EP0342484A2 - Very noiseless motor driven centrifugal fan - Google Patents

Very noiseless motor driven centrifugal fan Download PDFInfo

- Publication number

- EP0342484A2 EP0342484A2 EP89108330A EP89108330A EP0342484A2 EP 0342484 A2 EP0342484 A2 EP 0342484A2 EP 89108330 A EP89108330 A EP 89108330A EP 89108330 A EP89108330 A EP 89108330A EP 0342484 A2 EP0342484 A2 EP 0342484A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- volute

- motor driven

- centrifugal fan

- driven centrifugal

- roughness

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/66—Combating cavitation, whirls, noise, vibration or the like; Balancing

- F04D29/661—Combating cavitation, whirls, noise, vibration or the like; Balancing especially adapted for elastic fluid pumps

- F04D29/667—Combating cavitation, whirls, noise, vibration or the like; Balancing especially adapted for elastic fluid pumps by influencing the flow pattern, e.g. suppression of turbulence

Definitions

- the present invention generally relates to centrifugal fans and more particularly to a motor driven centrifugal fan having high noiselessness features.

- the inner surface of the volute sidewalls are roughened.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

The motor driven centrifugal fan (10) according to the present invention has the inner surface (18) of the volute (12) and possibly also the inner surfaces of the sidewalls (13) laterally defining the volute which are roughened.

The roughness can comprise projections or recesses of irregular shape, for example of orange-peel type, or of regular shape, for example regular polygons or circles which can be arranged along parallel lines which are or not offset from each other.

Description

- The present invention generally relates to centrifugal fans and more particularly to a motor driven centrifugal fan having high noiselessness features.

- As known, the motor driven centrifugal fans are intended to artificially generate the movement of a fluid. The centrifugal fans are a class of fans in which the fluid is sucked parallel to the rotation axis of the fan wheel and is ejected from a conduit the axis of which is perpendicular to the first one. The fan wheel rotates in an envelope provided with a spiral conduit or volute which collects the fluid forced towards the periphery by the centrifugal force and conveys it towards the outlet.

- The envelope generally consists of a metal sheet with smooth surfaces in order to reduce the friction that the moved fluid experiences against the sheet surface and the fan is provided with an eletric motor to the drive shaft of which the fan wheel is coupled.

- One of the features required to the fans of this type is the noiseless and this particularly when they are to be applied to air conditioning apparatus intended to be located in dwelling house rooms. In fact, these fans trasmit their noise to these rooms, so that the air conditioning apparatus installation is somewhat jeopardized, especially if the fans must operate also by night when this noise, not being masked by other stronger noises which occur by day, is sensed in a greater manner.

- The present invention aims at providing a motor driven centrifugal fan having such a noiselessness as to be able to be employed also in these applications.

- It is known that in various aerodynamical phenomena the presence of turbulent rather than laminar boundary layers can allow the separation of the fluid flow from the surface of the body licked by the fluid to be substantially delayed.

- Although the tangential stresses at the wall under the same conditions are greater in a turbulent boundary layer then in a laminar boundary layer, a strong reduction of the aerodynamical resistance of the body can be however obtained due to the reduction of the extension of the separated fluid regions and of the wakes.

- It is upon this observation that the golf balls are manufactured with a rough outer surface and that in aerodynamical tests carried out in the wind tunnel strips of rough material are applied on the ball models which artificially cause the transition of the boundary layer from laminar to turbulent flow.

- The present invention starts from this observation for providing a motor driven centrifugal fan of new design which permits the noiseness bonded to the rotation movement of the motor and to the resistance of the air forced against the inner surface of the volute to be considerably reduced.

- According to the invention the motor driven centrifugal fan is characterized in that its volute has an inner surface which is roughened.

- According to a feature of the present invention the roughness of the inner surface of the volute comprises projections or recesses of irregular shape, for example of the orange-peel shape.

- According to another feature of the present invention, the roughness of the inner surface of the volute comprises projections or recesses of regular shape.

- According to still another feature of the present invention, the projections or recesses forming the roughness of the inner surface of the volute are in the shape of regular polygons arranged along parallel lines which are or not offset from each other.

- According to a further feature of the present invention the projections or recesses forming the roughness of the inner surface of the volute are in the shape of circles arranged along parallel lines which are or not offset from each other.

- According to a still further feature of the present invention also the inner surface of the volute sidewalls are roughened.

- The present invention will be now described in connection to two preferred embodiments thereof, given only by way of example and therefore non limitative, illustrated in the accompanying drawings, wherein:

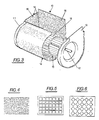

- Fig. 1 is a broken-away perspective view of the spiral conduit or volute of a motor driven centrifugal fan of the prior art;

- Fig. 2 is a broken-away perspective view of the spiral conduit or volute of the motor driven centrifugal fan according to the present invention;

- Fig. 3 is a broken-away perspective view of a modified embodiment of the volute of the motor driven centrifugal fan of Fig. 2;

- Fig. 4 is a partial plan view, in an enlarged scale, of a first shape of the roughness provided on the inner surface of the volute;

- Fig. 5 is a partial plan view, in an enlarged scale, of a second shape of the roughness provided on the inner surface of the volute; and

- Fig. 6 is a partial plan view, in an enlarged scale, of a third shape of the roughness provided on the inner surface of the volute.

- Referring now to the drawings and more particularly to Fig. 1, there is shown a motor driven centrifugal fan of the prior art, generally designated with 10.

- It comprises an

envelope 11 presenting a spiral conduit orvolute 12 and a pair ofsidewalls 13. Thisconduit 12 collects the fluid forced towards the periphery under the action of the centrifugal force and conveys it towards theoutlet 14. Theenvelope 11 is generally produced from a smooth sheet in order to reduce the resistance that the moving fluid encounters against the inner surface of the volute and the fan is provided with afan wheel 15 comprising ablade row 16. This fan wheel is provided with ashaft 17 to which the driving electric motor (not shown) is coupled. - The sucked air axially enters an opening provided in one of the

sidewalls 13 and flows out from theoutlet 14 being guided by thevolute 12. - In Fig. 2 there is shown the centrifugal fan according to the present invention. It differs from that illustrated in Fig. 1 only in that the

inner surface 18 of thevolute 12 is roughened. This roughness allows turbulent boundary layers to be created. - For centrifugal fans of small dimensions operating to a low RPM (300-1000 RPM, to which relatively low values of the Reynold's number 10³+10⁵ correspond) this roughness allows the aerodynamic performances to be substantially improved. This is due to the reduction of the cross sectional areas which are taken up by the boundary layer and the separated regions, mainly at the corners between the flat sidewalls and the curved surface of the volute.

- Because of the increase of the fluid flow section and the absence of recirculation regions, there is a decrease of the revolving speed and therefore a reduction of the acoustical emissions under the same flow rates.

- If a constant absorbed power is considered, there is a performance increase in terms of flow rate, head and noiseness.

- It should be understood that, in the case of the specific application in which it is necessary to assure a nominal flow rate, a further reduction of the noiseness can be obtained and this because of the possibility of reducing the revolving speed.

- In Fig. 3 there is shown a modification of the centrifugal fan of Fig. 2, in which also the

inner surface 19 of thesidewalls 13 are roughened similarly to theinner surface 18 of thevolute 12 having the orange-peel roughness. - Fig. 4 is a plan view, in an enlarged scale, showing the roughness of orange-peel type provided on the

inner surfaces volute 12 and thesidewalls 13 of the centrifugal fan illustrated in Fig. 3. - Fig. 5 is a plan view, in an enlarged scale, showing another type of roughness comprising a plurality of projections or recesses of squared shape regularly arranged on parallel lines offset from each other.

- Fig. 6 is a plan view, in an enlarged scale, showing still another type of roughness comprising a plurality of projections or recesses of squared shape, the squares being rotated by 90° with respect to those of Fig. 5.

- Tests of noiseness of centrifugal fans according to the invention, as applied in air conditioning apparatus of so called "fancoil" type have been conducted and the registered data are shown in the following tables, taking into account that the data included therein refer to the rated revolving speed of the fan wheel.

- Three similar fancoils provided with the same type of electric motor have been employed.

- In the first fancoil the volute is of the standard or prior art type, as illustrated in Fig. 1.

- In the second fancoil the inner surface of the volute has an irregular roughness of the orange-peel type, as shown in Fig. 2, in Fig. 3 and in Fig.4.

- In the third fancoil the inner surface of the volute has regular roughness, as that shown in Fig. 5.

- The noiseness tests have been carried out in a reverbering chamber and the test conditions were the following:

- 1) The insulation from the outer noises was sufficient and permitted constant background noise values during the tests to be obtained.

- 2) The fancoils were rested to a wall to simulate the real operation and the acoustical pressure detecting probe was arranged 1 meter in distance and 1 meter in heigth.

- 3) All the tests have been carried out at the rated RPM by employing a variac to this purpose.

- From the foregoing it is readily apparent that the motor driven centrifugal fan according to the present invention has a higher noiselessness than that of a conventional motor driven centrifugal fan, the volute of which has smooth inner surfaces.

- Table I shows that the noise ranges from 35,5 dB with the smooth surface volute, to 33 dB with the volute having the roughened inner surfaces of Fig. 4 and to 31,7 dB with he volute having the roughened inner surfaces of Fig. 5 at 480 RPM.

- Table II shows that the noise ranges from 39,5 dB with the smooth surface volute to 40 dB with the volute having the roughened inner surfaces of Fig. 4 and to 39 dB with the volute having the roughened inner surfaces of Fig. 5 at 610 RPM.

- Table III shows that the noise ranges from 49 dB with the smooth surface volute to 48,5 dB with the volute having the roughened inner surfaces of Fig. 4 and to 47,8 dB with the volute having the roughened inner surfaces of Fig. 5 at 820 RPM.

- Table IV shows that the noise ranges from 54,5 dB with the smooth surface volute to 54 dB with the volute having the roughened inner surfaces of Fig. 4 and to 53,5 dB with the volute having the roughened inner surfaces of Fig.5 at 1000 RPM.

- Therefore, the centrifugal fan according to the invention lends itself in a much favorable manner to be applied to the air conditioning plants and apparatus intended to be located in dwelling house rooms, for example the so called fancoils, particularly with low and mean RPM, whereas the phenomenum tends to desappear at higher RPM.

- Although the invention has been illustrated in connection with two preferred embodiments thereof only, it should be understood that it is not limited thereto, but that further modifications of roughness shapes of the inner surfaces of the volute of the motor driven centrifugal fans can be provided without departing from the scope of the invention.

| MINIMUM REVOLVING SPEED (480 RPM) | ||||

| frequency (Hz) | volute (standard) | volute (Fig.4) | volute (Fig.5) | Background noise |

| 63 | 43 | 42 | 37 | - |

| 125 | 40,5 | 37,5 | 36 | 26 |

| 250 | 38 | 37,5 | 37 | 23 |

| 500 | 35 | 34,5 | 31,5 | (13) |

| 1000 | 28 | 25 | 23 | (10,5) |

| 2000 | (18,5) | (16) | (14,5) | (10) |

| 4000 | (13) | (12,5) | (11) | (10) |

| 8000 | (11,5) | (11) | (10,5) | (10) |

| 16000 | (10) | (10) | (9) | (9,5) |

| dB(A) | 35,5 | 33 | 31,7 | 21 |

| MEAN REVOLVING SPEED (610 RPM) | |||

| freq.(Hz) | volute(standard) | volute(Fig.4) | volute(Fig.5) |

| 63 | 41 | 41 | 37,5 |

| 125 | 43 | 43,5 | 39 |

| 250 | 43 | 43,5 | 43 |

| 500 | 39,5 | 40,5 | 39,5 |

| 1000 | 32 | 32,5 | 31 |

| 2000 | 24,5 | 25 | 24 |

| 4000 | (16) | (16,5) | (15,5) |

| 8000 | (11) | (11,5) | (10,5) |

| 16000 | (9,5) | (10) | (9,5) |

| dB(A) | 39,5 | 40 | 39 |

| MAXIMUM REVOLVING SPEED (820 RPM) | |||

| freq.(Hz) | volute(standard) | volute(Fig.4) | volute(Fig.5) |

| 63 | 45 | 42 | 41 |

| 125 | 47 | 47 | 46,5 |

| 250 | 51,5 | 51,5 | 50 |

| 500 | 49,5 | 49 | 47,5 |

| 1000 | 42 | 42 | 41 |

| 2000 | 36,5 | 36,5 | 35,5 |

| 4000 | 28,5 | 29 | 28,5 |

| 8000 | (15,5) | (16,5) | (16) |

| 16000 | (10) | (10) | (10) |

| dB(A) | 49 | 48,5 | 47,8 |

| REVOLVING SPEED INCREASED TO 1000 RPM | |||

| freq.(Hz) | volute(standard) | volute(Fig.4) | volute(Fig.5) |

| 63 | 45 | 44 | 43 |

| 125 | 52,5 | 52 | 53 |

| 250 | 56,5 | 56,5 | 56 |

| 500 | 54,5 | 54 | 54 |

| 1000 | 48 | 47,5 | 47,5 |

| 2000 | 43 | 42,5 | 42 |

| 4000 | 37,5 | 37 | 36 |

| 8000 | 25,5 | 25 | 24,5 |

| 16000 | (13) | (12,5) | (13) |

| dB(A) | 54,5 | 54 | (53,5) |

Claims (7)

1) Motor driven centrifugal fan, particularly for use in air conditioning apparatus, characterized in that its volute has an inner surface which is roughened.

2) Motor driven centrifugal fan according to claim 1, characterized in that the roughness of the inner surfaces of the volute comprises projections or recesses of irregular shape, for example of the orange-peel type.

3) Motor driven centrifugal fan according to claim 1, characterized in that the roughness of the inner surface of the volute comprises projections or recesses of regular shape.

4) Motor driven centrifugal fan according to claim 3, characterized in that the projections or recesses forming the regular roughness are in the shape of regular polygons arranged along parallel lines which are or not offset from each other.

5) Motor driven centrifugal fan according to claim 3 or 4, characterized in that the projections or recesses of regular shape comprise squares or rectangles arranged along parallel lines offset or not from each other.

6) Motor driven centrifugal fan according to claim 3, characterized in that the projections or recesses forming the roughness are in the shape of circles arranged along parallel lines which are or not offset from each other.

7) Motor driven centrifugal fan according to claim 1, characterized in that also the inner surfaces of the volute sidewalls are similarly roughened.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT20595/88A IT1217607B (en) | 1988-05-16 | 1988-05-16 | CENTRIFUGAL MOTOR FAN PARTICULARLY SILENT |

| IT2059588 | 1988-05-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0342484A2 true EP0342484A2 (en) | 1989-11-23 |

| EP0342484A3 EP0342484A3 (en) | 1990-10-03 |

Family

ID=11169315

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19890108330 Withdrawn EP0342484A3 (en) | 1988-05-16 | 1989-05-09 | Very noiseless motor driven centrifugal fan |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0342484A3 (en) |

| IT (1) | IT1217607B (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1378668A1 (en) * | 2002-07-02 | 2004-01-07 | Comefri S.p.A. | Anti-noise and anti-vortex stabilizer |

| DE102008027845A1 (en) * | 2008-06-11 | 2009-12-17 | Behr Gmbh & Co. Kg | Motor vehicle air conditioning system has pipe or channel for guiding fluid, and wall, which comprises flow area, where upper surface of wall restricts flow area |

| US20150118054A1 (en) * | 2013-10-31 | 2015-04-30 | MAHLE BEHR GmbH & Co., KG | Radial blower |

| CN104675752A (en) * | 2015-03-16 | 2015-06-03 | 中国机械工业集团有限公司 | Centrifugal fan volute employing granular damping vibration attenuation |

| CN105115060A (en) * | 2015-09-29 | 2015-12-02 | 北京卫家环境技术有限公司 | Air purifier |

| WO2017041727A1 (en) * | 2015-09-11 | 2017-03-16 | 珠海格力电器股份有限公司 | Air conditioner, drum-shaped volute air duct system and air duct volute thereof |

| CN107940585A (en) * | 2017-12-26 | 2018-04-20 | 海信(广东)空调有限公司 | Air duct bottom plate structure, air duct device and air conditioner indoor unit |

| CN111089070A (en) * | 2019-08-14 | 2020-05-01 | 锐奇控股股份有限公司 | High wind speed air blower |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE600692C (en) * | ||||

| DE2203450A1 (en) * | 1972-01-26 | 1973-08-02 | Christ & Co O | FACILITY ON FAN AIR DUCTS |

| FR2347539A1 (en) * | 1976-04-05 | 1977-11-04 | Rolls Royce | ACOUSTIC COATING FOR TURBOREACTOR DUCTED BLOWER DUCT |

| FR2596108A1 (en) * | 1986-03-22 | 1987-09-25 | Usui Kokusai Sangyo Kk | BLADES FOR FAN PROPELLER |

-

1988

- 1988-05-16 IT IT20595/88A patent/IT1217607B/en active

-

1989

- 1989-05-09 EP EP19890108330 patent/EP0342484A3/en not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE600692C (en) * | ||||

| DE2203450A1 (en) * | 1972-01-26 | 1973-08-02 | Christ & Co O | FACILITY ON FAN AIR DUCTS |

| FR2347539A1 (en) * | 1976-04-05 | 1977-11-04 | Rolls Royce | ACOUSTIC COATING FOR TURBOREACTOR DUCTED BLOWER DUCT |

| FR2596108A1 (en) * | 1986-03-22 | 1987-09-25 | Usui Kokusai Sangyo Kk | BLADES FOR FAN PROPELLER |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1378668A1 (en) * | 2002-07-02 | 2004-01-07 | Comefri S.p.A. | Anti-noise and anti-vortex stabilizer |

| US6935835B2 (en) | 2002-07-02 | 2005-08-30 | Comefri S.P.A. | Anti-noise and anti-vortex stabilizer |

| CN100416110C (en) * | 2002-07-02 | 2008-09-03 | 科梅弗里股份公司 | Stabilizer for noise-proof and vortex-proof |

| DE102008027845A1 (en) * | 2008-06-11 | 2009-12-17 | Behr Gmbh & Co. Kg | Motor vehicle air conditioning system has pipe or channel for guiding fluid, and wall, which comprises flow area, where upper surface of wall restricts flow area |

| US20150118054A1 (en) * | 2013-10-31 | 2015-04-30 | MAHLE BEHR GmbH & Co., KG | Radial blower |

| CN104675752A (en) * | 2015-03-16 | 2015-06-03 | 中国机械工业集团有限公司 | Centrifugal fan volute employing granular damping vibration attenuation |

| WO2017041727A1 (en) * | 2015-09-11 | 2017-03-16 | 珠海格力电器股份有限公司 | Air conditioner, drum-shaped volute air duct system and air duct volute thereof |

| CN105115060A (en) * | 2015-09-29 | 2015-12-02 | 北京卫家环境技术有限公司 | Air purifier |

| CN107940585A (en) * | 2017-12-26 | 2018-04-20 | 海信(广东)空调有限公司 | Air duct bottom plate structure, air duct device and air conditioner indoor unit |

| CN111089070A (en) * | 2019-08-14 | 2020-05-01 | 锐奇控股股份有限公司 | High wind speed air blower |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0342484A3 (en) | 1990-10-03 |

| IT1217607B (en) | 1990-03-30 |

| IT8820595A0 (en) | 1988-05-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5709531A (en) | Centrifugal compressor and vaned diffuser | |

| EP1563191B1 (en) | A centrifugal fan impeller with blades inclined relative to the axis of rotation | |

| US7014423B2 (en) | High efficiency air conditioner condenser fan | |

| US4089618A (en) | Fan with noise reduction | |

| US7249931B2 (en) | High efficiency air conditioner condenser fan with performance enhancements | |

| EP0526387B1 (en) | Centrifugal compressor | |

| EP0789149A1 (en) | Design method for a multi-blade radial fan and multi-blade radial fan | |

| US4668160A (en) | Vacuum pump | |

| US7494325B2 (en) | Fan blade with ridges | |

| CA1172223A (en) | Compressor diffuser and method | |

| US6293753B1 (en) | Air moving apparatus and method of optimizing performance thereof | |

| CN211398054U (en) | Diffusion device, fan and dust catcher | |

| EP0342484A2 (en) | Very noiseless motor driven centrifugal fan | |

| US5707209A (en) | Centrifugal ventilator fan | |

| JP3366265B2 (en) | Centrifugal blower | |

| US20040018090A1 (en) | Rotor blade with a reduced tip | |

| JP3077863B2 (en) | Propeller fan and air conditioner equipped with the same | |

| CN216044508U (en) | Blade, impeller and centrifugal fan | |

| CN112377457B (en) | Impeller, centrifugal fan applying same and range hood | |

| CN212691898U (en) | Air duct assembly and range hood | |

| USRE33129E (en) | Vacuum pump | |

| JPS6090999A (en) | Axial flow fan free from guide blade | |

| US7914597B2 (en) | Dust collector | |

| US11536279B1 (en) | Thin type counter-rotating axial air moving device | |

| JPS62271995A (en) | Multi blade type impeller |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): BE DE ES FR |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE DE ES FR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19910404 |