 parts) is used in place of benzene as the polymerization solvent and that azobisisobutyronitrile (0.3 part) is used in place of benzoyl peroxide as a polymerization catalyst.

- An interpolymer (0.86 carboxyl equivalent) of styrene and maleic anhydride (prepared from an equal molar mixture of styrene and maleic anhydride and having a reduced specific viscosity of 0.69) is mixed with mineral oil to form a slurry, and then esterified with a commercial alcohol mixture (0.77 mole; comprising primary alcohols having from 8 to 18 carbon atoms) at 150-160°C. in the presence of a catalytic amount of sulfuric acid until about 70% of the carboxyl radicals are converted to ester radicals. The partially esterified interpolymer is then further esterified with a n-butyl alcohol (0.31 mole) until 95% of the carboxyl radicals of the interpolymer are converted to the mixed ester radicals. The esterified interpolymer is then treated with aminopropyl morpholine (slight excess of the stoichiometric amount to neutralize the free carboxyl radicals of the interpolymer) at 150-160°C. until the resulting product is substantially neutral (acid number of 1 to phenolphthalein indicator). The resulting product is mixed with mineral oil so as to form an oil solution containing 34% of the polymeric product.

- Examples (B-1) through (B-8) are prepared using mineral oil as the diluent. All of the mineral oil or a portion thereof may be replaced with the triglyceride oil (A). The preferred triglyceride oil is the high oleic sunflower oil.

- Charged to a 12 liter 4 neck flask is 3621 parts of the interpolymer of Example (B-8) as a toluene slurry. The percent toluene is about 76 percent. Stirring is begun and 933 parts (4.3 equivalents) Alfol 1218 alcohol and 1370 parts xylene are added. The contents are heated and toluene is removed by distillation. Additional xylene is added in increments of 500, 500, 300 and 300 parts while continuing to remove toluene, the object being to replace the lower boiling toluene with the higher boiling xylene. The removal of solvent is stopped when the temperature of 140°C. is reached. The flask is then fitted with an addition funnel and the condenser is set to reflux. At 140°C., 23.6 parts (0.17 equivalents) methanesulfonic acid in 432 parts (3 equivalents) Alfol 810 alcohol is added in about 20 minutes. The contents are stirred overnight at reflux while collecting water in a Dean Stark trap. Then added is 185 parts (2.5 equivalents) of n-butanol containing therein 3.0 parts (0.02 equivalents) of methanesulfonic acid. This addition occurs over a 60 minute time period. The contents are maintained at reflux for 8 hours and then an additional 60 parts (0.8 equivalents) n-butanol is added and the contents are permitted to reflux overnight. At 142°C. is added 49.5 parts (0.34 equivalents) aminopropylmorpholine in 60 minutes. After a 2 hour reflux 13.6 parts (equivalents) 50% aqueous sodium hydroxide is added over 60 minutes and after an additional 60 minutes of stirring there is added 17 parts of an alkylated phenol.

- To a 1 liter flask is added 495 parts of the above esterified product. The contents are heated to 140°C. and 337 parts Sunyl® 80 is added. Solvent is removed at 155°C. with nitrogen blowing at 1 cubic foot per hour. The final stripping conditions are 155°C. and 20 mm Hg. At 100°C. the contents are filtered using diatomaceous earth. The filtrate is a vegetable oil solution of the nitrogen-containing mixed ester having a nitrogen content of 0.14%.

- Examples (B-10) and (B-11) employ an interpolymerizable monomer as part of the carboxy-containing interpolymer.

- One mole each of maleic anhydride and styrene and 0.05 moles methyl methacrylate are polymerized in toluene in the presence of benzoyl peroxide (1.5 parts) at 75-95°C. The resulting interpolymer has a reduced specific viscosity of 0.13 and is a 12% slurry in toluene. Added to a 2 liter 4 neck flash is 868 parts (1 equivalent) of the polymer along with 68 parts (0.25 equivalents) oleyl alcohol, 55 parts (0.25 equivalents) Neodol 45, 55 parts (0.25 equivalents) Alfol 1218 and 36 parts (0.25 equivalents) Alfol 8-10. The contents are heated to 115°C and added is 2 parts (0.02 moles) methanesulfonic acid. After a 2 hour reaction period, toluene is distilled off. With a neutralization number of 18.7 to phenolphthalein (indicating an 89% esterification), 15 parts (0.20 equivalents) n-butanol is added dropwise over 5 hours. The neutralization number/esterification level is 14.0/92.5%. Then added is 1.6 parts (0.02 moles) 50% aqueous sodium hydroxide to neutralize the catalyst. This is followed by the addition of 5.5 parts (0.038 equivalents) of aminopropylmorpholine and 400 parts Sunyl® 80. The contents are vacuum stripped to 15 millimeters mercury at 100°C and filtered using a diatomaceous earth filter aid. The filtrate is the product containing 0.18 percent nitrogen and 54.9 percent Sunyl® 80.

- The following example is similar to Example (B-10) but employs different alcohols and different levels in a different order of addition.

- Added to a 2 liter 4 neck flask is 868 parts (1 equivalent) of the polymer of Example (B-10), 9.25 parts (0.125 equivalents) isobutyl alcohol, 33.8 parts (0.125 equivalents) oleyl alcohol, 11 parts each (0.125 equivalents) of 2-methyl-1-butanol, 3-methyl-1-butanol and 1-pentanol, 23.4 parts (0.125 equivalents) hexyl alcohol, and 16.25 parts each (0.125 equivalents) 1-octanol and 2-octanol. At 110°C 2 parts (0.02 moles) methanesulfonic acid is added. One hour later toluene is distilled off and when the distillation is complete, the neutralization number/esterification level is 62.5/70 percent. At 140°C 31.2 parts (0.43 equivalents) n-butanol is added dropwise over 28 hours and the neutralization number/esterification level is 36.0/79.3 percent. At 120°C 0.3 parts (0.03 moles) methanesulfonic acid is added followed by 20.4 parts (0.20 equivalents) hexyl alcohol. After esterification the neutralization number/esterification level is 10.5/95 percent. Then added is 1.9 parts (0.023 moles) of 50% sodium hydroxide followed by 5.9 parts (0.04 equivalents aminopropylmorpholine and 400 parts Sunyl® 80. The contents are filtered and the product has a nitrogen analysis of 0.18 percent.

- In another aspect Component (B) may be at least one hydrocarbon-soluble acrylate polymer of the formula

wherein R⁵ is hydrogen or a lower alkyl group containing from 1 to about 4 carbon atoms, R⁶ is a mixture of alkyl, cycloalkyl or aromatic groups containing from about 4 to about 24 carbon atoms, and x is an integer providing a weight average molecular weight (Mw) to the acrylate polymer of about 5000 to about 1,000,000. - Preferably R⁵ is a methyl or ethyl group and more preferably, a methyl group. R⁶ is primarily a mixture of alkyl groups containing from 4 to about 18 carbon atoms. In one embodiment, the weight average molecular weight of the acrylate polymer is from about 100,000 to about 1,000,000 and in other embodiments, the molecular weight of the polymer may be from 100,000 to about 700,000 and 300,000 to about 700,000.

- Specific examples of the alkyl groups R⁶ which may be included in the polymers of the present invention include, for example, n-butyl, octyl, decyl, dodecyl, tridecyl, octadecyl, hexadecyl, octadecyl. The mixture of alkyl groups can be varied so long as the resulting polymer is hydrocarbon-soluble.

- The following non-limiting examples are illustrative of the preparations of the acrylate polymers of the present invention. All parts and percentages are by weight unless indicated to the contrary.

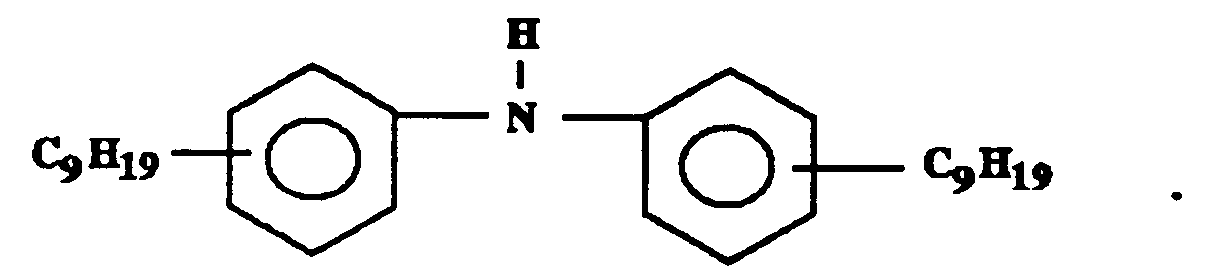

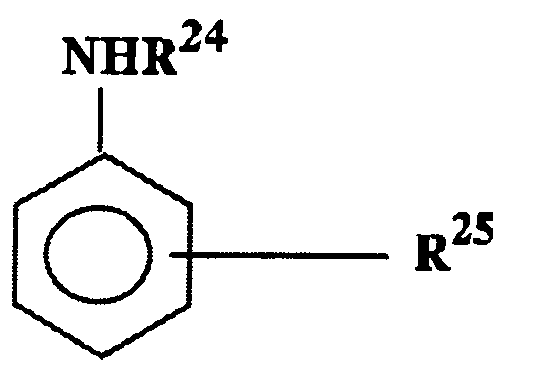

- Added to a 2 liter 4 neck flask is 50.8 parts (0.20 moles) lauryl methacrylate, 44.4 parts (0.20) isobornyl methacrylate, 38.4 parts (0.20 moles) 2-phenoxy ethyl acrylate, 37.6 parts (0.20 moles) 2-ethylhexyl acrylate, 45.2 parts (0.20 moles) isodecyl methacrylate and 500 parts toluene. At 100°C 1 parts Vazo® 67 (2,2' azobis(2-methylbutyronitrile)) in 20 parts toluene is added over 7 hours. The reaction is held at 100°C for 16 hours after which the temperature is increased to 120°C to remove toluene and added is 216 parts of Sunyl® 80. Volatiles are removed by vacuum distillation at 20 millimeters mercury at 140°C. The contents are filtered to give the desired product.