CN216400085U - Utensil dustproof concrete reation kettle - Google Patents

Utensil dustproof concrete reation kettle Download PDFInfo

- Publication number

- CN216400085U CN216400085U CN202123088392.6U CN202123088392U CN216400085U CN 216400085 U CN216400085 U CN 216400085U CN 202123088392 U CN202123088392 U CN 202123088392U CN 216400085 U CN216400085 U CN 216400085U

- Authority

- CN

- China

- Prior art keywords

- sealing ring

- inlet pipe

- dustproof

- tank body

- upper cover

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Accessories For Mixers (AREA)

Abstract

A dustproof concrete reaction kettle relates to the technical field of concrete mixing equipment and comprises a stirring tank, a support rod, a stirring device, a first dustproof part and a second dustproof part, wherein the stirring tank consists of a tank body, an upper cover, a lower cover, a feeding pipe, a discharging pipe and a valve; the utility model has strong practicability and very convenient use, can prevent the waste caused by the scattering of dry concrete powder when the concrete is added into the reaction kettle, can avoid the pollution of the production environment and protect the personal health of surrounding workers.

Description

Technical Field

The utility model belongs to the technical field of concrete mixing equipment, and particularly relates to a dustproof concrete reaction kettle.

[ background of the utility model ]

According to actual construction requirements, different water reducing agents are added into a reaction kettle to be mixed when the concrete is stirred, when the concrete is put into the reaction kettle, dry concrete particles are scattered around, waste of raw materials can be caused when the concrete falls out of the reaction kettle, economic burden of enterprises is increased, and the dry concrete particles scattered in the air can cause pollution to production environment and influence physical health of workers.

[ Utility model ] content

In order to overcome the defects in the background art, the utility model discloses a dustproof concrete reaction kettle, and the aim of preventing dry powdery concrete from floating is fulfilled by arranging a support rod, a stirring device, a first dustproof part and a second dustproof part on a stirring tank.

In order to realize the purpose of the utility model, the utility model adopts the following technical scheme:

the utility model provides an utensil dustproof concrete reation kettle, includes agitator tank, vaulting pole, agitating unit, first dust-proof portion and second dust-proof portion, and the agitator tank comprises a jar body, upper cover, lower cover, inlet pipe, unloading pipe and valve, is equipped with upper cover, lower cover and second dust-proof portion on the jar body, covers on and is equipped with inlet pipe, agitating unit and first dust-proof portion, covers under and is equipped with unloading pipe and vaulting pole, is equipped with the valve on the unloading pipe.

The tank body is of a hollow cylindrical structure, an upper cover is arranged on the upper bottom surface of the tank body, the lower surface of the upper cover is connected with the upper bottom surface of the tank body, a lower cover is arranged on the lower bottom surface of the tank body, the upper surface of the lower cover is connected with the lower bottom surface of the tank body, and a second dustproof portion is arranged on the inner wall of the tank body.

The upper cover is provided with an upper fixing hole, the upper fixing hole penetrates through the upper surface and the lower surface of the upper cover, the upper fixing hole is provided with a stirring device, at least one feeding pipe is arranged beside the upper fixing hole, the structures of the feeding pipes are the same, each feeding pipe penetrates through the upper cover, and the lower surface of the upper cover is provided with a first dustproof portion.

The stirring device is composed of a motor, a rotating shaft and stirring blades, the motor is arranged above the upper cover, a driving shaft of the motor penetrates through the upper fixing hole, the rotating shaft is arranged on the driving shaft of the motor, the upper bottom surface of the rotating shaft is connected with the lower end of the driving shaft of the motor, and the stirring blades are uniformly distributed on the side surface of the rotating shaft.

First dust-proof part is by first sealing ring, the connecting rod, inlet tube and nozzle constitute, be equipped with the connecting rod on the first sealing ring, inlet tube and nozzle, first sealing ring is cavity ring type structure, pivot and inlet pipe all set up in first sealing ring, epaxial stirring vane all sets up in first sealing ring below, the upper portion face of first sealing ring is equipped with at least one connecting rod, the lower part face of connecting rod is connected with the upper portion face of first sealing ring, the upper portion face of connecting rod is connected with the lower part face of upper cover, the upper portion face of first sealing ring is equipped with the inlet tube, the lower part face of first sealing ring is equipped with the connecting hole, be equipped with the nozzle in the connecting hole.

The upper end of the water inlet pipe penetrates through the upper cover and is arranged above the upper cover, and the lower end of the water inlet pipe penetrates through the upper surface of the first sealing ring and is communicated with the cavity of the first sealing ring.

The lower part face of first sealing ring is equipped with at least one connecting hole, and each connecting hole structure is the same, and each connecting hole evenly sets up the lower part face at first sealing ring, and the lower extreme of connecting hole passes the lower part face of first sealing ring, and the upper end of connecting hole and the cavity intercommunication of first sealing ring all are equipped with the nozzle in each connecting hole.

The second dustproof part comprises a second sealing ring and an air inlet pipe, the air inlet pipe is arranged on the second sealing ring, the second sealing ring is of a hollow circular ring type structure, the side face of the second sealing ring is connected with the inner wall of the tank body, the second sealing ring is arranged in parallel with the first sealing ring, the second sealing ring is arranged below the first sealing ring, a rotating shaft and an inlet pipe are arranged in the second sealing ring, the lower end of the inlet pipe is arranged below the second sealing ring, one end of the air inlet pipe penetrates through the side face of the tank body and the inner wall face of the tank body, the other end of the air inlet pipe is communicated with the cavity of the second sealing ring, air holes are uniformly distributed on the inner wall of the second sealing ring, the inner wall face of the second sealing ring is penetrated through one end of each air hole, and the other end of each air hole is communicated with the cavity of the second sealing ring.

The lower cover is provided with a lower fixing hole, the lower fixing hole penetrates through the upper surface and the lower surface of the lower cover, a discharging pipe is arranged in the lower fixing hole, the side surface of the upper end of the discharging pipe is connected with the inner wall of the lower fixing hole, and support rods are uniformly distributed on the lower surface of the lower cover.

The dustproof concrete reaction kettle comprises a stirring tank, a support rod, a stirring device, a first dustproof part and a second dustproof part, wherein the support rod, the stirring device, the first dustproof part and the second dustproof part are arranged on the stirring tank, so that the aim of preventing dry powdery concrete from floating is fulfilled; the utility model has strong practicability and very convenient use, can prevent the waste caused by the scattering of dry concrete powder when the concrete is added into the reaction kettle, can avoid the pollution of the production environment and protect the personal health of surrounding workers.

[ description of the drawings ]

FIG. 1 is a schematic perspective view of the present invention;

FIG. 2 is a cross-sectional view of the present invention;

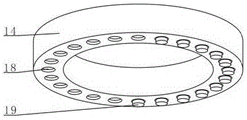

FIG. 3 is a schematic perspective view of a first seal ring according to the present invention;

FIG. 4 is a cross-sectional view of a second seal ring of the present invention;

in the figure: 1. a tank body; 2. an upper cover; 3. a lower cover; 4. a stay bar; 5. a motor; 6. a feed pipe; 7. a water inlet pipe; 8. an air inlet pipe; 9. a discharging pipe; 10. a valve; 11. an upper fixing hole; 12. a lower fixing hole; 13. a connecting rod; 14. a first seal ring; 15. a second seal ring; 16. a rotating shaft; 17. a stirring blade; 18. connecting holes; 19. a nozzle; 20. and (4) air holes.

[ detailed description ] embodiments

The present invention will be explained in detail by the following examples, which are disclosed for the purpose of protecting all technical improvements within the scope of the present invention.

Combine 1~4 a utensil dustproof concrete reation kettle of attached figure, including agitator tank, vaulting pole 4, agitating unit, first dustproof portion and second dustproof portion, the agitator tank comprises jar body 1, upper cover 2, lower cover 3, inlet pipe 6, unloading pipe 9 and valve 10, be equipped with upper cover 2 on jar body 1, lower cover 3 and second dustproof portion, be equipped with inlet pipe 6 on upper cover 2, agitating unit and first dustproof portion, be equipped with unloading pipe 9 and vaulting pole 4 on the lower cover 3, be equipped with valve 10 on the unloading pipe 9.

The tank body 1 is of a hollow cylindrical structure, the upper bottom surface of the tank body 1 is provided with the upper cover 2, the lower surface of the upper cover 2 is connected with the upper bottom surface of the tank body 1, the lower bottom surface of the tank body 1 is provided with the lower cover 3, the upper surface of the lower cover 3 is connected with the lower bottom surface of the tank body 1, and the inner wall of the tank body 1 is provided with the second dustproof part.

Be equipped with fixed orifices 11 on the upper cover 2, go up the upper portion face and the lower part face that fixed orifices 11 run through upper cover 2, upward be equipped with agitating unit on the fixed orifices 11, go up the other at least one inlet pipe 6 that is equipped with of fixed orifices 11, each inlet pipe 6 structure is the same, and each inlet pipe 6 all passes upper cover 2, and the lower part face of upper cover 2 is equipped with first dust guard.

The stirring device is composed of a motor 5, a rotating shaft 16 and stirring blades 17, wherein the motor 5 is arranged above the upper cover 2, a driving shaft of the motor 5 penetrates through the upper fixing hole 11, the rotating shaft 16 is arranged on the driving shaft of the motor 5, the upper bottom surface of the rotating shaft 16 is connected with the lower end of the driving shaft of the motor 5, and the stirring blades 17 are uniformly distributed on the side surface of the rotating shaft 16.

First dust-proof part is by first sealing ring 14, connecting rod 13, inlet tube 7 and nozzle 19 constitute, be equipped with connecting rod 13 on first sealing ring 14, inlet tube 7 and nozzle 19, first sealing ring 14 is cavity ring type structure, pivot 16 and inlet pipe 6 all set up in first sealing ring 14, stirring vane 17 in the pivot 16 all sets up in first sealing ring 14 below, the upper portion face of first sealing ring 14 is equipped with at least one connecting rod 13, the lower part face of connecting rod 13 is connected with the upper portion face of first sealing ring 14, the upper portion face of connecting rod 13 is connected with the lower part face of upper cover 2, the upper portion face of first sealing ring 14 is equipped with inlet tube 7, the lower part face of first sealing ring 14 is equipped with connecting hole 18, be equipped with nozzle 19 in the connecting hole 18.

The upper end of the water inlet pipe 7 penetrates through the upper cover 2 and is arranged above the upper cover 2, and the lower end of the water inlet pipe 7 penetrates through the upper surface of the first sealing ring 14 and is communicated with the cavity of the first sealing ring 14.

The lower surface of the first sealing ring 14 is provided with at least one connecting hole 18, the connecting holes 18 have the same structure, the connecting holes 18 are uniformly arranged on the lower surface of the first sealing ring 14, the lower end of the connecting hole 18 penetrates through the lower surface of the first sealing ring 14, the upper end of the connecting hole 18 is communicated with the cavity of the first sealing ring 14, and a nozzle 19 is arranged in each connecting hole 18.

The second dustproof portion is composed of a second sealing ring 15 and an air inlet pipe 8, the air inlet pipe 8 is arranged on the second sealing ring 15, the second sealing ring 15 is of a hollow circular ring structure, the side face of the second sealing ring 15 is connected with the inner wall of the tank body 1, the second sealing ring 15 is arranged in parallel with the first sealing ring 14, the second sealing ring 15 is arranged below the first sealing ring 14, the rotating shaft 16 and the inlet pipe 6 are both arranged in the second sealing ring 15, the lower end of the inlet pipe 6 is arranged below the second sealing ring 15, one end of the air inlet pipe 8 penetrates through the side face of the tank body 1 and is arranged outside the tank body 1, the other end of the air inlet pipe 8 is communicated with the cavity of the second sealing ring 15, air holes 20 are uniformly distributed on the inner wall of the second sealing ring 15, one end of each air hole 20 penetrates through the inner wall of the second sealing ring 15, and the other end of each air hole 20 is communicated with the cavity of the second sealing ring 15.

The lower cover 3 is provided with a lower fixing hole 12, the lower fixing hole 12 penetrates through the upper surface and the lower surface of the lower cover 3, a blanking pipe 9 is arranged in the lower fixing hole 12, the side surface of the upper end of the blanking pipe 9 is connected with the inner wall of the lower fixing hole 12, and the lower surface of the lower cover 3 is uniformly distributed with support rods 4.

The embodiment of the dustproof concrete reaction kettle, when in use, a water source is connected to a water inlet pipe 7, then an air inlet pipe 8 is connected with an air pump, the air pump is opened to supply air into the air inlet pipe 8, the air flow flows into a second sealing ring 15 through the air inlet pipe 8, the air flow is finally blown to the center of the second sealing ring 15 through air holes 20 on the second sealing ring 15 to form an air wall, then a concrete raw material is conveyed into a stirring tank through an inlet pipe 6, the dry concrete falls into the stirring tank, the dust floats upwards in a tank body 1, the dust is blocked below the air wall after encountering the upper air wall to prevent the dust from floating out of the stirring tank, after the concrete is added, the water source is opened, the water flow enters a first sealing ring 14 through the water inlet pipe 7 and is sprayed downwards through a nozzle 19 below the first sealing ring 14, and the floating dust and water can be combined and fall on the concrete raw material below when the water falls, also can wash the concrete dust on the second sealing ring 15, keep the cleanness of second sealing ring 15, then close the air pump and make things convenient for the water droplet to drip on the concrete raw materials for further mix, open motor 5 after adding sufficient water and make pivot 16 rotate, the last stirring vane 17 of pivot 16 mixes concrete and water-reducing agent etc. in with the agitator tank, after the mixture finishes, open valve 10 on the unloading pipe 9, it can to emit the concrete in the agitator tank.

