EP0432485B1 - Process and apparatus for the production of light alloy tubing of larger diameter starting from tubing of smaller diameter - Google Patents

Process and apparatus for the production of light alloy tubing of larger diameter starting from tubing of smaller diameter Download PDFInfo

- Publication number

- EP0432485B1 EP0432485B1 EP90121705A EP90121705A EP0432485B1 EP 0432485 B1 EP0432485 B1 EP 0432485B1 EP 90121705 A EP90121705 A EP 90121705A EP 90121705 A EP90121705 A EP 90121705A EP 0432485 B1 EP0432485 B1 EP 0432485B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tubing

- mandrel

- tube

- diameter

- pressing roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 12

- 229910001234 light alloy Inorganic materials 0.000 title claims abstract description 10

- 238000000034 method Methods 0.000 title claims description 13

- 238000003825 pressing Methods 0.000 claims abstract description 22

- 230000003247 decreasing effect Effects 0.000 claims 1

- 230000007423 decrease Effects 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D41/00—Application of procedures in order to alter the diameter of tube ends

- B21D41/02—Enlarging

Definitions

- the invention concerns a process and an apparatus for the production of light alloy tubing according to the preambles of claims 1 and 3, as for example known from GB-A- 2007134.

- Said apparatus comprises a mandrel (1) which is rotated by the motor (6) and a pressing roller (2) whose rotating motion is idling and which begins to rotate when between it and the mandrel (1) there is placed the tube to be processed (12) and the mandrel (1) begins to rotate.

- the tube decreases in thickness and increases in diameter and length and there can be produced tubing having a diameter from 300mm to 1000mm starting from tubing having a diameter from 100mm to 400mm.

- the apparatus consists basically of a mandrel (1) and a pressing roller (2).

- the mandrel (1) is mounted on ball bearings and rotated by a pair of gears (4) integral with the pulley shaft (5) which is integral in turn with the motor (6) through a clutch.

- the pressing roller (2) is mounted on large ball bearings and its motion is idling. It begins to rotate when it rests on the tube (12) to be processed and said tube rests in turn on the rotating mandrel.

- the thrust of the pressing roller (2) against the tube (12) is exerted by rotating the pair of gears (7).

- the pressing roller (2) is mounted on a misaligned axle and hence the rotation results in approach to and in withdrawal from the roller of the tube to be processed.

- This arrangement makes it possible to secure high thrust on the roller with low torques at the shaft thereof.

- a lever system (10) with its fulcrum (11) on the supporting structure and driven by the cylinder (3) makes the pressing roller unit (2) more rigid and eliminates bending almost entirely.

- the process for production of tubing in accordance with the present invention is accomplished by means of the following operations.

- the cylinder (3) holds the lever (10) in an oblique position as shown in FIG. 4 in broken lines while in the mandrel (1) is introduced the tube (12) to be processed.

- the lever (10) is thrust by the cylinder (3) and moves to a vertical position engaging the terminal part of the shaft of the pressing roller (2).

- the mandrel (1) is made to begin rotating and the shaft (14) of the pressing roller (2) is also made to begin operating and the misaligned rotation thereof permits approach of the pressing roller to the internal wall of the mandrel.

- tubing with a diameter from 100mm to 400mm and thickness from 5mm to 40mm can be processed to produce tubing having a diameter from 300mm to 1000mm and thickness from 1mm to 20mm.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Metal Extraction Processes (AREA)

- Forging (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Heat Treatment Of Articles (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

Abstract

Description

- The invention concerns a process and an apparatus for the production of light alloy tubing according to the preambles of

claims - Light alloy tubing of average outside diameter up to 250mm and thickness of 10-15mm is normally manufactured on extruding press. However the case where tubing of larger diameter up to 1000mm is needed is not rare.

- Plants for manufacture of this tubing, always based on the extruding press, are few because too costly for limited production. In addition this tubing is often used at a considerable distance from the factories so that transportation costs are very high.

- This situation makes necessary the installation of plants based on new processes which permit economical installations and production in any geographical area requiring larger diameter light alloy tubing.

- Processes for the production of aluminium alloy rings are disclosed for example in GB-A- 2007134, GB-A-2025818 and DE-A-3237295 but none of the known documents teaches a process for the production of tubes of larger diameter by simply compressing a tube of smaller diameter by a pressing roller.

- We have now found a new process and new apparatus which permit to overcome the problems of the known art.

- Said apparatus comprises a mandrel (1) which is rotated by the motor (6) and a pressing roller (2) whose rotating motion is idling and which begins to rotate when between it and the mandrel (1) there is placed the tube to be processed (12) and the mandrel (1) begins to rotate.

- Said process is performed by the following steps:-

- a) a light alloy tube (12) of average diameter is introduced in said mandrel (1),

- b) the mandrel (1) begins to rotate, and

- c) the tube (12) is compressed by the pressing roller (2) against the inner wall of the mandrel (1).

- By this process the tube decreases in thickness and increases in diameter and length and there can be produced tubing having a diameter from 300mm to 1000mm starting from tubing having a diameter from 100mm to 400mm.

- The characteristics and advantages of the process and apparatus for production of light alloy tubing of increased diameter starting from tubing of smaller diameter in accordance with the present invention are more fully explained in the following detailed description of an embodiment of the invention.

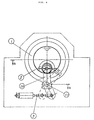

- The equipment is illustrated in FIGS. 1, 2, 3 and 4.

- FIG. 1 shows the mandrel, the pressing roller and the tube in its initial state,

- FIG. 2 shows the mandrel, the pressing roller and the tube in the final stage,

- FIG. 3 shows the complete plant, and

- FIG. 4 shows the apparatus with the supporting structure.

- With reference to the reference numbers of the various figures the apparatus consists basically of a mandrel (1) and a pressing roller (2).

- The mandrel (1) is mounted on ball bearings and rotated by a pair of gears (4) integral with the pulley shaft (5) which is integral in turn with the motor (6) through a clutch.

- The pressing roller (2) is mounted on large ball bearings and its motion is idling. It begins to rotate when it rests on the tube (12) to be processed and said tube rests in turn on the rotating mandrel.

- The thrust of the pressing roller (2) against the tube (12) is exerted by rotating the pair of gears (7).

- The pressing roller (2) is mounted on a misaligned axle and hence the rotation results in approach to and in withdrawal from the roller of the tube to be processed.

- This arrangement makes it possible to secure high thrust on the roller with low torques at the shaft thereof.

- Engagement and disengagement of the pressing roller (2) is provided by friction.

- A lever system (10) with its fulcrum (11) on the supporting structure and driven by the cylinder (3) makes the pressing roller unit (2) more rigid and eliminates bending almost entirely.

- The process for production of tubing in accordance with the present invention is accomplished by means of the following operations.

- The cylinder (3) holds the lever (10) in an oblique position as shown in FIG. 4 in broken lines while in the mandrel (1) is introduced the tube (12) to be processed.

- After introduction of the tube (12) the lever (10) is thrust by the cylinder (3) and moves to a vertical position engaging the terminal part of the shaft of the pressing roller (2). At this point the mandrel (1) is made to begin rotating and the shaft (14) of the pressing roller (2) is also made to begin operating and the misaligned rotation thereof permits approach of the pressing roller to the internal wall of the mandrel.

- The thrust on the tube placed between the pressing roller (2) and the mandrel (1) results in decrease of the thickness of the tube and increase of its diameter and, even if moderately, its length. After rotation through 360 degrees of the shaft (14) of the pressing roller there is obtained the tube (13) of increased diameter.

- At this point the clutch (8) is disengaged and rotation of the mandrel (1) is also stopped with disengagement of the clutch (5). When the mandrel (1) is completely stopped the cylinder (3) brings the lever (10) to the oblique position allowing extraction of the tube (13) with increased diameter.

- By the described process tubing with a diameter from 100mm to 400mm and thickness from 5mm to 40mm can be processed to produce tubing having a diameter from 300mm to 1000mm and thickness from 1mm to 20mm.

Claims (4)

- Process for the production of light alloy tubing wherein:a) a light alloy tube (12) is introduced in a mandrel (1),b) the mandrel (1) is rotated, andc) the tube (12) is compressed by the pressing roller (2) against the inner wall of the mandrel (1), characterized in that from a tube (12) having a diameter from 100mm to 400mm and thickness from 5mm to 40mm, a tube (13) is obtained having diameter from 300mm to 1000mm and thickness from 1mm to 20mm.

- Process in accordance with claim 1, characterized in that the tube (13) with increased diameter and decreased thickness is produced after a 360-degree rotation of the shaft (14) of the pressing roller (2).

- Apparatus for the production of light alloy tubing of increased diameter starting from tubing of smaller diameter comprising a mandrel (1) which is rotated by the motor (6) and a pressing roller (2) whose rotating motion is idling and begins to rotate when between it and the mandrel (1) there is placed the tube (12) to be processed and the mandrel (1) begins to rotate, characterized in that a lever system (10) with its fulcrum (11) on the support structure stiffens the pressing roller (2).

- Apparatus in accordance with claim 3, characterized in that said pressing roller (2) is mounted on a misaligned axle.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT02238689A IT1236712B (en) | 1989-11-15 | 1989-11-15 | PROCESS AND EQUIPMENT FOR THE PRODUCTION OF LIGHT ALLOY DIAMETER ALLOY TUBES STARTING FROM LOWER DIAMETER TUBES. |

| IT2238689 | 1989-11-15 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0432485A2 EP0432485A2 (en) | 1991-06-19 |

| EP0432485A3 EP0432485A3 (en) | 1991-07-03 |

| EP0432485B1 true EP0432485B1 (en) | 1994-06-22 |

Family

ID=11195577

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90121705A Expired - Lifetime EP0432485B1 (en) | 1989-11-15 | 1990-11-13 | Process and apparatus for the production of light alloy tubing of larger diameter starting from tubing of smaller diameter |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0432485B1 (en) |

| AT (1) | ATE107550T1 (en) |

| DE (1) | DE69010163T2 (en) |

| DK (1) | DK0432485T3 (en) |

| ES (1) | ES2055851T3 (en) |

| IT (1) | IT1236712B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8777277B2 (en) | 2010-12-02 | 2014-07-15 | Victaulic Company | Pipe element having shoulder, groove and bead and methods and apparatus for manufacture thereof |

| US9038428B2 (en) | 2011-09-02 | 2015-05-26 | Victaulic Company | Spin forming method |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3464253A (en) * | 1967-06-29 | 1969-09-02 | United States Pipe Foundry | Method for rounding pipe |

| FR2195491B1 (en) * | 1972-08-09 | 1975-03-07 | Roulements Soc Nouvelle | |

| GB2007134B (en) * | 1977-11-04 | 1982-03-10 | Honda Motor Co Ltd | Apparatus for roll-forming seamless annular products |

| GB2025818B (en) * | 1978-07-19 | 1982-06-09 | Doncaster & Sons Ltd D | Method of producing rings from aluminium-based alloys |

| DE3237295A1 (en) * | 1982-10-08 | 1984-04-12 | Stahlwerke Plate GmbH & Co KG, 5880 Lüdenscheid | Ring rolling mill |

| DE3717423A1 (en) * | 1987-04-07 | 1988-10-27 | Ragettli Christian Ag | METHOD FOR PROFILE FORMING WORKPIECES DESIGNED AS ROLLER BODIES AND DEVICE FOR EXERCISING THE METHOD |

-

1989

- 1989-11-15 IT IT02238689A patent/IT1236712B/en active IP Right Grant

-

1990

- 1990-11-13 AT AT90121705T patent/ATE107550T1/en not_active IP Right Cessation

- 1990-11-13 DE DE69010163T patent/DE69010163T2/en not_active Expired - Fee Related

- 1990-11-13 EP EP90121705A patent/EP0432485B1/en not_active Expired - Lifetime

- 1990-11-13 ES ES90121705T patent/ES2055851T3/en not_active Expired - Lifetime

- 1990-11-13 DK DK90121705.9T patent/DK0432485T3/en active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8777277B2 (en) | 2010-12-02 | 2014-07-15 | Victaulic Company | Pipe element having shoulder, groove and bead and methods and apparatus for manufacture thereof |

| US10161547B2 (en) | 2010-12-02 | 2018-12-25 | Victaulic Company | Device and method for forming pipe elements |

| US9038428B2 (en) | 2011-09-02 | 2015-05-26 | Victaulic Company | Spin forming method |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0432485A2 (en) | 1991-06-19 |

| DE69010163T2 (en) | 1994-10-06 |

| ES2055851T3 (en) | 1994-09-01 |

| DK0432485T3 (en) | 1994-07-25 |

| IT8922386A1 (en) | 1991-05-15 |

| IT1236712B (en) | 1993-03-26 |

| DE69010163D1 (en) | 1994-07-28 |

| EP0432485A3 (en) | 1991-07-03 |

| IT8922386A0 (en) | 1989-11-15 |

| ATE107550T1 (en) | 1994-07-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1538102A (en) | Method for producing joint between corrugated tube and coupling | |

| CN101642789B (en) | A method of forming a boss in a plate and plate with boss bearing periodic fatigue load in use | |

| US20090049880A1 (en) | Rolling tool with integrated drawing stage | |

| EP0432485B1 (en) | Process and apparatus for the production of light alloy tubing of larger diameter starting from tubing of smaller diameter | |

| CN1638887A (en) | Annulus gear and drive shell | |

| US5904060A (en) | Sheet metal member having a peripheral wall and method of thickening the peripheral wall thereof | |

| CN217251871U (en) | A indent equipment for plastic-coated pipe | |

| CN112983943A (en) | Low-temperature-resistant stainless steel flange and punching processing die thereof | |

| US5357776A (en) | Method of forming bushing rings | |

| CA2119344C (en) | Tube bending apparatus and method | |

| RU2152838C1 (en) | Method for making tubes with helical corrugations | |

| CN212397881U (en) | Pipe fitting flaring mechanism | |

| US20010052184A1 (en) | Multi-stage pulley and production method thereof | |

| CN214866457U (en) | Brass cage locking device | |

| JP2887585B2 (en) | Method of forming inner flange portion of sheet metal member having cylindrical portion | |

| JPS63295034A (en) | Manufacture of polyvinyl pulley wherein rim and disk are coupled and polyvinyl pulley manufactured by that method | |

| SU867468A1 (en) | Method of producing flat flanges on tubes | |

| JPS5636320A (en) | Manufacture of steel pipe with polygonal section | |

| CN217252520U (en) | Bearing ring forges forming die | |

| CN216399487U (en) | Frock is dismantled to tapered roller bearing outer lane | |

| US5931042A (en) | Method of forming a key portion of a sheet metal member having a cylindrical portion | |

| CN221620413U (en) | Rolling die of welding pipe forming sizing mill | |

| CN213915820U (en) | Waste material stirring device of aluminum shell stamping equipment | |

| CN219262699U (en) | Machine seal positioning device for multistage pump | |

| CN1198691A (en) | Method of molding cylindrical portion of central bore-carrying sheet metal |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19920111 |

|

| 17Q | First examination report despatched |

Effective date: 19930402 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 107550 Country of ref document: AT Date of ref document: 19940715 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REF | Corresponds to: |

Ref document number: 69010163 Country of ref document: DE Date of ref document: 19940728 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2055851 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19941001 Year of fee payment: 5 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19941021 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19941116 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 19941129 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19941130 Year of fee payment: 5 Ref country code: GR Payment date: 19941130 Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3013213 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19950110 Year of fee payment: 5 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 90121705.9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19950223 Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950504 Year of fee payment: 5 |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19951113 Ref country code: GB Effective date: 19951113 Ref country code: DK Effective date: 19951113 Ref country code: AT Effective date: 19951113 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19951114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19951130 Ref country code: CH Effective date: 19951130 Ref country code: BE Effective date: 19951130 |

|

| BERE | Be: lapsed |

Owner name: VIS S.R.L. Effective date: 19951130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19960531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19960601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19951113 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: MM2A Free format text: 3013213 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19960601 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 90121705.9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19961104 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19961125 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19970110 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19971130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980801 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19981212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051113 |