EP0307364B1 - Interrupteur actionné mécaniquement - Google Patents

Interrupteur actionné mécaniquement Download PDFInfo

- Publication number

- EP0307364B1 EP0307364B1 EP19880830248 EP88830248A EP0307364B1 EP 0307364 B1 EP0307364 B1 EP 0307364B1 EP 19880830248 EP19880830248 EP 19880830248 EP 88830248 A EP88830248 A EP 88830248A EP 0307364 B1 EP0307364 B1 EP 0307364B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cam element

- movable contact

- key

- free end

- opening position

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H13/00—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch

- H01H13/50—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member

- H01H13/56—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member the contact returning to its original state upon the next application of operating force

- H01H13/60—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a single operating member the contact returning to its original state upon the next application of operating force with contact-driving member moved alternately in opposite directions

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H11/00—Apparatus or processes specially adapted for the manufacture of electric switches

- H01H11/0006—Apparatus or processes specially adapted for the manufacture of electric switches for converting electric switches

Definitions

- the present invention relates to a mechanically operated switch according to the preamble of claim 1.

- a switch is known from FR-A-2 565 730.

- the technical solutions provided by the present invention particularly lend themselves to be applied in the case in which it is necessary to provide switches or the like the operation keys of which have very restricted working strokes, in the range of 2 mm.

- switches and the like which have a merely mechanical operation and which comprise a housing accommodating the fixed contacts and at least a movable contact capable of oscillating from a closure position to an opening position respectively to close and break the electrical connection between the fixed contacts.

- the movable contact is formed with a metal element rotatably fitted in the housing and acted upon at least by a release spring which is disposed between the movable contact and an operation key oscillatably mounted in the housing.

- the release spring acts such as to cause the movable contact to trip from a closure position to an opening position and viceversa when the key is acted upon by the user.

- the operation key In all mechanically operated switches the operation key must always undergo rather important strokes in order to allow the movable contact to be brought from a closure position to an opening position and viceversa. So it is not possible to use mechanically operated switches in the cases in which the operation key must have very restricted working strokes, which often occurs due to technical and/or commercial requirements.

- the above specified requirements are presently met by the use of switches interlocked to electrically and/or electronically operated servo-controls which can be actuated upon command of pushbuttons having very restricted working strokes. By virtue of this particular feature servo-controlled switches can be operated by the slight touching of the respective control pushbuttons on the part of the user.

- a further drawback of the known art resides in that it is impossible to achieve several different operation characteristics from a single switch by merely replacing one of its components. On the contrary, in order to make a single switch perform different functions it is always necessary to replace the movable contacts as well as to add and/or to replace other components.

- a further object of the present invention is to provide a switch which is capable of performing different functions by merely replacing only one component thereof.

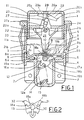

- a mechanically operated switch according to the invention has been globally identified by reference numeral 1.

- the switch 1 comprises a housing 2 substantially formed with a box-shaped portion 3 and a closure portion 4 fitted on the box-shaped portion 3.

- the box-shaped portion 3 is provided with hooking spring means 5 to allow the switch 1 to be fastened, in known manner, into a shaped opening formed in a supporting board not shown.

- At least a pair of fixed contacts 6 are fitted in the closure portion 4, each of said contacts facing the inside of the housing 2 and having an attachment portion 7 projecting past the housing.

- a movable contact 8 located in the housing 2 is at least a movable contact 8 contained with a slight side floating between the walls of the closure portion 4 and acting upon the fixed contacts 6 to selectively close and break the electrical connection between said fixed contacts.

- the movable contact 8 has an elongated plate-like configuration and terminates with one bent end 8a forming an arc of a circle and constantly abutting against one fixed contact 6a being part of the pair of fixed contacts 6.

- the movable contact 8 is provided with a free end 8b extending over the second fixed contact 6b.

- the movable contact 8 is submitted to the action of spring compression means tending to urge its ends 8a and 8b against the corresponding fixed contacts 6a and 6b.

- this spring means consists of a compression spring 9, partially shown, which has one end engaged with a boss 10 formed along the movable contact 8, and abuts against an operation key 11.

- the key 11 is slidably guided along the box-shaped portion 3 and projects therefrom on the side thereof opposite that facing the closure portion 4.

- Switch 1 further comprises trip means drivingly operated by the key 11 so that they cause the movable contact 8 to move from a closure position (not shown in the drawing) in which the fixed contacts 6 are electrically connected to each other, to an opening position (diagrammatically shown in phantom) in which the electrical connection between the fixed contacts is broken.

- said trip means comprises a cam element 12 rotatably engaged about one pivot 13 extending through the closure portion 4 at right angles to the longitudinal extension of the movable contact 8.

- the cam element 12 is provided with one projection 12a to which one end of a release spring 14 is fastened, the other end of the spring engaging with a second projection 15 provided on the bottom of the closure portion 4.

- the cam element 12 On its opposite sides the cam element 12 also has one abutment surface 16a and a second abutment surface 16b, each of them being designed to abut against a corresponding wall of the closure portion 4 to counteract the action exerted by the release spring 14 when the cam element 12 is held in a respective working position.

- a lifting arm 17 extending radially from the cam element 12 with respect to the pivoting axis of the cam element itself is at least a lifting arm 17 the free end 17a of which operates between the ends 8a and 8b of the movable contact 8 to bring the latter, against the action of the compression spring 9, from a closure position to an opening position when the cam element 12 is brought from a first to a second working positions, as more clearly seen in the following.

- the sliding surfaces 19a and 19b symmetrically converge towards each other so as to form a cusp 20 which is in alignment with the axis of the pivot 13 and the projection 12a.

- each locating seat 18a, 18b is spaced apart from the pivoting axis of the cam element 12 a distance smaller than the distance between the free end 17a of the lifting arm 17 and the pivoting axis itself.

- a global lowering of the thrust element 21 allows the free end 8b of the contact 8 to carry out a corresponding raising the amount of which is directly proportional to the ratio of the distance between the free end 17a of the lifting arm 17 and the pivoting axis of the cam element 12 to the distance between the locating seat 18a or 18b and the pivoting axis itself.

- the switch 1 further comprises a thrust element 21 provided with one fork-shaped end 21a rotatably engaged about a second pivot 22 fastened to the operation key 11 and extending parallelly to the first pivot 13. On its opposite side, the thrust element 21 has a free end 21b disposed in the vicinity of the cam element 12.

- the thrust element 21 can elastically oscillate about the second pivot 22 in opposition to elastic deformations consequently undergone by return arms 23 extending symmetrically from the thrust element and exhibiting respective free ends 23a which abut against a bottom wall 24 of the operation key 11.

- the key 11 is associated with an indicator element 25 adapted to reveal the operation state of the switch 1.

- the indicator element 25 comprises a block 26 supported by a swinging arm 27 rotatably pivoted to the key 11 according to an axis parallel to the second pivot 22.

- the free end 27a of the swinging arm 27 is interposed between the two half-portions of the fork-shaped end 21a.

- indicating surface 26a Formed on the block 26 and exactly on its side opposite that facing the swinging arm 27 is one indicating surface 26a and a second indicating surface 26b designed to alternately and selectively appear at a reading slot 28 formed in the upper part of the key 11.

- indications On each surface 26a and 26a there are indications concerning the operation state of the switch 1. Said indications may for example consist of a printed inscription, or the surfaces may be differently coloured.

- FIG 1 there is shown a condition of normal operation of switch 1, in which the cam element 12, by virtue of the release spring 14, is kept in the first working position corresponding to the first abutment surface 16a bearing against the wall of the closure portion 4.

- the lifting arm 17 extends parallelly below the movable contact 8 which is kept in a closed condition being acted upon by the compression spring 9, so that the closure of the electrical connection between the fixed contacts 6a and 6b is ensured.

- the operation key 11 is kept in a rest condition in which it projects to its greatest extent from the box-shaped portion 3 of housing 2.

- the orientation of the indicator element 25 is like that of the cam element 12 and the first indicating surface 26a thereof faces the slot 28.

- the thrust element 21 acted upon by the return arms 23, keeps such an orientation that it is in alignment with the centres of pivots 13 and 22.

- the key 11 is slightly moved towards the inside of the housing 1, being counteracted by the compression spring 9. So there is first the shifting of the thrust element 21 towards the cam element 12 as far as the free end 21b thereof comes in contact with the first sliding surface 19a.

- the free end 21b slides along the surface 19a so that the thrust element 21 is slightly rotated clockwise with reference to the figure, until said free end engages with the first locating seat 18a.

- the angular rotation carried out by the thrust element 21 causes the fork-shaped end 21a to act on the free end 27a of the swinging arm 27 such as to cause a variation in the orientation of the indicator element 25 and, as a result, the second indicating surface appears at the reading slot 28.

- the positioning of the indicator element 25 in its two working conditions as described above is maintained by virtue of a boss 29 provided sideways on the block 26 and adapted to engage in grooves 29a formed in an inner wall of the operation key 11, as diagrammatically shown in dotted line.

- the action of the release spring 14 causes a further angular rotation of the cam element 12 so that the latter is brought to the second working position in which the second surface 16b abuts against the corresponding inner wall of the closure portion 4.

- the lifting arm 17 causes the movable contact 8 to move from its closure position to its opening position, by raising the free end 8b thereof with respect to the second fixed contact 6b. So the electrical connection between the fixed contacts 6a and 6b is interrupted. Since the lifting arm 17 acts between the boss 10 and free end 8b, as shown in the figure, the action exerted by the compression spring 9 is capable of maintaining the end 8a against the fixed contact 6a even when the movable contact 8 is brought to the opening position.

- the cam element 12 is oriented in such a way that when a subsequent thrust action is exerted on the key 11, the free end 21b of the thrust element 21 comes in contact with the second sliding surface 19b.

- the thrust element 21 will be angularly rotated in a direction opposite the previous one so that the indicating surface 26a of the indicator element 25 will face again the reading slot 28.

- the cam element 12 will undergo an angular rotation in a direction opposite the previous one, which will involve the new arrangement of the movable contact 8 in a closure position by the action of the compression spring 9.

- the switch 1 is provided with only a pair of fixed contacts 6 and therefore with a single movable contact 8.

- the cam element 12 has only one lifting arm 17.

- a cam element designated by reference numeral 30 which is adapted to be used when the switch 1 is provided with two pairs of fixed contacts, a movable contact being associated with each of said pairs.

- the cam element 30 is equipped with a first lifting arm 31 and a second lifting arm 32 having a mutually offset orientation according to an angle equal to the angle of the rotation performed by the cam element on passing from the first to the second working positions and viceversa. Due to the arrangement of arms 31 and 32, when the key 11 is actuated one of the movable contacts will be disposed in an opening position and at the same time the other movable contact will be disposed in a closure position. In this manner the switch 1 can perform the function of a shunter.

- the two arms 31 and 32 can also be disposed in parallel relationship with respect to each other.

- the switch lends itself to carry out the simultaneous opening and closing of two distinct electrical circuits.

- the present invention attains the intended purposes.

- the switch of the invention exhibits several technical features by virtue of which the distance between the fixed contact 6b and the free end 8b of the movable contact 8 in an opening position (which must meet a minimum value as stated by the rules) is greater than the working stroke performed by the key 11 to bring the movable contact 8 to an opening position.

- the present invention allows the accomplishment of different operational characteristics from one and the same switch by merely replacing the cam element thereof.

- the cam element of figure 2 starting from a switch arranged to perform the functions of a shunter, it is possible to produce a switch adapted to carry out the simultaneous opening and closing of two electrical circuits by replacing the cam element of figure 2 with a cam element having parallel lifting arms.

Landscapes

- Push-Button Switches (AREA)

Claims (8)

- Interrupteur actionné mécaniquement, comprenant :- un boîtier (2);- au moins une paire de contacts fixes (6a, 6b) placés dans le boîtier (2);- au moins un contact mobile (8) placé dans le boîtier (2) et susceptible d'oscillation, contre l'action de moyens de compression élastiques (9), d'une position de fermeture à une position d'ouverture, respectivement pour fermer et ouvrir électriquement les contacts fixes (6a, 6b), l'un par rapport à l'autre;- des moyens de déclenchement commandés par une touche de commande (11) et agissant sur le contact mobile (8) pour le déplacer d'une position de fermeture à une position d'ouverture, lesdits moyens de déclenchement ayant;- un élément à came (12, 30) engagé à rotation dans le boîtier (2) et susceptible d'osciller d'une première position de travail à une deuxième position de travail;- au moins un bras de levage (17, 31, 32) s'étendant à partir de l'élément à came (12, 30) et agissant sur le contact mobile (8) pour le déplacer d'une position de fermeture à une position d'ouverture quand l'élément à came (12, 30) est amené de sa première position de travail à sa deuxième position de travail;- au moins un ressort de détente (14) agissant entre ledit boîtier (2) et l'élément à came (12, 30) pour retenir ce dernier à sa première position de travail et à sa deuxième position de travail;- et un élément de poussée (21) monté à pivotement sur la touche de commande (11) de manière qu'il peut osciller par rapport à cette dernière, et venant buter contre des sièges de référence (18a, 18b) présentés par l'élément à came (12, 30) pour causer la rotation de l'élément à came de sa première position de travail à sa deuxième position de travail et vice-versa, en fonction de l'actionnement de ladite touche (11) et en même temps que ledit ressort de détente (14) exerce son action, ledit élément de poussée agissant sur lesdits sièges de référence (18a, 18b) par son extrémité libre (21a),caractérisé en ce que ledit élément de poussée (21) oscille par rapport à ladite touche de commande (11) en opposition à des déformations élastiques subies par des bras de rappel (23) divergeant symétriquement de l'élément de poussée (21) et venant buter contre la paroi inférieure (24) de ladite touche (11) de sorte que ladite extrémité libre (21a), quand l'élément de poussée est au repos, est sensiblement en alignement avec les centres de rotation de l'élément de poussée (21) et de l'élément à came (12, 30).

- Interrupteur selon la revendication 1, caractérisé en ce que chacun desdits sièges de référence (18a, 18b) est écarté de l'axe d'articulation de l'élément à came (12, 30) d'une distance inférieure à la distance entre l'extrémité libre (17a) du bras de levage (17) et ledit axe d'articulation.

- Interrupteur selon la revendication 1, caractérisé en ce que ledit contact mobile (8) a une première extrémité (8a) agissant constamment contre un premier contact fixe (6a) et une extrémité libre (8b) qui est mobile par rapport à un deuxième contact fixe (8b) quand le contact mobile (8) est amené d'une position de fermeture à une position d'ouverture et vice-versa, ledit bras de levage (17, 31, 32) agissant entre ladite première extrémité (8a) et l'extrémité libre (8b).

- Interrupteur selon la revendication 1, caractérisé en ce que la course de travail de ladite touche de commande (11) est plus courte que la distance minimum entre le contact mobile (8) et au moins un (6a) des contacts fixes, quand le contact mobile (8) est dans une position d'ouverture.

- Interrupteur selon la revendication 1, caractérisé en ce que ledit élément à came (12) est pourvu d'un bras de levage (17) s'tendant radialement à l'axe d'articulation de l'élément à came et agissant sur ledit contact mobile (8) pour le déplacer d'une position de fermeture à une position d'ouverture.

- Interrupteur selon la revendication 1, caractérisé en ce que ledit élément à came (30) comporte un premier bras de levage (31) s'étendant radialement à l'axe d'articulation de l'élément à came pour porter un premier contact mobile d'une position de fermeture à une position d'ouverture, quand on cause la rotation de l'élément à came (30) de sa première position de travail à sa deuxième position de travail, et un deuxième bras de levage (31) s'étendant radialement à l'axe d'articulation dudit élément à came pour porter un deuxième contact mobile d'une position de fermeture à une position d'ouverture quand on cause la rotation de l'élément à came (30) de sa deuxième position de travail à sa première position de travail.

- Interrupteur selon la revendication 1, caractérisé en ce que ledit élément à came est pourvu d'une paire de bras de levage s'étendant radialement à l'axe d'articulation de l'élément à came et parallèles entre eux, pour déplacer le respectif contact mobile d'une position de fermeture à une position d'ouverture, à la suite de la rotation angulaire de l'élément à came de sa première à sa deuxième position de travail.

- Interrupteur selon la revendication 1, caractérisé en ce qu'un élément indicateur (25) est associé à ladite touche de commande (11), cet élément indicateur comprenant un bloc (26) pourvu d'une première et d'une deuxième surface d'indication (26a, 26b) disposées de manière qu'elles apparaissent alternativement et sélectivement en correspondance d'une fente de lecture (28) formée dans la touche, ledit bloc étant supporté rigidement par un bras oscillant (27) monté a pivotement sur la touche (11) suivant un axe parallèle à l'axe d'articulation dudit élément de poussée (21) et ayant une extrémité libre (27a) qui s'engage entre les deux moitiés (25a) d'un élément en forme de fourche présenté par l'élément de poussée.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT2228487U | 1987-09-09 | ||

| IT2228487U IT211825Z2 (it) | 1987-09-09 | 1987-09-09 | Interruttore ad azionamento automatico. |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0307364A2 EP0307364A2 (fr) | 1989-03-15 |

| EP0307364A3 EP0307364A3 (en) | 1990-09-05 |

| EP0307364B1 true EP0307364B1 (fr) | 1994-04-20 |

Family

ID=11194162

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19880830248 Expired - Lifetime EP0307364B1 (fr) | 1987-09-09 | 1988-05-31 | Interrupteur actionné mécaniquement |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0307364B1 (fr) |

| JP (1) | JPS6472432A (fr) |

| DE (1) | DE3889179D1 (fr) |

| IT (1) | IT211825Z2 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114521280A (zh) * | 2019-09-13 | 2022-05-20 | 比亚乔及C.股份公司 | 键开关 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITRM20050163A1 (it) * | 2005-04-07 | 2006-10-08 | Bticino Spa | Interruttore a pulsante. |

| ITRM20120544A1 (it) * | 2012-11-08 | 2014-05-09 | Bticino Spa | Interruttore a pulsante con morsetti di cablaggio rapido |

| EP3726551B1 (fr) * | 2019-04-15 | 2024-07-17 | Honeywell International Inc. | Ensemble interrupteur mural plat |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3133338A1 (de) * | 1981-08-22 | 1983-03-10 | Brown, Boveri & Cie Ag, 6800 Mannheim | Elektrischer installationsschalter |

| DE3247319A1 (de) * | 1982-12-21 | 1984-06-28 | Brown, Boveri & Cie Ag, 6800 Mannheim | Elektrischer drucktastenschalter mit einem schwenkbar gelagerten druckbuegel |

| DE3412027A1 (de) * | 1984-03-31 | 1985-10-10 | Preh, Elektrofeinmechanische Werke Jakob Preh Nachf. Gmbh & Co, 8740 Bad Neustadt | Druckknopfschalter |

| DE3421021A1 (de) * | 1984-06-06 | 1985-12-12 | Fa. Albrecht Jung, 5885 Schalksmühle | Stoessellagerung eines elektrischen tastschalters |

| IT1187602B (it) * | 1985-11-05 | 1987-12-23 | Bruno Martinetti | Interruttore universale a linguette contattori integrali |

| DE3604765C1 (de) * | 1986-02-14 | 1987-10-29 | Swf Auto Electric Gmbh | Elektrischer Schalter,insbesondere fuer Kraftfahrzeuge |

-

1987

- 1987-09-09 IT IT2228487U patent/IT211825Z2/it active

-

1988

- 1988-05-31 DE DE3889179T patent/DE3889179D1/de not_active Expired - Lifetime

- 1988-05-31 EP EP19880830248 patent/EP0307364B1/fr not_active Expired - Lifetime

- 1988-06-14 JP JP14490488A patent/JPS6472432A/ja active Pending

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114521280A (zh) * | 2019-09-13 | 2022-05-20 | 比亚乔及C.股份公司 | 键开关 |

| CN114521280B (zh) * | 2019-09-13 | 2024-03-12 | 比亚乔及C.股份公司 | 键开关 |

Also Published As

| Publication number | Publication date |

|---|---|

| IT211825Z2 (it) | 1989-05-25 |

| EP0307364A3 (en) | 1990-09-05 |

| EP0307364A2 (fr) | 1989-03-15 |

| DE3889179D1 (de) | 1994-05-26 |

| IT8722284V0 (it) | 1987-09-09 |

| JPS6472432A (en) | 1989-03-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4983788A (en) | Electric switch mechanism for relays and contactors | |

| US2669613A (en) | Cam switch | |

| US3510612A (en) | Mechanical interlock for electrical switches or the like | |

| CA1232631A (fr) | Coupe-circuit a glissiere de selection de mode de fonctionnement | |

| US2441614A (en) | Push button switch | |

| JPH07169370A (ja) | デテント付きスイッチアセンブリ | |

| EP0307364B1 (fr) | Interrupteur actionné mécaniquement | |

| US3794785A (en) | Switch actuating mechanism for turn indicator type switches | |

| US4276458A (en) | Switch arrangement with switch contacts which can be changed as desired to normally open or normally closed operation | |

| GB2308496A (en) | Electrical switch | |

| US3912895A (en) | Electric switch | |

| US3566058A (en) | Snap action switch with low force differential | |

| US7667153B2 (en) | Double-pole change-over switch | |

| US6005202A (en) | Switching device having an unlocking device | |

| US3767870A (en) | Multiple circuit control switch with spring biased slide operating means engaging pivoted contact assembly | |

| US3410971A (en) | Double throw, snap acting electric switch | |

| US2722135A (en) | Mechanical interlock | |

| US3371179A (en) | Electrical switch having a floating actuator which is detented into various circuit controlling positions by a leaf spring contact | |

| US3683144A (en) | Non-snap-acting switch devices with s-shaped contact spring blade | |

| US2399462A (en) | Electric switch | |

| US3838237A (en) | Light load type push button switch | |

| US4835348A (en) | Electrical switch device | |

| JPH09306270A (ja) | 電気スイッチ | |

| US3051810A (en) | Push button switch | |

| US3504144A (en) | Arrangement in safety switches for microwave stoves |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES FR GB |

|

| 17P | Request for examination filed |

Effective date: 19900927 |

|

| 17Q | First examination report despatched |

Effective date: 19930715 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19940420 Ref country code: DE Effective date: 19940420 |

|

| REF | Corresponds to: |

Ref document number: 3889179 Country of ref document: DE Date of ref document: 19940526 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940720 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940720 |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950510 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19970131 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |