EP0457645B1 - Lighting device - Google Patents

Lighting device Download PDFInfo

- Publication number

- EP0457645B1 EP0457645B1 EP91401168A EP91401168A EP0457645B1 EP 0457645 B1 EP0457645 B1 EP 0457645B1 EP 91401168 A EP91401168 A EP 91401168A EP 91401168 A EP91401168 A EP 91401168A EP 0457645 B1 EP0457645 B1 EP 0457645B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- reflector

- accordance

- radiation

- tongues

- support component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V9/00—Elements for modifying spectral properties, polarisation or intensity of the light emitted, e.g. filters

- F21V9/04—Elements for modifying spectral properties, polarisation or intensity of the light emitted, e.g. filters for filtering out infrared radiation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V17/00—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages

- F21V17/06—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages the fastening being onto or by the lampholder

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V19/00—Fastening of light sources or lamp holders

- F21V19/0005—Fastening of light sources or lamp holders of sources having contact pins, wires or blades, e.g. pinch sealed lamp

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V29/00—Protecting lighting devices from thermal damage; Cooling or heating arrangements specially adapted for lighting devices or systems

- F21V29/15—Thermal insulation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V29/00—Protecting lighting devices from thermal damage; Cooling or heating arrangements specially adapted for lighting devices or systems

- F21V29/50—Cooling arrangements

- F21V29/502—Cooling arrangements characterised by the adaptation for cooling of specific components

- F21V29/505—Cooling arrangements characterised by the adaptation for cooling of specific components of reflectors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V29/00—Protecting lighting devices from thermal damage; Cooling or heating arrangements specially adapted for lighting devices or systems

- F21V29/50—Cooling arrangements

- F21V29/70—Cooling arrangements characterised by passive heat-dissipating elements, e.g. heat-sinks

- F21V29/74—Cooling arrangements characterised by passive heat-dissipating elements, e.g. heat-sinks with fins or blades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V29/00—Protecting lighting devices from thermal damage; Cooling or heating arrangements specially adapted for lighting devices or systems

- F21V29/50—Cooling arrangements

- F21V29/70—Cooling arrangements characterised by passive heat-dissipating elements, e.g. heat-sinks

- F21V29/83—Cooling arrangements characterised by passive heat-dissipating elements, e.g. heat-sinks the elements having apertures, ducts or channels, e.g. heat radiation holes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V29/00—Protecting lighting devices from thermal damage; Cooling or heating arrangements specially adapted for lighting devices or systems

- F21V29/85—Protecting lighting devices from thermal damage; Cooling or heating arrangements specially adapted for lighting devices or systems characterised by the material

- F21V29/89—Metals

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V7/00—Reflectors for light sources

- F21V7/10—Construction

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V7/00—Reflectors for light sources

- F21V7/22—Reflectors for light sources characterised by materials, surface treatments or coatings, e.g. dichroic reflectors

- F21V7/24—Reflectors for light sources characterised by materials, surface treatments or coatings, e.g. dichroic reflectors characterised by the material

Definitions

- the lighting devices include a reflector, the geometric shape of which is defined as a function of the shape of the desired light beam.

- These reflectors reflect all the radiation emitted by the bulb and therefore including the heat radiation, so that one obtains, along the axis of the reflector, a distribution curve of the reflected heat radiation which corresponds, in its shape, to that of reflected visible radiation.

- dichroic reflector lighting devices established so as to reflect, towards the front of the reflector, the light radiation coming from the bulb and, on the contrary, to be let through by the heat radiation.

- the external face of the reflector is of a structure such that it returns the heat radiation towards the interior of the reflector according to a particular distribution curve different from that of the light radiation reflected by the internal face.

- the reflecting structure of the external face of the reflector is obtained by depositing a reflecting material such as a metallization, which thus forms an integral part of the transparent support of the reflecting material for visible radiation.

- the present invention aims in particular to remedy these drawbacks and for this purpose relates to a lighting device comprising a light bulb arranged inside a reflector made of transparent material and having a selective reflecting surface capable of reflect the visible radiation from the bulb while allowing the heat radiation to pass through it, while on the external side of this reflector, a reflective surface is provided for the heat radiation passing through the reflector, device characterized in that the reflective surface for heat radiation is carried out on a support piece arranged outside the reflector.

- the support part is metallic.

- the cup is made in one piece from a flat metal plate, one of the faces of which is provided with a reflective coating, this plate then being arched in the shape of the cup.

- the present invention therefore aims to achieve a lighting device which avoids, in a simple and low cost, overheating inside the lighting device and in particular the bulb which can thus operate under normal temperature conditions and, therefore, without alteration.

- This device also makes it possible to reduce the pronounced undesirable thermal effects on objects or people lit by this device, while promoting and standardizing the thermal diffusion on the side of the reflector opposite to the lit side.

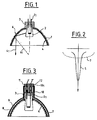

- the device shown in Figure 1 thus schematically comprises a reflector 1 and a light bulb 2 which is fixed to the focus of this reflector on its base 3.

- the pins 21 of this bulb protrude from the base and are intended to be connected to a corresponding female plug.

- the reflector 1 constitutes first of all a dichroic reflector insofar as it is made of transparent material and that it comprises, in general on its internal face, a selective reflective coating 4, which reflects visible radiation but which can be passed through by infrared heat radiation.

- the visible radiation from the bulb is thus reflected towards the front of the reflector along rays 41 and is reflected by a light beam whose distribution curve 5 ( Figure 2) is defined by the shape of the reflective surface 4 of the reflector 1.

- a support piece 6 provided, on its internal face, with a reflecting surface 6 for the heat radiation, so that this radiation, which passes through the dichroic reflector, is partly diffused by the support 6 constituting a heat exchanger and is partly reflected by this support surface 6 and to pass through the reflector again 1 and produce towards the front of this reflector, reflected rays 61 whose direction is different from that of the reflected light rays 41.

- This different direction of the spokes 61 results from the different position of the surface 6 relative to the surface 4, taking into account the position of the filament of the bulb 2.

- This direction of the rays 61 results in a distribution of the heat radiation 7 (FIG. 2) which is different from that of the visible radiation 5.

- This distribution curve will thus be spread over a large surface in front of and near the lighting device, so as to avoid undesirable thermal effects on people and illuminated objects, while of course avoiding overheating of the elements situated towards the rear of the reflector.

- the reflecting surface of the support 6 can be frosted in order to increase the diffusion of the reflected visible radiation.

- this reflecting surface 8 is produced on the internal face of a support piece 9 in the form of a cup arranged in the immediate vicinity of the external face of the reflector 1.

- This reflecting surface 8 is constituted either by a metallization of the internal face of a support piece 9 made of plastic material, or by the polished or frosted reflecting internal face of a piece 9 made of metal.

- This piece whose shape corresponds or not to that of the dichroic reflector, has in its center an opening or a housing of dimensions such that it can receive the base 3 of the dichroic reflector.

- the reflective support piece 9, constituting both a heat shield and a heat exchanger, is provided with an axial tip 10 ending in an internal flange 101.

- This rim hangs on the plug 11 comprising the female pins 12 on which the male pins 21 of the bulb 2 come to be sealed in the base 3 of the reflector 1.

- This arrangement allows the replacement of the bulb 2 and of the reflector 1 while retaining in the lighting device the reflector 9 which is automatically positioned with respect to the bulb 2 and to the reflector 1 when this bulb is placed on the plug 11.

- the axial end piece 10 in the form of lugs provided with its flange 101, will hang on a clip surrounding the plug 11.

- This support piece 9 may also, instead of being supported by the plug 11, be supported by the base 3 of the reflector 1 or by this reflector.

- the support part 1 may be fixed by its internal surface against the external face of the reflector 1.

- the reflector 1 will, in this case, be obtained by overmolding on the support 9.

- the present invention will find all its interest insofar as the lighting device is of a simple and inexpensive realization and insofar as its assembly is carried out quickly by automatically positioning the external reflector for the heat radiation on the internal reflector for visible radiation.

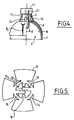

- the cup 9 forming a heat shield and a heat exchanger is produced by cutting a flat plate, preferably made of metal, which is previously coated on one of its faces, with a reflective material.

- This reflecting flat plate is cut to form radial tongues 13, for example four in number, regularly distributed around the periphery of a central part 14. These tongues 13 are cut so that by bending, the shape of the cup 9 is obtained , the edges of the tongues juxtaposing each other and against the edge of the central part 14.

- the cutting and bending are carried out so as to form between the tongues narrow openings in the form of slits resulting, as shown in 91 in Figure 1, from the non-joined assembly of the cut edges .

- This arrangement will promote the cooling of the lamp by allowing the establishment of convection currents as well as promoting the decorative effect.

- the cut tabs 13 are subject to a bending of relatively low amplitude which does not modify the structure of the reflecting surface, which makes it possible to use as starting material a metal plate previously provided with a reflecting surface in order to considerably reduce the manufacturing cost of this reflector.

- tongues 15 and 16 form two pairs of tongues, the tongues of each pair being parallel and opposite, while the tongues of one pair are perpendicular to the tongues of the other pair.

- the tongues 15 of one of the pairs are of a length such that after folding they are applied by their ends 151, possibly laterally to the base 3, but above all substantially vertically against the opposite face 111 of the base of the connection plug 11.

- the two other parallel and opposite tongues 16 are of a shorter length and have the sole function of clamping effectively, due to their shorter length, against the side wall of the base 3 in order to ensure centering. of the cup 9, while the longer tongues 15 mainly have the function of ensuring the axial positioning of the reflector 9 by pushing it axially towards the reflector 1.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

- Control Of Eletrric Generators (AREA)

- Liquid Crystal (AREA)

- Liquid Crystal Substances (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

- Vehicle Body Suspensions (AREA)

- Polarising Elements (AREA)

- Seal Device For Vehicle (AREA)

Abstract

Description

Les dispositifs d'éclairage comportent un réflecteur dont la forme géométrique est définie en fonction de la forme du faisceau lumineux désiré.The lighting devices include a reflector, the geometric shape of which is defined as a function of the shape of the desired light beam.

Ces réflecteurs réfléchissent la totalité du rayonnement émis par l'ampoule et donc y compris le rayonnement calorifique, si bien que l'on obtient, suivant l'axe du réflecteur, une courbe de répartition du rayonnement calorifique réfléchi qui correspond, dans sa forme, à celle du rayonnement visible réfléchi.These reflectors reflect all the radiation emitted by the bulb and therefore including the heat radiation, so that one obtains, along the axis of the reflector, a distribution curve of the reflected heat radiation which corresponds, in its shape, to that of reflected visible radiation.

Cette réflexion du rayonnement calorifique vers l'avant du réflecteur se traduit cependant par un inconvénient important en raison des effets thermiques indésirables qu'il engendre sur les personnes, les objets ou les surfaces éclairées.This reflection of the heat radiation towards the front of the reflector, however, results in a significant drawback due to the undesirable thermal effects which it generates on people, objects or illuminated surfaces.

Cet inconvénient est particulièrement sensible avec les réflecteurs de petites dimensions contenant des ampoules miniatures du type halogène, qui produisent un faisceau lumineux concentré de forte puissance.This drawback is particularly noticeable with small reflectors containing miniature bulbs of the halogen type, which produce a concentrated light beam of high power.

On connaît déjà des dispositifs d'éclairage dits à "réflecteur dichroïque" établis de façon à réfléchir, vers l'avant du réflecteur, le rayonnement lumineux issu de l'ampoule et de façon, au contraire, à se laisser traverser par le rayonnement calorifique.There are already known so-called "dichroic reflector" lighting devices established so as to reflect, towards the front of the reflector, the light radiation coming from the bulb and, on the contrary, to be let through by the heat radiation.

Dans ce cas, la face externe du réflecteur est d'une structure telle qu'elle renvoie le rayonnement calorifique vers l'intérieur du réflecteur suivant une courbe de répartition particulière différente de celle du rayonnement lumineux réfléchi par la face interne.In this case, the external face of the reflector is of a structure such that it returns the heat radiation towards the interior of the reflector according to a particular distribution curve different from that of the light radiation reflected by the internal face.

La structure réfléchissante de la face externe du réflecteur est obtenue par le dépôt d'un matériau réfléchissant tel qu'une métallisation, qui fait ainsi partie intégrante du support transparent du matériau réfléchissant pour le rayonnement visible.The reflecting structure of the external face of the reflector is obtained by depositing a reflecting material such as a metallization, which thus forms an integral part of the transparent support of the reflecting material for visible radiation.

Une telle réalisation est, par exemple, décrite dans le brevet français N° 72 29395.Such an embodiment is, for example, described in French patent No. 72 29395.

Un tel dispositif d'éclairage n'a cependant pas pu trouver de développement industriel notable dans la mesure où la métallisation réfléchissante pour le rayonnement calorifique de la face externe du réflecteur constitue un bouclier thermique, si bien que la chaleur est absorbée en très grande partie par le matériau de support transparent, ce qui engendre une surchauffe de l'intérieur du dispositif d'éclairage en entraînant une destruction prématurée de l'ampoule.However, such a lighting device has not been able to find any significant industrial development since the reflective metallization for the heat radiation of the external face of the reflector constitutes a heat shield, so that the heat is largely absorbed. by the transparent support material, which causes the interior of the lighting device to overheat, leading to premature destruction of the bulb.

Cette surchauffe qui est d'autant plus importante que le réflecteur est de petites dimensions et que la puissance de la source est importante, devient rapidement inadmissible et peut alors être la cause d'incendies.This overheating, which is all the more important as the reflector is small and the power of the source is large, quickly becomes unacceptable and can then be the cause of fires.

La présente invention a notamment pour but de remédier à ces inconvénients et concerne à cet effet un dispositif d'éclairage comportant une ampoule d'éclairage disposée à l'intérieur d'un réflecteur réalisé en matériau transparent et présentant une surface réfléchissante sélective susceptible de réfléchir le rayonnement visible issu de l'ampoule tout en se laissant traverser par le rayonnement calorifique, tandis que du côté externe de ce réflecteur, il est prévu une surface réfléchissante pour le rayonnement calorifique traversant le réflecteur, dispositif caractérisé en ce que la surface réfléchissante pour le rayonnement calorifique est réalisée sur une pièce de support disposée à l'extérieur du réflecteur.The present invention aims in particular to remedy these drawbacks and for this purpose relates to a lighting device comprising a light bulb arranged inside a reflector made of transparent material and having a selective reflecting surface capable of reflect the visible radiation from the bulb while allowing the heat radiation to pass through it, while on the external side of this reflector, a reflective surface is provided for the heat radiation passing through the reflector, device characterized in that the reflective surface for heat radiation is carried out on a support piece arranged outside the reflector.

Suivant une autre caractéristique de l'invention, la pièce de support est métallique.According to another characteristic of the invention, the support part is metallic.

Suivant une autre caractéristique de l'invention, la coupelle est réalisée en une seule pièce à partir d'une plaque plane de métal dont l'une des faces est pourvue d'un revêtement réfléchissant, cette plaque étant ensuite cambrée à la forme de la coupelle.According to another characteristic of the invention, the cup is made in one piece from a flat metal plate, one of the faces of which is provided with a reflective coating, this plate then being arched in the shape of the cup.

L'invention est représentée à titre d'exemple non limitatif sur les dessins ci-joints dans lesquels :

- la figure 1 est une vue en coupe schématique d'un dispositif d'éclairage conforme à l'invention,

- la figure 2 représente schématiquement la répartition du rayonnement visible et calorifique obtenu vers l'avant du réflecteur par le dispositif d'éclairage conforme à l'invention,

- la figure 3 est une vue en coupe axiale d'un autre mode de réalisation du dispositif de l'invention,

- la figure 4 est une vue en demi-coupe axiale d'un dispositif d'éclairage conforme à l'invention,

- la figure 5 est une vue à plat du réflecteur pour le rayonnement calorifique prévu à l'extérieur du réflecteur pour le rayonnement visible.

- FIG. 1 is a schematic sectional view of a lighting device according to the invention,

- FIG. 2 schematically represents the distribution of visible and heat radiation obtained towards the front of the reflector by the lighting device according to the invention,

- FIG. 3 is a view in axial section of another embodiment of the device of the invention,

- FIG. 4 is a view in axial half-section of a lighting device according to the invention,

- FIG. 5 is a flat view of the reflector for the heat radiation provided for the outside of the reflector for visible radiation.

La présente invention a en conséquence pour but la réalisation d'un dispositif d'éclairage qui permet d'éviter, de manière simple et à faible coût, la surchauffe de l'intérieur du dispositif d'éclairage et notamment de l'ampoule qui peut ainsi fonctionner dans des conditions de température normales et, donc, sans altération. Ce dispositif permet également de réduire les effets thermiques prononcés indésirables sur les objets ou les personnes éclairés par ce dispositif, tout en favorisant et en uniformisant la diffusion thermique du côté du réflecteur opposé au côté éclairé.The present invention therefore aims to achieve a lighting device which avoids, in a simple and low cost, overheating inside the lighting device and in particular the bulb which can thus operate under normal temperature conditions and, therefore, without alteration. This device also makes it possible to reduce the pronounced undesirable thermal effects on objects or people lit by this device, while promoting and standardizing the thermal diffusion on the side of the reflector opposite to the lit side.

Le dispositif représenté sur la figure 1 comprend ainsi schématiquement un réflecteur 1 et une ampoule d'éclairage 2 qui est fixée au foyer de ce réflecteur sur son embase 3. Les broches 2₁ de cette ampoule font saillie de l'embase et sont destinées à être raccordées à une fiche femelle correspondante.The device shown in Figure 1 thus schematically comprises a reflector 1 and a

Le réflecteur 1 constitue tout d'abord un réflecteur dichroïque dans la mesure où il est réalisé en matériau transparent et qu'il comporte, en général sur sa face interne, un revêtement 4 réfléchissant sélectif, qui réfléchit le rayonnement visible mais qui se laisse traverser par le rayonnement calorifique infrarouge.The reflector 1 constitutes first of all a dichroic reflector insofar as it is made of transparent material and that it comprises, in general on its internal face, a selective

Le rayonnement visible issu de l'ampoule est ainsi réfléchi vers l'avant du réflecteur suivant des rayons 4₁ et se traduit par un faisceau lumineux dont la courbe de répartition 5 (figure 2) est définie par la forme de la surface réfléchissante 4 du réflecteur 1.The visible radiation from the bulb is thus reflected towards the front of the reflector along

Conformément à l'invention, il est cependant prévu du côté de la face externe du réflecteur 1 une pièce de support 6 pourvue, sur sa face interne, d'une surface réfléchissante 6 pour le rayonnement calorifique, de façon que ce rayonnement, qui traverse le réflecteur dichroïque, soit en partie diffusé par le support 6 constituant un échangeur thermique et soit en partie réfléchi par cette surface de support 6 et pour traverser à nouveau le réflecteur 1 et produire vers l'avant de ce réflecteur, des rayons réfléchis 6₁ dont la direction est différente de celle des rayons lumineux réfléchis 4₁. Cette direction différente des rayons 6₁ résulte de la position différente de la surface 6 par rapport à la surface 4, compte tenu de la position du filament de l'ampoule 2.According to the invention, there is however provided on the side of the external face of the reflector 1 a support piece 6 provided, on its internal face, with a reflecting surface 6 for the heat radiation, so that this radiation, which passes through the dichroic reflector, is partly diffused by the support 6 constituting a heat exchanger and is partly reflected by this support surface 6 and to pass through the reflector again 1 and produce towards the front of this reflector, reflected rays 6₁ whose direction is different from that of the

Cette direction des rayons 6₁ se traduit par une répartition du rayonnement calorifique 7 (figure 2) qui est différente de celle du rayonnement visible 5. Cette courbe de répartition sera ainsi étalée sur une surface importante devant et à proximité du dispositif d'éclairage, de façon à éviter des effets thermiques indésirables sur les personnes et les objets éclairés, tout en évitant bien entendu la surchauffe des éléments situés vers l'arrière du réflecteur.This direction of the rays 6₁ results in a distribution of the heat radiation 7 (FIG. 2) which is different from that of the

Si on le désire, la surface réfléchissante du support 6 pourra être dépolie afin d'augmenter la diffusion du rayonnement visible réfléchi.If desired, the reflecting surface of the support 6 can be frosted in order to increase the diffusion of the reflected visible radiation.

Suivant l'exemple de la figure 3, cette surface réfléchissante 8 est réalisée sur la face interne d'une pièce de support 9 en forme de coupelle disposée à proximité immédiate de la face externe du réflecteur 1.According to the example of FIG. 3, this reflecting surface 8 is produced on the internal face of a support piece 9 in the form of a cup arranged in the immediate vicinity of the external face of the reflector 1.

Cette surface réfléchissante 8 est constituée, soit par une métallisation de la face interne d'une pièce de support 9 en matière plastique, soit par la face interne réfléchissante polie ou dépolie d'une pièce 9 réalisée en métal. Cette pièce, dont la forme correspond ou non à celle du réflecteur dichroïque, présente en son centre une ouverture ou un logement de dimensions telles qu'il peut recevoir l'embase 3 du réflecteur dichroïque.This reflecting surface 8 is constituted either by a metallization of the internal face of a support piece 9 made of plastic material, or by the polished or frosted reflecting internal face of a piece 9 made of metal. This piece, whose shape corresponds or not to that of the dichroic reflector, has in its center an opening or a housing of dimensions such that it can receive the

Dans l'exemple représenté sur la figure 3, la pièce de support réfléchissante 9, constituant à la fois un bouclier thermique et un échangeur thermique, est pourvue d'un embout axial 10 se terminant par un rebord interne 10₁. Ce rebord s'accroche sur la fiche 11 comportant les broches femelles 12 sur lesquelles viennent s'emboîter les broches mâles 2₁ de l'ampoule 2 scellée dans l'embase 3 du réflecteur 1. Cette disposition permet le remplacement de l'ampoule 2 et du réflecteur 1 en conservant dans le dispositif d'éclairage le réflecteur 9 qui se trouve automatiquement positionné par rapport à l'ampoule 2 et au réflecteur 1 lors de la mise en place de cette ampoule sur la fiche 11.In the example shown in Figure 3, the reflective support piece 9, constituting both a heat shield and a heat exchanger, is provided with an

Suivant une variante de réalisation non représentée, l'embout axial 10 en forme de pattes pourvu de son rebord 10₁, viendra s'accrocher sur une agrafe entourant la fiche 11.According to a variant embodiment not shown, the

Cette pièce de support 9 pourra également, au lieu d'être supportée par la fiche 11, être supportée par l'embase 3 du réflecteur 1 ou par ce réflecteur.This support piece 9 may also, instead of being supported by the

Dans ce dernier cas, la pièce de support 1 pourra être fixée par sa surface interne contre la face externe du réflecteur 1. Eventuellement, le réflecteur 1 sera, dans ce cas, obtenu par surmoulage sur le support 9.In the latter case, the support part 1 may be fixed by its internal surface against the external face of the reflector 1. Optionally, the reflector 1 will, in this case, be obtained by overmolding on the support 9.

Dans la mesure où l'on désire adapter la courbe de répartition du rayonnement calorifique réfléchi 7, il sera possible de donner à la surface 6 ou 8 réfléchissant le rayonnement calorifique une courbure différente de celle de la surface 4 réfléchissant le rayonnement lumineux.Insofar as it is desired to adapt the distribution curve of the

La présente invention trouvera tout son intérêt dans la mesure où le dispositif d'éclairage est d'une réalisation simple et peu coûteuse et dans la mesure où son montage est réalisé rapidement en positionnant automatiquement le réflecteur extérieur pour le rayonnement calorifique sur le réflecteur intérieur pour le rayonnement visible.The present invention will find all its interest insofar as the lighting device is of a simple and inexpensive realization and insofar as its assembly is carried out quickly by automatically positioning the external reflector for the heat radiation on the internal reflector for visible radiation.

Ainsi, suivant les figures 4 et 5, la coupelle 9 formant bouclier thermique et échangeur thermique est réalisée par découpage d'une plaque plane de préférence en métal, qui est préalablement revêtue sur l'une de ses faces, d'un matériau réfléchissant. Cette plaque plane réfléchissante est découpée pour former des languettes radiales 13, par exemple au nombre de quatre, régulièrement réparties à la périphérie d'une partie centrale 14. Ces languettes 13 sont découpées de façon que par cintrage on obtienne la forme de la coupelle 9, les bords des languettes venant se juxtaposer l'un l'autre et contre le bord de la partie centrale 14.Thus, according to FIGS. 4 and 5, the cup 9 forming a heat shield and a heat exchanger is produced by cutting a flat plate, preferably made of metal, which is previously coated on one of its faces, with a reflective material. This reflecting flat plate is cut to form

Suivant un mode de réalisation particulier, le découpage et le cintrage sont réalisés de manière à former entre les languettes des ouvertures étroites en forme de fentes résultant, comme cela est représenté en 9₁ sur la figure 1, de l'assemblage non jointif des bords découpés. Cette disposition permettra de favoriser le refroidissement de la lampe en permettant l'établissement des courants de convection ainsi que de favoriser l'effet décoratif.According to a particular embodiment, the cutting and bending are carried out so as to form between the tongues narrow openings in the form of slits resulting, as shown in 9₁ in Figure 1, from the non-joined assembly of the cut edges . This arrangement will promote the cooling of the lamp by allowing the establishment of convection currents as well as promoting the decorative effect.

Du fait de cette construction, du réflecteur 9, les languettes découpées 13 font l'objet d'un cintrage d'amplitude relativement faible quine modifie pas la structure de la surface réfléchissante, ce qui permet d'utiliser comme matériau de départ une plaque métallique préalablement pourvue d'une surface réfléchissante afin de réduire considérablement le coût de fabrication de ce réflecteur.Because of this construction, of the reflector 9, the

Conformément à l'invention, il est également prévu d'effectuer, simultanément au découpage des languettes 13, le découpage de languettes 15 et 16 à l'intérieur de la zone centrale 14.In accordance with the invention, it is also planned to carry out, simultaneously with the cutting of the

Ces languettes 15 et 16 forment deux paires de languettes, les languettes de chaque paire étant parallèles et opposées, alors que les languettes d'une paire sont perpendiculaires par rapport aux languettes de l'autre paire.These

Egalement, les languettes 15 de l'une des paires sont d'une longueur telle qu'après repliage elles viennent s'appliquer par leurs extrémités 15₁, éventuellement latéralement à l'embase 3, mais surtout sensiblement verticalement contre la face en regard 11₁ de la base de la fiche de raccordement 11.Also, the

Par contre, les deux autres languettes parallèles et opposées 16 sont d'une longueur moindre et ont exclusivement pour fonction de se serrer efficacement, du fait de leur longueur plus faible, contre la paroi latérale de l'embase 3 afin d'assurer un centrage de la coupelle 9, alors que les languettes plus longues 15 ont principalement pour fonction d'assurer le positionnement axial du réflecteur 9 en le repoussant axialement vers le réflecteur 1.On the other hand, the two other parallel and

Claims (12)

- Lighting device including a light bulb arranged inside a reflector made from transparent material and exhibiting a selective reflective surface (4) capable of reflecting the visible radiation coming from the bulb (2) while still allowing the thermal radiation to pass, whereas on the external side of this reflector a reflective surface (6, 8) is provided for the thermal radiation passing through the reflector (1), which device is characterized in that the reflective surface (8) for the thermal radiation is produced on a support component arranged outside the reflector.

- Device in accordance with Claim 1, characterized in that the support component (9) forms a dish arranged in the immediate proximity of the reflector.

- Device in accordance with any one of the preceding claims, characterized in that the support component or dish (9) is supported by the reflector.

- Device in accordance with Claim 3, characterized in that the support component or dish is supported by a plug (11) receiving the pins (2₁) of the bulb (2) supporting the reflector (1) for the light radiation.

- Device in accordance with Claim 3, characterized in that the support component forms a dish against the thermal-radiation-reflecting internal face of which the reflector (1) for the visible radiation is fixed.

- Device in accordance with any one of Claims 2 to 6, characterized in that the support component is metallic.

- Device in accordance with any one of the preceding claims, characterized in that the curvature of the reflective surfaces for the thermal radiation and for the visible radiation is different, this difference in curvature being obtained by producing the reflective surface for the thermal radiation on a support component (9) of curvature different from that of the reflector (1) for the more visible radiation.

- Device in accordance with Claim 6, characterized in that the dish (9) is produced as a single piece from a flat metal plate, one of the faces of which is provided with a reflective coating, this plate being subsequently bent to the shape of the dish.

- Device in accordance with Claim 8, characterized in that the plate is cut out. in order to form radial tongues (13) which are placed in proximity to each other by the bending operation.

- Device in accordance with either of Claims 8 and 9, characterized in that the metal plate is cut out in order to form radial tongues (13) distributed on the outside of the periphery of a central zone itself provided on the inside with cut-out tongues (15, 16).

- Device in accordance with Claim 10, characterized in that the tongues cut out on the inside of the central zone (14) have a length such that they bear by their ends on the base surface (11₁) of the connecting plug (11) receiving the pins (2₁) of the bulb (2) provided on the reflector for the visible radiation (1).

- Device in accordance with Claim 11, characterized in that the tongues cut out on the inside of the central zone (14) comprise a pair of opposed parallel tongues (15) which have a length such that they bear by their ends on the base surface (11₁) of the plug (11) and a pair of opposed parallel tongues (16), which are perpendicular to the previous ones and shorter, in order to be applied exclusively on the cap of the reflector.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR909006026A FR2662235B1 (en) | 1990-05-15 | 1990-05-15 | LIGHTING DEVICE COMPRISING A LIGHTING BULB ARRANGED INSIDE A REFLECTOR. |

| FR9006026 | 1990-05-15 | ||

| FR9104291A FR2675239B1 (en) | 1991-04-09 | 1991-04-09 | LIGHTING DEVICE WITH THERMAL SHIELD. |

| FR9104291 | 1991-04-09 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0457645A2 EP0457645A2 (en) | 1991-11-21 |

| EP0457645A3 EP0457645A3 (en) | 1992-02-26 |

| EP0457645B1 true EP0457645B1 (en) | 1994-07-13 |

Family

ID=26228019

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91401168A Expired - Lifetime EP0457645B1 (en) | 1990-05-15 | 1991-05-03 | Lighting device |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5130913A (en) |

| EP (1) | EP0457645B1 (en) |

| JP (1) | JPH04229503A (en) |

| AT (1) | ATE108532T1 (en) |

| CA (1) | CA2041906A1 (en) |

| DE (1) | DE69102819T2 (en) |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5798611A (en) * | 1990-10-25 | 1998-08-25 | Fusion Lighting, Inc. | Lamp having controllable spectrum |

| US6020676A (en) * | 1992-04-13 | 2000-02-01 | Fusion Lighting, Inc. | Lamp with light reflection back into bulb |

| US5323301A (en) * | 1992-12-08 | 1994-06-21 | Robert Kaufman | Dimmable studio lighting device |

| US5535110A (en) * | 1995-02-16 | 1996-07-09 | Cooper Industries, Inc. | Ceiling mounted wallwash light fixture |

| US6291936B1 (en) | 1996-05-31 | 2001-09-18 | Fusion Lighting, Inc. | Discharge lamp with reflective jacket |

| KR20000016099A (en) | 1996-05-31 | 2000-03-25 | 켄트 키플링 | Multi-reflection electrodeless lamp filled with sulphur or selenium filling material and supply method of radiation light using the same |

| US5873650A (en) * | 1996-11-19 | 1999-02-23 | Luk; John F. | Modular heat sink adapter for lamp bases |

| CA2228534A1 (en) * | 1998-02-03 | 1999-08-03 | Cooper Industries, Inc. | Recessed light fixture |

| FR2782551B1 (en) * | 1998-08-19 | 2000-11-10 | Thorn Europhane Sa | LIGHTING REFLECTOR, PARTICULARLY FOR PUBLIC HIGHWAYS |

| US6227682B1 (en) | 2000-03-22 | 2001-05-08 | Cogent Light Technologies, Inc. | Coupling of light from a small light source for projection systems using parabolic reflectors |

| WO2002063390A2 (en) | 2001-02-05 | 2002-08-15 | Wavien, Inc. | An illumination engine for a projection display using a tapered light pipe |

| US6856727B2 (en) * | 2001-03-02 | 2005-02-15 | Wavien, Inc. | Coupling of light from a non-circular light source |

| US6926435B2 (en) * | 2001-08-23 | 2005-08-09 | Wavien, Inc. | Led illumination engine using a reflector |

| US20040264201A1 (en) * | 2003-06-30 | 2004-12-30 | Guide Corporation, A Delaware Corporation | Chromatic effect using light sources and condensing lenses |

| US9696021B2 (en) | 2004-03-25 | 2017-07-04 | Cooper Technologies Company | Hanger bar for recessed luminaires |

| US20050247842A1 (en) * | 2004-05-10 | 2005-11-10 | Grzegorz Wronski | Hanger bar assemblies for recessed luminaires |

| US7673841B2 (en) | 2004-03-25 | 2010-03-09 | Cooper Technologies Company | Hangar bar for recessed luminaires with integral nail |

| US20070019421A1 (en) * | 2005-07-12 | 2007-01-25 | Kregness Christopher A | Removable, multi-purpose utility light for motor vehicles |

| JP4640215B2 (en) * | 2006-02-28 | 2011-03-02 | ウシオ電機株式会社 | Light source device |

| US8491166B2 (en) * | 2007-09-21 | 2013-07-23 | Cooper Technologies Company | Thermal management for light emitting diode fixture |

| DE102008053488B4 (en) * | 2008-10-28 | 2013-04-04 | Osram Gmbh | reflector lamp |

| CA2768777C (en) | 2009-07-21 | 2017-11-28 | Cooper Technologies Company | Interfacing a light emitting diode (led) module to a heat sink assembly, a light reflector and electrical circuits |

| US8596837B1 (en) | 2009-07-21 | 2013-12-03 | Cooper Technologies Company | Systems, methods, and devices providing a quick-release mechanism for a modular LED light engine |

| US9060607B1 (en) | 2012-10-17 | 2015-06-23 | Cooper Technologies Company | Hanger bar for recessed light fixture mounting |

| US8939418B2 (en) | 2013-04-05 | 2015-01-27 | Cooper Technologies Company | Adjustable hanger bar for luminaires |

| US9732904B1 (en) | 2015-06-05 | 2017-08-15 | Cooper Technologies Company | Adjustable hanger bar assembly for luminaires |

| US9239131B1 (en) | 2015-06-05 | 2016-01-19 | Cooper Technologies Company | Adjustable hanger bars with detachment stop |

| US11134618B2 (en) * | 2016-08-30 | 2021-10-05 | Current Lighting Solutions, Llc | Luminaire including a heat dissipation structure |

| US10584837B2 (en) | 2016-10-28 | 2020-03-10 | Cordelia Lighting, Inc. | Bar hanger system for recessed fixtures |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1735181A (en) * | 1927-03-30 | 1929-11-12 | Lambert L Raymond | Reflector-attaching device |

| US3322946A (en) * | 1964-11-27 | 1967-05-30 | George D Cooper | Reflector for reflecting color corrected light and heat |

| US3654455A (en) * | 1969-08-20 | 1972-04-04 | Holophane Co Inc | Luminaire |

| US3745325A (en) * | 1971-08-17 | 1973-07-10 | Eastman Kodak Co | Photographic light |

| US3769503A (en) * | 1972-06-23 | 1973-10-30 | Gen Electric | Lamp fixture having dichoric filter arrangement for selectively directing heat and light |

| FR2192272B1 (en) * | 1972-07-11 | 1975-03-07 | Cibie Projecteurs | |

| US4028542A (en) * | 1974-09-11 | 1977-06-07 | Esquire, Inc. | Faceted parabolic-type reflector system |

| DE2713615A1 (en) * | 1977-03-28 | 1978-10-05 | Patra Patent Treuhand | UNIT OF HALOGEN LIGHT BULB AND REFLECTOR |

| FR2484720A1 (en) * | 1980-06-13 | 1981-12-18 | David Francis | Lamp to standard to halogen lamp base converter - allows pin based halogen lamps to replace most low voltage lamps in existing housings and has reflective dome which holds and protects lamp |

| JPS6217904A (en) * | 1985-07-15 | 1987-01-26 | 双葉電子工業株式会社 | Light source |

| DE9002879U1 (en) * | 1990-03-14 | 1990-05-17 | Nafa-Light Kurt Maurer, Zumikon | lamp |

-

1991

- 1991-05-03 DE DE69102819T patent/DE69102819T2/en not_active Expired - Fee Related

- 1991-05-03 AT AT91401168T patent/ATE108532T1/en not_active IP Right Cessation

- 1991-05-03 EP EP91401168A patent/EP0457645B1/en not_active Expired - Lifetime

- 1991-05-07 CA CA002041906A patent/CA2041906A1/en not_active Abandoned

- 1991-05-14 US US07/699,885 patent/US5130913A/en not_active Expired - Fee Related

- 1991-05-15 JP JP3109973A patent/JPH04229503A/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JPH04229503A (en) | 1992-08-19 |

| US5130913A (en) | 1992-07-14 |

| DE69102819T2 (en) | 1995-02-23 |

| EP0457645A2 (en) | 1991-11-21 |

| CA2041906A1 (en) | 1991-11-16 |

| ATE108532T1 (en) | 1994-07-15 |

| EP0457645A3 (en) | 1992-02-26 |

| DE69102819D1 (en) | 1994-08-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0457645B1 (en) | Lighting device | |

| FR3058501A1 (en) | VEHICLE HEADLIGHT | |

| EP0276780B1 (en) | Reflector lamp having a multifunctional supporting member | |

| FR2670562A1 (en) | LIGHTING DEVICE FOR VEHICLES. | |

| FR2813946A1 (en) | VEHICLE LAMP | |

| EP0531186A1 (en) | Signalling light with electroluminescent elements, especially for motor vehicles | |

| FR2606125A1 (en) | IMPROVED PROJECTOR FOR MOTOR VEHICLE | |

| FR2669398A1 (en) | Motor vehicle headlamp | |

| FR3062460A1 (en) | LUMINOUS MODULE FOR VEHICLE PROJECTOR | |

| EP1184618A1 (en) | Signal light with a simplified optical structure and method to produce such a structure | |

| EP3016791B1 (en) | Heating module comprising a lamp and a lens fastened by a brace to a non-emissive portion of the lamp | |

| CA1141728A (en) | Sealed beam with interchangeable | |

| FR2496841A1 (en) | LAMP WITH REFLECTOR AND OPTICAL PROFILES | |

| FR2954458A1 (en) | Port-hole type lamp for use at e.g. ceiling of corridor, has base provided with basin, where basin crossed by light emitted by light source is opalescent in part of non surface occupied by transparent surface constituting translucent zone | |

| FR2500116A1 (en) | Vehicle headlamp with hot air deflector over bulb - uses semi-cylindrical plate over bulb to divert hot air towards front glass of headlamp for better cooling | |

| FR2687762A1 (en) | Headlamp with lens, equipped with improved lens mounting means | |

| FR2562638A1 (en) | Lighting projector | |

| FR2662235A1 (en) | Lighting device including a light bulb arranged inside a reflector | |

| FR2525733A1 (en) | Headlamp reflector with sub-reflector to aim beam downwards - uses main reflector with stepped parabolic segments moulded in to deflect down part of light beam | |

| FR2732655A1 (en) | INDICATOR LIGHTING DEVICE AND DASHBOARD INCORPORATING THE SAME | |

| FR2675239A1 (en) | Lighting device with heat shield | |

| EP1388709A1 (en) | A method for manufacturing a lighting or signalling device, and a lighting or signalling device obtained by this method | |

| EP0810400B1 (en) | Light projector, especially for vehicles, having an enhanced mechanical structure | |

| FR2565672A1 (en) | Reflector of IR heater | |

| FR2802704A1 (en) | ELECTRIC MIRROR BULB AND LIGHTING RAMP COMPRISING AT LEAST ONE SUCH BULB |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19920627 |

|

| 17Q | First examination report despatched |

Effective date: 19931215 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19940713 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19940713 Ref country code: NL Effective date: 19940713 Ref country code: DK Effective date: 19940713 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19940713 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19940713 |

|

| REF | Corresponds to: |

Ref document number: 108532 Country of ref document: AT Date of ref document: 19940715 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 69102819 Country of ref document: DE Date of ref document: 19940818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941013 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19941019 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950503 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19950531 Ref country code: CH Effective date: 19950531 Ref country code: LI Effective date: 19950531 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19950531 |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: DAVID FRANCIS Effective date: 19950531 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950503 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960201 |