CN219189542U - Sheet metal structural part for protective cover - Google Patents

Sheet metal structural part for protective cover Download PDFInfo

- Publication number

- CN219189542U CN219189542U CN202320236660.4U CN202320236660U CN219189542U CN 219189542 U CN219189542 U CN 219189542U CN 202320236660 U CN202320236660 U CN 202320236660U CN 219189542 U CN219189542 U CN 219189542U

- Authority

- CN

- China

- Prior art keywords

- sheet metal

- frame

- panel beating

- protective cover

- cover body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Protection Of Pipes Against Damage, Friction, And Corrosion (AREA)

- Tents Or Canopies (AREA)

Abstract

The utility model discloses a sheet metal structural part for a protective cover, which comprises a protective cover body, wherein a first sheet metal frame is fixedly connected to the outer surface of the protective cover body in a sleeved mode, a second sheet metal frame is connected to the outer surface of the protective cover body in a sleeved mode at a position below the first sheet metal frame in a sliding mode, and a plurality of quick dismounting connecting mechanisms are arranged between the first sheet metal frame and the second sheet metal frame. According to the utility model, the screw tube at the external screw thread joint can be directly replaced under the condition of not replacing the protective cover body by the arranged quick dismounting connecting mechanism, so that the later maintenance cost can be reduced, and meanwhile, the integral structural strength can be increased by the arranged connecting limiting mechanism and the reinforcing mechanism, so that the protective cover body is not easy to fall off and damage between the protective cover body and the first sheet metal frame and the second sheet metal frame, and the service life is prolonged.

Description

Technical Field

The utility model relates to the technical field of protective covers, in particular to a sheet metal structural part for a protective cover.

Background

The protective cover can strictly prevent dust, chips, hard sand grains and the like from entering the rail, reduce the damage of hard granular foreign matters to the sliding rail surface, reduce the influence of the operation deformation of the guide rail on the machining precision, and keep the machining precision of the machine tool. The surface of the protective cover should be smooth, burr-free and sharp-edged, and should not become a new dangerous source; the protective cover does not influence the sight and normal operation, and is convenient for the inspection and maintenance of the equipment;

the sheet metal structural part that current safety cover was used is comparatively simple in structure, generally is the corresponding sheet metal structural part of fixedly connected with all around of safety cover, then has offered the screw hole that is used for the safety cover to be fixed at sheet metal structural part's surface, then connects through screw or screw, because the dismouting of maintaining or the vibration of equipment, will appear the wearing and tearing of screw hole after long-time use to lead to the safety cover to connect not hard up, unstable, thereby influence the normal use of safety cover.

Disclosure of Invention

The utility model aims to solve the defects in the prior art, and provides a sheet metal structural part for a protective cover.

In order to achieve the above purpose, the present utility model adopts the following technical scheme: the utility model provides a panel beating structure that safety cover was used, includes the safety cover body, the first panel beating frame of fixedly connected with is established to the surface cover of safety cover body, the second panel beating frame of sliding connection is established to the position cover that the surface of safety cover body just is located first panel beating frame below, be equipped with a plurality of quick assembly disassembly coupling mechanism between first panel beating frame and the second panel beating frame, be equipped with connection stop gear between the surface of first panel beating frame and second panel beating frame, be fixed with strengthening mechanism between the surface of first panel beating frame and the safety cover body.

Further, quick assembly disassembly coupling mechanism includes the screwed pipe, the screwed pipe runs through the surface of first panel beating frame and second panel beating frame in proper order, the surface of screwed pipe just is close to the annular fixedly connected with of position a plurality of stoppers in center, the limiting groove with stopper matched with is all seted up to the inner wall of first panel beating frame and second panel beating frame.

Further, a plurality of through holes matched with the threaded pipes are formed in the outer surfaces of the first sheet metal frame and the second sheet metal frame, and the limiting groove is formed in the inner wall of one end of the through hole.

Further, the connection limiting mechanism comprises a plurality of limiting rods, one ends of the limiting rods are sequentially connected with the lower surface of the first sheet metal frame in a fixed manner, one ends of the limiting rods penetrate through the second sheet metal frame, and a plurality of limiting holes which are in sliding connection with the limiting rods are formed in the outer surface of the second sheet metal frame.

Further, the reinforcing mechanism comprises a plurality of reinforcing plates, two sides of the outer surface of each reinforcing plate are fixedly connected with the outer surface of the protective cover body and the upper surface of the first sheet metal frame respectively, and the reinforcing plates are isosceles right triangles.

Further, rectangular grooves are formed in the periphery of the inner wall of the second sheet metal frame, and rectangular blocks which are in sliding connection with the inner wall of the rectangular grooves are fixedly connected to the periphery of the outer surface of the protective cover body.

Further, be equipped with sealed pad between the surface of first panel beating frame and second panel beating frame, the surface of safety cover body, first panel beating frame and second panel beating frame all is coated with anticorrosive coating.

The utility model has the beneficial effects that:

when the sheet metal structural part for the protective cover is used, the threaded pipe at the external threaded connection part can be directly replaced under the condition of not replacing the protective cover body through the quick assembly disassembly connecting mechanism, so that the later maintenance cost can be reduced, and meanwhile, the integral structural strength can be increased through the connecting limiting mechanism and the reinforcing mechanism, so that the protective cover body, the first sheet metal frame and the second sheet metal frame are not easy to fall off and damage, and the service life is prolonged.

Drawings

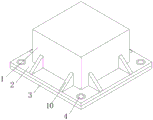

FIG. 1 is a perspective view of the present utility model;

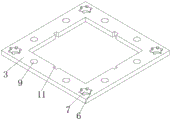

FIG. 2 is a schematic diagram of the overall structure of the present utility model;

FIG. 3 is a perspective view of a first sheet metal frame of the present utility model;

FIG. 4 is a perspective view of a second sheet metal frame of the present utility model;

fig. 5 is a perspective view of a threaded pipe according to the present utility model.

Legend description:

1. a protective cover body; 2. a first sheet metal frame; 3. a second sheet metal frame; 4. a threaded tube; 5. a limiting block; 6. a limit groove; 7. a through hole; 8. a limit rod; 9. a limiting hole; 10. a reinforcing plate; 11. rectangular grooves.

Description of the embodiments

Fig. 1 to 5 show, relate to panel beating structure that safety cover was used, including safety cover body 1, the first panel beating frame 2 of fixedly connected with is established to the surface cover of safety cover body 1, and sliding connection has second panel beating frame 3 is established to the position cover that the surface of safety cover body 1 just is located first panel beating frame 2 below, is equipped with a plurality of quick assembly disassembly coupling mechanism between first panel beating frame 2 and the second panel beating frame 3, is equipped with connection stop gear between the surface of first panel beating frame 2 and second panel beating frame 3, is fixed with strengthening mechanism between the surface of first panel beating frame 2 and the safety cover body 1.

The quick assembly disassembly coupling mechanism includes screwed pipe 4, screwed pipe 4 runs through the surface of first panel beating frame 2 and second panel beating frame 3 in proper order, the surface of screwed pipe 4 just is close to the annular fixedly connected with of position of center a plurality of stopper 5, first panel beating frame 2 and the inner wall of second panel beating frame 3 are seted up all to be equipped with stopper 5 matched with spacing groove 6, through the cooperation of stopper 5 with spacing groove 6, alright carry out spacing fixedly with screwed pipe 4 and the inside of first panel beating frame 2 and second panel beating frame 3 this moment, thereby avoid appearing rotating, when changing, only need to separate first panel beating frame 2 and second panel beating frame 3, alright take off screwed pipe 4 from first panel beating frame 2 and second panel beating frame 3 finger between this moment, then change can, easy operation, need not change whole safety cover body 1, thereby reduce the maintenance cost.

The surface of first panel beating frame 2 and second panel beating frame 3 has all seted up a plurality of and screwed pipe 4 matched with through-hole 7, and spacing groove 6 is seted up at the one end inner wall of through-hole 7, is convenient for install spacingly to screwed pipe 4 through the through-hole 7 that sets up.

The connection limiting mechanism comprises a plurality of limiting rods 8, one ends of the limiting rods 8 are sequentially connected with the lower surface of the first sheet metal frame 2 in a fixed mode, one ends of the limiting rods 8 penetrate through the second sheet metal frame 3, a plurality of limiting holes 9 which are slidably connected with the limiting rods 8 are formed in the outer surface of the second sheet metal frame 3, the limiting rods 8 and the limiting holes 9 are used for conveniently positioning and limiting the first sheet metal frame 2 and the second sheet metal frame 3, and meanwhile the connection strength between the first sheet metal frame 2 and the second sheet metal frame 3 can be increased.

The reinforcing mechanism comprises a plurality of reinforcing plates 10, two sides of the outer surface of each reinforcing plate 10 are fixedly connected with the outer surface of the protective cover body 1 and the upper surface of the first sheet metal frame 2 respectively, the reinforcing plates 10 are isosceles right triangles, and the connecting strength between the first sheet metal frame 2 and the protective cover body 1 can be increased through the reinforcing plates 10.

Be equipped with sealed pad between the surface of first panel beating frame 2 and second panel beating frame 3, the surface of safety cover body 1, first panel beating frame 2 and second panel beating frame 3 all is coated with anticorrosive coating, and sealed pad can increase the leakproofness between first panel beating frame 2 and the second panel beating frame 3, and anticorrosive coating can increase the anticorrosive performance of safety cover body 1, first panel beating frame 2 and second panel beating frame 3 to improve life.

When the sheet metal structural part for the protection cover is used, the limiting blocks 5 on the threaded pipes 4 are matched with the limiting grooves 6, then the first sheet metal frame 2 and the second sheet metal frame 3 are matched with each other through the limiting rods 8 and the limiting holes 9, the rectangular grooves 11 and the rectangular blocks are also matched with each other, then the external bolts penetrate through the threaded pipes 4 and are connected with the installation positions of the protection cover body 1, at the moment, the first sheet metal frame 2 and the protection cover body 1 are fixed through the external bolts, when the inside of the threaded pipes 4 is worn after long-time use, only the external bolts are required to be taken down, and then the first sheet metal frame 2 and the second sheet metal frame 3 can be separated, at the moment, the threaded pipes 4 can be taken down from the space between the first sheet metal frame 2 and the second sheet metal frame 3, and then replacement can be performed, operation is simple, the whole protection cover body 1 is not required to be replaced, and therefore maintenance cost is reduced.

The foregoing description of the preferred embodiments of the utility model is not intended to limit the utility model to the precise form disclosed, and any such modifications, equivalents, and alternatives falling within the spirit and scope of the utility model are intended to be included within the scope of the utility model.

Claims (7)

1. Sheet metal structure that safety cover was used, including safety cover body (1), its characterized in that: the utility model discloses a safety cover, including safety cover body (1), first panel beating frame (2) of fixedly connected with is established to the surface cover of safety cover body (1), the surface of safety cover body (1) and the position cover that is located first panel beating frame (2) below establish sliding connection have second panel beating frame (3), be equipped with a plurality of quick assembly disassembly coupling mechanism between first panel beating frame (2) and second panel beating frame (3), be equipped with connection stop gear between the surface of first panel beating frame (2) and second panel beating frame (3), be fixed with strengthening mechanism between the surface of first panel beating frame (2) and safety cover body (1).

2. The sheet metal structural part for a protective cover according to claim 1, wherein: the quick assembly disassembly coupling mechanism includes screwed pipe (4), screwed pipe (4) run through the surface of first panel beating frame (2) and second panel beating frame (3) in proper order, the surface of screwed pipe (4) just is close to the annular fixedly connected with of position of center a plurality of stopper (5), the inner wall of first panel beating frame (2) and second panel beating frame (3) is seted up and is equipped with spacing groove (6) with stopper (5) matched with.

3. The sheet metal structural part for a protective cover according to claim 2, wherein: the outer surfaces of the first sheet metal frame (2) and the second sheet metal frame (3) are provided with a plurality of through holes (7) matched with the threaded pipes (4), and the limiting grooves (6) are formed in the inner walls of one ends of the through holes (7).

4. The sheet metal structural part for a protective cover according to claim 1, wherein: the connecting limiting mechanism comprises a plurality of limiting rods (8), one ends of the limiting rods (8) are sequentially fixedly connected with the lower surface of the first sheet metal frame (2), one ends of the limiting rods (8) penetrate through the second sheet metal frame (3), and a plurality of limiting holes (9) which are slidably connected with the limiting rods (8) are formed in the outer surface of the second sheet metal frame (3).

5. The sheet metal structural part for a protective cover according to claim 1, wherein: the reinforcing mechanism comprises a plurality of reinforcing plates (10), two sides of the outer surface of each reinforcing plate (10) are fixedly connected with the outer surface of the protective cover body (1) and the upper surface of the first sheet metal frame (2) respectively, and the reinforcing plates (10) are isosceles right triangles.

6. The sheet metal structural part for a protective cover according to claim 1, wherein: rectangular grooves (11) are formed in the periphery of the inner wall of the second sheet metal frame (3), and rectangular blocks which are in sliding connection with the inner wall of the rectangular grooves (11) are fixedly connected to the periphery of the outer surface of the protective cover body (1).

7. The sheet metal structural part for a protective cover according to claim 1, wherein: sealing gaskets are arranged between the outer surfaces of the first sheet metal frame (2) and the second sheet metal frame (3), and anti-corrosion coatings are coated on the outer surfaces of the protective cover body (1), the first sheet metal frame (2) and the second sheet metal frame (3).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202320236660.4U CN219189542U (en) | 2023-02-17 | 2023-02-17 | Sheet metal structural part for protective cover |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202320236660.4U CN219189542U (en) | 2023-02-17 | 2023-02-17 | Sheet metal structural part for protective cover |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN219189542U true CN219189542U (en) | 2023-06-16 |

Family

ID=86711283

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202320236660.4U Active CN219189542U (en) | 2023-02-17 | 2023-02-17 | Sheet metal structural part for protective cover |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN219189542U (en) |

-

2023

- 2023-02-17 CN CN202320236660.4U patent/CN219189542U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN219189542U (en) | Sheet metal structural part for protective cover | |

| CN102966744A (en) | Chlorine stop valve | |

| CN202343958U (en) | Main shaft compound sealing device | |

| CN202811772U (en) | Connection locking device | |

| CN209726806U (en) | A kind of sintering machine bellows end part self-adapting seal cover board | |

| CN203487245U (en) | Acid tank cover for acid-washing production line | |

| CN207661268U (en) | A kind of flange of easy access | |

| CN210265853U (en) | Crusher bearing block end cover sealing device | |

| CN209095429U (en) | A kind of multifunctional wrench | |

| CN209262482U (en) | A kind of medium pipeline Quick Connect Kit | |

| CN113701037A (en) | Butter filling pipe structure convenient for butt joint and assembling method thereof | |

| CN207839598U (en) | It is capable of the piecing devices of self- steering | |

| CN107611298A (en) | Battery bag sealing installation structure and electric automobile | |

| CN110643782A (en) | Novel tool for installing oxygen lance head | |

| CN210452739U (en) | Constant force actuating mechanism | |

| CN208138508U (en) | Without the full packet three-chip type pneumatic operated valve of delay | |

| CN212429711U (en) | Pipe orifice connecting and sealing device for laser pipe | |

| CN218454770U (en) | Real-time monitoring equipment for underground ventilation | |

| CN215980550U (en) | Five-axis machining surrounding fixed brake device | |

| CN213393577U (en) | Spring stop valve of mine spraying dust suppression system | |

| CN220775253U (en) | Tensile high-strength cable protection tube | |

| CN203903802U (en) | Combined device for guiding disassembly and assembly of pin shaft and crane | |

| CN216951769U (en) | Explosion-proof valve ball for petrochemical industry | |

| CN212963816U (en) | Novel visual pressure measuring filler neck | |

| CN219994182U (en) | Bearing seal end cover |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |