EP0134907B1 - Device for the pulsating supply of a gaseous medium to a kiln or suchlike - Google Patents

Device for the pulsating supply of a gaseous medium to a kiln or suchlike Download PDFInfo

- Publication number

- EP0134907B1 EP0134907B1 EP84106165A EP84106165A EP0134907B1 EP 0134907 B1 EP0134907 B1 EP 0134907B1 EP 84106165 A EP84106165 A EP 84106165A EP 84106165 A EP84106165 A EP 84106165A EP 0134907 B1 EP0134907 B1 EP 0134907B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- mixing nozzle

- combustion chamber

- lance

- mixing

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS, OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D7/00—Forming, maintaining, or circulating atmospheres in heating chambers

- F27D7/04—Circulating atmospheres by mechanical means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23K—FEEDING FUEL TO COMBUSTION APPARATUS

- F23K5/00—Feeding or distributing other fuel to combustion apparatus

- F23K5/002—Gaseous fuel

- F23K5/005—Gaseous fuel from a central source to a plurality of burners

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS, OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B9/00—Furnaces through which the charge is moved mechanically, e.g. of tunnel type; Similar furnaces in which the charge moves by gravity

- F27B9/30—Details, accessories, or equipment peculiar to furnaces of these types

- F27B9/3005—Details, accessories, or equipment peculiar to furnaces of these types arrangements for circulating gases

- F27B9/3011—Details, accessories, or equipment peculiar to furnaces of these types arrangements for circulating gases arrangements for circulating gases transversally

Definitions

- the invention relates to a device for the pulsed introduction of a combustible gas or air into a combustion chamber or the like., In particular for firing a tunnel furnace of the ceramic industry operated above the ignition temperature with gas, by means of a lance projecting into the combustion chamber, which is connected to a a supply line for the medium to be introduced is connected to a pulse-controlled solenoid valve.

- furnaces used in the ceramic industry are designed as tunnel furnaces. In principle, these consist of two counterflow heat exchangers connected in series with a combustion zone in between.

- the air mass flow required for heating and cooling the material to be burned corresponds approximately to the mass flow of the material to be burned and is entirely or largely passed through the combustion zone.

- air heated to between 700 and 1250 degrees C with sufficient oxygen content is usually available in the combustion zone.

- the burners used here have the task of generating the required temperature with a homogeneous temperature distribution and an oxidizing furnace atmosphere.

- each burner must be set individually to adjust the power distribution across the furnace cross-section or length.

- the air volumes in the heating and cooling zone cannot be freely selected. Therefore, when adding secondary air to the burners, a corresponding part of the air required for heat exchange in the cooling zone must be extracted from the furnace before entering the combustion zone.

- This hot air is generally used for drying.

- the heat requirement of the dryer often does not match the heat requirement of the furnace, neither in time nor in quantity, so that in addition to heat losses in the pipes, especially at the weekend, the furnace waste heat cannot be fully utilized.

- measures to reduce the amount of flue gas and the recovery of the heat contained in the flue gas lead to a steady increase in the amount of heat that can neither be used sensibly by the dryer nor by other facilities.

- the efficiency of the dryer also increases to the extent that the energy used for drying is supplied by intermediate heating. Even in terms of an optimal dryer efficiency, large amounts of air available from the oven are therefore not desirable.

- the disadvantage here is that the gas is only mixed with the furnace atmosphere in the combustion chamber and a reducing atmosphere is generated there by a strong yellow flame.

- the burners are switched sequentially individually. Even in this way, however, it cannot be prevented that local reductions occur, which lead to discolouration of the firing material.

- a complete combustion of the gas is not ensured, especially in the area of the pre-fire and at high burner outputs, since the gas cloud with the furnace atmosphere can reach temperatures below the ignition temperature without sufficient mixing with the oxygen-containing furnace atmosphere. Therefore, conventional burners with the addition of secondary air are provided in the first burner rows of this system.

- the object of the invention is to provide a device of the aforementioned type which enables an oxidizing, flame-free combustion or a homogenization of the atmosphere in the combustion chamber without any addition of secondary air.

- the mixing of the added fuel gas or the air with the gas present in the combustion chamber should be extremely intensive, in addition, an intensive circulation and further mixing should be achieved by the emerging free jet.

- the construction effort with which this can be accomplished should be kept low, and trouble-free operation should also be guaranteed.

- this is achieved in a device for the pulsed introduction of a combustible gas or air into a combustion chamber or the like by means of a lance projecting into this by placing a mixing nozzle on it which receives the jet of the medium to be introduced into the combustion chamber is, which has a continuously tapering cross-section in the flow direction and which verse with one or more openings hen, through which gas can be sucked from the combustion chamber to mix the injected medium with the furnace atmosphere and can be introduced into the latter as a bundled jet by means of the mixing nozzle.

- the mixing nozzle in the area in front of the outlet opening with conically shaped and / or convexly curved inner surface areas and to arrange the openings worked into it for sucking gas from the combustion chamber to the side of the lance in its end region in the wall, the openings should be designed as bores with a circular cross-section and should be provided in a cylindrical part of the mixing nozzle, to which the region of the mixing nozzle which tapers in cross-section adjoins.

- a throttle can be provided at its end protruding into the mixing nozzle.

- the mixing nozzle It is also appropriate to equip the mixing nozzle with a casing which forms a flow channel and is arranged at a distance from the lance and through which the fresh air or another gas can preferably be supplied to the mixing nozzle through its openings.

- the casing it is advantageous to arrange the casing in a height-adjustable manner and to cover all or part of the lateral openings of the mixing nozzle. In this way, fresh air can be added to the mixing nozzle if necessary, and this can also be partially mixed with the furnace atmosphere.

- the lance, the mixing nozzle and / or the casing should be made entirely or partially of a heat-resistant material, preferably of silicon carbide.

- the lance can be equipped with a mixing chamber, to which supply lines, each provided with a pulse valve that can be controlled, can be connected.

- the firing of a kiln can, for example, be switched from firing with gas to firing with oil in a very short time and without any structural measures being necessary, wherein compressed air can be used as the propellant gas and for atomizing the oil.

- the mixing nozzle designed according to the invention is used for firing a kiln, it is expedient to combine several mixing nozzles into a jointly controlled group, each of which is assigned a control unit by means of which the solenoid valves of the mixing nozzles can be individually controlled in such a way that with a variable, constant opening duration Opening frequency depending on the temperature in the combustion chamber is adjustable via a controller.

- the switching of the solenoid valves should always be staggered, and a thermocouple that is connected to the controller should also be arranged in the area of at least one mixing nozzle of a group in the combustion chamber.

- the device designed according to the invention for the pulsed introduction of a combustible gas or air into a combustion chamber or the like is not only very simple in its structural design and therefore easy to manufacture economically, but also reliable, but above all it becomes an oxidizing flame-free Combustion possible without the addition of secondary air. If a mixing nozzle with a continuously tapering cross section and openings is placed on the lance, the injected medium is mixed intensively in the mixing nozzle using the full available gas pressure of approx. 1-3 bar with the furnace atmosphere, since gas is drawn in from the combustion chamber through the openings and introduced into it as a bundled jet. As a result of the injector effect, intensive mixing of the medium supplied from the combustion chamber occurs within the mixing nozzle.

- the emerging bundled jet in turn sucks in the furnace atmosphere according to the injector principle and, in addition to the circulation effect, causes a further admixture of the hot furnace atmosphere.

- Tests have shown that oxidizing, often flame-free combustion is achieved at gas pressures of more than 0.8 bar. In this way, the reducing atmosphere during direct injection is avoided and the maximum possible air preheating is achieved without any piping. If, instead of introducing flammable gas, but air, into a room via the mixing nozzle designed according to the invention, the existing atmosphere can be circulated and homogenized in a simple manner.

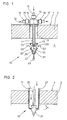

- the device shown in FIG. 1 and designated 10 serves for introducing a medium into the combustion chamber 4 of a tunnel kiln 1 and consists of a lance 11 held by means of a plate 12 in a stoke hole 3 incorporated in the ceiling 2 of the tunnel kiln 1 and a lance 11 on the latter in the combustion chamber 4 protruding end attached mixing nozzle 21.

- a throttle 13 is attached to the end of the lance 11.

- the mixing nozzle 21 consists of a cylindrical part 23 and a region 24 which tapers continuously in cross section, the inner surface 25 of which is convexly curved.

- openings 26 are machined, in the exemplary embodiment shown these are two mutually opposite bores, through which, as represented by the arrows denoted by 32, gas 31 exits through the jet 31 emerging from the throttle 13 is sucked into the combustion chamber 4.

- this mixture emerges as a bundled jet 33 from the outlet opening 22 of the mixing nozzle 21 and is burned flame-free in the combustion chamber 4.

- the lance 11 is provided with a mixing chamber 14, to which supply lines 15, 17 and 19 are connected.

- a solenoid valve 16, 18 and 20 is used, so that, for. B. alternately to be able to carry out firing with gas or atomized oil, via line 15 a combustible gas which flows through the mixing chamber 14, or this via lines 17 and 19 oil and compressed air, which are mixed in the mixing chamber 14, supplied becomes. If necessary, the lighting can be changed quickly and without any structural measures being necessary.

- the power is controlled by switching the solenoid valves 16 or 18 and 20, the switching frequency and duration of opening are proportional to the power of the mixing nozzle 21.

- the mixing nozzle 21 can also be supplied with air.

- the lance 11 is provided with a sheath 27 which is adjustable in height by the path s, so that a flow channel 28 is created.

- fresh air lower layer

- gas from the combustion chamber 4 upper layer

- a mixture of both a mixture of both

- the air can also be supplied under pressure.

- the amount of air is partially controlled by the gas flow, since the resistance in the mixing nozzle 21 is greatly reduced during the gas injection and the amount of air is considerably increased.

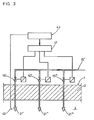

- the mixing nozzle is used to fire a tunnel furnace, it is appropriate, as shown schematically in FIG. 3, in each case a plurality of mixing nozzles 21 ', 21 ", 21"', to which the combustible gas can be controlled via a common gas supply line 15 'and also in a pulsed manner Solenoid valves 16 ' " 16", 16 "flowed in to form a group.

- a control unit 41 By means of a control unit 41, the opening time of one of the solenoid valves 16', 16" or 16 “” is set individually according to the required power distribution, while the opening frequency for the mixing nozzles is one Group is specified together by a controller 42 as a function of the temperature in the combustion chamber 4, which is measured via a thermocouple 43, via the control unit 41.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Furnace Details (AREA)

- Chemical Vapour Deposition (AREA)

Abstract

Description

Die Erfindung bezieht sich auf eine Vorrichtung zur impulsweisen Einbringung eines brennbaren Gases oder von Luft in einen Brennraum oder dgl., insbesondere zur Befeuerung eines oberhalb der Zündtemperatur betriebenen Tunnelofens der keramischen Industrie mit Gas, mittels einer in den Brennraum ragenden Lanze, die an eine mit einem impulsweise steuerbaren Magnetventil versehenen Zuführungsleitung für das einzubringende Medium angeschlossen ist.The invention relates to a device for the pulsed introduction of a combustible gas or air into a combustion chamber or the like., In particular for firing a tunnel furnace of the ceramic industry operated above the ignition temperature with gas, by means of a lance projecting into the combustion chamber, which is connected to a a supply line for the medium to be introduced is connected to a pulse-controlled solenoid valve.

Ein Grossteil der in der keramischen Industrie verwendeten Ofen sind als Tunnelöfen ausgebildet. Diese bestehen prinzipiell aus zwei hintereinander geschalteten Gegenstrom-Wärmetauschern mit dazwischenliegender Brennzone. Der zur Erwärmung und Kühlung des Brenngutes erforderliche Luftmassenstrom entspricht in etwa dem Massenstrom des Brenngutes und wird ganz oder grossenteils durch die Brennzone geführt. Dadurch steht in der Regel in der Brennzone zwischen 700 und 1250 Grad C aufgeheizte Luft mit für die Verbrennung ausreichendem Sauerstoffgehalt zur Verfügung.Most of the furnaces used in the ceramic industry are designed as tunnel furnaces. In principle, these consist of two counterflow heat exchangers connected in series with a combustion zone in between. The air mass flow required for heating and cooling the material to be burned corresponds approximately to the mass flow of the material to be burned and is entirely or largely passed through the combustion zone. As a result, air heated to between 700 and 1250 degrees C with sufficient oxygen content is usually available in the combustion zone.

Den hierbei verwendeten Brennern kommt die Aufgabe zu, die erforderliche Temperatur bei homogener Temperaturverteilung und oxidierender Ofenatmosphäre zu erzeugen. Ausserdem ist zur Einstellung der Leistungsverteilung über den Ofenquerschnitt bzw. die Ofenlänge eine individuelle Einstellung jeden Brenners erforderlich.The burners used here have the task of generating the required temperature with a homogeneous temperature distribution and an oxidizing furnace atmosphere. In addition, each burner must be set individually to adjust the power distribution across the furnace cross-section or length.

Zur Erzeugung der für eine homogene Temperaturverteilung notwendigen Austrittsgeschwindigkeit und der oxidierenden Verbrennung werden die weitaus meisten Brenner heute unter Zugabe von Sekundärluft betrieben.To generate the exit velocity necessary for a homogeneous temperature distribution and the oxidizing combustion, the vast majority of burners today are operated with the addition of secondary air.

Aufgrund des Gegenstromprinzips beim Tunnelofen können aber die Luftmengen in der Aufheiz- und Kühlzone nichtfrei gewählt werden. Daher muss bei Sekundärluftzugabe an den Brennern ein entsprechender Teil der zum Wärmetausch in der Kühlzone benötigten Luft vor Eintritt in die Brennzone vom Ofen abgezogen werden. Diese Heissluft wird im allgemeinen zur Trocknung verwendet. Allerdings stimmt der Wärmebedarf des Trockners häufig weder zeitlich noch quantitativ mit dem Wärmebedarf des Ofens überein, so dass neben Wärmeverlusten in den Leitungen besonders am Wochenende die Ofenabwärme nicht vollständig verwertet werden kann. Neben häufig anzutreffenden Wärmemengen zur Decken- und Wandkühlung führen Massnahmen zur Verringerung der Rauchgasmenge und die Rückgewinnung der im Rauchgas enthaltenen Wärme zu einer stetigen Vergrösserung des Wärmeangebots, das weder vom Trockner noch von anderen Einrichtungen sinnvoll verwertet werden kann. Der Wirkungsgrad des Trockners steigt zudem in dem Masse, in dem der zur Trocknung verwendeten Luft die Energie durch Zwischenaufheizung zugeführt wird. Auch im Sinne eines optimalen Trocknerwirkungsgrades sind somit grosse vom Ofen zur Verfügung stehende Luftmengen nicht wünschenswert.Due to the counterflow principle of the tunnel kiln, the air volumes in the heating and cooling zone cannot be freely selected. Therefore, when adding secondary air to the burners, a corresponding part of the air required for heat exchange in the cooling zone must be extracted from the furnace before entering the combustion zone. This hot air is generally used for drying. However, the heat requirement of the dryer often does not match the heat requirement of the furnace, neither in time nor in quantity, so that in addition to heat losses in the pipes, especially at the weekend, the furnace waste heat cannot be fully utilized. In addition to frequently encountered amounts of heat for ceiling and wall cooling, measures to reduce the amount of flue gas and the recovery of the heat contained in the flue gas lead to a steady increase in the amount of heat that can neither be used sensibly by the dryer nor by other facilities. The efficiency of the dryer also increases to the extent that the energy used for drying is supplied by intermediate heating. Even in terms of an optimal dryer efficiency, large amounts of air available from the oven are therefore not desirable.

Um die vom Ofen abzuführende Heissluftmenge zu verringern, ist es bereits bekannt, Luft und Gas zu mischen, wobei durch die mechanische Energie des Gasdrucks Heissluft aus der Kühlzone des Ofens über Rohrleitungen vom Brenner angesaugt wird. Die Steuerung der Brennerleistung erfolgt dabei über Gasimpulse, deren Dauer und Häufigkeit individuell eingestellt werden können.In order to reduce the amount of hot air to be discharged from the furnace, it is already known to mix air and gas, with the mechanical energy of the gas pressure drawing hot air from the cooling zone of the furnace via pipes from the burner. The burner output is controlled via gas pulses, the duration and frequency of which can be set individually.

Mit diesem Verfahren können ohne Einsatz von Ventilatoren zwar Sekundärlufttemperaturen bis 600 Grad C erzielt werden, nachteilig ist hierbei aber, dass die Sekundärlufttemperatur erheblich unter der Ofenraumtemperatur bleibt und ein isoliertes Rohrleitungssystem zur Zuführung der Verbrennungsluft erforderlich ist.With this method, secondary air temperatures of up to 600 degrees C can be achieved without the use of fans, but the disadvantage here is that the secondary air temperature remains significantly below the furnace chamber temperature and an insulated pipe system is required to supply the combustion air.

Ferner ist es bekannt, mittels einer Brennerlanze impulsweise Gas unter hohem Druck in den Brennraum zu injizieren. Die Mischung des Gases mit der Ofenatmosphäre erfolgt durch die Injektorwirkung. Die Leistung der Brenner wird durch ein Drosselventil individuell eingestellt.It is also known to use a burner lance to inject gas at high pressure into the combustion chamber in pulses. The gas is mixed with the furnace atmosphere by the injector effect. The burner output is individually adjusted by a throttle valve.

Nachteilig ist hierbei, dass die Mischung des Gases mit der Ofenatmosphäre erst im Brennraum erfolgt und dort durch eine stark gelbe Flamme eine reduzierende Atmosphäre erzeugt wird. Um dem örtlichen Sauerstoffmangel entgegenzuwirken, werden die Brenner sequenziell einzeln geschaltet. Auch auf diese Weise kann allerdings nicht verhindert werden, dass örtliche Reduktionen auftreten, welche zu Verfärbungen am Brenngut führen. Weiterhin ist insbesondere im Bereich des Vorfeuers und bei hohen Brennerleistungen eine vollständige Verbrennung des Gases nicht sichergestellt, da die Gaswolke mit der Ofenatmosphäre in den Bereich von Temperaturen unterhalb der Zündtemperatur gelangen kann, ohne dass eine ausreichende Mischung mit der sauerstoffhaltigen Ofenatmosphäre erfolgt wäre. Daher sind in den ersten Brennerreihen dieses Systems herkömmliche Brenner mit Sekundärluftzugabe vorgesehen.The disadvantage here is that the gas is only mixed with the furnace atmosphere in the combustion chamber and a reducing atmosphere is generated there by a strong yellow flame. In order to counteract the local lack of oxygen, the burners are switched sequentially individually. Even in this way, however, it cannot be prevented that local reductions occur, which lead to discolouration of the firing material. Furthermore, a complete combustion of the gas is not ensured, especially in the area of the pre-fire and at high burner outputs, since the gas cloud with the furnace atmosphere can reach temperatures below the ignition temperature without sufficient mixing with the oxygen-containing furnace atmosphere. Therefore, conventional burners with the addition of secondary air are provided in the first burner rows of this system.

Aufgabe der Erfindung ist es, eine Vorrichtung der vorgenannten Art zu schaffen, die ohne jede Zugabe von Sekundärluft eine oxidierende, flammenfreie Verbrennung bzw. eine Homogenisierung der Atmosphäre in dem Brennraum ermöglicht. Die Vermischung des zugegebenen Brenngases bzw. der Luft mit dem in dem Brennraum vorhandenen Gas soll hierbei äusserst intensiv sein, ausserdem soll durch den austretenden Freistrahl eine intensive Umwälzung und eine weitere Vermischung erreicht werden. Der Bauaufwand, mit dem dies zu bewerkstelligen ist, soll gering gehalten werden, ferner soll ein störungsfreier Betrieb gewährleistet sein.The object of the invention is to provide a device of the aforementioned type which enables an oxidizing, flame-free combustion or a homogenization of the atmosphere in the combustion chamber without any addition of secondary air. The mixing of the added fuel gas or the air with the gas present in the combustion chamber should be extremely intensive, in addition, an intensive circulation and further mixing should be achieved by the emerging free jet. The construction effort with which this can be accomplished should be kept low, and trouble-free operation should also be guaranteed.

Gemäss der Erfindung wird dies bei einer Vorrichtung zur impulsweisen Einbringung eines brennbaren Gases oder von Luft in einen Brennraum oder dgl. mittels einer in diesen ragenden Lanze dadurch erreicht, dass auf diese eine den aus dieser austretenden Strahl des in den Brennraum einzubringenden Mediums aufnehmende Mischdüse aufgesetzt ist, die in Strömungsrichtung einen sich stetig verjüngenden Querschnitt aufweist und die mit einer oder mehreren Öffnungen versehen ist, über die zur Vermischung des injizierten Mediums mit der Ofenatmosphäre Gas aus dem Brennraum ansaugbar und mittels der Mischdüse in diesen als gebündelter Strahl einbringbar ist.According to the invention, this is achieved in a device for the pulsed introduction of a combustible gas or air into a combustion chamber or the like by means of a lance projecting into this by placing a mixing nozzle on it which receives the jet of the medium to be introduced into the combustion chamber is, which has a continuously tapering cross-section in the flow direction and which verse with one or more openings hen, through which gas can be sucked from the combustion chamber to mix the injected medium with the furnace atmosphere and can be introduced into the latter as a bundled jet by means of the mixing nozzle.

Zweckmässig ist es hierbei, die Mischdüse im Bereich vor der Austrittsöffnung mit kegelig ausgebildeten und/oder konvex gekrümmten Innenmantelflächen zu versehen und die in diese eingearbeiteten Öffnungen zum Ansaugen von Gas aus dem Brennraum seitlich der Lanze in deren Endbereich in der Wandung anzuordnen, wobei die Öffnungen als Bohrungen mit kreisförmigem Querschnitt ausgebildet und in einem zylindrischen Teil der Mischdüse vorgesehen sein sollten, an die sich der im Querschnitt stetig verjüngende Bereich der Mischdüse anschliesst.It is expedient here to provide the mixing nozzle in the area in front of the outlet opening with conically shaped and / or convexly curved inner surface areas and to arrange the openings worked into it for sucking gas from the combustion chamber to the side of the lance in its end region in the wall, the openings should be designed as bores with a circular cross-section and should be provided in a cylindrical part of the mixing nozzle, to which the region of the mixing nozzle which tapers in cross-section adjoins.

Um die Geschwindigkeit des aus der Lanze austretenden Gasstrahles zu erhöhen, kann an deren in die Mischdüse ragendem Ende eine Drossel vorgesehen werden.In order to increase the speed of the gas jet emerging from the lance, a throttle can be provided at its end protruding into the mixing nozzle.

Angebracht ist es ferner, die Mischdüse mit einer mit Abstand zu der Lanze angeordneten, einen Strömungskanal bildenden Ummantelung auszustatten, durch den der Mischdüse vorzugsweise über deren Öffnungen Frischluft oder ein anderes Gaszuführbar ist. Hierbei ist es vorteilhaft, die Ummantelung höhenverstellbar anzuordnen und durch diese die seitlichen Öffnungen der Mischdüse ganz oder teilweise abzudecken. Auf diese Weise kann im Bedarfsfall der Mischdüse sowohl Frischluft zugegeben als auch diese teilweise mit der Ofenatmosphäre gemischt werden.It is also appropriate to equip the mixing nozzle with a casing which forms a flow channel and is arranged at a distance from the lance and through which the fresh air or another gas can preferably be supplied to the mixing nozzle through its openings. In this case, it is advantageous to arrange the casing in a height-adjustable manner and to cover all or part of the lateral openings of the mixing nozzle. In this way, fresh air can be added to the mixing nozzle if necessary, and this can also be partially mixed with the furnace atmosphere.

Die Lanze, die Mischdüse und/oder die Ummantelung sollten wegen der in dem Brennraum herrschenden hohen Temperaturen ganz oder teilweise aus einem hitzebeständigen Werkstoff, vorzugsweise aus Siliziumcarbid, hergestellt sein.Because of the high temperatures prevailing in the combustion chamber, the lance, the mixing nozzle and / or the casing should be made entirely or partially of a heat-resistant material, preferably of silicon carbide.

Zur Einbringung unterschiedlicher Medien in den Brennraum kann, um mittels der Vorrichtung somit verschiedene Brennstoffe verbrennen zu können, die Lanze mit einer Mischkammer ausgestattet werden, an die jeweils mit einem impulsweise steuerbaren Magnetventil versehene Zuführungsleitungen anzuschliessen sind. Die Befeuerung eines Brennofens kann beispielsweise von einer Befeuerung mit Gas auf eine Befeuerung mit Öl demnach in sehr kurzer Zeit und ohne dass bauliche Massnahmen erforderlich sind, umgestellt werden, wobei als Treibgas und zur Zerstäubung des Öls Pressluft verwendet werden kann.In order to introduce different media into the combustion chamber, in order to be able to burn different fuels by means of the device, the lance can be equipped with a mixing chamber, to which supply lines, each provided with a pulse valve that can be controlled, can be connected. The firing of a kiln can, for example, be switched from firing with gas to firing with oil in a very short time and without any structural measures being necessary, wherein compressed air can be used as the propellant gas and for atomizing the oil.

Wird die erfindungsgemäss ausgebildete Mischdüse zur Befeuerung eines Brennofens verwendet, ist es zweckmässig, jeweils mehrere Mischdüsen zu einer gemeinsam gesteuerten Gruppe zusammenzufassen, der jeweils ein Steuergerät zuzuordnen ist, mittels dem die Magnetventile der Mischdüsen individuell derart steuerbar sind, dass bei veränderbarer, konstanter Öffnungsdauer die Öffnungsfrequenz in Abhängigkeit von der Temperatur im Brennraum über einen Regler einstellbar ist. Die Schaltung der Magnetventile sollte hierbei stets versetzt erfolgen, auch sollte im Bereich zumindest einer Mischdüse einer Gruppe im Brennraum ein Thermoelement angeordnet werden, das mit dem Regler verbunden ist.If the mixing nozzle designed according to the invention is used for firing a kiln, it is expedient to combine several mixing nozzles into a jointly controlled group, each of which is assigned a control unit by means of which the solenoid valves of the mixing nozzles can be individually controlled in such a way that with a variable, constant opening duration Opening frequency depending on the temperature in the combustion chamber is adjustable via a controller. The switching of the solenoid valves should always be staggered, and a thermocouple that is connected to the controller should also be arranged in the area of at least one mixing nozzle of a group in the combustion chamber.

Die gemäss der Erfindung ausgebildete Vorrichtung zur impulsweisen Einbringung eines brennbaren Gases oder von Luft in einen Brennraum oder dgl. ist nicht nur sehr einfach in ihrer konstruktiven Ausgestaltung und demnach ohne Schwierigkeiten auf wirtschaftliche Weise herzustellen, sondern auch betriebssicher, vor allem aber wird eine oxidierende flammenfreie Verbrennung ohne Zusatz von Sekundärluft ermöglicht. Wird nämlich auf die Lanze eine Mischdüse aufgesetzt, die einen sich stetig verjüngenden Querschnitt und Öffnungen aufweist, so wird in der Mischdüse eine intensive Vermischung des injizierten Mediums unter Ausnutzung des vollen zur Verfügung stehenden Gasdruckes von ca. 1 -3 bar mit der Ofenatmosphäre vorgenommen, da durch die Öffnungen Gas aus dem Brennraum angesaugt und in diesen als gebündelter Strahl eingebracht wird. Durch die Injektorwirkung tritt somit innerhalb der Mischdüse eine intensive Vermischung des zugeführten Mediums aus dem Brennraum ein. Ausserdem wird durch die hohe Temperatur der Ofenatmosphäre und den durch die Injektorwirkung erzeugten, mit steigendem Gasdruck sich vergrössernden Luftüberschuss eine stark oxidierende Verbrennung bereits in der Düse erreicht, so dass aus der Düse ein gebündelter Heissgasstrahl austritt, dessen Geschwindigkeit weitgehend vom Gasdruck bestimmt wird und in der Grössenordnung von herkömmlichen, mit Sekundärluft betriebenen Brennern liegt. Eine ausreichende Umwälzung der Ofenatmosphäre ist somit sichergestellt.The device designed according to the invention for the pulsed introduction of a combustible gas or air into a combustion chamber or the like is not only very simple in its structural design and therefore easy to manufacture economically, but also reliable, but above all it becomes an oxidizing flame-free Combustion possible without the addition of secondary air. If a mixing nozzle with a continuously tapering cross section and openings is placed on the lance, the injected medium is mixed intensively in the mixing nozzle using the full available gas pressure of approx. 1-3 bar with the furnace atmosphere, since gas is drawn in from the combustion chamber through the openings and introduced into it as a bundled jet. As a result of the injector effect, intensive mixing of the medium supplied from the combustion chamber occurs within the mixing nozzle. In addition, due to the high temperature of the furnace atmosphere and the excess air generated by the injector effect, which increases with increasing gas pressure, a strongly oxidizing combustion is already achieved in the nozzle, so that a bundled hot gas jet emerges from the nozzle, the speed of which is largely determined by the gas pressure and in the order of magnitude of conventional burners operated with secondary air. Adequate circulation of the furnace atmosphere is thus ensured.

Der austretende gebündelte Strahl saugt nach dem Injektorprinzip wiederum Ofenatmosphäre an und bewirkt neben dem Umwälzeffekt eine weitere Zumischung von heisser Ofenatmosphäre. Versuche haben ergeben, dass bei Gasdrücken von mehr als 0,8 bar eine oxidierende, häufig flammenfreie Verbrennung erreicht wird. Auf diese Weise wird die reduzierende Atmosphäre bei direkter Injektion vermieden und dabei eine maximal mögliche Luftvorwärmung ohne jegliche Rohrleitungen erreicht. Wird über die erfindungsgemäss ausgebildete Mischdüse kein brennbares Gas, sondern Luft in einen Raum eingebracht, ist auf einfache Weise eine Umwälzung der vorhandenen Atmosphäre und eine Vergleichmässigung zu erreichen.The emerging bundled jet in turn sucks in the furnace atmosphere according to the injector principle and, in addition to the circulation effect, causes a further admixture of the hot furnace atmosphere. Tests have shown that oxidizing, often flame-free combustion is achieved at gas pressures of more than 0.8 bar. In this way, the reducing atmosphere during direct injection is avoided and the maximum possible air preheating is achieved without any piping. If, instead of introducing flammable gas, but air, into a room via the mixing nozzle designed according to the invention, the existing atmosphere can be circulated and homogenized in a simple manner.

In der Zeichnung ist ein Ausführungsbeispiel der gemäss der Erfindung ausgebildeten Vorrichtung zur impulsweisen Einbringung eines gasförmigen Mediums in einen Brennofen oder dgl. dargestellt, das nachfolgend im einzelnen erläutert ist. Hierbei zeigen:

- Fig. 1 die in einem Brennraum eines Tunnelofens angeordnete Vorrichtung, teilweise im Schnitt,

- Fig. 2 die Vorrichtung nach Fig. 1 mit einer der die Mischdüse tragenden Lanze zugeordneten Ummantelung und

- Fig. 3 mehrere zu einer Gruppe zusammengefasste und gemeinsam regelbare Mischdüsen nach Fig. 1 in schematischer Darstellung.

- 1 shows the device arranged in a combustion chamber of a tunnel furnace, partly in section,

- Fig. 2 shows the device of FIG. 1 with a casing associated with the lance carrying the mixing nozzle and

- FIG. 3 shows a plurality of mixing nozzles according to FIG. 1 combined and controllable in a group in a schematic representation.

Die in Fig. 1 dargestellte und mit 10 bezeichnete Vorrichtung dient zur Einbringung eines Mediums in den Brennraum 4 eines Tunnelofens 1 und besteht aus einer mittels einer Platte 12 in einem in der Decke 2 des Tunnelofens 1 eingearbeiteten Schürloch 3 gehaltenen Lanze 11 sowie einer auf deren in den Brennraum 4 ragendes Ende aufgesetzten Mischdüse 21. Um eine möglichst hohe Austrittsgeschwindigkeit des in die Mischdüse 21 injizierten Mediums zu erzielen, ist an dem Ende der Lanze 11 eine Drossel 13 angebracht.The device shown in FIG. 1 and designated 10 serves for introducing a medium into the

Die Mischdüse 21 besteht aus einem zylindrischen Teil 23 und einem sich im Querschnitt stetig verjüngenden Bereich 24, dessen Innenfläche 25 konvex gekrümmt ausgebildet ist. In den zylindrischen Teil 23 der Mischdüse 21 sind Öffnungen 26, bei dem gezeigten Ausführungsbeispiel sind dies zwei einander gegenüberliegende Bohrungen, eingearbeitet, durch die, wie dies durch die mit 32 bezeichneten Pfeile dargestellt ist, durch den aus der Drossel 13 austretenden Strahl 31 Gas aus dem Brennraum 4 angesaugt wird. In der Mischdüse 21 erfolgt somit bereits eine intensive Vermischung des zugeführten Mediums mit aus dem Brennraum 4 angesaugtem Gas. Und dieses Gemisch tritt als gebündelter Strahl 33 aus der Austrittsöffnung 22 der Mischdüse 21 aus und wird flammenfrei in dem Brennraum 4 verbrannt.The mixing

Um mittels der Mischdüse 21 unterschiedliche Medien in den Brennraum 4 einbringen zu können, ist die Lanze 11 mit einer Mischkammer 14 versehen, an die Zuführungsleitungen 15, 17 und 19 angeschlossen sind. In jede der Zuführungsleitungen 15, 17 und 19 ist jeweils ein Magnetventil 16, 18 und 20 eingesetzt, so dass, um z. B. wechselweise eine Befeuerung mit Gas oder zerstäubtem Öl vornehmen zu können, über die Leitung 15 ein brennbares Gas, das die Mischkammer 14 durchströmt, oder dieser über die Leitungen 17 und 19 Öl und Pressluft, die in der Mischkammer 14 miteinander vermischt werden, zugeführt wird. Im Bedarfsfall kann somit rasch und ohne dass bauliche Massnahmen erforderlich sind, eine Änderung der Befeuerung vorgenommen werden. Die Leistungssteuerung erfolgtdurch Schalten der Magnetventile 16 bzw. 18 und 20, dessen Schalthäufigkeit und Offnungsdauer der Leistung der Mischdüse 21 proportional sind.In order to be able to introduce different media into the

Tritt aufgrund der Ofenbetriebsweise in Fällen, in denen der Tunnelofen 1 nicht oder nur teilweise als durchgehender Wärmetauscher betrieben wird, Sauerstoffmangel in dem Brennraum 4 auf, so kann der Mischdüse 21 zusätzlich Luft zugeführt werden. Dazu ist, wie dies bei der Vorrichtung 10' in Fig. 2 gezeigt ist, die Lanze 11 mit einer um den Weg s höhenverstellbar angeordneten Ummantelung 27 versehen, so dass ein Strömungskanal 28 geschaffen ist. Je nach Stellung der Ummantelung 27 kann somit Frischluft (untere Lage), Gas aus dem Brennraum 4 (obere Lage) oder eine Mischung aus beiden (mittlere Lage) angesaugt werden. Neben der Einsparung der Ventilatorenenergie und der stufenlosen Einstellung des Ofenatmosphären-Luftverhältnisses hat dieses Zugabeprinzip den Vorteil, dass Luft nur dann angesaugt wird, wenn Gas strömt.If, due to the furnace mode of operation, in cases in which the

Zur Vergrösserung des Austritts-Impulses kann die Luft auch unter Druck zugeführt werden. Hierbei erfolgt eine teilweise Steuerung der Luftmenge durch den Gasfluss, da während der Gasinjektion der Widerstand in der Mischdüse 21 sehr stark vermindert und die Luftmenge erheblich vergrössert wird.To increase the exit impulse, the air can also be supplied under pressure. The amount of air is partially controlled by the gas flow, since the resistance in the mixing

Wird die Mischdüse zur Befeuerung eines Tunnelofens verwendet, so ist es angebracht, wie dies in Fig. 3 schematisch gezeigt ist, jeweils mehrere Mischdüsen 21', 21", 21"', denen das brennbare Gas über eine gemeinsame Gaszuführungsleitung 15' sowie impulsweise steuerbare Magnetventile 16'" 16", 16"' zuströmt, zu einer Gruppe zusammenzufassen. Mittels eines Steuergerätes 41 wird die Öffnungszeit eines der Magnetventile 16', 16" oder 16'" nach der erforderlichen Leistungsverteilung individuell eingestellt, während die Öffnungsfrequenz für die Mischdüsen einer Gruppe gemeinsam von einem Regler 42 in Abhängigkeit von der Temperatur in dem Brennraum 4, die über ein Thermoelement 43 gemessen wird, über das Steuergerät 41 vorgegeben wird.If the mixing nozzle is used to fire a tunnel furnace, it is appropriate, as shown schematically in FIG. 3, in each case a plurality of mixing

Claims (14)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84106165T ATE23220T1 (en) | 1983-07-04 | 1984-05-30 | DEVICE FOR PULSING A GASEOUS MEDIUM INTO A KILN OR LIKE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3324050 | 1983-07-04 | ||

| DE3324050A DE3324050A1 (en) | 1983-07-04 | 1983-07-04 | DEVICE FOR IMPLEMENTING A GAS-SHAPED MEDIUM INTO A FURNACE OR THE LIKE. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0134907A1 EP0134907A1 (en) | 1985-03-27 |

| EP0134907B1 true EP0134907B1 (en) | 1986-10-29 |

Family

ID=6203098

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84106165A Expired EP0134907B1 (en) | 1983-07-04 | 1984-05-30 | Device for the pulsating supply of a gaseous medium to a kiln or suchlike |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0134907B1 (en) |

| AT (1) | ATE23220T1 (en) |

| DE (2) | DE3324050A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3835360A1 (en) * | 1988-10-17 | 1990-04-19 | Keller Spezialtechnik Gmbh | Tunnel furnace |

| DE59305014D1 (en) * | 1992-03-04 | 1997-02-20 | Bacher & Schmidt Gmbh | Method and device for gas firing a furnace in the ceramic industry |

| DE4423221A1 (en) * | 1994-07-01 | 1996-01-04 | Lingl Anlagenbau | Heat transfer in the tunnel oven |

| DE4430267A1 (en) * | 1994-08-26 | 1996-02-29 | Bosch Gmbh Robert | Burner for flameless combustion of a fuel gas-air mixture |

| DE10036774A1 (en) * | 2000-07-28 | 2002-02-14 | Aichelin Gmbh | Furnace used for thermally cleaning waste gases produced during the treatment of workpieces has an eddying effect in the region of the combustion chamber so that waste gases produced |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE90411C (en) * | ||||

| US1646208A (en) * | 1926-07-07 | 1927-10-18 | American Dressler Tunnel Kilns | Tunnel kiln |

| FR1570036A (en) * | 1968-04-25 | 1969-06-06 | ||

| DE2130072A1 (en) * | 1971-06-18 | 1972-12-21 | Andreas Haessler | Tunnel kiln gas circulation - reduces temp differences within heating - and cooling zones |

-

1983

- 1983-07-04 DE DE3324050A patent/DE3324050A1/en not_active Withdrawn

-

1984

- 1984-05-30 EP EP84106165A patent/EP0134907B1/en not_active Expired

- 1984-05-30 AT AT84106165T patent/ATE23220T1/en not_active IP Right Cessation

- 1984-05-30 DE DE8484106165T patent/DE3461118D1/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| EP0134907A1 (en) | 1985-03-27 |

| ATE23220T1 (en) | 1986-11-15 |

| DE3324050A1 (en) | 1985-01-17 |

| DE3461118D1 (en) | 1986-12-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69314903T2 (en) | Thermal nozzle combustion process | |

| DE69522691T2 (en) | BURNER WITH LOW NOX PRODUCTION | |

| DE10217524A1 (en) | Side burner for flameless oxidation | |

| DE1401853B2 (en) | ||

| EP0134907B1 (en) | Device for the pulsating supply of a gaseous medium to a kiln or suchlike | |

| DE1178767B (en) | Process for heating coarse ceramic kilns and kilns with a device for carrying out this process | |

| DE4113412C2 (en) | Device for burning liquid or gaseous fuel for a furnace | |

| AT410843B (en) | TUNNEL KILN | |

| WO2022117345A1 (en) | Device and method for supplying combustion air and for recirculating exhaust gas for a burner | |

| DE352795C (en) | Method for heating melting furnaces | |

| EP3650753A1 (en) | Method and device for flameless staged combustion | |

| DE4014693A1 (en) | Burner for combustion chamber of a tunnel furnace - uses coanda effect to control supply of combustion air | |

| DE606168C (en) | Rotary kiln | |

| DE2254551C3 (en) | Process and device for lintel cooling of the kiln by lowering the temperature in tunnel kilns | |

| AT387456B (en) | Tunnel kiln for firing ceramic products | |

| EP0559144B1 (en) | Method and device for firing by gas a furnace used in the ceramics industry | |

| DE585188C (en) | Regenerative furnace with constant flame direction, the working area of which gas and air are fed in simultaneously from opposite sides | |

| DE246106C (en) | ||

| EP0344600B1 (en) | Process for increasing scrap addition by preparing the scrap in the converter | |

| DE3119198A1 (en) | Method and shaft furnace for burning lumpy articles to be burned such as limestone, dolomite, magnesite or the like and use of the shaft furnace | |

| DE19603482A1 (en) | Low NOx burner with improved operating behavior | |

| DE2306009C3 (en) | Device for the flameless combustion of gaseous or vaporous fuel-air mixtures | |

| DE440747C (en) | Method and apparatus for burning Portland cement and the like like in the rotary kiln | |

| DE2323920A1 (en) | BURNER | |

| AT25632B (en) | Shaft furnace for burning lime, dolomite etc. Like. With generator gas firing. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT DE FR GB NL |

|

| 17P | Request for examination filed |

Effective date: 19850207 |

|

| 17Q | First examination report despatched |

Effective date: 19860304 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE FR GB NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19861029 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19861029 |

|

| REF | Corresponds to: |

Ref document number: 23220 Country of ref document: AT Date of ref document: 19861115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3461118 Country of ref document: DE Date of ref document: 19861204 |

|

| EN | Fr: translation not filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| 26 | Opposition filed |

Opponent name: C. KELLER GMBH U.CO. KG Effective date: 19870323 |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| GBPR | Gb: patent revoked under art. 102 of the ep convention designating the uk as contracting state | ||

| 27W | Patent revoked |

Effective date: 19880717 |