While the utility model has been particularly shown and described with reference to a preferred embodiment, it will be understood by those skilled in the art that various changes in form and detail may be made therein without departing from the spirit and scope of the utility model as defined by the appended claims.

Claims (9)

1. The utility model provides an utensil dustproof concrete reation kettle, includes agitator tank, vaulting pole (4), agitating unit, first dustproof portion and second dustproof portion, characterized by: the agitator tank comprises a tank body (1), an upper cover (2), a lower cover (3), an inlet pipe (6), a discharging pipe (9) and a valve (10), wherein the tank body (1) is provided with the upper cover (2), the lower cover (3) and a second dustproof part, the upper cover (2) is provided with the inlet pipe (6), an agitating device and a first dustproof part, the lower cover (3) is provided with the discharging pipe (9) and a support rod (4), and the discharging pipe (9) is provided with the valve (10).

2. The dustproof concrete reaction kettle as claimed in claim 1, which is characterized in that: the tank body (1) is of a hollow cylindrical structure, an upper cover (2) is arranged on the upper bottom surface of the tank body (1), the lower surface of the upper cover (2) is connected with the upper bottom surface of the tank body (1), a lower cover (3) is arranged on the lower bottom surface of the tank body (1), the upper surface of the lower cover (3) is connected with the lower bottom surface of the tank body (1), and a second dustproof portion is arranged on the inner wall of the tank body (1).

3. The dustproof concrete reaction kettle as claimed in claim 1, which is characterized in that: be equipped with fixed orifices (11) on upper cover (2), go up fixed orifices (11) and run through the upper portion face and the lower part face of upper cover (2), go up and be equipped with agitating unit on fixed orifices (11), go up other at least one inlet pipe (6) that are equipped with of fixed orifices (11), each inlet pipe (6) structure is the same, and each inlet pipe (6) all passes upper cover (2), and the lower part face of upper cover (2) is equipped with first dust guard.

4. The dustproof concrete reaction kettle as claimed in claim 1, which is characterized in that: agitating unit comprises motor (5), pivot (16) and stirring vane (17), and motor (5) set up the top in upper cover (2), and last fixed orifices (11) are passed to the drive shaft of motor (5), are equipped with pivot (16) in motor (5) drive shaft, and the last bottom surface of pivot (16) is connected with the lower extreme of motor (5) drive shaft, and the side evenly distributed of pivot (16) has stirring vane (17).

5. The dustproof concrete reaction kettle as claimed in claim 1, which is characterized in that: the first dustproof part is composed of a first sealing ring (14), a connecting rod (13), a water inlet pipe (7) and a nozzle (19), the connecting rod (13), the water inlet pipe (7) and the nozzle (19) are arranged on the first sealing ring (14), the first sealing ring (14) is of a hollow circular ring type structure, a rotating shaft (16) and a feeding pipe (6) are arranged in the first sealing ring (14), stirring blades (17) on the rotating shaft (16) are arranged below the first sealing ring (14), the upper surface of the first sealing ring (14) is provided with at least one connecting rod (13), the lower surface of the connecting rod (13) is connected with the upper surface of the first sealing ring (14), the upper surface of the connecting rod (13) is connected with the lower surface of the upper cover (2), the upper surface of the first sealing ring (14) is provided with the water inlet pipe (7), the lower surface of the first sealing ring (14) is provided with a connecting hole (18), a nozzle (19) is arranged in the connecting hole (18).

6. The dustproof concrete reaction kettle of claim 5, which is characterized in that: the upper end of the water inlet pipe (7) penetrates through the upper cover (2) and is arranged above the upper cover (2), and the lower end of the water inlet pipe (7) penetrates through the upper surface of the first sealing ring (14) and is communicated with the cavity of the first sealing ring (14).

7. The dustproof concrete reaction kettle of claim 5, which is characterized in that: the lower surface of the first sealing ring (14) is provided with at least one connecting hole (18), the connecting holes (18) are identical in structure, the connecting holes (18) are uniformly formed in the lower surface of the first sealing ring (14), the lower end of each connecting hole (18) penetrates through the lower surface of the first sealing ring (14), the upper end of each connecting hole (18) is communicated with a cavity of the first sealing ring (14), and a nozzle (19) is arranged in each connecting hole (18).

8. The dustproof concrete reaction kettle as claimed in claim 1, which is characterized in that: the second dustproof part is composed of a second sealing ring (15) and an air inlet pipe (8), the air inlet pipe (8) is arranged on the second sealing ring (15), the second sealing ring (15) is of a hollow circular ring structure, the side surface of the second sealing ring (15) is connected with the inner wall of the tank body (1), the second sealing ring (15) is arranged in parallel with the first sealing ring (14), the second sealing ring (15) is arranged below the first sealing ring (14), a rotating shaft (16) and the air inlet pipe (6) are both arranged in the second sealing ring (15), the lower end of the air inlet pipe (6) is arranged below the second sealing ring (15), one end of the air inlet pipe (8) penetrates through the side surface and the inner wall surface of the tank body (1) and is arranged outside the tank body (1), the other end of the air inlet pipe (8) is communicated with the cavity of the second sealing ring (15), and air holes (20) are uniformly distributed on the inner wall of the second sealing ring (15), one end of the air hole (20) penetrates through the inner wall surface of the second sealing ring (15), and the other end of the air hole (20) is communicated with the cavity of the second sealing ring (15).

9. The dustproof concrete reaction kettle as claimed in claim 1, which is characterized in that: the lower cover (3) is provided with a lower fixing hole (12), the lower fixing hole (12) penetrates through the upper surface and the lower surface of the lower cover (3), a blanking pipe (9) is arranged in the lower fixing hole (12), the side surface of the upper end of the blanking pipe (9) is connected with the inner wall of the lower fixing hole (12), and support rods (4) are uniformly distributed on the lower surface of the lower cover (3).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202123088392.6U CN216400085U (en) | 2021-12-10 | 2021-12-10 | Utensil dustproof concrete reation kettle |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202123088392.6U CN216400085U (en) | 2021-12-10 | 2021-12-10 | Utensil dustproof concrete reation kettle |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN216400085U true CN216400085U (en) | 2022-04-29 |

Family

ID=81282147

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202123088392.6U Active CN216400085U (en) | 2021-12-10 | 2021-12-10 | Utensil dustproof concrete reation kettle |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN216400085U (en) |

-

2021

- 2021-12-10 CN CN202123088392.6U patent/CN216400085U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN208894066U (en) | A kind of concrete admixture agitating device | |

| CN210915490U (en) | Coating production wastewater treatment device | |

| CN206374035U (en) | A kind of concrete mixer of anti-airborne dust | |

| CN216400085U (en) | Utensil dustproof concrete reation kettle | |

| CN210758551U (en) | Mixing machine | |

| CN109834832A (en) | A kind of concrete mixer | |

| CN210584608U (en) | Automatic change dyestuff mixing arrangement for spinning machine | |

| CN207913622U (en) | The fragrant base raw material mixing machine of mosquito-repellent incense | |

| CN206935363U (en) | A kind of chemical laboratory reactor | |

| CN207929106U (en) | Powder material mixing arrangement | |

| CN206465267U (en) | One kind energy-conservation dry mixed mortar mixer | |

| CN214871616U (en) | Mixing device for producing double-doped concrete | |

| CN212595495U (en) | Additive hedging circulating type mixing kettle | |

| CN210791533U (en) | Injection formula additive adds equipment | |

| CN209317593U (en) | A kind of water paint is dispersed with stirring tank | |

| CN208406681U (en) | A kind of novel dispensing tank | |

| CN208194247U (en) | A kind of molten material mixing plant of electronic ceramics production | |

| CN208514722U (en) | A kind of pervious concrete powder stirrer cleaned automatically | |

| CN217725382U (en) | High-efficient feed mixer | |

| CN216825803U (en) | Novel reation kettle is used in preparation of pentane foamer | |

| CN111546499A (en) | Cement raw material seals conveying equipment | |

| CN213674765U (en) | Improved pouring mixer | |

| CN211069764U (en) | Aviation fuel preparation is with inside agitating unit of allocation pump | |

| CN215877562U (en) | Large-scale stationary flow low-cost mixer | |

| CN218077438U (en) | Mixing device in phosphogypsum recycling system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |