EP0462586A2 - Woody board - Google Patents

Woody board Download PDFInfo

- Publication number

- EP0462586A2 EP0462586A2 EP91110039A EP91110039A EP0462586A2 EP 0462586 A2 EP0462586 A2 EP 0462586A2 EP 91110039 A EP91110039 A EP 91110039A EP 91110039 A EP91110039 A EP 91110039A EP 0462586 A2 EP0462586 A2 EP 0462586A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- woody

- board

- substrate

- coniferous tree

- plywood

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/02—Manufacture of substantially flat articles, e.g. boards, from particles or fibres from particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/06—Making particle boards or fibreboards, with preformed covering layers, the particles or fibres being compressed with the layers to a board in one single pressing operation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27D—WORKING VENEER OR PLYWOOD

- B27D1/00—Joining wood veneer with any material; Forming articles thereby; Preparatory processing of surfaces to be joined, e.g. scoring

Definitions

- the present invention relates to a woody board, which has a sufficient mechanical strength as a woody material and which has a smooth surface.

- a wood powder and woody fibers are well known in this technical field. Briefly, the former is one to be obtained by finely pulverizing wood like sawdust; and the latter are ones to be obtained by disintegrating wood into fibers. Wood chips in this case are also known, which are obtained by shaving or cutting a wood bar from the top end thereof, with the bar being rotated in such a way that a pencil is shaven, into chips each having a size of about 1.5 mm or less as the thickness, about 30 mm or less as the width and about 100 mm or less as the length. Examples of molded boards made of such woody material will be mentioned.

- simplex boards made of a wood powder there is known a particle board; as examples of simplex boards made of woody fibers, there are a hard board, a middle density fiber board (MDF) and an insulation board; and as examples of simplex boards made of wood chips, there are a strand board and an oriented strand board (OSB).

- MDF middle density fiber board

- OSB oriented strand board

- the latter method also has a troublesome problem that the mechanical strength of the resulting laminate board is low, because of the following reasons.

- an MDF could not be thinner than 3 mm, as too thin MDF sheets would curve owing to insufficiency of the strength of them. Therefore, even when an thinnest MDF sheet having a thickness of 3 mm is laminated to the both surfaces of a substrate woody material by the method, the resulting plywood is to have a total thickness of the both laminated MDF's of being 6 mm, so that the mechanical strength of the plywood is lowered relative to the thickness.

- the resulting plywood laminate is also disadvantageous as it is often warped.

- One object of the present invention is to provide a woody board, which has good physical properties with respect to the mechanical strength, the surface smoothness and the screw-drawing resistance value and which is prepared at a low manufacture cost.

- Another object of the present invention is to provide a method of preparing a woody board having a good surface smoothness and a sufficient mechanical strength.

- Still another object of the present invention is to provide a method of preparing a woody material of a coniferous tree material, which has a woody substrate of a coniferous tree woody material and which has a smooth surface with neither warp nor reduction of the mechanical strength.

- a woody board which is characterized in that said woody board uses a coniferous tree material of a coniferous tree plywood or coniferous tree LVL as a woody substrate and is formed with molded layer of woody material such as wood powder or woody fibers on one surface or both surfaces of the woody substrate.

- a coniferous tree material of a coniferous tree plywood or coniferous tree LVL as a woody substrate

- molded layer of woody material such as wood powder or woody fibers

- the present invention provides a method of preparing a woody board in which a woody substrate of coniferous tree LVL, coniferous tree plywood or the like is sandwiched between molded layers of a woody material such as a wood powder or woody fibers to form a woody board, and the method is carried out by first forming a woody material layer of a wood powder or woody fibers, as previously blended with an adhesive by spraying, then putting an LVL, plywood or the like thereon, and thereafter further forming said woody material layer thereon, whereupon all the piled-up layers are integrated by hot-pressing under pressure and heat.

- the coniferous tree plywood or LVL may be either in the form of a previously shaped one or in the form of a combination of plural veneers as merely piled up prior to being shaped into a plywood.

- the raw material of a board to be used in the present invention which comprises a woody material of a wood powder or woody fibers and an adhesive, may be one to be specifically prepared for repairing or may also be any general raw material for ordinary particle boards or fiber boards. Therefore, as a woody material for use in the present invention, a wood powder as well as fine wood chips to be prepared by finely pulverizing a wood material and small wood flakes to be obtained by cutting or shaving a wood material, and also shaped bodies to be formed by shaping such a wood powder, wood chips or wood flakes under pressure, and fibrous materials of them may be employed.

- the particle size of the wood powder as well as the size of the wood flakes may well be selected and determined in accordance with the intended surface smoothness of the final product of a woody board.

- MDF middle density fiber board

- the hot-pressing method of forming the woody board of the present invention may be either a hot plate-pressing method or a hot roll-pressing method.

- a hot plate or a hot roll may be applied to the materials to be laminated and molded under pressure, or a hot steam may also be applied thereto under pressure.

- the materials to be laminated and molded may previously be heated by blowing a hot steam thereto or by heating them in an oven, and the thus pre-heated materials may be pressed and integrated to obtain the intended woody board.

- a hot-gluing adhesive is used since the molding materials and laminates are pressed under heat to give an integrated woody board.

- Any conventional adhesives well known in this technical field such as phenolic resins and melamine resins, can be used for the purpose.

- thermosetting and water-proofing resins such as melamine resins are selectively used, the water-proofness of the molded board layers is advantageously improved.

- the thickness of the molded layer of a woody material may well be increased or decreased in accordance with the object of the woody board to be prepared. For instance, where the object of the board is to have merely a smooth surface, the layer of the molded layer may be thin to have a thickness of from 1 to 2 mm after shaped. On the other hand, where the surface of the woody material is to be further cut and machined, the thickness may be approximately from 5 to 10 mm.

- the molded layer of a woody material is put on the both surfaces of the substrate both in the same thickness, in view of the balance to be formed.

- the thickness of the molded layer of a woody material may well be much similar than that of the substrate, it is possible to prepare a one side-molded woody board with no warp and it is also possible to prepare a both sides-molded woody board where the both molded layer on the both surfaces each have a different thickness.

- the woody material for the molded layer may be either in the form of an already cold-pressed sheet or an adhesive-applied but not cold-pressed sheet. In the latter case, the woody material is in the form of a compound of a wood powder or woody fibers as already blended with an adhesive. If desired, the woody material for molded layer may also be in the form of a sheet to be obtained by pre-hot-pressing the woody material along with an adhesive. In the case, a two-stage polymerizing resin may advantageously be used as an adhesive. Precisely, the respective woody material layers may be pre-shaped by the first hot-pressing and thereafter they are integrated by the next hot-pressing.

- a coniferous tree plywood or a coniferous tree LVL is preferred in view of the object of the present invention.

- An adhesive may be coated to such a coniferous tree molded to give a molded coniferous tree plywood or LVL.

- the resulting confierous tree plywood or LVL layer can be used as a molded substrate.

- the woody substrate may also be in the form of a sheet as prepared by hot-pressing the corresponding plywood or LVL piled strips, or in the form of a cold-pressed piled strips prior to hot-pressing, or in the form of an adhesive-applied but not cold-pressed layer of veneers or laminars. Anyhow, all the woody substrate materials may be hot-pressed with putting other raw board materials thereon to give the woody board of the present invention.

- the mechanical strength of the resulting MDF board is lowered so that the flexibility of the board is large, as mentioned above. Therefore, a satisfactory board, e.g., large-sized board, could not be formed of such an MDF.

- the thickness thereof is generally up to 3 mm. Because of the reasons, a thin and strong woody material could not be obtained by molding of MDF layers.

- a woody substrate is a coniferous tree LVL

- a woody material layer is formed on one or both surfaces of the woody substrate so that the board layer may well have a thickness of 3 mm or less in order to obtain the intended woody board.

- the woody board to be obtained by the present invention may have a smooth surface and a high mechanical strength.

- an extremely thin woody material molded layer may be formed on the surface(s) of the woody laminate substrate. Therefore, even though the coat is formed on only one surface of the substrate to form a one surface-molded board, the resulting one surface-molded board is advantageously free from warping.

- a melamine resin adhesive was applied to five sheets of Douglas fir rotary veneer each having a thickness of 2.5 mm in the direction perpendicular to the fibrous direction of each sheet by a known method of forming a conventional plywood, and the thus adhesive coated sheets were cold-pressed to form a woody substrate.

- the veneers of constituting the surfaces of the substrate had 25 knots each having a diameter of approximately 35 mm in the area of 1850 mm x 980 mm.

- wood of Douglas fir rotary veneer was finely pulverized, and the resulting wood powder was blended with 12 % of a melamine resin adhesive by spraying to prepare an MDF material. This was put in an iron plate in a thickness of 15 mm, and the previously cold-pressed plywood was put thereover. Further, the wood powder was put over the plywood in a thickness of 15 mm.

- a decorative veneer of Douglas fir having a thickness of 0.6 mm was stuck to one surface of the woody board to give a decorative plywood having an extremely flat and smoothly finished surface.

- the woody board thus obtained warped with the smooth surface being convex in such a condition that the arrow height was 1.5 mm to the length of 1850 mm.

- the warp of such a degree has heretofore been said to cause no problem in practical use of the board, and the board stood the product standard test.

- Example 2 In accordance with the same process as in Example 1, except that the thickness of the rotary veneer of Douglas fir, which was 2.5 mm in Example 1, was varied to 1.7 mm, a laminate substrate was prepared. Both surfaces of the substrate were coated with an MDF having a thickness of 3 mm, in place of the woody material as used in Example 1. The thus piled-up woody layers were then hot-pressed in the same way as in Example 1 to obtained a woody material having the same thickness as that obtained in Example 1.

- the thus prepared woody material had a low and insufficient mechanical strength relative to the thickness thereof and therefore it was not suitable to practical use.

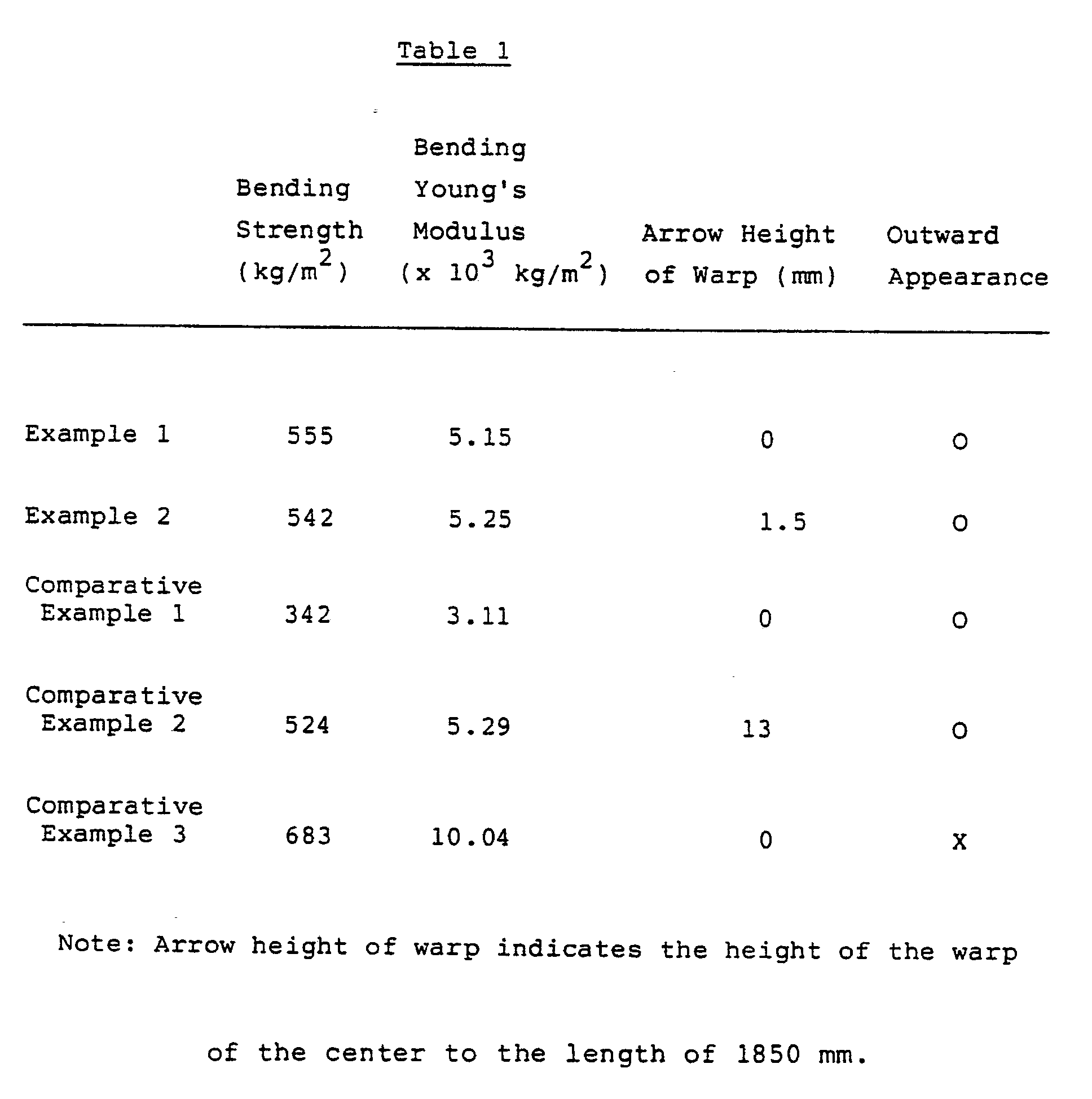

- the mechanical strength values of the product are shown in Table 1 below.

- Example 2 The same process as in Example 1 was repeated, except that the thickness of the rotary veneer of Douglas fir rotary veneer, which was 2.5 mm in Example 1, was varied to 2.9 mm and that the woody material was not used, but a coniferous tree plywood was only used. Accordingly, a decorative plywood having almost the same thickness as that of the product of Example 1 was prepared.

- the decorative plywood thus prepared had many knots and cracks, and the outward appearance thereof did not stand the test.

- substantially warp-free woody boards and decorated boards which have smooth and flat surfaces as their outward appearance and which have a sufficient mechanical strength are obtained by the method of the present invention, and the industrial advantage of the present invention is noticeable.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Wood Science & Technology (AREA)

- Forests & Forestry (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Dry Formation Of Fiberboard And The Like (AREA)

- Veneer Processing And Manufacture Of Plywood (AREA)

- Laminated Bodies (AREA)

Abstract

Description

- The present invention relates to a woody board, which has a sufficient mechanical strength as a woody material and which has a smooth surface.

- Various simplex boards to be prepared by separately shaping a wood powder, woody fibers or wood chips, optionally along with a binder, under pressure have heretofore been known, but a composite board composed of a plurality of such simplex boards is unkown.

- A wood powder and woody fibers are well known in this technical field. Briefly, the former is one to be obtained by finely pulverizing wood like sawdust; and the latter are ones to be obtained by disintegrating wood into fibers. Wood chips in this case are also known, which are obtained by shaving or cutting a wood bar from the top end thereof, with the bar being rotated in such a way that a pencil is shaven, into chips each having a size of about 1.5 mm or less as the thickness, about 30 mm or less as the width and about 100 mm or less as the length. Examples of molded boards made of such woody material will be mentioned. As an example of simplex boards made of a wood powder, there is known a particle board; as examples of simplex boards made of woody fibers, there are a hard board, a middle density fiber board (MDF) and an insulation board; and as examples of simplex boards made of wood chips, there are a strand board and an oriented strand board (OSB).

- These boards have both merits and demerits, and they often cause some inconvenience in actual use thereof.

- In manufacturing stairs, service counters, doors and the like, when substrates which have a sufficient thickness and a sufficient mechanicl strength and which have a smooth surface capable of being covered with a decorative sheet with screws are needed, but the above-mentioned simplex boards could not be used as such substrates. Of these boards, a hard board may be mentioned to have a relatively high mechanical strength and a relatively satisfactory surface smoothness. However, it is impossible to obtain a hard board having a sufficient thickness. Additionally, since a hard board is prepared by a wet method, it has a large specific gravity and is therefore defectively extremely heavy. Further, screws could hardly be applied to a hard board and the board has a low screw-drawing resistance value.

- It may be considered to laminate an MDF having a sufficient surface smoothness onto the both surfaces of a strand board or OSB, but adhesion between them would be poor and unstable since the strand board and OSB have a poor surface smoothness. Even if they could be laminated, the resulting laminate product is to have a problem that the laminating cost is high since double lamination is necessary. In addition, as an MDF has low mechanical strength, it is difficult to prepare a too thin MDF. As a result, where the both surfaces of a strand board or OSB are laminated with such a thick MDF by double lamination, the resulting laminate would thereby have a lowered mechanical strength, disadvantageously.

- In addition to the above-mentioned boards, where a plywood or LVL (laminated veneer lumber) is made from a coniferous tree material, there occurs a problem that the woody product could hardly have a smooth surface. This is because when a coniferous tree material is formed into veneers, in general, the surfaces of them often have knots and cracks. There are few coniferous trees which have no drawback, like lauan and other trees from the South Sea Islands. Though there would be some knot-free good tree materials to be derived from coniferous trees, the amount of them is small and the cost thereof is high. Additionally, even defectless coniferous tree materials often give shaped articles having uneven surfaces because of the pressure as applied thereto for shaping under pressure, since the hardness of them is not constant but various depending upon the winter-grown part being hard and the summer-grown part being soft.

- Under the situation, in order to overcome the problems, there have been proposed a patching method of holding the knot parts in the surface veneer followed by embedding wood patches into the holed parts and a method of laminating a woody material having a smooth surface, such as an MDF (middle density fiber board) to the both surfaces of a substrate woody material. However, the former patching method causes a disadvantageous drawback that the outward appearance of the patched surface is bad due to the existence of embedding traces. Even though an additional thin decorative paper or decorative veneer is laminated as a secondary lamination so as to cover the patched surface, such an unfavorable outward appearance of the patched surface would still appear through the surface of the covered decorative paper or veneer.

- On the other hand, the latter method also has a troublesome problem that the mechanical strength of the resulting laminate board is low, because of the following reasons. In general, an MDF could not be thinner than 3 mm, as too thin MDF sheets would curve owing to insufficiency of the strength of them. Therefore, even when an thinnest MDF sheet having a thickness of 3 mm is laminated to the both surfaces of a substrate woody material by the method, the resulting plywood is to have a total thickness of the both laminated MDF's of being 6 mm, so that the mechanical strength of the plywood is lowered relative to the thickness. In this connection, if an MDF sheet is laminated onto only one surface of a substrate, the resulting plywood laminate is also disadvantageous as it is often warped.

- One object of the present invention is to provide a woody board, which has good physical properties with respect to the mechanical strength, the surface smoothness and the screw-drawing resistance value and which is prepared at a low manufacture cost.

- Another object of the present invention is to provide a method of preparing a woody board having a good surface smoothness and a sufficient mechanical strength.

- Still another object of the present invention is to provide a method of preparing a woody material of a coniferous tree material, which has a woody substrate of a coniferous tree woody material and which has a smooth surface with neither warp nor reduction of the mechanical strength.

- Specifically, there is provided in accordance with the present invention a woody board, which is characterized in that said woody board uses a coniferous tree material of a coniferous tree plywood or coniferous tree LVL as a woody substrate and is formed with molded layer of woody material such as wood powder or woody fibers on one surface or both surfaces of the woody substrate. In preparing such a woody board of the present invention, it is desired, if possible, that the woody substrate and the molded layer of a woody material are pressed simultaneously under heat and pressure.

- As one embodiment, the present invention provides a method of preparing a woody board in which a woody substrate of coniferous tree LVL, coniferous tree plywood or the like is sandwiched between molded layers of a woody material such as a wood powder or woody fibers to form a woody board, and the method is carried out by first forming a woody material layer of a wood powder or woody fibers, as previously blended with an adhesive by spraying, then putting an LVL, plywood or the like thereon, and thereafter further forming said woody material layer thereon, whereupon all the piled-up layers are integrated by hot-pressing under pressure and heat. In this case, the coniferous tree plywood or LVL may be either in the form of a previously shaped one or in the form of a combination of plural veneers as merely piled up prior to being shaped into a plywood.

- The raw material of a board to be used in the present invention, which comprises a woody material of a wood powder or woody fibers and an adhesive, may be one to be specifically prepared for repairing or may also be any general raw material for ordinary particle boards or fiber boards. Therefore, as a woody material for use in the present invention, a wood powder as well as fine wood chips to be prepared by finely pulverizing a wood material and small wood flakes to be obtained by cutting or shaving a wood material, and also shaped bodies to be formed by shaping such a wood powder, wood chips or wood flakes under pressure, and fibrous materials of them may be employed. The particle size of the wood powder as well as the size of the wood flakes may well be selected and determined in accordance with the intended surface smoothness of the final product of a woody board.

- Recently, a special attention has been paid to a middle density fiber board (MDF), which is said to have a property similar to a plywood. As the material of such a board is composed of fine woody fibers, the final product to be obtained by using it may thereby have a better surface smoothness. Therefore, it is recommended to employ the raw material.

- The hot-pressing method of forming the woody board of the present invention may be either a hot plate-pressing method or a hot roll-pressing method. As a heating means in the method, a hot plate or a hot roll may be applied to the materials to be laminated and molded under pressure, or a hot steam may also be applied thereto under pressure. If desired, the materials to be laminated and molded may previously be heated by blowing a hot steam thereto or by heating them in an oven, and the thus pre-heated materials may be pressed and integrated to obtain the intended woody board.

- As the adhesive to be applied to the respective molding materials and laminates of the present invention, a hot-gluing adhesive is used since the molding materials and laminates are pressed under heat to give an integrated woody board. Any conventional adhesives well known in this technical field, such as phenolic resins and melamine resins, can be used for the purpose. Where thermosetting and water-proofing resins such as melamine resins are selectively used, the water-proofness of the molded board layers is advantageously improved.

- The thickness of the molded layer of a woody material may well be increased or decreased in accordance with the object of the woody board to be prepared. For instance, where the object of the board is to have merely a smooth surface, the layer of the molded layer may be thin to have a thickness of from 1 to 2 mm after shaped. On the other hand, where the surface of the woody material is to be further cut and machined, the thickness may be approximately from 5 to 10 mm.

- It is preferred that the molded layer of a woody material is put on the both surfaces of the substrate both in the same thickness, in view of the balance to be formed. In accordance with the present invention, however, since the thickness of the molded layer of a woody material may well be much similar than that of the substrate, it is possible to prepare a one side-molded woody board with no warp and it is also possible to prepare a both sides-molded woody board where the both molded layer on the both surfaces each have a different thickness.

- The woody material for the molded layer may be either in the form of an already cold-pressed sheet or an adhesive-applied but not cold-pressed sheet. In the latter case, the woody material is in the form of a compound of a wood powder or woody fibers as already blended with an adhesive. If desired, the woody material for molded layer may also be in the form of a sheet to be obtained by pre-hot-pressing the woody material along with an adhesive. In the case, a two-stage polymerizing resin may advantageously be used as an adhesive. Precisely, the respective woody material layers may be pre-shaped by the first hot-pressing and thereafter they are integrated by the next hot-pressing.

- Where a plywood or LVL is used as the woody substrate in preparing the woody board of the present invention, a coniferous tree plywood or a coniferous tree LVL is preferred in view of the object of the present invention. An adhesive may be coated to such a coniferous tree molded to give a molded coniferous tree plywood or LVL. The resulting confierous tree plywood or LVL layer can be used as a molded substrate. The woody substrate may also be in the form of a sheet as prepared by hot-pressing the corresponding plywood or LVL piled strips, or in the form of a cold-pressed piled strips prior to hot-pressing, or in the form of an adhesive-applied but not cold-pressed layer of veneers or laminars. Anyhow, all the woody substrate materials may be hot-pressed with putting other raw board materials thereon to give the woody board of the present invention.

- Where a board only is formed of an MDF, the mechanical strength of the resulting MDF board is lowered so that the flexibility of the board is large, as mentioned above. Therefore, a satisfactory board, e.g., large-sized board, could not be formed of such an MDF. In addition, since an MDF board is often waved or warped, the thickness thereof is generally up to 3 mm. Because of the reasons, a thin and strong woody material could not be obtained by molding of MDF layers. In accordance with the present invention, however, where a woody substrate is a coniferous tree LVL, a woody material layer is formed on one or both surfaces of the woody substrate so that the board layer may well have a thickness of 3 mm or less in order to obtain the intended woody board. As a result, the woody board to be obtained by the present invention may have a smooth surface and a high mechanical strength.

- In addition, in accordance with the present invention, an extremely thin woody material molded layer may be formed on the surface(s) of the woody laminate substrate. Therefore, even though the coat is formed on only one surface of the substrate to form a one surface-molded board, the resulting one surface-molded board is advantageously free from warping.

- The present invention will be explained in more detail by way of the following examples, which, however, are not intended to restrict the scope of the present invention. Unless otherwise specifically indicated, "%" is % by weight in these examples.

- A melamine resin adhesive was applied to five sheets of Douglas fir rotary veneer each having a thickness of 2.5 mm in the direction perpendicular to the fibrous direction of each sheet by a known method of forming a conventional plywood, and the thus adhesive coated sheets were cold-pressed to form a woody substrate. The veneers of constituting the surfaces of the substrate had 25 knots each having a diameter of approximately 35 mm in the area of 1850 mm x 980 mm.

- On the other hand, as woody material, wood of Douglas fir rotary veneer was finely pulverized, and the resulting wood powder was blended with 12 % of a melamine resin adhesive by spraying to prepare an MDF material. This was put in an iron plate in a thickness of 15 mm, and the previously cold-pressed plywood was put thereover. Further, the wood powder was put over the plywood in a thickness of 15 mm.

- The thus piled-up woody layers were inserted into a hot pressing machine along with the iron plate, where they are hot-pressed at a temperature of 130°C and a pressure of 12 kg/m² for 10 minutes. Accordingly, a flat and smooth 14.5 mm-thick woody board having a board layer of one mm thickness on both surfaces thereof was prepared.

- A decorative veneer of Douglas fir having a thickness of 0.6 mm was stuck to one surface of the woody board to give a decorative plywood having an extremely flat and smoothly finished surface.

- In accordance with the same process as in Example 1, except that the woody material layer was put on only one surface of the cold-pressed plywood substrate, a woody board having one smooth and flat surface was obtained by hot-pressing.

- The woody board thus obtained warped with the smooth surface being convex in such a condition that the arrow height was 1.5 mm to the length of 1850 mm. However, the warp of such a degree has heretofore been said to cause no problem in practical use of the board, and the board stood the product standard test.

- In accordance with the same process as in Example 1, except that the thickness of the rotary veneer of Douglas fir, which was 2.5 mm in Example 1, was varied to 1.7 mm, a laminate substrate was prepared. Both surfaces of the substrate were coated with an MDF having a thickness of 3 mm, in place of the woody material as used in Example 1. The thus piled-up woody layers were then hot-pressed in the same way as in Example 1 to obtained a woody material having the same thickness as that obtained in Example 1.

- The thus prepared woody material had a low and insufficient mechanical strength relative to the thickness thereof and therefore it was not suitable to practical use. The mechanical strength values of the product are shown in Table 1 below.

- The same process as in Comparative Example 1 was repeated, except that an MDF was coated on only one surface by hot-pressing. Though the woody material product obtained had a smooth surface, it warped with the MDF coated surface being convex in such a condition that the arrow height was 13 mm to the direction of the length of being 1850 mm.

- The warp was too large so that the product was no more practical.

- The same process as in Example 1 was repeated, except that the thickness of the rotary veneer of Douglas fir rotary veneer, which was 2.5 mm in Example 1, was varied to 2.9 mm and that the woody material was not used, but a coniferous tree plywood was only used. Accordingly, a decorative plywood having almost the same thickness as that of the product of Example 1 was prepared.

- The decorative plywood thus prepared had many knots and cracks, and the outward appearance thereof did not stand the test.

-

- As is understood from the results and data obtained in the above-mentioned examples and comparative examples, substantially warp-free woody boards and decorated boards which have smooth and flat surfaces as their outward appearance and which have a sufficient mechanical strength are obtained by the method of the present invention, and the industrial advantage of the present invention is noticeable.

- While the invention has been described in detail and with reference to specific embodiments thereof, it will be apparent to one skilled in the art that various changes and modifications can be made therein without departing from the spirit and scope thereof.

Claims (7)

- A woody board characterized in that woody fibers are provided on one surface or both surfaces of a woody substrate of a layer of wood chips or a coniferous tree plywood or coniferous tree LVL.

- A woody board as claimed in claim 1, wherein the woody substrate is a coniferous tree plywood or coniferous tree LVL.

- A method of preparing a woody board, in which a woody material mix obtained by blending an adhesive and a woody material of a wood powder or woody fibers is molded on at least one surface of a woody substrate.

- A method of preparing a woody board as claimed in claim 3, wherein a woody material mix obtained by blending an adhesive and a woody material of a wood powder or woody fibers is put on at least one surface of a woody substrate followed by hot-pressing the mix and the substrate.

- A method of preparing a woody board as claimed in claim 3, wherein the woody substrate is a coniferous tree plywood or coniferous tree LVL.

- A method of preparing a woody board as claimed in claim 3, wherein the woody substrate is a layer of wood chips.

- A method of preparing a woody board as claimed in claim 3, wherein the woody substrate is a layer for a coniferous tree plywood or coniferous tree LVL as prepared by adhesive-application.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP160399/90 | 1990-06-19 | ||

| JP16039990 | 1990-06-19 | ||

| JP2160399A JP3038488B2 (en) | 1990-06-19 | 1990-06-19 | Method of manufacturing coniferous wood |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0462586A2 true EP0462586A2 (en) | 1991-12-27 |

| EP0462586A3 EP0462586A3 (en) | 1993-01-13 |

| EP0462586B1 EP0462586B1 (en) | 1999-08-25 |

Family

ID=15714107

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91110039A Expired - Lifetime EP0462586B1 (en) | 1990-06-19 | 1991-06-19 | Woody board |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0462586B1 (en) |

| JP (1) | JP3038488B2 (en) |

| KR (1) | KR0183985B1 (en) |

| AU (1) | AU653529B2 (en) |

| CA (1) | CA2044865C (en) |

| DE (1) | DE69131547T2 (en) |

| NZ (1) | NZ238616A (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1998000272A1 (en) * | 1996-06-27 | 1998-01-08 | Clausi Robert N | Method of molding powdered plant fiber into high density materials |

| WO1999002766A1 (en) * | 1997-07-11 | 1999-01-21 | Roctex Oy Ab | Fibre mat |

| US6309492B1 (en) * | 1998-09-16 | 2001-10-30 | Marc A. Seidner | Polymer fill coating for laminate or composite wood products and method of making same |

| WO2009005409A3 (en) * | 2007-07-02 | 2009-04-23 | Michail Mukarasov Akhmedzhanov | Wood board production method |

| JP2012081720A (en) * | 2010-10-07 | 2012-04-26 | Hokkaido Research Organization | Method of preventing through knot, and woody material obtained thereby |

| JP2015196359A (en) * | 2014-04-02 | 2015-11-09 | ニチハ株式会社 | Woody board and decorative plywood |

| WO2018096213A1 (en) * | 2016-11-22 | 2018-05-31 | Metsäliitto Osuuskunta | Coated multi-ply wood panel and method of producing a core board |

| JP2019031104A (en) * | 2018-11-19 | 2019-02-28 | ニチハ株式会社 | Manufacturing method of wood board and decorative plywood |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100446710B1 (en) * | 2002-07-04 | 2004-09-07 | 김태홍 | Pannel for construction and producing method thereof |

| DE202006012116U1 (en) * | 2006-08-08 | 2007-12-27 | Vöhringer GmbH | Wood panel |

| JP2014083810A (en) * | 2012-10-25 | 2014-05-12 | Nichiha Corp | Woody decorative bed plate composite base material |

| JP6985657B2 (en) * | 2017-03-13 | 2021-12-22 | 地方独立行政法人北海道立総合研究機構 | Manufacturing method of wood composite board |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NO85681A (en) * | 1944-08-09 | |||

| FR1444912A (en) * | 1965-05-28 | 1966-07-08 | Composite panel and improved process for its manufacture | |

| DE1653323A1 (en) * | 1966-05-06 | 1971-02-04 | Triangel Spanplattenwerke Der | Process for the production of a multilayer board from wood materials |

| BE788503A (en) * | 1972-09-07 | 1973-01-02 | Santens Paul E G | EL MADE IN ACCORDANCE WITH THIS METHOD. PROCESS FOR THE MANUFACTURE OF A PANEL AND PANE |

| NZ200674A (en) * | 1981-05-26 | 1985-09-13 | Earl Herbert Robbins | A composite wood panel that is veneered and has an intermediate veneer |

| FR2568510B1 (en) * | 1984-08-01 | 1986-09-05 | Garcia Jean | MANUFACTURE OF PANELS OF AGGLOMERATE PARTICLES AND OR FIBERS, COMPRISING A WOODEN CORE, OR ANY OTHER MATERIAL. SLICED WOOD OR SAW |

| SE445568B (en) * | 1984-10-08 | 1986-06-30 | Hammarberg Lars | DISC MATERIALS, PREFERRED FOR USE AS A CASTING FORM, BUILT OUT OF COMPOSITE LAMINATE WITH THE GLASS FIBER CORD IN THE OUTER LAYER |

| SE461775B (en) * | 1986-04-24 | 1990-03-26 | Swedoor Ab | PROCEDURE FOR MANUFACTURE OF DEEP SHAPED DISC |

| SE458839B (en) * | 1988-03-16 | 1989-05-16 | Inst Traeteknisk Forskning | PROCEDURES FOR THE PREPARATION OF CHEESE DISCOVERED MACHINES DETAILED ACCORDING TO THE PROCEDURE |

| JP5611582B2 (en) | 2009-12-25 | 2014-10-22 | 株式会社東芝 | Electrical neutral substance separation method and electrical neutral substance separation device |

-

1990

- 1990-06-19 JP JP2160399A patent/JP3038488B2/en not_active Expired - Fee Related

-

1991

- 1991-06-14 KR KR1019910009849A patent/KR0183985B1/en not_active Expired - Lifetime

- 1991-06-18 CA CA002044865A patent/CA2044865C/en not_active Expired - Lifetime

- 1991-06-19 DE DE69131547T patent/DE69131547T2/en not_active Expired - Lifetime

- 1991-06-19 NZ NZ23861691A patent/NZ238616A/en not_active IP Right Cessation

- 1991-06-19 EP EP91110039A patent/EP0462586B1/en not_active Expired - Lifetime

- 1991-06-19 AU AU79149/91A patent/AU653529B2/en not_active Expired

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1998000272A1 (en) * | 1996-06-27 | 1998-01-08 | Clausi Robert N | Method of molding powdered plant fiber into high density materials |

| US6103377A (en) * | 1996-06-27 | 2000-08-15 | Clausi; Robert N. | Method of molding powdered plant fiber into high density materials |

| EP1201380A3 (en) * | 1996-06-27 | 2005-11-09 | Robert N. Clausi | Method of molding powdered plant fibers into high density materials |

| WO1999002766A1 (en) * | 1997-07-11 | 1999-01-21 | Roctex Oy Ab | Fibre mat |

| US6309492B1 (en) * | 1998-09-16 | 2001-10-30 | Marc A. Seidner | Polymer fill coating for laminate or composite wood products and method of making same |

| EA015896B1 (en) * | 2007-07-02 | 2011-12-30 | Михаил Мукарасович Ахмеджанов | Wood board production method |

| WO2009005409A3 (en) * | 2007-07-02 | 2009-04-23 | Michail Mukarasov Akhmedzhanov | Wood board production method |

| JP2012081720A (en) * | 2010-10-07 | 2012-04-26 | Hokkaido Research Organization | Method of preventing through knot, and woody material obtained thereby |

| JP2015196359A (en) * | 2014-04-02 | 2015-11-09 | ニチハ株式会社 | Woody board and decorative plywood |

| WO2018096213A1 (en) * | 2016-11-22 | 2018-05-31 | Metsäliitto Osuuskunta | Coated multi-ply wood panel and method of producing a core board |

| US11752657B2 (en) | 2016-11-22 | 2023-09-12 | Metsäliitto Osuuskunta | Coated multi-ply wood panel and method of producing a core board |

| EP4321336A3 (en) * | 2016-11-22 | 2024-04-24 | Metsäliitto Osuuskunta | Coated multi-ply wood panel and method of producing a core board |

| JP2019031104A (en) * | 2018-11-19 | 2019-02-28 | ニチハ株式会社 | Manufacturing method of wood board and decorative plywood |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2044865A1 (en) | 1991-12-20 |

| EP0462586A3 (en) | 1993-01-13 |

| AU653529B2 (en) | 1994-10-06 |

| KR920000447A (en) | 1992-01-29 |

| NZ238616A (en) | 1994-07-26 |

| EP0462586B1 (en) | 1999-08-25 |

| CA2044865C (en) | 2000-03-14 |

| DE69131547T2 (en) | 2000-01-13 |

| KR0183985B1 (en) | 1999-04-01 |

| AU7914991A (en) | 1992-01-02 |

| JPH0452102A (en) | 1992-02-20 |

| JP3038488B2 (en) | 2000-05-08 |

| DE69131547D1 (en) | 1999-09-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5425986A (en) | High pressure laminate structure | |

| CA1105365A (en) | Structural laminate | |

| US4689102A (en) | Method for the production of abrasion-resistant decorative laminates | |

| KR100424875B1 (en) | Manufacturing method of decorative thermosetting plastic laminate | |

| JP3044203B2 (en) | Method of coating melamine resin on laminated paper | |

| US4552792A (en) | Decorative laminated wall panel and process for making same | |

| WO2001064408A1 (en) | Impact resistant substrate particleboard and composite material using same | |

| EP0462586B1 (en) | Woody board | |

| WO2009135323A1 (en) | Manufacturing process for a laminated structure | |

| CN111806002A (en) | Composite board made of wood material | |

| CA2377417C (en) | One step multiple-ply panel pressing | |

| AU723544B2 (en) | Microveneer decorative laminate and method of making and articles made therefrom | |

| Kara et al. | Effect of overlay paper properties on the surface quality of laminate flooring | |

| JP2530952B2 (en) | Composite plate manufacturing method and composite plate | |

| RU217060U1 (en) | Panel for furniture and interior decoration for various purposes | |

| EP4252985A1 (en) | Process for the manufacture of a plywood panel, and plywood panel obtained by this process | |

| JPS59390B2 (en) | Manufacturing method of decorative veneer board suitable for bending workability | |

| JPH0818284B2 (en) | Veneer manufacturing method | |

| JPH08207009A (en) | Laminated sheet | |

| HK1023163A (en) | Microveneer decorative laminate, and method of making, and articles made therefrom | |

| JPH0439035A (en) | Composite plate and its manufacture | |

| HK1002966A (en) | Method of impregnating decorative paper with melamine resin | |

| MXPA97005353A (en) | Method for coating melamine resin on paper lamin |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19930629 |

|

| 17Q | First examination report despatched |

Effective date: 19940708 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT SE |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 69131547 Country of ref document: DE Date of ref document: 19990930 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20100702 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20100629 Year of fee payment: 20 Ref country code: GB Payment date: 20100524 Year of fee payment: 20 Ref country code: IT Payment date: 20100629 Year of fee payment: 20 Ref country code: SE Payment date: 20100628 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69131547 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69131547 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20110618 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20110618 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20110620 |