CN215151266U - Intelligent discharging and conveying device of injection molding machine - Google Patents

Intelligent discharging and conveying device of injection molding machine Download PDFInfo

- Publication number

- CN215151266U CN215151266U CN202121540950.5U CN202121540950U CN215151266U CN 215151266 U CN215151266 U CN 215151266U CN 202121540950 U CN202121540950 U CN 202121540950U CN 215151266 U CN215151266 U CN 215151266U

- Authority

- CN

- China

- Prior art keywords

- injection molding

- molding machine

- baffle

- cylinder

- motor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Injection Moulding Of Plastics Or The Like (AREA)

Abstract

The utility model belongs to the technical field of injection molding machine blanking and conveying devices, and discloses an intelligent blanking and conveying device of an injection molding machine, which comprises a blanking tank, wherein an upper baffle is arranged inside the blanking tank, two hydraulic cylinders are symmetrically arranged at the bottom inside the blanking tank, the telescopic end of each hydraulic cylinder is connected with a lower baffle, a groove is arranged inside the lower baffle, an electric telescopic cylinder is arranged inside the groove, and the telescopic end of the electric telescopic cylinder is connected with a telescopic plate; the utility model discloses be provided with overhead gage and lower baffle, according to the position of baffle under how much adjustment of required raw materials, the flexible end of pneumatic cylinder can drive down the baffle and reciprocate, falls into baffle top down after the raw materials stirring, and the back is filled with to the raw materials, and electronic telescoping cylinder drives the expansion plate and removes, makes the raw materials fall into the feed cylinder, and the unloading is all the same every time in control that can be accurate, avoids the inside jam of feed cylinder, has improved melting effect of raw materials.

Description

Technical Field

The utility model belongs to the technical field of injection molding machine unloading and conveyor, concretely relates to injection molding machine intelligence unloading and conveyor.

Background

An injection molding machine is also known as an injection molding machine or an injection machine. It is a main forming equipment for making various shaped plastic products from thermoplastic plastics or thermosetting plastics by using plastic forming mould. The device is divided into a vertical type, a horizontal type and a full-electric type. The injection molding machine can heat the plastic, apply high pressure to the molten plastic, and inject it to fill the mold cavity.

The problem that exists among the prior art is how much of control unloading that can not be accurate, easily causes the inside jam of feed cylinder to and the finished product does not completely cool down the transportation and can cause the harm.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide an injection molding machine intelligence unloading and conveyor to solve what of the control unloading that can not be accurate now, and the finished product does not have the problem that the transportation of cooling down completely can cause the harm.

In order to achieve the above object, the utility model provides a following technical scheme: the utility model provides an injection molding machine intelligence unloading and conveyor, includes unloading jar, feed cylinder, workstation and conveyor, the unloading jar is installed in the workstation top, the feed cylinder is installed in the workstation top, unloading jar internally mounted has the overhead gage, the bottom of overhead gage is connected with the connecting block, the internally mounted of connecting block has the second axis of rotation, one side of connecting block is connected with the rotor plate, two pneumatic cylinders are installed to the bottom symmetry of unloading jar inside, the flexible end of pneumatic cylinder is connected with down the baffle, the inside of baffle has seted up flutedly down, the internally mounted of recess has electronic telescoping cylinder, the flexible end of electronic telescoping cylinder is connected with the expansion plate, the expansion plate is installed inside the baffle down.

Preferably, the heat dissipation area is installed to conveyor's top, radiator fan is installed at the top of heat dissipation area, the suction fan is installed to one side at heat dissipation area top, the end of breathing in of suction fan is installed inside the heat dissipation area, the exhaust end of suction fan is connected with purifier.

Preferably, the feed inlet has been seted up at the top of unloading jar, first motor is installed at the top of unloading jar, the output of first motor is connected with first axis of rotation, the surface mounting of first axis of rotation has the stirring leaf, the surface mounting of unloading jar has the second motor, the output of second motor is connected with the second axis of rotation, the discharge gate has been seted up to the bottom of unloading jar, the discharge gate is installed in the feed cylinder top.

Preferably, a third motor is installed on one side of the charging barrel, and a heating zone is sleeved on the surface of the charging barrel.

Preferably, a stamping device is mounted on the surface of the workbench.

Preferably, one side of workstation is provided with the base, the surface mounting of base has robotic arm, the sucking disc is installed to robotic arm's one side.

Compared with the prior art, the utility model, following beneficial effect has:

(1) the utility model discloses be provided with overhead gage and lower baffle, according to the position of baffle under how much adjustment of required raw materials, the flexible end of pneumatic cylinder can drive down the baffle and reciprocate, the raw materials is through stirring the leaf stirring abundant back, the output of second motor drives the rotor plate and rotates, make the raw materials fall into baffle top down, the back is filled with to the raw materials, electronic telescoping cylinder drives the expansion plate and removes, make the raw materials fall into the feed cylinder, the unloading is all the same every time in the control that can be accurate, avoid the inside jam of feed cylinder, the effect of melting of raw materials has been improved.

(2) The utility model discloses be provided with radiator fan and suction fan, the finished product is taken and is put into the conveyor top by robotic arm, and radiator fan can cool down the finished product, and the suction fan will carry out purification treatment to steam, avoids the finished product not to cool down the transportation completely and can cause the harm to and the steam pollution workshop that the finished product produced has improved the quality of product.

Drawings

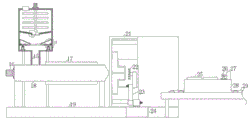

Fig. 1 is a schematic structural view of the present invention;

FIG. 2 is a cross-sectional view of the discharging tank of the present invention;

FIG. 3 is a cross-sectional view of the discharging tank of the present invention;

fig. 4 is a top view of the conveying device of the present invention;

FIG. 5 is an enlarged view of the point A of the present invention;

FIG. 6 is an enlarged view of the point B of the present invention;

fig. 7 is a circuit block diagram of the present invention;

in the figure: 1. feeding the material tank; 2. a first motor; 3. a feed inlet; 4. a first rotating shaft; 5. stirring blades; 6. an upper baffle plate; 7. connecting blocks; 8. a rotating plate; 9. a second rotating shaft; 10. a second motor; 11. a groove; 12. a lower baffle plate; 13. a retractable plate; 14. a hydraulic cylinder; 15. a discharge port; 16. a third motor; 17. a heating zone; 18. a charging barrel; 19. a work table; 20. an electric telescopic cylinder; 21. a stamping device; 22. a suction cup; 23. a robot arm; 24. a base; 25. a heat radiation fan; 26. a suction fan; 27. a purification device; 28. a heat dissipation area; 29. a conveying device.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

Referring to fig. 1-7, the present invention provides the following technical solutions: an intelligent blanking and conveying device of an injection molding machine comprises a blanking tank 1, a charging barrel 18, a workbench 19 and a conveying device 29, wherein the blanking tank 1 is arranged above the workbench 19, the charging barrel 18 is arranged above the workbench 19, an upper baffle 6 is arranged inside the blanking tank 1, the bottom of the upper baffle 6 is connected with a connecting block 7, a second rotating shaft 9 is arranged inside the connecting block 7, one side of the connecting block 7 is connected with a rotating plate 8, two hydraulic cylinders 14 are symmetrically arranged at the bottom inside the blanking tank 1, the telescopic end of each hydraulic cylinder 14 is connected with a lower baffle 12, a groove 11 is formed inside the lower baffle 12, an electric telescopic cylinder 20 is arranged inside the groove 11, the telescopic end of the electric telescopic cylinder 20 is connected with a telescopic plate 13, the telescopic plate 13 is arranged inside the lower baffle 12, the opening of the upper baffle 6 is circular, the rotating plate 8 is in a round cake shape, and two electric telescopic cylinders 20 are arranged, the expansion plate 13 is semicircular.

Further, a heat dissipation area 28 is installed above the conveying device 29, a heat dissipation fan 25 is installed at the top of the heat dissipation area 28, a suction fan 26 is installed on one side of the top of the heat dissipation area 28, the suction end of the suction fan 26 is installed inside the heat dissipation area 28, the exhaust end of the suction fan 26 is connected with a purification device 27, the heat dissipation fan 25 is used for cooling a product, the type of the suction fan 26 is A370, the power of the suction fan 26 is 370w, and an activated carbon filter screen is arranged inside the purification device 27.

Furthermore, the feed inlet 3 has been seted up at the top of unloading jar 1, first motor 2 is installed at the top of unloading jar 1, the output of first motor 2 is connected with first axis of rotation 4, the surface mounting of first axis of rotation 4 has stirring leaf 5, the surface mounting of unloading jar 1 has second motor 10, the output of second motor 10 is connected with second axis of rotation 9, discharge gate 15 has been seted up to the bottom of unloading jar 1, discharge gate 15 installs in the feed cylinder 18 top, first motor 2 model is Y90S-2, first motor 2 power is 1.5kw, stirring leaf 5 is used for stirring the raw materials, second motor 10 model is Y90S-6, second motor 10 power is 0.75kw, second motor 10 is used for driving rotor plate 8 to rotate.

Specifically, a third motor 16 is installed on one side of the charging barrel 18, a heating zone 17 is sleeved on the surface of the charging barrel 18, the model number of the third motor 16 is Y160M-6, the power of the third motor is 7.5kw, and the heating zone 17 is used for heating raw materials.

Note that a press 21 is attached to the surface of the table 19.

Further, a base 24 is arranged on one side of the workbench 19, a mechanical arm 23 is mounted on the surface of the base 24, a suction cup 22 is mounted on one side of the mechanical arm 23, and the mechanical arm 23 is used for taking a finished product.

The utility model discloses a theory of operation and use flow: pouring raw materials into a blanking tank 1 from a feeding hole 3, driving a stirring blade 5 to stir the raw materials by a first motor 2, adjusting the position of a lower baffle 12 according to the amount of the required raw materials, forming a material storage area by the distance between the lower baffle 12 and an upper baffle 6, driving the lower baffle 12 to move up and down by a telescopic end of a hydraulic cylinder 14, fully stirring the raw materials by the stirring blade 5, driving a rotating plate 8 to rotate by an output end of a second motor 10 to enable the raw materials to fall above the lower baffle 12, driving the rotating plate 8 to close an outlet by the second motor 10 after the raw materials are fully filled, driving the telescopic plate 13 to move by an electric telescopic cylinder 20 to enable the raw materials to fall into a charging barrel 18, accurately controlling the same feeding every time, heating and melting the raw materials by the inside of the charging barrel 18, injecting the melted raw materials into a die of a stamping device 21, taking a finished product by a mechanical arm 23 and placing the finished product above a conveying device 29 after molding, and cooling the finished product by a cooling fan 25, the suction fan 26 will purify the hot gas.

Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, the scope of which is defined in the appended claims and their equivalents.

Claims (6)

1. The utility model provides an injection molding machine intelligence unloading and conveyor, includes unloading jar (1), feed cylinder (18), workstation (19) and conveyor (29), unloading jar (1) is installed in workstation (19) top, install in workstation (19) top feed cylinder (18), its characterized in that: lower charging bucket (1) internally mounted has overhead gage (6), the bottom of overhead gage (6) is connected with connecting block (7), the internally mounted of connecting block (7) has second axis of rotation (9), one side of connecting block (7) is connected with rotor plate (8), two pneumatic cylinders (14) are installed to the bottom symmetry of lower charging bucket (1) inside, the flexible end of pneumatic cylinder (14) is connected with down baffle (12), baffle (12) are seted up flutedly (11) down to the inside, the internally mounted of recess (11) has electronic telescoping cylinder (20), the flexible end of electronic telescoping cylinder (20) is connected with expansion plate (13), expansion plate (13) are installed under in baffle (12) inside.

2. The intelligent blanking and conveying device of an injection molding machine according to claim 1, characterized in that: radiating area (28) are installed to the top of conveyor (29), radiator fan (25) are installed at the top of radiating area (28), suction fan (26) are installed to one side at radiating area (28) top, the end of breathing in of suction fan (26) is installed inside radiating area (28), the exhaust end of suction fan (26) is connected with purifier (27).

3. The intelligent blanking and conveying device of an injection molding machine according to claim 1, characterized in that: feed inlet (3) have been seted up at the top of lower charging bucket (1), first motor (2) are installed at the top of lower charging bucket (1), the output of first motor (2) is connected with first axis of rotation (4), the surface mounting of first axis of rotation (4) has stirring leaf (5), the surface mounting of lower charging bucket (1) has second motor (10), the output of second motor (10) is connected with second axis of rotation (9), discharge gate (15) have been seted up to the bottom of lower charging bucket (1), discharge gate (15) are installed in feed cylinder (18) top.

4. The intelligent blanking and conveying device of an injection molding machine according to claim 1, characterized in that: a third motor (16) is arranged on one side of the charging barrel (18), and a heating zone (17) is sleeved on the surface of the charging barrel (18).

5. The intelligent blanking and conveying device of an injection molding machine according to claim 1, characterized in that: and a stamping device (21) is arranged on the surface of the workbench (19).

6. The intelligent blanking and conveying device of an injection molding machine according to claim 1, characterized in that: one side of workstation (19) is provided with base (24), the surface mounting of base (24) has robotic arm (23), sucking disc (22) are installed to one side of robotic arm (23).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121540950.5U CN215151266U (en) | 2021-07-08 | 2021-07-08 | Intelligent discharging and conveying device of injection molding machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121540950.5U CN215151266U (en) | 2021-07-08 | 2021-07-08 | Intelligent discharging and conveying device of injection molding machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN215151266U true CN215151266U (en) | 2021-12-14 |

Family

ID=79396334

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202121540950.5U Active CN215151266U (en) | 2021-07-08 | 2021-07-08 | Intelligent discharging and conveying device of injection molding machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN215151266U (en) |

-

2021

- 2021-07-08 CN CN202121540950.5U patent/CN215151266U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN206748981U (en) | A kind of quick injection molding mould | |

| CN110757732B (en) | Injection molding process and injection molding device of multifunctional automobile instrument panel | |

| CN210415240U (en) | Injection molding equipment | |

| CN215151266U (en) | Intelligent discharging and conveying device of injection molding machine | |

| CN220129338U (en) | Injection mold rotating assembly | |

| CN210539289U (en) | Zipper forming machine | |

| CN211279307U (en) | Granulating device for producing regenerated plastics | |

| CN210969810U (en) | Circulating cooling device for injection molding of mold | |

| CN217144663U (en) | Environment-friendly injection molding equipment | |

| CN208118296U (en) | A kind of injection molding machine charging gear | |

| CN215882480U (en) | Rapid forming die | |

| CN214872237U (en) | Injection molding machine does not have residual device of moulding plastics | |

| CN212446191U (en) | Injection mold for automobile lamp reflector | |

| CN211390033U (en) | Hose injection molding device of vehicle-mounted dust collector | |

| CN212603092U (en) | Quick forming die of car lamp face guard | |

| CN208558212U (en) | A kind of plasticization and injection separated type nested injection machine | |

| CN215242484U (en) | Plastic mould with cooling demoulding structure | |

| CN212578947U (en) | Injection moulding processing is with material mixing apparatus who has rapid disassembly structure | |

| CN221584431U (en) | Cooling shaping mechanism for air conditioner shell production | |

| CN215203309U (en) | Intelligent precise screw injection molding machine | |

| CN214773639U (en) | Injection mold who possesses bullet material function | |

| CN214082532U (en) | Injection molding machine capable of improving heat energy utilization rate | |

| CN214872197U (en) | Mould is used in production of printer shell | |

| CN211709952U (en) | Quick cooling type injection molding device | |

| CN214645368U (en) | High-performance plastic injection molding equipment with quick waste material cleaning mechanism |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |