CN214362470U - Cloth pulling embroidery sewing and cutting integrated device - Google Patents

Cloth pulling embroidery sewing and cutting integrated device Download PDFInfo

- Publication number

- CN214362470U CN214362470U CN202120333761.4U CN202120333761U CN214362470U CN 214362470 U CN214362470 U CN 214362470U CN 202120333761 U CN202120333761 U CN 202120333761U CN 214362470 U CN214362470 U CN 214362470U

- Authority

- CN

- China

- Prior art keywords

- cloth

- embroidery

- cutting

- slide rail

- embroidery cloth

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Sewing Machines And Sewing (AREA)

Abstract

The utility model discloses a granny rag is embroidered and is made up and cut integrative device belongs to granny rag embroidery technical field, including a supporting bench, supporting bench one side top is supporting to be provided with the embroidery cloth, and embroidery cloth below fixed mounting has the dust catcher, and embroidery cloth rotates on one side to be provided with electronic roller, and the inside rotation in electronic roller below is provided with fastening screw, and the embedding of supporting bench bottom is provided with lead screw slide rail A. The utility model discloses in, when the embroidery cloth cuts, can slide it, accomplish the work of cutting, and the sword that cuts of tooth form when cutting the embroidery cloth, it is more stable, can not lead to the embroidery cloth fold when dragging, when cutting the sword for a long time and using the emergence ageing phenomenon messenger, can take out it from the draw-in groove, change, simultaneously through fastening screw, adjustable electronic roller and a supporting bench's distance, guarantee embroidery cloth is at the in-process of carrying, tighten it, be convenient for the expansion of the work of cutting.

Description

Technical Field

The utility model belongs to the technical field of the granny rag is embroidered, specifically be a granny rag is embroidered and is made up and cut integrative device.

Background

The cloth is a material commonly used in decorative materials. Comprises various fabrics such as chemical fiber carpets, non-woven wallcoverings, linen, nylon fabrics, colored rubberized fabrics, flannel and the like. Cloth plays a considerable role in decorative displays, often a major non-negligible effort in the overall sales space.

Embroidery cloth material is rolled up when adding man-hour, need to roll it out, whole preparation adds man-hour, the area is great, need be through the preparation of multichannel process, when cutting embroidery cloth, the surface fabric appears the phenomenon of coming loose easily, the edge that leads to cutting is uneven, produce a large amount of cloth pieces simultaneously, glue and glue on embroidery cloth surface, can influence wholly pleasing to the eye, and need the manual work to clear up, need the manual work to remove to sewing machine department after the cloth cuts, arrange in order the preparation, influence machining efficiency, and when making up, need stimulate the cloth according to sewing machine's position, the fold can appear to the embroidery cloth in the period, influence finished product outward appearance.

SUMMERY OF THE UTILITY MODEL

The utility model aims to provide a: in order to solve the cloth and appear the phenomenon of coming loose when cutting, influence the regularity of embroidery cloth edge, produce a large amount of cloth pieces, can't in time with its clearance, can directly glue and paste on the cloth is on the surface, during the embroidery cloth of sewing simultaneously, can stimulate it at will, lead to the embroidery cloth problem that fold phenomenon appears, provide a granny rag embroidery and make up and cut integrative device.

The utility model adopts the technical scheme as follows: a cloth-pulling embroidery sewing and cutting integrated device comprises a supporting table, wherein embroidery cloth is arranged above one side of the supporting table in a matching way, a dust collector is fixedly arranged below the embroidery cloth, an electric roller is rotationally arranged at one side of the embroidery cloth, a fastening screw rod is rotatably arranged in the lower part of the electric roller, a screw rod slide rail A is embedded in the bottom of the supporting platform, the screw rod slide rail A is fixedly provided with a clamping groove through a slide block, the inside of the clamping groove is movably connected with a cutting knife, a screw rod slide rail B is fixedly arranged on one side of the supporting platform, a bracket is fixedly arranged on the screw rod slide rail B through a slide block, an electric telescopic rod is fixedly arranged below the bracket, a supporting plate is arranged at one side below the bracket in a matching way, the sewing machine is fixedly installed on the other side above the supporting table, a clamping block is fixedly installed below the sewing machine, and a sliding groove is formed in the outer side of the clamping block in an embedded mode.

Wherein, the supporting lug that is provided with of cutting sword one side, lug and draw-in groove are the form setting of agreeing with, and cut the sword and be the setting of tooth form.

Wherein, the opening of the dust collector corresponds to the cutting knife.

The support sets up quantity and is two, is the symmetric form respectively and distributes in a brace table both sides, and the supporting clamp plate that is provided with in electric telescopic handle below.

Wherein, sewing machine is sliding connection through fixture block and spout with the brace table, and fixture block and spout are the setting of agreeing with the form.

The dust collector, the electric roller, the screw rod slide rail A, the screw rod slide rail B, the electric telescopic rod and the sewing machine are all electrically connected with an external power supply through a switch.

To sum up, owing to adopted above-mentioned technical scheme, the beneficial effects of the utility model are that:

1. the utility model discloses in, when the embroidery cloth cuts, can slide it, accomplish the work of cutting, and the sword that cuts of tooth form when cutting the embroidery cloth, it is more stable, can not lead to the embroidery cloth fold when dragging, when cutting the sword for a long time and using the emergence ageing phenomenon messenger, can take out it from the draw-in groove, change, simultaneously through fastening screw, adjustable electronic roller and a supporting bench's distance, guarantee embroidery cloth is at the in-process of carrying, tighten it, be convenient for the expansion of the work of cutting.

2. The utility model discloses in, the dust catcher opening part is corresponding with the sword of cutting, when cutting the embroidery cloth, can produce the cloth piece, utilizes the dust catcher in time to absorb it, prevents that the piece from gluing on the embroidery cloth, influences its outward appearance, uses manpower sparingly simultaneously and clears away.

3. The utility model discloses in, when the cloth cuts into the slice, place in the backup pad top, electric telescopic handle stretches out and draws back downwards, act on the embroidery cloth with the clamp plate, the clamp plate presss from both sides the cloth with the backup pad tightly, drive the slip of support through lead screw slide rail B, can pull the embroidery cloth and remove, make the embroidery cloth cut the back and in time remove the back and carry out sewing processing, and sewing machine accessible fixture block and spout slide on the workstation, make its be convenient for be used for making up at each position of cloth, avoid folding the cloth at will, lead to it to take place the fold.

Drawings

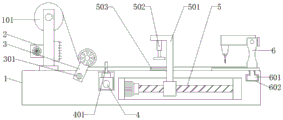

FIG. 1 is a schematic diagram of the overall side structure of the present invention;

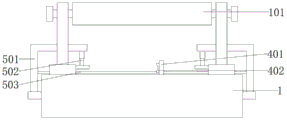

FIG. 2 is a schematic diagram of the front structure of the electric telescopic rod and the cutting knife of the present invention;

FIG. 3 is a schematic diagram of the front structure of the middle lead screw slide rail A of the present invention;

fig. 4 is a schematic diagram of a three-dimensional structure of the middle clamping groove and the cutting knife of the present invention.

The labels in the figure are: 1. a support table; 101. embroidering cloth; 2. a vacuum cleaner; 3. an electric roller; 301. fastening a screw rod; 4. a screw rod slide rail A; 401. a card slot; 402. cutting knife; 5. a screw rod slide rail B; 501. a support; 502. an electric telescopic rod; 503. a support plate; 6. a sewing machine; 601. a clamping block; 602. a chute.

Detailed Description

In order to make the objects, technical solutions and advantages of the present invention more clearly understood, the present invention is further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are for purposes of illustration only and are not intended to limit the invention.

In the description of the present invention, it should be noted that the terms "center", "upper", "lower", "left", "right", "vertical", "horizontal", "inner", "outer", and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplification of description, but do not indicate or imply that the device or element referred to must have a specific orientation, be constructed and operated in a specific orientation, and thus, should not be construed as limiting the present invention; the terms "first," "second," and "third" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance; furthermore, unless expressly stated or limited otherwise, the terms "mounted," "connected," and "connected" are to be construed broadly, as they may be fixedly connected, detachably connected, or integrally connected, for example; can be mechanically or electrically connected; they may be connected directly or indirectly through intervening media, or they may be interconnected between two elements. The specific meaning of the above terms in the present invention can be understood in specific cases to those skilled in the art.

The utility model discloses in:

referring to fig. 1-4, a cloth pulling embroidery is made up and is cut integrative device, includes a supporting bench 1, its characterized in that: supporting table 1 one side top is supporting to be provided with embroidery cloth 101, embroidery cloth 101 below fixed mounting has dust catcher 2, embroidery cloth 101 one side is rotated and is provided with electric roller 3, the inside rotation in electric roller 3 below is provided with fastening screw 301, supporting table 1 bottom embedding is provided with lead screw slide rail A4, lead screw slide rail A4 has draw-in groove 401 through slider fixed mounting, the inside swing joint of draw-in groove 401 has cutting sword 402, supporting table 1 one side fixed mounting has lead screw slide rail B5, lead screw slide rail B5 has support 501 through slider fixed mounting, support 501 below fixed mounting has electric telescopic handle 502, the supporting backup pad 503 that is provided with in support 501 below one side, supporting table 1 top opposite side fixed mounting has sewing machine 6, sewing machine 6 below fixed mounting has fixture block 601, the nested spout 602 that is provided with in the fixture block 601 outside.

Further, the supporting lug that is provided with in cutting sword 402 one side, and the lug is the form setting of agreeing with draw-in groove 401, the lug is the form setting of agreeing with draw-in groove 401, and cut sword 402 and be the tooth form setting, lead screw slide rail A4 drives draw-in groove 401 and slides with cutting sword 402, when the embroidery cloth cuts, can slide it, accomplish cutting work, and tooth form cut sword 402 is when cutting the embroidery cloth, and is more stable, can not lead to the fold of embroidery cloth when dragging, when cutting sword 402 long time when using the ageing phenomenon makes, can take out it from draw-in groove 401, change, simultaneously through fastening screw 301, adjustable electric roller 3 and the distance of brace table 1, guarantee the embroidery cloth is at the in-process of carrying, tighten it, be convenient for the expansion of cutting work.

Further, the 2 opening parts of dust catcher are corresponding with cutting sword 402, when cutting the embroidery cloth, can produce the cloth piece, utilize dust catcher 2 to in time absorb it, prevent that the piece from gluing on the embroidery cloth, influence its outward appearance, use manpower sparingly simultaneously and clear away.

Further, the number of the supports 501 is two, the supports are symmetrically distributed on two sides of the support table 1, the pressing plates are arranged below the electric telescopic rods in a matched mode, when the cloth is cut into pieces, the cloth is placed above the support plate 503, the electric telescopic rods 502 stretch downwards to act on the embroidery cloth, the pressing plates and the support plate 503 clamp the cloth tightly, the supports 501 are driven to slide through the lead screw slide rails B5, the embroidery cloth can be pulled to move, and sewing processing is carried out after the embroidery cloth is cut and timely moves.

Further, the sewing machine 6 and the support table 1 are in sliding connection through the fixture block 601 and the sliding groove 602, the fixture block 601 and the sliding groove 602 are arranged in a matched mode, the sewing machine 6 can slide on the workbench through the fixture block 601 and the sliding groove 602, and therefore the sewing machine is convenient for sewing of all parts of cloth, and the phenomenon that the cloth is folded randomly to cause wrinkles is avoided.

Further, the dust collector 2, the electric roller 3, the screw rod slide rail A4, the screw rod slide rail B5, the electric telescopic rod 502 and the sewing machine 6 are all electrically connected with an external power supply through a switch.

The working principle is as follows: firstly, the cloth in the embroidery cloth 101 above the support table 1 is stretched to the electric roller 3, the electric roller 3 is used for conveying the cloth, meanwhile, the distance between the electric roller 3 and the support table 1 can be adjusted through the fastening screw 301, the embroidery cloth is tightened in the conveying process, the cutting work is convenient to expand, the lead screw slide rail A4 drives the clamping groove 401 and the cutting knife 402 to slide, the embroidery cloth can slide when being cut, the cutting work is completed, the tooth-shaped cutting knife 402 is more stable when cutting the embroidery cloth, the embroidery cloth cannot be wrinkled when being pulled, the cutting knife 402 is aged for a long time, the embroidery cloth can be taken out of the clamping groove 401 and replaced, then the opening of the dust collector 2 corresponds to the cutting knife 402, when cutting the embroidery cloth, cloth scraps can be generated, and can be absorbed in time by the dust collector 2, prevent that the piece from gluing on the embroidery cloth, influence its outward appearance, use manpower sparingly simultaneously and clear away, secondly when the cloth cuts into the slice, place in backup pad 503 top, electric telescopic handle 502 stretches out and draws back downwards, act on the clamp plate on the embroidery cloth, the clamp plate presss from both sides the cloth with backup pad 503 tightly, drive the slip of support 501 through lead screw slide rail B5, can pull the embroidery cloth and remove, make the embroidery cloth cut in time remove the back and carry out sewing processing, sewing machine 6 accessible fixture block 601 and spout 602 slide on the workstation at last, make it be convenient for be used for making up of each position of cloth, avoid folding the cloth at will, lead to it to take place the fold.

The above description is only exemplary of the present invention and should not be taken as limiting the scope of the present invention, as any modifications, equivalents, improvements and the like made within the spirit and principles of the present invention are intended to be included within the scope of the present invention.

Claims (6)

1. The utility model provides a cloth pulling embroidery is made up and is cut integrative device, includes a supporting bench (1), its characterized in that: an embroidery cloth (101) is arranged above one side of the support table (1) in a matched manner, a dust collector (2) is fixedly arranged below the embroidery cloth (101), an electric roller (3) is rotatably arranged on one side of the embroidery cloth (101), a fastening screw (301) is rotatably arranged inside the lower side of the electric roller (3), a lead screw slide rail A (4) is embedded into the bottom of the support table (1), a clamping groove (401) is fixedly arranged on the lead screw slide rail A (4) through a sliding block, a cutting knife (402) is movably connected inside the clamping groove (401), a lead screw slide rail B (5) is fixedly arranged on one side of the support table (1), a support (501) is fixedly arranged on the lead screw slide rail B (5) through a sliding block, an electric telescopic rod (502) is fixedly arranged below the support (501), a support plate (503) is arranged on one side of the lower side of the support table (501) in a matched manner, the sewing machine (6) is fixedly mounted on the other side above the supporting table (1), a clamping block (601) is fixedly mounted below the sewing machine (6), and a sliding groove (602) is formed in the outer side of the clamping block (601) in an embedded mode.

2. The cloth pulling embroidery sewing and cutting integrated device as claimed in claim 1, characterized in that: the convex block is arranged on one side of the cutting knife (402) in a matched mode, the convex block is arranged in a matched mode with the clamping groove (401), and the cutting knife (402) is arranged in a tooth shape.

3. The cloth pulling embroidery sewing and cutting integrated device as claimed in claim 1, characterized in that: the opening of the dust collector (2) corresponds to the cutting knife (402).

4. The cloth pulling embroidery sewing and cutting integrated device as claimed in claim 1, characterized in that: the support (501) sets up quantity and is two, is the symmetry respectively and distributes in brace table (1) both sides, and electric telescopic handle (502) below is supporting to be provided with the clamp plate.

5. The cloth pulling embroidery sewing and cutting integrated device as claimed in claim 1, characterized in that: the sewing machine (6) and the support table (1) are in sliding connection through a fixture block (601) and a sliding groove (602), and the fixture block (601) and the sliding groove (602) are arranged in a matched mode.

6. The cloth pulling embroidery sewing and cutting integrated device as claimed in claim 1, characterized in that: the dust collector (2), the electric roller (3), the screw rod slide rail A (4), the screw rod slide rail B (5), the electric telescopic rod (502) and the sewing machine (6) are all electrically connected with an external power supply through a switch.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120333761.4U CN214362470U (en) | 2021-02-05 | 2021-02-05 | Cloth pulling embroidery sewing and cutting integrated device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120333761.4U CN214362470U (en) | 2021-02-05 | 2021-02-05 | Cloth pulling embroidery sewing and cutting integrated device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN214362470U true CN214362470U (en) | 2021-10-08 |

Family

ID=77965161

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202120333761.4U Active CN214362470U (en) | 2021-02-05 | 2021-02-05 | Cloth pulling embroidery sewing and cutting integrated device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN214362470U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114523510A (en) * | 2022-02-23 | 2022-05-24 | 申洲针织(安徽)有限公司 | Cloth ironing fork cutting device and operation method thereof |

-

2021

- 2021-02-05 CN CN202120333761.4U patent/CN214362470U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114523510A (en) * | 2022-02-23 | 2022-05-24 | 申洲针织(安徽)有限公司 | Cloth ironing fork cutting device and operation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN213866787U (en) | Automatic tie of blank function is bordured and is used sewing machine | |

| CN214362470U (en) | Cloth pulling embroidery sewing and cutting integrated device | |

| CN212127088U (en) | Winding device for textile processing | |

| CN213866747U (en) | Sewing machine for sewing scarf with smoothing function | |

| CN218147239U (en) | Automatic cloth dragging machine with stable sewing stitch | |

| CN207193526U (en) | Sewing positioner | |

| CN214300683U (en) | Sewing machine with cloth smooths mechanism | |

| CN213951561U (en) | Novel high-efficient woollen blanket is bordured device | |

| CN112726038B (en) | Envelope type pillowcase machine | |

| CN108978052B (en) | Multi-needle quilter for preventing sweater from wrinkling | |

| CN209779177U (en) | Flattening device of sewing machine | |

| CN210215961U (en) | Cloth cutting device for tailoring | |

| CN209602754U (en) | A kind of automatic sewing unit | |

| CN210561117U (en) | Automatic right-angle fillet four-side sewing equipment | |

| CN209555622U (en) | A kind of non-woven fabric process units suitable for interior leather for automobiles production | |

| CN215289197U (en) | High-speed automatic thread trimming quilter | |

| CN218756679U (en) | Textile garment fabric trimming device | |

| CN213708927U (en) | Fabric cutting device for textile machinery | |

| CN215051549U (en) | Device is tailor to cloth for textile production | |

| CN220284375U (en) | Hemming device for sofa cloth production | |

| CN210684152U (en) | Fixing clamp for sewing machine | |

| CN215920599U (en) | Scarf cuts hem mechanism fast | |

| CN213976270U (en) | Cloth cutting machine convenient to spread cloth | |

| CN215481657U (en) | Sewing equipment is used in handbag processing convenient to cutting thread end | |

| CN216688588U (en) | Efficient sewing machine set capable of continuously working |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |