CN218043498U - Dough forming device of deep-fried twisted dough sticks machine - Google Patents

Dough forming device of deep-fried twisted dough sticks machine Download PDFInfo

- Publication number

- CN218043498U CN218043498U CN202121902308.7U CN202121902308U CN218043498U CN 218043498 U CN218043498 U CN 218043498U CN 202121902308 U CN202121902308 U CN 202121902308U CN 218043498 U CN218043498 U CN 218043498U

- Authority

- CN

- China

- Prior art keywords

- forming

- shovel

- transmission

- belt

- dough

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn - After Issue

Links

Images

Landscapes

- Manufacturing And Processing Devices For Dough (AREA)

Abstract

A dough forming device of a deep-fried twisted dough sticks machine belongs to the field of automatic deep-fried twisted dough sticks machines and comprises a forming mounting frame, a forming transmission device, a forming sliding seat, a forming guide rail, a transmission shaft sleeve, a forming support frame, a forming belt wheel, a forming belt, a forming shovel, a cutter, a shovel guide rail, a shovel sliding seat and a shovel transmission mechanism; the molding mounting frame is arranged on the rack and is fixedly connected with the rack; the forming transmission device is arranged on the forming mounting frame, is connected with the forming mounting frame and is connected with a power and transmission system of the deep-fried twisted dough sticks machine; the dough forming machine has the characteristic of realizing the dough forming function of an automatic deep-fried twisted dough sticks machine.

Description

Technical Field

The invention belongs to the field of wheaten food machinery, and particularly relates to a dough forming device of an automatic deep-fried dough stick machine, which can realize automatic deep-fried dough sticks.

Background

The deep-fried dough sticks are one of common wheaten foods of Chinese people and are mostly used as breakfast foods; the edible fried bread sticks are various, and are single short and small, single flaky, cake-shaped and double overlapped; most often, the two are superimposed; the invention mainly aims at the double-superposed type to realize automatic frying; the existing frying method of double superposed deep-fried dough sticks (for avoiding confusion, hereinafter referred to as deep-fried dough sticks) comprises the steps of firstly adding water and additives into flour, wherein the additives generally comprise leavening agents, foaming agents and other additives pursuing special effects, then stirring and kneading dough, fermenting the dough after dough kneading, rolling the fermented dough into dough strips, cutting the dough strips into single strip-shaped dough blanks, then superposing the two strip-shaped dough blanks together, bonding the middle parts of the two strip-shaped dough blanks together to form the deep-fried dough sticks after pressing, putting the deep-fried dough sticks into a deep-fried pan for frying, putting the deep-fried dough sticks into the deep-fried dough pan, and stretching the deep-fried dough sticks by hands, so that the deep-fried dough sticks are easy to expand more fully, have good taste, and are easy to fry and scorch; after being put into a hot oil pan, the twisted cruller blank is quickly expanded and needs to be turned over frequently to ensure the uniform frying; fishing out after frying, and draining redundant oil to finish frying the deep-fried dough sticks; in the whole frying process of the deep-fried dough sticks, the deep-fried dough sticks are required to be fried beside a hot oil pan, operators can be subjected to hot smoking and roasting, the working environment is severe, and the health of the operators can be adversely affected; on the other hand, the fried bread stick frying process has a plurality of working procedures, the temperature of a frying pan is difficult to control, each working procedure is improper to operate, the final fried bread stick frying is not ideal, and the requirement on the technical comprehensiveness of operators is high; moreover, repeated contact by human hands during frying of the deep-fried dough sticks causes disadvantages to the sanitation requirement on one hand and the operation process of the deep-fried dough sticks on the other hand.

Disclosure of Invention

Aiming at the problems in the conventional deep-fried dough stick frying, the invention provides a full-automatic deep-fried dough stick frying machine which can realize automatic blank making and automatic frying of deep-fried dough sticks and does not need operators to contact with the deep-fried dough stick blanks or the deep-fried dough sticks in the whole process; its specific technical scheme is, an automatic deep-fried twisted dough sticks machine, its characterized in that: the dough stick frying machine comprises a rack, a dough strip input device, a dough strip initial pressing device, a dough strip pressing and conveying device, a second conveying belt, a dough blank forming device, a dough blank bonding device, a third conveying belt, a fried bread stick blank sending-out and stretching device, a fried bread stick frying device, a fried bread stick storage device, a control system, a power and transmission system and an outer cover; the rack is arranged on the installation foundation or the ground and is connected with the installation foundation or the ground; the surface belt input device is arranged on the rack and is fixedly connected with the rack; the power and transmission of the surface belt input device are connected with a power and transmission system; the dough belt initial pressing device is arranged on the rack, is fixedly connected with the rack, and is positioned at the tail end of the dough belt input device, namely one end of the output dough belt; the dough belt pressing and conveying device is arranged on the rack, is fixedly connected with the rack and is connected with the power and transmission system; the surface belt pressing and conveying device is positioned above the second conveying belt; the second conveying belt is arranged on the rack, is fixedly connected with the rack, is connected with the power and transmission system, is positioned below the flour belt pressing and conveying device, and is connected with the flour belt conveying device at the front end and the third conveying belt at the rear end; the dough forming device is arranged on the rack, is fixedly connected with the rack, is connected with the power and transmission system, and is positioned above the second conveying belt; the dough blank bonding device is arranged on the rack, is fixedly connected with the rack, is positioned above the third conveying belt and is connected with the power and transmission system; the third conveyer belt is arranged on the rack, is fixedly connected with the rack, is positioned below the dough blank bonding device and is connected with the power and transmission system; the dough stick blank sending and stretching device is arranged on the frame, is fixedly connected with the frame, is positioned at the rear end of the dough blank bonding device (the front end and the rear end in the section refer to the front end and the rear end which enter the dough strip according to the running direction of the dough strip), and is connected with a power and transmission system; the deep-fried dough stick frying device is arranged on the rack, connected with the rack, positioned at the rear ends of the third conveying belt and the deep-fried dough stick blank sending and stretching device and connected with the control system; the fried bread stick storage device is arranged at the rear end of the fried bread stick frying device and is connected with the fried bread stick outlet end of the fried bread stick frying device, and redundant oil on the surface of the fried bread stick can be stored and controlled; the control system is arranged on the rack and connected with the rack; the control system comprises a main controller, a display unit, an information acquisition unit, an instruction output unit and a power control unit; the main controller is arranged in the control box and is connected with the display unit, the information acquisition unit, the instruction output unit and the power control unit; the display unit is arranged on the control box, and the display of the display unit is exposed on the outer surface of the control box and is connected with the main controller; the information acquisition unit is arranged in the control box and is connected with the main controller and an information acquisition element (such as a sensor) arranged on the functional component; the command output unit is arranged in the control box and is connected with the main controller and the power and transmission system; the power control unit is arranged in the control box, is connected with the power supply and the main controller, and is connected with a strong electric element of the power and transmission system; the power and transmission system is arranged on the frame and provides power and motion transmission for the executive element of the functional component; the outer cover is arranged on the rack, is connected with the rack, is positioned at the periphery of the functional component and can cover or cage the functional component; the functional components are one or more component combinations which are arranged in a flour belt input device, a flour belt initial pressing device, a flour belt pressing and conveying device, a second conveying belt, a flour blank forming device, a flour blank transferring and overlapping device, a flour blank bonding device, a third conveying belt, a deep-fried dough stick blank sending and stretching device, a deep-fried dough stick frying device, a deep-fried dough stick storage device, a control system and a power and transmission system on a rack and have certain functions.

