CN217386741U - Watertight composite insulation flexible fireproof cable - Google Patents

Watertight composite insulation flexible fireproof cable Download PDFInfo

- Publication number

- CN217386741U CN217386741U CN202221508921.5U CN202221508921U CN217386741U CN 217386741 U CN217386741 U CN 217386741U CN 202221508921 U CN202221508921 U CN 202221508921U CN 217386741 U CN217386741 U CN 217386741U

- Authority

- CN

- China

- Prior art keywords

- layer

- water

- core

- insulation

- cable

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A30/00—Adapting or protecting infrastructure or their operation

- Y02A30/14—Extreme weather resilient electric power supply systems, e.g. strengthening power lines or underground power cables

Landscapes

- Insulated Conductors (AREA)

Abstract

The utility model discloses a flexible fireproof cable of watertight type composite insulation, including cable core, composite insulation layer, flame retardant coating, separate oxygen layer and oversheath, the cable core comprises many insulation core, and every insulation core comprises the conductor that blocks water and around the package at the outside composite insulation layer of the conductor that blocks water to crowded package has and is annular flame retardant coating between many insulation core that constitute the cable core and on the insulation core the outside from interior to exterior in proper order cladding of flame retardant coating has and separates oxygen layer and oversheath. Adopt fireproof cable, not only have superior radial and vertical water blocking performance, still have excellent fire-retardant fire-resistant, fire prevention and weather-resistant corrosion-resistant advantage, greatly satisfied the power consumption demand of present stage, can satisfy and use in the multiple abominable environment of laying, have simple structure, safe and reliable, the stable performance, its practicality is strong, can satisfy the user demand, has extensive application place.

Description

Technical Field

The utility model belongs to the technical field of the power cable technique and specifically relates to a flexible fireproof cable of watertight type composite insulation.

Background

With the continuous enlargement of the scale of the industries such as the power industry, the data communication industry, the urban rail transit industry, the automobile industry, the shipbuilding industry and the like, the demand of electric wires and cables is rapidly increased, meanwhile, with the rapid and steady increase of national economy and the rapid development of urban construction, buildings with various functions are built in large batches, people pay more and more attention to data safety, cables are used as highways for information transmission, the impact resistance of the cables to sudden disasters in the transmission process naturally becomes the hot field of the research of the cable industry, and the fire prevention as the first of comprehensive wiring 'three prevention' is also the most important.

As the demand of cables is increasing, higher requirements are also put on the safety and fire-proof performance of the cables. The existing fireproof cable can only be used in an environment without water erosion, and the waterproof performance is insufficient. In addition, the existing fireproof cable mostly adopts a fireproof mud or metal sleeve structure, when the cable is normally used, the generated heat can be in a relatively closed space, and due to the fact that the heat dissipation rate of the cable is greatly reduced, the temperature of a conductor of the cable is in a high state, the thermoelectric loss is increased, the resistance of the conductor is increased, and the current-carrying capacity of the cable is further reduced.

SUMMERY OF THE UTILITY MODEL

The to-be-solved technical problem of the utility model is to the problem that exists in the background art, provide one kind and not only have superior radial and vertical water blocking performance, still have excellent fire-retardant fire-resistant, fire prevention and the cable that resistant time corrosion resisting property is good, guarantee that the cable is transmission performance stable in long-term use, improve its security performance and life, specifically speaking is a flexible fireproof cable of watertight type composite insulation.

For solving the technical problem, the utility model discloses the technical scheme who adopts does: the utility model provides a flexible fireproof cable of watertight type compound insulation, includes cable core, composite insulation layer, flame retardant coating, separates oxygen layer and oversheath, the cable core comprises many insulation core, and every insulation core comprises the conductor that blocks water and around the package at the outside composite insulation layer of the conductor that blocks water to crowded package has and is annular flame retardant coating between many insulation core that constitute the cable core and on insulation core the outside from interior to exterior in proper order cladding of flame retardant coating has and separates oxygen layer and oversheath.

Further, a flexible fireproof cable of water-stop composite insulation, wherein the cable core comprises four insulation core mutual contacts and constitutes square structure, the conductor that blocks water is including leading electrical core, water stop and insulating band layer that blocks water, lead electrical core and adopt two types of annealing soft copper transposition conductors of GB/T3956-2008 regulation it has insulating band layer that blocks water to lead the electrical core outside around having packed between the electrical core has the water stop.

Further, a flexible fireproof cable of water-stop composite insulation, wherein composite insulation comprises mineral insulating layer, heat dissipation layer and the insulating layer that blocks water, wherein mineral insulating layer adopts mica tape material to make around the package, the heat dissipation layer adopts graphite heat dissipation cloth to make around the package, the insulating layer that blocks water adopts the crowded package of crosslinked polyethylene or polyolefin material to form, mineral insulating layer, heat dissipation layer and the insulating layer that blocks water are in proper order around the package from inside to outside on the conductor that blocks water.

Further, a water-stop composite insulation flexible fireproof cable, wherein the flame retardant coating adopts the crowded package of solid-state fire prevention mud to form, it adopts halogen-free low smoke high flame retardant belt material to form around the package through overlapping to separate the oxygen layer, the oversheath adopts the halogen-free low smoke fire retardant B1 level polyolefin sheath material that oxygen index is not less than 40 to make.

By adopting the watertight composite insulated flexible fireproof cable, as the cable core consists of a plurality of insulated wire cores, each insulated wire core consists of a water-blocking conductor 1 and a composite insulating layer 2 wrapped outside the water-blocking conductor 1, and a ring-shaped fireproof layer 3 is extruded and wrapped among a plurality of insulating wire cores and on the insulating wire cores, the oxygen-insulating layer 4 and the outer sheath 5 are sequentially coated outside the fireproof layer 3 from inside to outside, so that the prepared cable not only has excellent radial and longitudinal water-blocking performance, but also has the advantages of excellent flame retardance, fire resistance, weather resistance and corrosion resistance, and greatly meets the power consumption requirement at the present stage, the multifunctional paving machine can be used in various severe paving environments, is simple in structure, safe, reliable, stable in performance and strong in practicability, can meet the use requirements, and has wide application places.

Drawings

The present invention will be described in further detail with reference to the accompanying drawings.

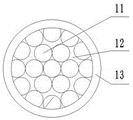

Fig. 1 is a schematic structural diagram of the present invention;

fig. 2 is a schematic structural diagram of the water blocking conductor of the present invention.

Shown in the figure: 1-water-blocking conductor, 11-conductive core, 12-water-tight layer, 13-insulating water-blocking tape layer, 2-composite insulating layer, 21-mineral insulating layer, 22-heat dissipation layer, 23-water-blocking insulating layer, 3-fire-proof layer, 4-oxygen isolation layer and 5-outer sheath.

Detailed Description

As shown in figure 1 and figure 2, a flexible fireproof cable of watertight type composite insulation, including cable core, composite insulation layer 2, flame retardant coating 3, separate oxygen layer 4 and oversheath 5, the cable core comprises many insulation core, every insulation core by the conductor 1 that blocks water with around the package at the composite insulation layer 2 that blocks water 1 outside constitutes to crowded package has and is annular flame retardant coating 3 between many insulation core that constitute the cable core and on the insulation core 3 outside from interior to exterior in proper order the cladding has and separates oxygen layer 4 and oversheath 5.

Further, the utility model discloses a flexible fireproof cable of water-stop type composite insulation, wherein the cable core is by four insulation core mutual contacts constitution square structure, the conductor that blocks water 1 is including electrically conductive core 11, water stop layer 12 and insulating band layer 13 that blocks water, electrically conductive core 11 adopts the two types of annealing soft copper stranded conductor of GB/T3956-2008 regulation, around having insulating band layer 13 that blocks water outside electrically conductive core 11, and it has water stop layer 12 to fill between electrically conductive core 11; the composite insulating layer 2 is composed of a mineral insulating layer 21, a heat dissipation layer 22 and a water-blocking insulating layer 23, wherein the mineral insulating layer 21 is formed by winding mica tape materials, the heat dissipation layer 22 is formed by winding graphite heat dissipation cloth, the water-blocking insulating layer 23 is formed by extruding crosslinked polyethylene or polyolefin materials, and the mineral insulating layer 21, the heat dissipation layer 22 and the water-blocking insulating layer 23 are sequentially wound on the water-blocking conductor 1 from inside to outside; fire-proof layer 3 adopts the crowded package of solid-state fire prevention mud to form, separate oxygen layer 4 and adopt no halogen low smoke high flame retardant belt material to form through overlapping around the package, oversheath 5 adopts the oxygen index to be not less than 40 halogen-free low smoke fire-retardant B1 level polyolefin sheath material to make.

In specific manufacture process, a flexible fireproof cable of water-stop composite insulation, wherein electrically conductive core 11 is made by the soft copper stranded conductor of two types of annealing of GB/T3956-2008 standard regulation, its compliance is good, the processing preparation of being convenient for can guarantee better that the cable has higher bendability at the in-process that the installation laid.

The watertight layer 12 is made of a semi-conductive water-blocking adhesive, and the semi-conductive water-blocking adhesive is formed by mixing a water-blocking adhesive containing cross-linked polyethylene, a water-absorbing polymer and a resin composition containing carbon black. In a specific manufacturing process, the semiconductive water-blocking adhesive comprises 100 parts by weight of water-blocking adhesive containing crosslinking polyethylene, 15 parts by weight of water-absorbing polymer and 85 parts by weight of resin composition containing carbon black, wherein the resin composition containing the carbon black comprises 60 parts by weight of acetylene carbon black and 25 parts by weight of resin composition. The conductor watertight layer 12 made of the semi-conductive water-blocking adhesive has few coatings and simple manufacturing steps, and can ensure that the surface of each conductor core body 11 can be uniformly and firmly attached with the water-blocking adhesive layer, so that the water-blocking and moisture-proof performance of the stranded conductor can be greatly improved, the soft bending performance of a cable is not influenced, and the outer diameter of the conductor is not increased.

The insulating water-blocking tape layer 13 is made by adopting a non-conductive water-blocking tape material and performing a wrapping process after the conductor twisting process, so that the increase of production cost caused by wrapping again is reduced, and the compactness of the water-blocking layer 12 filled between the conductive cores 11 is further enhanced.

The composite insulation 2 consists of a mineral insulation layer 21, a heat dissipation layer 22 and a water blocking insulation layer 23, wherein the mineral insulation layer 21 is made of mica tape material, and the mica tape material is a non-metallic insulation material, so that the mica tape material has the characteristics of good electrical insulation, extremely low vacuum outgassing at high temperature, acid and alkali resistance, transparency, strippable property, high elasticity and the like, is difficult to ignite by fire, ensures that the cable has higher high-temperature resistance, and can better isolate the damage of external open fire to the conductive core; the heat dissipation layer 22 is formed by wrapping graphite heat dissipation cloth, so that instantaneous large current when the cable is started and heat generated by the cable when the cable normally works can be effectively and quickly conducted out, the cable conductor is reduced and guaranteed to be within a proper working temperature, the current-carrying capacity of the cable is improved, the damage to an insulating layer due to overhigh conductor temperature is relieved, the fire hazard is greatly reduced, and the service life of a product is prolonged; the water-blocking insulating layer 23 is made of cross-linked polyethylene or polyolefin materials and is formed by extrusion through extrusion equipment, so that the compactness is good, the radial waterproof performance and the insulating performance are very good, the damage of water to the mineral insulating layer in the production and use processes is effectively prevented, and the insulating performance in the use process is enhanced.

The flame retardant coating 3 adopts solid-state fire prevention mud, utilize the crowded package of twin-screw extrusion equipment on insulating layer 2 and between insulating layer 2, thereby form closely knit and soft structure, when the conflagration breaing out, crowded package flame retardant coating can form ceramic flame retardant coating the very first time when receiving outside high temperature, and absorb a large amount of heats, make the inside and outside temperature difference of crowded package flame retardant coating about 200 ~ 300 ℃, prevent the destruction of conflagration to the cable core, guarantee that crowded package flame retardant coating inner structure is complete effective, increase the life and the security performance of cable.

The oxygen isolation layer 4 is made of halogen-free low-smoke high-flame-retardant belt materials through an overlapping wrapping process, has a good oxygen isolation effect, can effectively fix the extruded fireproof layer, can enhance the fireproof effect of the extruded fireproof layer, and does not release toxic and harmful components.

The outer protective layer 5 is made of a halogen-free low-smoke flame-retardant B1-grade polyolefin sheath material with the oxygen index not less than 40, has good flame-retardant and heat-absorbing effects, and has the characteristics of low viscosity, no halogen, special wear resistance, excellent waterproofness, weather aging resistance and the like, so that the whole cable reaches the B1-grade combustion standard in GB 31247 2014 standard, and the service life of the product is greatly prolonged.

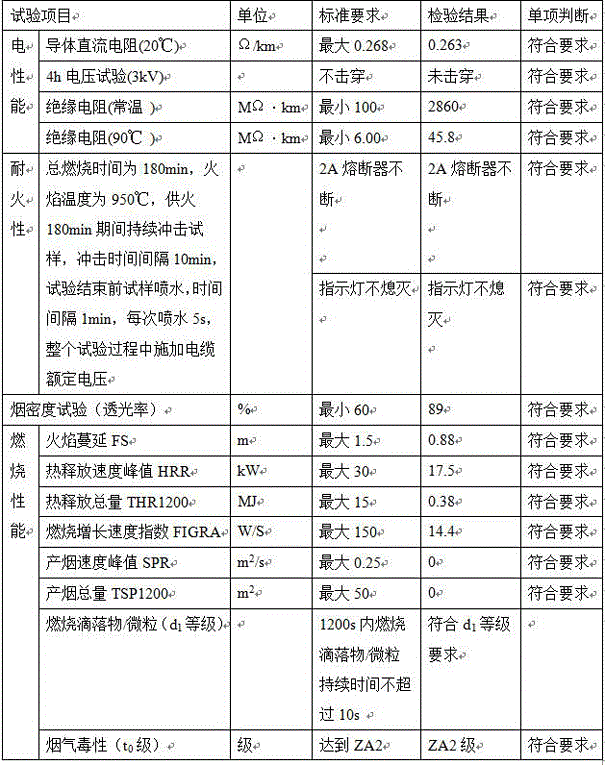

Adopt fireproof cable, test according to GB 31247-2014 cable and optical cable combustion behavior in grades, through its flame spread FS of test, heat release speed peak value HRR, heat release total amount THR1200, burning growth rate index FIGRA, production cigarette speed peak value SPR, production cigarette total amount TSP1200, burning drippage/particle (d 1 grade) and flue gas toxicity (t 1 grade), through experimental, above-mentioned test result all meets the requirements. Meanwhile, according to B1-level combustion tests in B/T18380.33-2007A-type bundled combustion and GB 31247-2014 standards, test results meet requirements, in addition, through a BS 8491 power cable fire-resistant impact water injection test, under the standard conditions that the flame temperature is 950-1000 ℃ and the time is 180 minutes, through tests, the test results meet requirements, and part of test data are shown in Table 1.

To sum up, adopt fireproof cable, not only have superior radial and vertical water-blocking performance, still have excellent fire-retardant fire-resistant, fire prevention and resistant corrosion-resistant advantage of waiting, greatly satisfied the power consumption demand in present stage, can satisfy and use in multiple abominable environment of laying, have simple structure, safe and reliable, the stable performance, its practicality is strong, can satisfy the user demand, has extensive application.

The utility model discloses a protection scope is not only limited to the disclosed technical scheme of embodiment, above only do the utility model discloses a preferred embodiment, and not the restriction the utility model discloses, all basis the utility model discloses an any slight modification, equivalent replacement and improvement that technical scheme did all should contain within the utility model discloses within technical scheme's the protection scope.

Claims (4)

1. The utility model provides a flexible fireproof cable of water-stop type composite insulation, including cable core, composite insulation layer (2), flame retardant coating (3), separate oxygen layer (4) and oversheath (5), its characterized in that: the cable core comprises many insulation core, and every insulation core comprises at the outside composite insulation layer (2) of conductor (1) that blocks water by conductor (1) and around the package to crowded package has between many insulation core that constitute the cable core and on the insulation core and is annular flame retardant coating (3) outside from interior to exterior in proper order the cladding have oxygen layer (4) and oversheath (5) separate.

2. The watertight type composite insulated flexible fireproof cable according to claim 1, wherein: the cable core is of a square structure formed by four insulated wire cores in mutual contact, the water-blocking conductor (1) comprises a conductive core body (11), a water-tight layer (12) and an insulated water-blocking tape layer (13), the conductive core body (11) adopts a class II annealed soft copper stranded conductor specified in GB/T3956-2008, the insulated water-blocking tape layer (13) is wound on the outer side of the conductive core body (11), and the water-tight layer (12) is filled between the conductive core bodies (11).

3. The watertight type composite insulated flexible fireproof cable according to claim 1, wherein: composite insulation layer (2) comprises mineral insulating layer (21), heat dissipation layer (22) and water-blocking insulation layer (23), wherein mineral insulating layer (21) adopts mica tape material to make around the package, heat dissipation layer (22) adopt graphite heat dissipation cloth to make around the package, water-blocking insulation layer (23) adopt cross-linked polyethylene or the crowded package of polyolefin material to form, mineral insulating layer (21), heat dissipation layer (22) and water-blocking insulation layer (23) are by interior to exterior in proper order around the package on water-blocking conductor (1).

4. The watertight type composite insulated flexible fireproof cable according to claim 1, wherein: fire-proof layer (3) adopt the crowded package of solid-state fire prevention mud to form, separate oxygen layer (4) and adopt the high fire-retardant tape material of zero halogen low smoke to form around the package through overlapping, oversheath (5) adopt the oxygen index to be not less than 40 the fire-retardant B1 level polyolefin sheath material of zero halogen low smoke to make.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202221508921.5U CN217386741U (en) | 2022-06-17 | 2022-06-17 | Watertight composite insulation flexible fireproof cable |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202221508921.5U CN217386741U (en) | 2022-06-17 | 2022-06-17 | Watertight composite insulation flexible fireproof cable |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN217386741U true CN217386741U (en) | 2022-09-06 |

Family

ID=83091886

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202221508921.5U Active CN217386741U (en) | 2022-06-17 | 2022-06-17 | Watertight composite insulation flexible fireproof cable |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN217386741U (en) |

-

2022

- 2022-06-17 CN CN202221508921.5U patent/CN217386741U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN215007651U (en) | Mineral-filled flame-retardant fireproof isolated special cable for modern buildings | |

| CN211319787U (en) | Fire-resistant cable | |

| CN209880229U (en) | Waterproof directly-buried photovoltaic cable | |

| CN217386741U (en) | Watertight composite insulation flexible fireproof cable | |

| CN201489859U (en) | Halogen-free flame retardant control cable | |

| CN212782841U (en) | Flame-retardant B1-grade fireproof single-core power cable with corrugated metal sheath | |

| CN211578436U (en) | Low-voltage flexible mineral insulated fireproof cable | |

| CN205487545U (en) | Oil platform is with this ampere of instrument communication cable | |

| CN217880959U (en) | Ultralow smoke volume interlocking armor power cable | |

| CN216054005U (en) | Halogen-free low-smoke flame-retardant B1-grade fireproof waterproof variable frequency cable | |

| CN218214746U (en) | Flame-retardant B1-grade crosslinked polyethylene insulated power cable for construction engineering | |

| CN220137996U (en) | Fire-resistant B1-level cable | |

| CN213752010U (en) | Fire-resistant environment-friendly halogen-free crosslinking line | |

| CN209804323U (en) | Digital cable with good fireproof effect | |

| RU222081U1 (en) | Power fireproof cable | |

| CN217485137U (en) | Double-layer co-extrusion convenient home decoration electric wire with long service life | |

| CN212113271U (en) | Flexible mineral substance insulation fireproof cable | |

| CN209843347U (en) | Ultraviolet-proof environment-friendly inorganic mineral insulated power cable | |

| CN219085707U (en) | 6-35kV rated voltage crosslinked polyethylene insulation flame-retardant environment-friendly power cable | |

| CN212624872U (en) | High flame-retardant fire-resistant aluminum alloy cable | |

| CN219738606U (en) | Soft fire-retardant type energy storage cable of fire prevention of level | |

| CN201489884U (en) | Smoke-free, halogen-free and fire-resistant meter cable | |

| CN213400657U (en) | Water-blocking fireproof carbon fiber woven home decoration cloth cable | |

| CN220420316U (en) | Flame-retardant halogen-free super-crosslinked polyethylene insulated ultrahigh-voltage power cable | |

| CN213781625U (en) | Compound insulating flexible fireproof cable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |