EP0192621B1 - A seal device - Google Patents

A seal device Download PDFInfo

- Publication number

- EP0192621B1 EP0192621B1 EP86850033A EP86850033A EP0192621B1 EP 0192621 B1 EP0192621 B1 EP 0192621B1 EP 86850033 A EP86850033 A EP 86850033A EP 86850033 A EP86850033 A EP 86850033A EP 0192621 B1 EP0192621 B1 EP 0192621B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ring

- seal

- slot

- impeller

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007789 sealing Methods 0.000 claims description 7

- 230000000903 blocking effect Effects 0.000 claims 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 239000010802 sludge Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/08—Sealings

- F04D29/16—Sealings between pressure and suction sides

- F04D29/165—Sealings between pressure and suction sides especially adapted for liquid pumps

- F04D29/167—Sealings between pressure and suction sides especially adapted for liquid pumps of a centrifugal flow wheel

Definitions

- This invention concerns a seal device as claimed in claim 1 to prevent leakage between an impeller and a non-rotating part.

- the purpose of our invention is to replace the wear parts made of rubber by a more resistant material which extends the service intervals.

- At least one of the seal rings is attached by help of an O-ring.

- a mechanical seal is thus arranged between the impeller 1 and the housing 2 preventing medium that has passed through the impeller to flow back to the inlet.

- the mechanical seal which has an radial sealing surface, consists of a seal ring 3 attached to the impeller and another ring 4 attached to the housing.

- at least one of the rings 3 is attached by an O-ring.

- a slot 6 is made in the impeller, extending axially along a part of a mantle surface of the impeller. The slot has then such a configuration that it is deeper in the radial direction at some distance from the opening.

- a sealing is obtained which is very resistant to wear and in addition the 0-ring attachment means that the rings are easy to replace and problems due to the seal rings not being sufficiently plain are eliminated.

- a specific advantage occurs if the sealing surface has a radial direction. This means that the demands for tolerances decrease as a sufficient sealing is obtained, even if the rings are somewhat displaced relative each other. This quality is especially important if the pump contains several steps, that is to say several continuous impellers on the same shaft.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Mechanical Sealing (AREA)

Description

- This invention concerns a seal device as claimed in claim 1 to prevent leakage between an impeller and a non-rotating part.

- Pumps having a rotating impeller such as centrifugal pumps, take in the pumped medium atthe center of the impeller and leave it by the periphery. It is then important that the inlet of the impeller fits closely with the inlet of the housing and that pumped medium is prevented from flowing back to the inlet. Such a backflow creates efficiency losses and turbulence at the inlet.

- In order to obtain the requested sealing between impeller and non-rotating parts, it is common to arrange a wear part, for instance made of rubber, on the non-rotating part and let the impeller contact that part during rotation. In this way an effective sealing is obtained as long as the wear part is intact. When pumping liquids containing heavily wearing objects, such as sand and sludge cuttings in mines, the lifetime of the wear parts become very short which means short service intervals.

- According to US-A-1521226 subject problem has been solved by a device where parts may be adjusted to take up for wear. The adjustment is obtained by pressing an inclined surface of its seal ring towards a gasket.

- The purpose of our invention is to replace the wear parts made of rubber by a more resistant material which extends the service intervals.

- This is obtained by providing the impeller as well as the non-rotating part with seal rings made of hard metal or ceramics, which together form a mechanical seal which in an effective way prevents the pumped medium from flowing back to the inlet and which has a very good wear resistance.

- According to a preferred embodiment of the invention, at least one of the seal rings is attached by help of an O-ring. This means that the seal ring may be easily replaced and also eliminates problems due to the seal ring not being sufficiently plain. The latter may easily be the case if the ring is mounted in another way, for instance as a shrinkage fit; as the diameters in question are big.

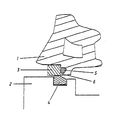

- The invention is described more closely below with reference to the enclosed drawing.

- In the drawing 1 stands for an impeller, 2 a part of a pump housing, 3 and 4 mechanical seal rings, 5 an 0-ring and 6 a slot for the latter.

- According to the invention a mechanical seal is thus arranged between the impeller 1 and the

housing 2 preventing medium that has passed through the impeller to flow back to the inlet. - The mechanical seal, which has an radial sealing surface, consists of a

seal ring 3 attached to the impeller and anotherring 4 attached to the housing. In order to make replacement possible, at least one of therings 3 is attached by an O-ring. For that purpose aslot 6 is made in the impeller, extending axially along a part of a mantle surface of the impeller. The slot has then such a configuration that it is deeper in the radial direction at some distance from the opening. - When mounting a seal ring on the impeller, an O-ring is first placed in the slot and then the seal ring is pressed downwards outside the O-ring. This means that the O-ring becomes deformed and thus locks the seal ring. Thanks to the fact that the slot is more shallow at the opening, the locking becomes very effective as the 0-ring must be deformed even more to be able to slip out of the slot. This means that the locking becomes stronger the higher pressure the seal is exposed to. Even the

other seal ring 4 may be mounted in the same way. - The advantages in the invention are several. A sealing is obtained which is very resistant to wear and in addition the 0-ring attachment means that the rings are easy to replace and problems due to the seal rings not being sufficiently plain are eliminated.

- A specific advantage occurs if the sealing surface has a radial direction. This means that the demands for tolerances decrease as a sufficient sealing is obtained, even if the rings are somewhat displaced relative each other. This quality is especially important if the pump contains several steps, that is to say several continuous impellers on the same shaft.

Claims (2)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE8500691A SE459755B (en) | 1985-02-14 | 1985-02-14 | DEVICE TO ACHIEVE A SEAL BETWEEN A ROTARY PUMP WHEEL AND A SURROUNDING PUMP HOUSE |

| SE8500691 | 1985-02-14 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0192621A1 EP0192621A1 (en) | 1986-08-27 |

| EP0192621B1 true EP0192621B1 (en) | 1990-10-24 |

Family

ID=20359116

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86850033A Expired - Lifetime EP0192621B1 (en) | 1985-02-14 | 1986-02-04 | A seal device |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0192621B1 (en) |

| JP (1) | JPS61192896A (en) |

| AU (1) | AU593534B2 (en) |

| DE (1) | DE3675032D1 (en) |

| SE (1) | SE459755B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB9616020D0 (en) * | 1996-07-31 | 1996-09-11 | Framo Dev Ltd | Dynamic weir ring |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4018544A (en) * | 1976-02-20 | 1977-04-19 | Hale Fire Pump Company | Centrifugal pump |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE142214C (en) * | ||||

| US1521226A (en) * | 1921-01-28 | 1924-12-30 | Paul G Bogdanoff | Centrifugal pump |

| DE422681C (en) * | 1923-03-21 | 1925-12-09 | Edwin Letts Oliver | Gap seal for turbines, pumps and similar centrifugal machines |

| AU476959B2 (en) * | 1973-09-18 | 1976-10-07 | Westinghouse Electric Corporation | Improvements in or relating to rotating element fluid seal for centrifugal compressor |

| AU8739075A (en) * | 1974-12-24 | 1977-06-16 | Warman Int Ltd | Self centring festrictor bush |

-

1985

- 1985-02-14 SE SE8500691A patent/SE459755B/en not_active IP Right Cessation

-

1986

- 1986-02-03 AU AU52920/86A patent/AU593534B2/en not_active Ceased

- 1986-02-04 EP EP86850033A patent/EP0192621B1/en not_active Expired - Lifetime

- 1986-02-04 DE DE8686850033T patent/DE3675032D1/en not_active Expired - Fee Related

- 1986-02-14 JP JP61029187A patent/JPS61192896A/en active Granted

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4018544A (en) * | 1976-02-20 | 1977-04-19 | Hale Fire Pump Company | Centrifugal pump |

Also Published As

| Publication number | Publication date |

|---|---|

| AU5292086A (en) | 1986-08-21 |

| SE8500691L (en) | 1986-08-15 |

| EP0192621A1 (en) | 1986-08-27 |

| JPH0217719B2 (en) | 1990-04-23 |

| SE459755B (en) | 1989-07-31 |

| DE3675032D1 (en) | 1990-11-29 |

| JPS61192896A (en) | 1986-08-27 |

| SE8500691D0 (en) | 1985-02-14 |

| AU593534B2 (en) | 1990-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR0125009B1 (en) | Dynamic seal arrangement for impeller pump | |

| US3551067A (en) | Lined corrosion resistant pump | |

| EP0252037B1 (en) | A seal device | |

| EP0037210A1 (en) | High pressure upstream pumping seal combination | |

| US3953150A (en) | Impeller apparatus | |

| EP1231419A2 (en) | Shaft seal device | |

| US4613281A (en) | Hydrodynamic seal | |

| US4842286A (en) | Slide ring seal with circumferentially variably-beveled counter-surface on a shrink fitted slide ring thereof | |

| EP0192621B1 (en) | A seal device | |

| EP0719943B1 (en) | Bearing device for use in a pump | |

| EP0945656A2 (en) | A sealing washer | |

| EP0211051A1 (en) | Mechanical seal. | |

| GB2193257A (en) | Pump with improved seal | |

| US5934683A (en) | Rotary seal assembly having grooved seal facing | |

| US3771926A (en) | Leakage preventing arrangement for pressurized fluid system such as pumps and the like | |

| EP0672832B1 (en) | Sealing device for pump impeller | |

| EP0388384A1 (en) | Mechanical seal | |

| EP0807776A1 (en) | A seal housing | |

| USRE34319E (en) | Dynamic seal arrangement for impeller pump | |

| US4411593A (en) | Rotary type pump resistant to muddy water | |

| KR20000019437U (en) | Axial-flow pump | |

| KR0136795Y1 (en) | Centrifugal pump | |

| KR200229322Y1 (en) | Centrifugal pump | |

| GB2205129A (en) | Pump | |

| AU628372C (en) | Dynamic seal arrangement for impeller pump |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19860213 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19870512 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19901024 |

|

| REF | Corresponds to: |

Ref document number: 3675032 Country of ref document: DE Date of ref document: 19901129 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| ITTA | It: last paid annual fee | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITPR | It: changes in ownership of a european patent |

Owner name: CAMBIO RAGIONE SOCIALE;ITT FLYGT AKTIEBOLAG |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930127 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930225 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19930228 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930427 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940901 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940204 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19941101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050204 |