Furthermore, the surface belt input device is a belt type conveying belt or a multi-chain plate type conveying belt.

Furthermore, the driving device of the surface belt input device is a stepping motor or a servo motor; this allows for precise control of the speed and cadence of the face tape input.

Furthermore, the automatic deep-fried twisted dough sticks machine also comprises a primary noodle-beating device, wherein the primary device is arranged on the noodle belt input device, is connected with the noodle belt input device and is positioned above the noodle belt input device, and flour can be beaten and sprinkled on the surface of the noodle belt on the noodle belt input device.

Furthermore, the automatic deep-fried twisted dough sticks machine further comprises a secondary noodle-beating device, wherein the secondary noodle-beating device is installed on the rack and connected with the rack, is positioned above the second conveying belt and is positioned at the rear end of the noodle belt pressing and conveying device.

Furthermore, the automatic deep-fried twisted dough sticks machine further comprises a face brushing device, the face brushing device is installed above the second conveying belt, bristles of the face brushing device are in contact with the upper surface of the face belt on the second conveying belt, and the width of the bristles is matched with the width of the face belt.

Furthermore, the primary face-flapping device comprises a face-flapping mounting rack, a face-flapping driver, a face-flapping box and a face-flapping roller; the face mounting frames are arranged on two sides of the face box and connected with the face box, and the lower ends of the face mounting frames are connected with the face belt input device; the face-flapping driver is arranged on one side of the face-flapping box and is connected with the face-flapping box or the face-flapping mounting rack, and the power output shaft is connected with one end of the face-flapping roller and is connected with the control system through a circuit; the face-flapping box is arranged on the face-flapping mounting frame and is connected with the face-flapping mounting frame; the face-beating box is a cavity body, and the lower end of the face-beating box is in a gradually-reduced form; the lower end of the face-beating box is provided with a face-beating opening, the face-beating opening is arranged at the bottom of the face-beating box and is composed of a plurality of small holes; the face-beating roller is arranged in the face-beating box, is positioned at the lower end of the inner cavity of the face-beating box, is connected with the face-beating box and can rotate in the face-beating box, and one end of the face-beating roller is connected with a power output shaft of the face-beating driver and can rotate in the face-beating box under the driving of the face-beating driver.

Furthermore, the face-flapping device for one time further comprises a face-flapping box cover, wherein the face-flapping box cover is arranged at the upper opening of the face-flapping box and can cover the upper opening of the face-flapping box.

Furthermore, a box cover handle is arranged on the face-beating box cover, and the box cover handle is arranged on the face-beating box cover and connected with the face-beating box cover.

Furthermore, the flapping surface driver is a stepping motor or a combination of a servo motor and a speed reducer.

Furthermore, the face-beating roller is provided with face-beating brushes which are made of elastic materials and are uniformly distributed on the outer circumference of the face-beating roller.

Further, the dough belt primary pressing device comprises a primary pressing upper pressing roller, a primary pressing transmission mechanism, a primary pressing dough belt receiving roller, a primary pressing dough box, a receiving roller position detector, a primary pressing mounting rack, a primary pressing sensor, a detector supporting seat and a counterweight device; the primary pressing upper compression roller is arranged on the primary pressing mounting frame and is connected with the rack or the surface belt input device, and the end part of the primary pressing upper compression roller is connected with the primary pressing transmission mechanism and can rotate on the primary pressing mounting frame under the driving of the primary pressing transmission mechanism; the primary pressing transmission mechanism is arranged at the end part of the upper pressing roller and is connected with the power and transmission system; the primary pressing surface belt bearing roller is arranged on the primary pressing mounting frame and is in floating connection with the primary pressing mounting frame, namely the upper position and the lower position of the primary pressing surface belt bearing roller freely float in a self-rotating state; the primary pressing surface box is arranged below the primary pressing surface belt receiving roller, is a cavity body with an upper opening and can receive flour scattered from the dough belt passing through the primary pressing surface belt receiving roller; the bearing roller position detector is arranged on the detector supporting seat, one end of the bearing roller position detector is sleeved with the end part of the bearing roller with the primary pressing surface, and the other end of the bearing roller position detector is hinged with the detector supporting seat; a primary pressure sensor trigger device is arranged on the bearing roller position detector and corresponds to the position of a touch element of the primary pressure sensor; the primary pressure mounting rack is arranged on the rack and connected with the rack or the surface belt input device; the primary pressure sensor is arranged on the primary pressure mounting frame, is connected with the primary pressure mounting frame and the control system, and can transmit control signals to the control system; the detector supporting seat is arranged on the primary pressure mounting frame and is connected with the primary pressure mounting frame or the surface belt input device; the counterweight device is arranged on the detector supporting seat, is hinged with the detector supporting seat and synchronously moves with the position detector of the carrying roller.

Furthermore, the distance between the primary pressing upper press roller and the upper surface of the conveying belt of the surface belt input device can be adjusted.

Furthermore, the counterweight device comprises a counterweight rod and a counterweight block; the counterweight rod is arranged on the detector supporting seat and is connected with the detector supporting seat or the position detector of the carrying roller; the counterweight block is arranged on the counterweight rod and is connected with the counterweight rod; the position of the balancing weight on the counterweight rod can be adjusted.

Furthermore, the dough belt pressing and conveying device comprises a dough belt pressing and conveying transmission device, a dough belt pressing and conveying installation frame, a sun shaft, a planetary roller transmission wheel, a planetary roller shaft frame, an elastic frame and a planetary roller system adjusting mechanism; the dough belt pressure feeding transmission device is arranged on the dough belt pressure feeding mounting frame, is connected with the power and transmission system, and can transmit the power or motion of the power and transmission system to the planetary roller system; the dough belt pressure feeding mounting frame is mounted on the rack, is fixedly connected with the rack, and can be used for mounting and supporting the planetary roller system, the planetary roller system adjusting mechanism and the dough belt pressure feeding transmission device; the sun shaft, the planetary roller transmission wheel, the planetary rollers and the planetary roller shaft form a planetary roller system; the sun shaft is arranged on the surface belt pressure feeding mounting frame, is connected with the surface belt pressure feeding mounting frame through a bearing and can rotate on the surface belt pressure feeding mounting frame, the end part of the sun shaft is connected with the surface belt pressure feeding transmission device, the periphery of the sun shaft is connected with the planetary roller shaft frame, and the planetary roller shaft frame can be driven to rotate; the planetary roller transmission wheel is arranged at the end part of the planetary roller, is connected with the shaft end of the planetary roller, is connected with the dough belt pressure feeding transmission device and can rotate under the driving of the dough belt pressure feeding transmission device; a plurality of planetary roller driving wheels are arranged at the end part of each planetary roller and connected with the planetary rollers; the plurality of planetary roller transmission wheels are connected and linked by a planetary roller transmission belt; the planet roller is arranged on the planet roller shaft frame and is connected with the planet roller shaft frame through a bearing, can rotate on the planet roller shaft frame and can rotate around a sun shaft along with the planet roller shaft frame; the planetary rollers are uniformly arranged on the planetary roller shaft bracket and are positioned on the circumference taking the axis of the sun shaft as the center; the planet roller shaft carrier is arranged on the sun shaft and is fixedly connected with the sun shaft; the elastic frame is arranged on the surface belt pressure feeding mounting frame and is connected with the surface belt pressure feeding mounting frame, and the lower part of the elastic frame is in contact with the planetary roller transmission belt and can elastically tension the planetary roller transmission belt; the planetary roller system adjusting mechanism is arranged on the surface belt pressure feeding mounting frame, is connected with the surface belt pressure feeding mounting frame and is connected with the movable shaft bracket of the solar shaft through the transmission mechanism, and the movable shaft bracket of the solar shaft can be pulled to move on the surface belt pressure feeding mounting frame.

Furthermore, the surface belt pressure transmission device is a gear transmission or a chain transmission.

Furthermore, the planetary roller transmission belt is a belt or a chain.

Furthermore, the planetary roller system adjusting mechanism comprises an adjusting hand wheel, an adjusting shaft bracket, a driving bevel gear, a driven bevel gear, a traction shaft, a tension spring and a movable shaft bracket; the adjusting hand wheel is arranged on the adjusting shaft, is connected with the adjusting shaft and is positioned at the end part of the adjusting shaft; the adjusting shaft is arranged on the adjusting shaft frame, is sleeved with the adjusting shaft frame and can rotate on the adjusting shaft frame; the adjusting shaft bracket is arranged on the flour belt pressure feeding mounting bracket and is connected with the flour belt pressure feeding mounting bracket; the driving bevel gear is arranged on the adjusting shaft and is fixedly connected with the adjusting shaft; the tooth part of the driving bevel gear is meshed with the tooth part of the driven bevel gear, so that the driven bevel gear can be driven to rotate; the driven bevel gear is arranged at the upper end of the traction shaft and is fixedly connected with the traction shaft; the tooth part of the driven bevel gear is meshed with the tooth part of the driving bevel gear; the traction shaft is arranged on the movable shaft bracket and is a screw rod with external threads on the periphery, the threads are matched with the threads on the movable shaft bracket and can be screwed with the movable shaft bracket, and the traction shaft can drive the movable shaft bracket to move up and down on the surface belt pressure feeding mounting bracket when rotating and is used for adjusting the distance between the planetary roller system and the surface belt; the upper end of the traction shaft is connected with a driven bevel gear; the tensioning spring is arranged on the traction shaft, is sleeved with the traction shaft and is a spiral compression spring; the movable shaft bracket is arranged on the flour belt compression mounting bracket, is embedded with the flour belt compression mounting bracket along the vertical direction and can move up and down in the embedded structure; the middle part of the movable shaft bracket is provided with a hole, and the hole is sleeved with the shaft end of the solar shaft (can be connected with the solar shaft through a bearing).

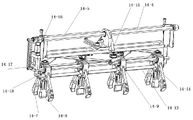

In order to better realize the dough forming function of the automatic deep-fried twisted dough sticks machine, a dough forming device is arranged and comprises a forming mounting frame, a forming transmission device, a forming sliding seat, a forming guide rail, a transmission shaft sleeve, a forming support frame, a forming belt wheel, a forming belt, a forming shovel, a cutter, a shovel guide rail, a shovel sliding seat and a shovel transmission mechanism; the molding mounting frame is arranged on the rack and fixedly connected with the rack; the forming transmission device is arranged on the forming mounting frame, connected with the forming mounting frame and connected with the power and transmission system; the forming slide seat is arranged on the forming guide rail, is sleeved with the forming guide rail and can move on the forming guide rail along the forming guide rail; the forming guide rail is arranged on the forming mounting frame, is positioned below the forming mounting frame and is connected with the forming mounting frame; the transmission shaft sleeve is arranged on a lifting frame of the oil bar blank transferring and lengthening device and is of a hollow structure, and the inside of the hollow part is sleeved with the key type transmission shaft; the key type transmission shaft is arranged in the transmission shaft sleeve and can slide in the transmission shaft sleeve, the upper end of the key type transmission shaft is connected with the forming transmission device, the lower end of the key type transmission shaft is connected with the shovel transmission mechanism and can rotate under the driving of the forming transmission device, so that the shovel transmission mechanism is driven to move, and the forming shovel is opened and closed; the forming support frame is arranged below the transmission shaft sleeve and is fixedly connected with the lifting frame of the oil bar blank transferring and lengthening device; the forming belt wheels are arranged on the forming support frame, connected with the forming support frame and provided with a plurality of belt wheels; the molding belt wheel can rotate; the forming belt is arranged at the periphery of the forming belt wheel and the forming shovel and is wound on the forming belt wheel and the forming shovel in a winding way; the forming shovel is arranged on the shovel sliding seat and is connected with the shovel sliding seat; the forming shovels are arranged in pairs and oppositely; the cutter is arranged on the forming support frame, is connected with the forming support frame and is positioned on one side of the front end of the forming shovel, and the cutting edge of the cutter faces downwards; the shovel guide rail is arranged on the forming support frame and is connected with the forming support frame; the shovel sliding seat is arranged on the forming guide rail and can slide on the forming guide rail along the forming guide rail; shovel drive mechanism install on the shaping support frame, one end is connected with key formula transmission shaft, the other end is connected with the shovel slide, can drive the motion of shovel slide under the drive of key formula transmission shaft.

Further, the forming transmission device is a mechanical transmission device.

Furthermore, the forming transmission device comprises a cam lever transmission mechanism.

Furthermore, the forming belt is a flexible thin-wall flat belt.

Further, the forming shovel is wedge-shaped.

Furthermore, the shovel transmission mechanism is a multi-connecting-rod transmission mechanism.

Furthermore, the dough blank bonding device is arranged on a lifting frame of the fried dough stick blank transferring and stretching device, is connected with the lifting frame and comprises a bonding pressing plate, a bonding support, a bonding pressing block, a bonding connecting shaft and a bonding spring; the bonding pressure plate is arranged at the lower end of the bonding support and is connected with the bonding support; the middle part of the bonding pressing plate is provided with a guide groove, the guide groove is arranged in the middle part of the bonding pressing plate, penetrates through the thickness of the bonding pressing plate, and the size of the guide groove is matched with that of the bonding pressing block, so that the bonding pressing block can move in the guide groove; the bonding support is arranged above the bonding pressure plate and is fixedly connected with the bonding pressure plate; the upper part of the bonding bracket is provided with a bonding connecting shaft guide hole; the bonding and pressing block is arranged on the bonding and connecting shaft and is fixedly connected with the bonding and connecting shaft; the bonding connecting shaft is arranged in a guide hole on the bonding support, the lower end of the bonding connecting shaft is connected with the bonding pressing block, and the upper end of the bonding connecting shaft is fixedly connected with a lifting frame of the oil bar blank transferring and elongating device; the bonding spring is sleeved on the bonding connecting shaft, the lower end of the bonding spring is in contact with the bonding support, and the upper end of the bonding spring is in contact with the lifting frame of the oil bar blank transferring and lengthening device and is a spiral compression spring.

Furthermore, the dough blank bonding device also comprises a water wetting device, wherein the water wetting device is arranged at the lower end of the bonding connecting shaft, is connected with the bonding connecting shaft and can move up and down under the driving of the bonding connecting shaft; the water dipping device comprises a water dipping mounting seat, a water dipping rod and a water dipping connecting rod; the water dipping mounting seat is arranged on the bonding connecting shaft and connected with the water dipping connecting shaft; the water dipping rod is arranged at the lower end of the water dipping connecting rod, is connected with the water dipping connecting rod and is horizontally arranged; the water dipping rod is a hollow cavity, the lower surface of the water dipping rod is provided with a plurality of water outlet holes, and the water outlet holes are communicated with the inner cavity of the water dipping rod; the inner cavity of the water dipping rod is communicated with the inner cavity of the water dipping connecting rod; the length and width of the water dipping rod are matched with the size of the deep-fried dough stick dough blank; the water dipping connecting rod is arranged on the water dipping mounting seat, is connected with the water dipping mounting seat and can adjust the height position on the water dipping mounting seat; the water dipping connecting rod is a hollow cavity body, the lower end of the water dipping connecting rod is connected with the water dipping rod, the inner cavity of the water dipping connecting rod is communicated with the inner cavity of the water dipping rod, and the upper end of the water dipping connecting rod is connected with a water source.

Furthermore, the fried bread stick storage device comprises a storage bracket, a storage box and an oil control device; the storage bracket is arranged at the lower part of the storage box and is connected with the storage box; the storage box is arranged on the storage support and is a thin-wall cavity body with an opening at the upper part, and the size of the storage box body is matched with that of the finished fried bread stick; the oil control device is arranged in the storage box, and is a hollow cavity body made of porous or grid-shaped materials, and one end of the hollow cavity body is higher than the other end of the hollow cavity body and is in a low-inclination shape.

Furthermore, the fried bread stick storage device also comprises an oil receiving disc, wherein the oil receiving disc is arranged below the storage box, and an oil outlet is formed in the lower part of the storage box.

Furthermore, the fried bread stick frying device comprises an oil temperature controller, a fried bread stick outer cover, a stepping fried bread stick conveying mechanical arm, a fried bread stick shell, a stepping mechanical arm transmission device, a fried bread stick conveying mechanical arm, a fried bread stick conveying device, an upper outer cover, a frying control system and an oil smoke discharge device; the oil temperature controller is arranged on the outer cover of the fryer, is connected with the outer cover of the fryer and is connected with the power supply and the frying control system; the fryer hood is arranged outside the fryer shell and comprises a framework and a cover plate; the stepping fried bread stick feeding mechanical arm is arranged in the inner cavity of the fryer and is provided with more than two; the fryer shell is arranged inside the fryer outer cover, is a cavity body with an upper opening and is connected with the fryer outer cover; the stepping manipulator transmission device is arranged on the outer side of the fryer shell, is connected with each stepping fried bread stick feeding manipulator and is connected with the frying control system, and can drive the stepping fried bread stick feeding manipulators and control the motion state of the stepping fried bread stick feeding manipulators; the fried bread stick delivering mechanical arm transmission device is arranged on the outer side of the frying pan shell, is connected with the fried bread stick delivering mechanical arm and a frying control system, and can drive the fried bread stick delivering mechanical arm and control the motion state of the fried bread stick delivering mechanical arm; the fried bread stick sending-out mechanical arm is arranged on the fryer shell, is connected with the fryer shell, is positioned at one end of the fryer shell and is adjacent to the fried bread stick storage device; the fried bread stick delivery device is arranged on the fryer outer cover or the fryer shell, is connected with the fryer outer cover or the fryer shell, and extends to the upper part of the fried bread stick storage device; the upper outer cover is arranged above the fryer shell, is connected with the fryer outer cover and the oil smoke discharge device and can cover the upper opening of the fryer shell; the frying control system is arranged on the outer cover of the fryer or the upper outer cover, and is internally provided with an element for controlling and driving the mechanical hand and the exhaust fan, an element for controlling the oil temperature and a power control element which are respectively connected with the power, the mechanical hand driving motor and the oil temperature controller element; the oil fume discharge device is arranged above the fryer shell and comprises an air exhaust fan and an air outlet; the exhaust fan is arranged on the upper outer cover, is positioned at the air outlet and is connected with the frying control system; the air outlet is arranged on the upper shell, the inner end of the air outlet is communicated with the air outlet end of the air exhaust fan, and the outer end of the air outlet is communicated with a system smoke exhaust pipeline.

Furthermore, the stepping fried bread stick feeding mechanical arm comprises a stepping arm and a stepping claw, wherein the arm is arranged on the fryer shell, is connected with the mechanical arm transmission device and can rotate on the fryer shell; the stepping paw is arranged on the stepping arm and is in a grid shape, one end of the stepping paw is connected with the stepping arm, and the other end of the stepping paw is suspended; step-by-step hand claw be the arc in step-by-step arm radial, when step-by-step hand claw swings, the fried bread stick in the step-by-step hand claw can be automatic upset in step-by-step hand claw arc.

Furthermore, the device for transferring and elongating the deep-fried twisted dough sticks comprises an elongating mounting frame, a clamping hand transmission beam, a clamping hand opening and closing transmission shaft, a clamping hand opening and closing control frame, a clamping hand support frame, clamping hand claws, a dough pressing claw, a clamping hand seat, a clamping hand moving transmission mechanism, a lifting frame, a deep-fried twisted dough sticks lifting mechanism, an elongating transmission device, a clamping hand opening and closing shaft, a clamping hand support shaft and a clamping hand support shaft seat; the elongated mounting rack is arranged on the rack and connected with the rack; the clamping hand transmission frame is arranged on the elongated mounting frame and connected with the elongated mounting frame, one end of the clamping hand transmission frame is connected with the elongated transmission device, the other end of the clamping hand transmission frame is connected with the clamping hand transmission mechanism, the power and the motion of the elongated transmission device can be transmitted to the clamping hand moving transmission mechanism, and then the clamping hand claw and the dough pressing claw are driven to transversely move; the gripper transmission beam is arranged above the gripper support frame and connected with the gripper assembly, so that the gripper jaws can be opened and closed; the gripper opening and closing transmission shaft is arranged on the lifting frame, is fixedly connected with the lifting frame through a bearing seat, is positioned on the side edge of the gripper opening and closing control frame, and is matched with the gripper opening and closing control frame to realize the opening and closing of the gripper jaws; the middle part of the clamping transmission shaft is provided with a power swing rod, and the power swing rod is connected with the lengthening transmission mechanism through a pull rod; the clamping hand opening and closing control frame is arranged on the clamping hand supporting frame and is connected with the clamping hand supporting frame through the sliding seat, and the clamping hand opening and closing control frame can move up and down on the clamping hand supporting frame along the sliding seat; the gripper support frame is arranged on the lifting frame and is fixedly connected with the lifting frame; the clamping claws are arranged on the clamping claw seats, are arranged in pairs, are clamped with the clamping claw opening and closing shaft and can swing on the clamping claw seats under the driving of the clamping claw opening and closing shaft; the surface pressing claw is arranged on the clamping jaw seat, is connected with the clamping jaw seat and is positioned between the two clamping jaws; the clamping hand seats are arranged on the clamping hand supporting shaft and are provided with a plurality of clamping hand claws and a plurality of dough pressing claws, and each clamping hand seat is provided with a clamping hand claw and a dough pressing claw which can slide on the clamping hand supporting shaft; the gripper moving transmission mechanism is arranged on the gripper seats and is simultaneously connected with the plurality of gripper seats, and the power input end of the gripper moving transmission mechanism is connected with the gripper transmission beam and further connected with the lengthening transmission device, so that the plurality of gripper seats can be separated or folded under the driving of the lengthening transmission device; the lifting frame is arranged on the forming slide carriage through the lifting upright post, is connected with the forming slide carriage, can move up and down on the forming slide carriage and can horizontally move on the forming guide rail along with the forming slide carriage; the upper end of the lifting upright post of the lifting frame is connected with the elongation transmission device, and the horizontal movement and the up-and-down movement or the two movements can be realized simultaneously under the driving of the elongation transmission device; the oil bar blank supporting mechanism is arranged on the elongation mounting frame, connected with the elongation mounting frame and connected with the elongation transmission device; the oil bar blank supporting mechanism is provided with more than two supporting claws, the supporting claws can swing on the elongated mounting frame, the lower swinging position is positioned at the lower part of the dough pressing claw, and the upper swinging position is separated from the gripper claws; the stretching conveying device is arranged on the stretching mounting frame, is fixedly connected with the stretching mounting frame, and is connected with the power and transmission system and the control system; the clamping hand opening and closing shaft is arranged on the clamping hand seat, penetrates through the plurality of clamping hand seats, and is connected with the clamping hand opening and closing control frame at the end part; the clamping hand supporting shaft is arranged on the clamping hand supporting shaft seat and is connected with the clamping hand supporting shaft seat; the clamping hand supporting shaft seat is arranged on the clamping hand supporting frame, is fixedly connected with the clamping hand supporting frame and is positioned below the clamping hand supporting frame.

Further, said elongated transmission means is a mechanical transmission.

Furthermore, the elongation transmission device is composed of a plurality of cam transmission mechanisms driven by servo motors or stepping motors.

Furthermore, the anti-sticking knife device comprises an anti-sticking mounting seat, an anti-sticking knife shaft and an anti-sticking knife roller; the anti-sticking mounting seat is arranged on the second conveying belt and is connected with the frameworks on two sides of the second conveying belt; the anti-sticking cutter shaft of the conveying belt is arranged on the anti-sticking mounting seat and is connected with the anti-sticking mounting seat; the anti-sticking cutter roller of the conveying belt is arranged on the anti-sticking cutter shaft and can rotate freely; the outer surface of the anti-sticking knife roller is positioned on the side surface of the cutting knife, and is in contact with the side surface of the cutting knife or has a gap smaller than the width of the dough.

Advantageous effects

The invention has the beneficial effect that the dough forming function of the automatic deep-fried twisted dough sticks machine can be realized.

Drawings

FIG. 1 is a schematic view of the external structure of an automatic deep fryer;

FIG. 2 is a schematic view of an automatic deep-fried twisted dough stick machine with a portion of the housing removed;

FIG. 3 is a schematic view of the automatic deep fryer with a portion of the casing removed;

FIG. 4 is a schematic diagram of the appearance structure of the face-flapping device;

FIG. 5 is a schematic diagram of the internal structure of the face-flapping device;

FIG. 6 is a schematic view of the structure of the preliminary press device for noodle strings;

FIG. 7 is a schematic view of the structure of the dough belt press conveyor;

FIG. 8 is a schematic view showing another direction of the surface belt press conveyor;

FIG. 9 is a schematic view of the combination of the dough forming apparatus and dough bonding apparatus with the transfer and elongation apparatus for the dough sticks;

FIG. 10 is a schematic view showing the structure of the dough forming apparatus of the present invention;

FIG. 11 is a schematic view showing the structure of the dough forming apparatus of the present invention;

FIG. 12 is a schematic view showing the structure of the dough bonding apparatus;

FIG. 13 is a schematic view of the combined structure of a deep-fried twisted dough stick storage device and a fryer;

FIG. 14 is a schematic view of the combined structure of a deep-fried dough stick storage device and a fryer;

FIG. 15 is a schematic view of the configuration of the apparatus for transferring and elongating a dough strip;

FIG. 16 is a schematic view showing the configuration of the gripping portion of the apparatus for transferring and elongating a twisted dough piece;

FIG. 17 is a schematic view of the structure of the anti-sticking device;

in the figure, 1, a dough throwing device, 2, a frame, 3, an observation window, 4, a dough storage device, 5, a dough frying device, 6, a control system, 7, an outer cover, 8, a second conveying belt, 9, a dough forming device, 10, a dough bonding device, 11, a frying pan, 12, an oil control device, 13, a dough lifting device, 14, a dough transferring and stretching device, 15, a power and transmission system, 16, a second dough throwing device, 17, an elastic bracket, 18, a dough pressing and conveying device, 19, a dough preliminary pressing device, 20, a dough input device, 21, an anti-sticking knife device, 22, a dough conveying and overlapping device, 23, a third conveying belt, 24, a second conveying belt movement control device, 25, a dough sending mechanism, 1-1, a face mounting rack, 1-2, a face driver, 1-3, a face box, 1-4, a face box cover, 1-5, a box cover handle, 1-6, a face roller, 19-1, a primary pressing upper compression roller, 19-2, a primary pressing transmission mechanism, 19-3, a primary pressing belt receiving roller, 19-4, a primary pressing face box, 19-5, a receiving roller position detector, 19-6, a primary pressing mounting rack, 19-7, a primary pressing sensor, 19-8, a detector supporting seat, 19-9, a counterweight device, 15-1, a face belt pressing transmission device, 15-2, a face belt pressing mounting rack, 15-3, a sun shaft, 15-4, a planetary roller transmission wheel, 15-5, a planetary roller, 15-6, a planetary roller shaft rack, 15-7, an elastic rack, 15-8, a planetary roller system adjusting mechanism, 15-9, a driven bevel gear, 15-10 of movable bevel gear, 15-11 of adjusting shaft bracket, 15-12 of adjusting shaft, 15-13 of tensioning spring, 15-14 of movable shaft bracket, 9-1 of forming mounting bracket, 9-2 of forming transmission device, 9-3 of forming slide seat, 9-4 of forming guide rail, 9-5 of transmission shaft sleeve, 9-6 of forming support frame, 9-7 of forming belt wheel, 9-8 of forming belt, 9-9 of forming shovel, 9-10 of cutter, 9-11 of shovel guide rail, 9-12 of shovel slide seat, 9-13 of shovel transmission mechanism, 10-1 of water dipping device, 10-2 of bonding press plate, 10-3 of bonding support frame, 10-4 of bonding press block, 10-5 of bonding connecting shaft, 10-6 of bonding spring, 4-1, a storage bracket, 4-2, a storage box, 5-1, an oil temperature controller, 5-2, a fryer cover, 5-3, a stepping fried dough stick feeding mechanical arm, 5-4, a fryer shell, 5-5, a mechanical arm transmission device, 5-6, a fried dough stick feeding mechanical arm transmission device, 5-7, a fried dough stick feeding mechanical arm, 5-8, a fried dough stick feeding device, 5-9, an upper cover, 5-10, a frying control system, 5-11, an oil smoke discharging device, 14-1, an extension mounting frame, 14-2, a gripper transmission frame, 14-3, a gripper transmission beam, 14-4, a gripper opening and closing transmission shaft, 14-5, a gripper opening and closing control frame, 14-6, a gripper support frame and 14-7 gripper jaws, 14-8 of a dough pressing claw, 14-9 of a clamping hand moving transmission mechanism, 14-10 of a lifting frame, 14-11 of a twisted dough strip blank supporting mechanism, 14-12 of an elongation transmission device, 14-13 of a clamping hand opening and closing shaft, 14-14 of a clamping hand supporting shaft, 14-15 of a power swing rod, 14-16 of a sliding seat, 14-17 of a clamping hand supporting shaft seat, 14-18 of a clamping hand seat, 21-1 of an anti-sticking mounting seat, 21-2 of an anti-sticking cutter shaft and 21-3 of an anti-sticking cutter roller.

Detailed Description

In order to better illustrate the technical solution of the present invention, the specific embodiment of the present invention will be further described with reference to the accompanying drawings, as shown in fig. 1-3, the frame 1 is installed on the installation base or the ground, and is connected with the installation base or the ground; the dough belt input device 20 is arranged on the frame 1 and is fixedly connected with the frame 1; the power and transmission of the surface belt input device 20 are connected with a power and transmission system 15; the dough belt initial pressing device 19 is arranged on the frame 1, is fixedly connected with the frame 1 and is positioned at the tail end of the dough belt input device 20, namely one end of the output dough belt; the dough belt pressing and conveying device 18 is arranged on the frame 1, is fixedly connected with the frame 1 and is connected with the power and transmission system 15; the dough strip pressing and conveying device 18 is positioned above the second conveying belt 8; the second conveyer belt 8 is arranged on the frame 1, is fixedly connected with the frame 1, is connected with the power and transmission system 15, is positioned below the flour belt pressing and conveying device 18, and has the front end connected with the flour belt conveying device 20 and the rear end connected with the third conveyer belt 23; the dough forming device 9 is arranged on the frame 1, is fixedly connected with the frame 1, is connected with the power and transmission system 15 and is positioned above the second conveying belt 8; the dough blank bonding device 10 is arranged on the frame 1, is fixedly connected with the frame 1, is positioned above the third conveying belt 23 and is connected with the power and transmission system 15; the third conveyer belt 23 is arranged on the frame 1, is fixedly connected with the frame 1, is positioned below the dough blank bonding device 10 and is connected with the power and transmission system 15; the oil bar blank sending-out and stretching device 14 is arranged on the frame 1, is fixedly connected with the frame 1, is positioned at the rear end of the dough blank bonding device 10 and is connected with a power and transmission system 15; the deep-fried dough stick frying device 5 is arranged on the rack 1, is connected with the rack 1, is positioned at the rear end of the third conveyer belt 23 and the deep-fried dough stick blank sending and stretching device 14, and is connected with the control system 6; the fried bread stick storage device 4 is arranged at the rear end of the fried bread stick frying device 5 and is connected with the fried bread stick end of the fried bread stick frying device 5, and redundant oil on the surface of the fried bread stick can be stored and controlled to be dry; the control system 6 is arranged on the frame 1 and connected with the frame 1; the power and transmission system 15 is arranged on the frame 1 and provides power and motion transmission for the executive elements of the functional components; the outer cover 7 is arranged on the frame 1, is connected with the frame 1, is positioned at the periphery of the functional component and can cover or cover the functional component; the functional components are one or more component combinations which are arranged in a flour belt input device 20, a flour belt initial pressing device 19, a flour belt pressing and conveying device 18, a second conveying belt 8, a flour blank forming device 9, a flour blank bonding device 10, a third conveying belt 23, a deep-fried dough stick blank sending and stretching device 14, a deep-fried dough stick frying device 5, a deep-fried dough stick storage device 4, a control system 6 and a power and transmission system 15 which are arranged on a machine frame and have certain functions; the front end and the rear end are referred to herein as the entrance end and the exit end, respectively, in terms of the running direction of the surface belt.

The dough forming device selected in the embodiment comprises a forming mounting frame 9-1, a forming transmission device 9-2, a forming slide seat 9-3, a forming guide rail 9-4, a transmission shaft sleeve 9-5, a forming support frame 9-6, a forming belt wheel 9-7, a forming belt 9-8, a forming shovel 9-9, a cutting knife 9-10, a shovel guide rail 9-11, a shovel slide seat 9-12 and a shovel transmission mechanism 9-13; the molding mounting frame 9-1 is mounted on the rack 1 and fixedly connected with the rack 1; the forming transmission device 9-2 is arranged on the forming mounting frame 9-1, is connected with the forming mounting frame 9-1 and is connected with the power and transmission system 15; the forming slide seat 9-3 is arranged on the forming guide rail 9-4 and is sleeved with the forming guide rail 9-4, and can move along the forming guide rail 9-4 on the forming guide rail 9-4; the forming guide rail 9-4 is arranged on the forming mounting frame 9-1, is positioned below the forming mounting frame 9-1 and is connected with the forming mounting frame 9-1; the driving shaft sleeve 9-5 is arranged on a lifting frame 14-10 of the oil bar blank transferring and lengthening device 14, a hollow structure is selected, and the inside of the hollow part is sleeved with a key type driving shaft (a spline shaft is taken as an example in the example); the key type transmission shaft is arranged in a transmission shaft sleeve 9-5 and can slide in the transmission shaft sleeve 9-5, the upper end of the key type transmission shaft is connected with a forming transmission device 9-2, the lower end of the key type transmission shaft is connected with a shovel transmission mechanism 9-13, and the key type transmission shaft can be driven by the forming transmission device 9-2 to rotate so as to drive the shovel transmission mechanism 9-13 to move and realize the opening and closing of the forming shovel 9-9; the forming support frame 9-6 is arranged below the transmission shaft sleeve 9-5 and is fixedly connected with a lifting frame 14-10 of a twisted dough stick blank transferring and stretching device 14; the forming belt wheels 9-7 are arranged on the forming support frame 9-6 and are connected with the forming support frame 9-6, and the number of the forming belt wheels is multiple; the forming belt wheel 9-7 can rotate; the forming belt 9-8 is arranged at the periphery of the forming belt wheel 9-7 and the forming shovel 9-9 and wound on the forming belt wheel 9-7 and the forming shovel 9-9; the forming shovel 9-9 is arranged on a shovel sliding seat 9-12 and is connected with the shovel sliding seat 9-12; a pair of forming shovels 9-9 are oppositely arranged; the cutter 9-10 is arranged on the forming support frame 9-6, is connected with the forming support frame 9-6 and is positioned at one side of the front end of the forming shovel 9-9, and the cutting edge is downward; installing the shovel guide rail 9-11 on the forming support frame 9-6 and connecting the shovel guide rail with the forming support frame 9-6; the shovel sliding seat 9-12 is arranged on the forming guide rail 9-11 and can slide on the forming guide rail 9-11 along the forming guide rail 9-11; the shovel transmission mechanism 9-13 is arranged on the forming support frame 9-6 and is a connecting rod transmission mechanism, one end of the connecting rod transmission mechanism is connected with the key type transmission shaft, the other end of the connecting rod transmission mechanism is connected with the shovel sliding seat 9-12, and the shovel sliding seat 9-12 can be driven by the key type transmission shaft to move along the forming guide rail 9-11.

When the noodle forming device is used, a noodle belt is conveyed by the second conveying belt 8 and reaches the position below the noodle blank forming device 9, the noodle blank forming device 9 descends, the pair of forming shovels 9-9 is separated, the cutter 9-10 transversely cuts the noodle belt to form a strip-shaped noodle blank, the forming shovels 9-9 are folded to shovel the noodle blank from two ends, the lifting frame 14-10 ascends, the forming conveying device 9-2 drives the lifting frame 14-10 to move to the rear end of the second conveying belt 8, then the lifting frame 14-10 descends, the pair of forming shovels 9-9 is separated to put down the noodle blank, the action is repeated, the second noodle blank is stacked on the first noodle blank and is wetted between the two noodle blanks, and the two noodle blanks are bonded by the noodle blank bonding device 10, so that the noodle blank forming function is completed; the forming belt 9-8 is adopted and wound around the periphery of the forming shovel 9-9, so that when the forming shovel 9-9 shovels the dough blank, the dough blank is prevented from being deformed due to extrusion of the dough blank, and because the forming belt 9-8 is in a moving state, no extrusion force is applied to the dough blank; a plurality of forming belt wheels 9-7 are adopted to adapt to the movement of the forming shovels 9-9 in the opening and closing process, and the forming belts 9-8 can be always attached to the periphery of the forming shovels 9-9 and move through the transformation of the plurality of forming belt wheels 9-7; the forming transmission device 9-2 transmits the movement to the shovel transmission mechanism 9-13 through a spline shaft, and pokes the shovel sliding seats 9-12 to move oppositely through the action of the connecting rod mechanism, so that the opening and closing of the forming shovels 9-9 are realized.

Claims (6)

1. The utility model provides a deep-fried twisted dough sticks machine's face base forming device which characterized in that: the forming device comprises a forming mounting frame, a forming transmission device, a forming sliding seat, a forming guide rail, a transmission shaft sleeve, a forming support frame, a forming belt wheel, a forming belt, a forming shovel, a cutter, a shovel guide rail, a shovel sliding seat and a shovel transmission mechanism; the molding mounting frame is arranged on the rack and fixedly connected with the rack; the forming transmission device is arranged on the forming mounting frame, is connected with the forming mounting frame and is connected with a power and transmission system of the deep-fried twisted dough sticks machine; the forming slide seat is arranged on the forming guide rail, is sleeved with the forming guide rail and can move on the forming guide rail along the forming guide rail; the forming guide rail is arranged on the forming mounting frame, is positioned below the forming mounting frame and is connected with the forming mounting frame; the transmission shaft sleeve is arranged on a lifting frame of the oil bar blank transferring and lengthening device and is of a hollow structure, and the inside of the hollow part is sleeved with the key type transmission shaft; the key type transmission shaft is arranged in the transmission shaft sleeve and can slide in the transmission shaft sleeve, the upper end of the key type transmission shaft is connected with the forming transmission device, the lower end of the key type transmission shaft is connected with the shovel transmission mechanism and can rotate under the driving of the forming transmission device, so that the shovel transmission mechanism is driven to move, and the forming shovel is opened and closed; the forming support frame is arranged below the transmission shaft sleeve and is fixedly connected with the lifting frame of the oil bar blank transferring and stretching device; the forming belt wheels are arranged on the forming support frame, are connected with the forming support frame and are provided with a plurality of belt wheels; the molding belt wheel can rotate; the forming belt is arranged at the periphery of the forming belt wheel and the forming shovel and is wound on the forming belt wheel and the forming shovel in a winding way; the forming shovel is arranged on the shovel sliding seat and is connected with the shovel sliding seat; the forming shovels are arranged in pairs and oppositely; the cutter is arranged on the forming support frame, is connected with the forming support frame and is positioned on one side of the front end of the forming shovel, and the cutting edge of the cutter faces downwards; the shovel guide rail is arranged on the forming support frame and is connected with the forming support frame; the shovel sliding seat is arranged on the forming guide rail and can slide on the forming guide rail along the forming guide rail; shovel drive mechanism install on the shaping support frame, one end is connected with key formula transmission shaft, the other end is connected with the shovel slide, can drive the motion of shovel slide under the drive of key formula transmission shaft.

2. The noodle forming apparatus of claim 1, wherein: the forming transmission device is a mechanical transmission device.

3. The noodle forming apparatus of claim 1, wherein: the forming transmission device comprises a cam lever transmission mechanism.

4. The noodle forming apparatus of claim 1, wherein: the forming belt is a flexible thin-wall flat belt.

5. The noodle forming apparatus of claim 1, wherein: the forming shovel is wedge-shaped.

6. The noodle forming apparatus of claim 1, wherein: the shovel transmission mechanism is a multi-connecting-rod transmission mechanism.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121902308.7U CN218043498U (en) | 2021-08-15 | 2021-08-15 | Dough forming device of deep-fried twisted dough sticks machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121902308.7U CN218043498U (en) | 2021-08-15 | 2021-08-15 | Dough forming device of deep-fried twisted dough sticks machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN218043498U true CN218043498U (en) | 2022-12-16 |

Family

ID=84412009

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202121902308.7U Withdrawn - After Issue CN218043498U (en) | 2021-08-15 | 2021-08-15 | Dough forming device of deep-fried twisted dough sticks machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN218043498U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113647431A (en) * | 2021-08-15 | 2021-11-16 | 王军杰 | Dough forming device of deep-fried twisted dough sticks machine |

-

2021

- 2021-08-15 CN CN202121902308.7U patent/CN218043498U/en not_active Withdrawn - After Issue

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113647431A (en) * | 2021-08-15 | 2021-11-16 | 王军杰 | Dough forming device of deep-fried twisted dough sticks machine |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105010446B (en) | Full-automatic fried bread stick forming machine | |

| CN218043498U (en) | Dough forming device of deep-fried twisted dough sticks machine | |

| CN108684772B (en) | Full-automatic deep-fried dough stick blank synthesizer | |

| CN113647421A (en) | Automatic deep-fried twisted dough sticks machine | |

| CN218736848U (en) | Device for sending out and elongating deep-fried twisted dough sticks of deep-fried twisted dough sticks machine | |

| CN210043082U (en) | Automatic production equipment for filling cake type cakes | |

| CN210054480U (en) | Tea leaf withering equipment | |

| CN108850047B (en) | Household dumpling machine | |

| CN219020059U (en) | Automatic deep-fried dough stick frying machine | |

| CN113647431B (en) | Dough forming device of deep-fried dough stick machine | |

| CN113678849A (en) | Oil bar blank transferring and lengthening device | |

| CN113647422A (en) | Deep-fried twisted dough sticks frying device of deep-fried twisted dough sticks machine | |

| CN106689254A (en) | Base production device for deep-fried dough sticks | |

| CN205547144U (en) | Full -automatic fried bread stick former | |

| CN204811694U (en) | Full -automatic deep -fried twisted dough sticks make -up machine | |

| CN214178830U (en) | Full-automatic fried bread stick preparation system | |

| CN206518041U (en) | A kind of deep-fried twisted dough sticks dough producing device | |

| CN216018802U (en) | Water dipping device of deep-fried twisted dough sticks machine | |

| TWI558321B (en) | Automatic triangular trapezoidal pastry cutting and reciprocating crawling device and method | |

| CN218043494U (en) | Noodle belt pressing and conveying device of deep-fried twisted dough sticks machine | |

| CN216018811U (en) | Dough binding device of deep-fried twisted dough sticks machine | |

| CN218043495U (en) | Planetary roller system regulating mechanism of deep-fried twisted dough sticks machine | |

| CN113142262A (en) | Food stuffing wrapping device | |

| CN213074233U (en) | Cake filling and forming device | |

| CN210043877U (en) | Household dumpling machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| AV01 | Patent right actively abandoned | ||

| AV01 | Patent right actively abandoned | ||

| AV01 | Patent right actively abandoned |

Granted publication date: 20221216 Effective date of abandoning: 20230620 |

|

| AV01 | Patent right actively abandoned |

Granted publication date: 20221216 Effective date of abandoning: 20230620 |