EP0361643A1 - Multi-stage selector valve - Google Patents

Multi-stage selector valve Download PDFInfo

- Publication number

- EP0361643A1 EP0361643A1 EP89305711A EP89305711A EP0361643A1 EP 0361643 A1 EP0361643 A1 EP 0361643A1 EP 89305711 A EP89305711 A EP 89305711A EP 89305711 A EP89305711 A EP 89305711A EP 0361643 A1 EP0361643 A1 EP 0361643A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ports

- port

- cylinder ports

- selector valve

- pump port

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B13/00—Details of servomotor systems ; Valves for servomotor systems

- F15B13/02—Fluid distribution or supply devices characterised by their adaptation to the control of servomotors

- F15B13/06—Fluid distribution or supply devices characterised by their adaptation to the control of servomotors for use with two or more servomotors

Definitions

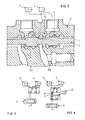

- a multi-stage selector valve as shown in Fig. 2, comprises a housing 2 having a pump port P formed in the middle of a spool receiving hole 1, two sets of cylinder ports D, A and C, B on opposite sides of said pump port P, and tank ports T1 and T2 at opposite ends of said hole communicating with each other through a bypass circuit T3, all ports being disposed at equal intervals, and a spool 5 switchably slidably inserted in said spool receiving hole 1 in said housing 2 so that it is movable between right and left positions, said spool having control sections 5a and 5b, whereby in one position (left-hand side position) the cylinder ports D and C on the one hand are blocked while the cylinder ports A and B on the other hand are allowed to communicate with the pump port P and tank port T1 to thereby drive one hydraulic cylinder 3 and in the other position (right-hand side position) the cylinder ports A and B on the other hand are blocked while the cylinder ports D and C on the one hand are allowed to communicate with

- the arrangement of the selector valve described above is as shown in Fig. 3 using hydraulic circuit symbols.

- the switching action of this selector valve makes it possible to alternately activate the two hydraulic cylinders 3 and 4, the switching of the operating direction for the respective hydraulic valves being effected by a directional control valve S.

- the selector valve described above employs a directional control valve to activate two hydraulic cylinders 3 and 4; however, when the number of hydraulic valves 3 and 4 is increased to more than two, one selector valve must be added for each increase in the number. Thus, as shown in Fig. 4, pipe lines 6 and 7 for connecting the selector valves are needed. If, therefore, the number of hydraulic cylinders 3 and 4 is increased, the pipe lines for connecting the selector valves become complicated, resulting in problems including increased cost, wider space for installation, higher probability of the pipe lines 16 and 7 being damaged or broken, and increased tendency for oil to leak.

- the present invention has been proposed in view of the problems in the prior art described above, and its object is to provide a multi-stage selector valve which makes it possible to simplify pipe lines even if the number of hydraulic cylinders is increased.

- the present invention provides a multi-stage selector valve comprising a housing 2 in which ports are formed in a plurality of parallel rows each consisting of a pump port P formed in the middle of a spool receiving hole 1, two sets of cylinder ports D, A and C, B disposed on opposite sides of said pump port P, and tank ports T1 and T2 at opposite ends of said hole communicating with each other through a bypass circuit T3, wherein the cylinder ports D and C in one set in one of the two adjacent rows communicate with the tank port T2 and pump port P in the other row through communication passages 8 and 9, and a plurality of spools 5 independently switchably slidably inserted in said spool receiving holes 1 in said housing 2 and having control sections whereby in one switch position the cylinder ports A and B in one set communicates with the pump port P and tank port T1 while the cylinder ports D and C in the other set are blocked, and in the other switch position the cylinder ports A and B in said one set are blocked while the cylinder ports D and C

- the single housing 2 is formed with selector valve ports in a plurality of parallel rows, wherein the cylinder ports D and C in one set in one of the two adjacent rows communicate with the tank port T2 and pump port P in the other row through the communication passages 8 and 9; thus, the selector valves are connected inside the housing 2 by said communication passages 8 and 9, whereby the pipe lines can be simplified.

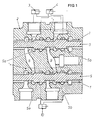

- Fig. 1 is a middle longitudinal sectional view of a two-stage selector valve showing an embodiment of the present invention.

- the numeral 1 denotes spool receiving holes; 2 denotes a housing; 3, 4 and 10 denote hydraulic cylinders; and 5 denotes spools.

- the spool receiving holes 1 are disposed in parallel, extending transversely through the housing 2.

- Each spool receiving port 1 is formed with a pump port P in the middle, two sets of cylinder ports D, A and C, B on opposite sides of the pump port, and tank ports T1 and T2 at opposite ends of the hole, all these ports being disposed at equal intervals, said tank ports T1 and T2 at opposite ends communicating with each other through a bypass circuit T3 formed in the housing 2.

- the cylinder ports in one set in one of the two adjacent rows communicate with the tank port T2 and pump port P in the other row through the communication passages 8 and 9 formed in the housing 2.

- the spools 5 are inserted in said spool receiving holes 1 in said housing 2 so that they are independently switchably slidable between two positions, each spool having control sections 5a and 5b whereby in one switch position the cylinder ports A and B in one set communicate with the pump port P and tank port T1 while the cylinder ports D and C in the other set are blocked, and in the other switch position the cylinder ports A and B in said one set are blocked while the cylinder ports D and C in the other set are allowed to communicate with the pump port P and tank port T2.

- the cylinder ports D, C and A, B connected to the hydraulic cylinders 3 and 4 can be formed in the same plane, opposed planes or planes orthogonal to each other in the housing 2. This also applies to the port arrangement on the other side (lower side).

- the ports D and C will be arranged to communicate with the pump port P and tank port T2 of the selector valve in the next row through the communication passages 8 and 9 in the housing 2, while the ports A and B will be formed in the plane of the front or back of the paper of Fig. 1.

- Multi-stage selector valves having more than three stages may be constructed by utilizing the arrangement described above.

- connections by pipe lines between selector valves can be omitted, providing advantages including simplification of pipe lines, prevention of damage and oil leakage, reduced cost, compact size and reduced installation space.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Multiple-Way Valves (AREA)

- Valve Housings (AREA)

Abstract

A single housing (2) is formed with selector valve ports (A, B, C, D, P, T₁, T₂) in a plurality of parallel rows each forming a selector valve, wherein the cylinder ports (D, C) in one set in one of the two adjacent rows communicate with the tank port (T₂) and pump port (P) in the other row through communication passages (8, 9); thus, the selector valves are connected inside the housing (2) by the communication passages (8, 9), whereby pipe lines (6, 7) can be simplified.

Description

- Generally, a multi-stage selector valve, as shown in Fig. 2, comprises a

housing 2 having a pump port P formed in the middle of a spool receiving hole 1, two sets of cylinder ports D, A and C, B on opposite sides of said pump port P, and tank ports T₁ and T₂ at opposite ends of said hole communicating with each other through a bypass circuit T₃, all ports being disposed at equal intervals, and aspool 5 switchably slidably inserted in said spool receiving hole 1 in saidhousing 2 so that it is movable between right and left positions, said spool havingcontrol sections hydraulic cylinder 3 and in the other position (right-hand side position) the cylinder ports A and B on the other hand are blocked while the cylinder ports D and C on the one hand are allowed to communicate with the pump port P and tank port T₂ to thereby drive the other hydraulic cylinder 4. - The arrangement of the selector valve described above is as shown in Fig. 3 using hydraulic circuit symbols. The switching action of this selector valve makes it possible to alternately activate the two

hydraulic cylinders 3 and 4, the switching of the operating direction for the respective hydraulic valves being effected by a directional control valve S. - The selector valve described above employs a directional control valve to activate two

hydraulic cylinders 3 and 4; however, when the number ofhydraulic valves 3 and 4 is increased to more than two, one selector valve must be added for each increase in the number. Thus, as shown in Fig. 4,pipe lines hydraulic cylinders 3 and 4 is increased, the pipe lines for connecting the selector valves become complicated, resulting in problems including increased cost, wider space for installation, higher probability of thepipe lines 16 and 7 being damaged or broken, and increased tendency for oil to leak. - The present invention has been proposed in view of the problems in the prior art described above, and its object is to provide a multi-stage selector valve which makes it possible to simplify pipe lines even if the number of hydraulic cylinders is increased.

- To achieve the above object, the present invention provides a multi-stage selector valve comprising a

housing 2 in which ports are formed in a plurality of parallel rows each consisting of a pump port P formed in the middle of a spool receiving hole 1, two sets of cylinder ports D, A and C, B disposed on opposite sides of said pump port P, and tank ports T₁ and T₂ at opposite ends of said hole communicating with each other through a bypass circuit T₃, wherein the cylinder ports D and C in one set in one of the two adjacent rows communicate with the tank port T₂ and pump port P in the other row throughcommunication passages 8 and 9, and a plurality ofspools 5 independently switchably slidably inserted in said spool receiving holes 1 in saidhousing 2 and having control sections whereby in one switch position the cylinder ports A and B in one set communicates with the pump port P and tank port T₁ while the cylinder ports D and C in the other set are blocked, and in the other switch position the cylinder ports A and B in said one set are blocked while the cylinder ports D and C in the other set are allowed to communicate with the pump port P and tank port T₂. - The

single housing 2 is formed with selector valve ports in a plurality of parallel rows, wherein the cylinder ports D and C in one set in one of the two adjacent rows communicate with the tank port T₂ and pump port P in the other row through thecommunication passages 8 and 9; thus, the selector valves are connected inside thehousing 2 by saidcommunication passages 8 and 9, whereby the pipe lines can be simplified. -

- Fig. 1 is a middle longitudinal sectional view of a two-stage selector valve showing an embodiment of the present invention;

- Fig. 2 is a middle longitudinal sectional view of a conventional selector valve;

- Fig. 3 is a hydraulic symbol circuit diagram of the selector valve of Fig. 2; and

- Fig. 4 is a hydraulic symbol circuit diagram for activating three hydraulic cylinders using a conventional selector valve.

- Fig. 1 is a middle longitudinal sectional view of a two-stage selector valve showing an embodiment of the present invention. The numeral 1 denotes spool receiving holes; 2 denotes a housing; 3, 4 and 10 denote hydraulic cylinders; and 5 denotes spools.

- The spool receiving holes 1 are disposed in parallel, extending transversely through the

housing 2. Each spool receiving port 1 is formed with a pump port P in the middle, two sets of cylinder ports D, A and C, B on opposite sides of the pump port, and tank ports T₁ and T₂ at opposite ends of the hole, all these ports being disposed at equal intervals, said tank ports T₁ and T₂ at opposite ends comunicating with each other through a bypass circuit T₃ formed in thehousing 2. - The cylinder ports in one set in one of the two adjacent rows communicate with the tank port T₂ and pump port P in the other row through the

communication passages 8 and 9 formed in thehousing 2. - The

spools 5 are inserted in said spool receiving holes 1 in saidhousing 2 so that they are independently switchably slidable between two positions, each spool havingcontrol sections - In the two-stage selector valve described above, on one side (upper side), the cylinder ports D, C and A, B connected to the

hydraulic cylinders 3 and 4 can be formed in the same plane, opposed planes or planes orthogonal to each other in thehousing 2. This also applies to the port arrangement on the other side (lower side). - In the case of a three-stage selector valve, of the two sets of cylinder ports D, C and A, B in the intermediate row, the ports D and C will be arranged to communicate with the pump port P and tank port T₂ of the selector valve in the next row through the

communication passages 8 and 9 in thehousing 2, while the ports A and B will be formed in the plane of the front or back of the paper of Fig. 1. - Multi-stage selector valves having more than three stages may be constructed by utilizing the arrangement described above.

- According to the present invention, even if the number of hydraulic cylinders is increased, connections by pipe lines between selector valves can be omitted, providing advantages including simplification of pipe lines, prevention of damage and oil leakage, reduced cost, compact size and reduced installation space.

Claims (1)

- A multi-stage selector valve comprising a housing (2) in which ports are formed in a plurality of parallel rows each consisting of a pump port (P) formed in the middle of a spool receiving hole (1), two sets of cylinder ports (D, A and C, B) disposed on opposite sides of said pump port (P), and tank ports (T₁, T₂) at the opposite ends of said hole communicating with each other through a bypass circuit (T₃), wherein the cylinder ports (D, C) in one set in one of the two adjacent rows communicate with the tank port (T₂) and pump port (P) in the other row through communication passages (8, 9), and a plurality of spools (5) independently switchably slidably inserted in said spool receiving holes (1) in said housing (2) and having control sections whereby in one switch position the cylinder ports (A, B) in one set communicate with the pump port (P) and tank port (T₁) while the cylinder ports (D, C) in the other set are blocked, and in the other switch position the cylinder ports (A, B) in said one set are blocked while the cylinder ports (D, C) in the other set are allowed to communicate with the pump port (P) and tank port (T₂).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP129376/88U | 1988-09-30 | ||

| JP1988129376U JPH0740780Y2 (en) | 1988-09-30 | 1988-09-30 | Multiple selector valve |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0361643A1 true EP0361643A1 (en) | 1990-04-04 |

Family

ID=15008052

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89305711A Withdrawn EP0361643A1 (en) | 1988-09-30 | 1989-06-07 | Multi-stage selector valve |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0361643A1 (en) |

| JP (1) | JPH0740780Y2 (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2362944A (en) * | 1942-06-30 | 1944-11-14 | Hydraulic Control Engineering | Control valve for hydraulic systems |

| US2710628A (en) * | 1954-10-11 | 1955-06-14 | New York Air Brake Co | Control valve with inherent circuit protection |

| US3162095A (en) * | 1962-03-26 | 1964-12-22 | New York Air Brake Co | Fluid distribution system |

| US3216443A (en) * | 1963-03-11 | 1965-11-09 | Parker Hannifin Corp | Multiple spool valve assembly |

| GB2107434A (en) * | 1981-08-06 | 1983-04-27 | Toshiba Machine Co Ltd | Multiple control valves |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS57157804A (en) * | 1981-03-25 | 1982-09-29 | Mazda Motor Corp | Multi-valve construction |

| JPS5821007A (en) * | 1981-07-29 | 1983-02-07 | Uchida Yuatsu Kiki Kogyo Kk | Multiple-type changeover valve device |

-

1988

- 1988-09-30 JP JP1988129376U patent/JPH0740780Y2/en not_active Expired - Lifetime

-

1989

- 1989-06-07 EP EP89305711A patent/EP0361643A1/en not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2362944A (en) * | 1942-06-30 | 1944-11-14 | Hydraulic Control Engineering | Control valve for hydraulic systems |

| US2710628A (en) * | 1954-10-11 | 1955-06-14 | New York Air Brake Co | Control valve with inherent circuit protection |

| US3162095A (en) * | 1962-03-26 | 1964-12-22 | New York Air Brake Co | Fluid distribution system |

| US3216443A (en) * | 1963-03-11 | 1965-11-09 | Parker Hannifin Corp | Multiple spool valve assembly |

| GB2107434A (en) * | 1981-08-06 | 1983-04-27 | Toshiba Machine Co Ltd | Multiple control valves |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0740780Y2 (en) | 1995-09-20 |

| JPH0250577U (en) | 1990-04-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0846872A1 (en) | Transfer valve manifold | |

| US6026730A (en) | Flow control apparatus in a hydraulic circuit | |

| US8464757B2 (en) | Hydraulic valve device | |

| KR960011218A (en) | Pilot Type Directional Valve | |

| US4924902A (en) | Hydraulic control valves | |

| US3765441A (en) | Fluid manifolding arrangement | |

| US5107753A (en) | Automatic pressure control device for hydraulic actuator driving circuit | |

| EP0361643A1 (en) | Multi-stage selector valve | |

| US3744518A (en) | Directional control valve | |

| US20230013888A1 (en) | Multi-control valve device | |

| GB2156050A (en) | Sectional valve having dual pressure relief | |

| CN116771741A (en) | Hydraulic system | |

| US3547139A (en) | Fluid logic pack | |

| US5040565A (en) | Pilot operated control valve system | |

| EP0070005B1 (en) | Hydraulic fluid circuit of hydraulic shovel | |

| US4167197A (en) | Directional change-over valve | |

| US5046400A (en) | Control valve system | |

| JPS58211001A (en) | Collected control valve | |

| US5471839A (en) | Valve apparatus and hydraulic drive system | |

| US5056415A (en) | Pilot operated control valve system performing a support function | |

| JP2000266002A (en) | Hydraulic controller | |

| JP2843656B2 (en) | Multiple hydraulic control valve | |

| EP0704631A1 (en) | Mono-block control valve with side bypass passage | |

| US3635244A (en) | Valve for distributing fluid to a system of fluid-actuated machines | |

| US4114513A (en) | Step-by-step controlled servomechanism |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19900516 |

|

| 17Q | First examination report despatched |

Effective date: 19910524 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19911004 |