CN213422572U - Multi-shaft vibration load bolt loosening testing device - Google Patents

Multi-shaft vibration load bolt loosening testing device Download PDFInfo

- Publication number

- CN213422572U CN213422572U CN202022938062.0U CN202022938062U CN213422572U CN 213422572 U CN213422572 U CN 213422572U CN 202022938062 U CN202022938062 U CN 202022938062U CN 213422572 U CN213422572 U CN 213422572U

- Authority

- CN

- China

- Prior art keywords

- support

- sliding block

- bolt

- guide rail

- speed regulating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn - After Issue

Links

- 238000012360 testing method Methods 0.000 title claims abstract description 36

- 230000001105 regulatory effect Effects 0.000 claims description 26

- 238000002474 experimental method Methods 0.000 claims description 11

- 230000007246 mechanism Effects 0.000 claims description 11

- 238000011160 research Methods 0.000 abstract description 7

- 238000010998 test method Methods 0.000 abstract description 2

- 230000002265 prevention Effects 0.000 abstract 1

- 238000000034 method Methods 0.000 description 5

- 230000009471 action Effects 0.000 description 3

- 238000009434 installation Methods 0.000 description 3

- 230000003068 static effect Effects 0.000 description 2

- 230000005483 Hooke's law Effects 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000001808 coupling effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

Images

Landscapes

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

- Testing Of Devices, Machine Parts, Or Other Structures Thereof (AREA)

Abstract

The utility model discloses a multi-axis vibration load bolt loosening testing device, wherein a mounting plate with a through hole is arranged on a test bench, a support a and a support b are both in a shape like 'r' and are arranged on the support a, a guide rail a is vertical to a base and is arranged on the support a, and a guide rail b is horizontal to the base and is arranged on the support b; and selecting a tension spring corresponding to the elastic stiffness coefficient according to the stroke of the slide block a or the slide block b, and connecting the tension spring with the connecting test board. The test device can be used for testing the bolt loosening caused by unidirectional or multidirectional vibration loads of different bolt groups, has the advantages of simple structure, simple test method, simple and convenient parameter adjustment mode, high test reliability and the like, and has important significance and reference value for the research on the vibration fatigue failure of the bolt group to be tested and the vibration looseness prevention of the bolt.

Description

Technical Field

The utility model relates to a bolt assembly connects reliability testing technique, in particular to multiaxis vibration load causes bolt looseness testing arrangement.

Background

With the continuous development of the current automation process, the bolt connection plays an important role in various mechanical equipment, and the connection reliability of the bolt connection is an important guarantee for the safe operation of the mechanical equipment. The bolt connection has the advantages that the bolt connection is convenient to mount and dismount, and the bolt connection also has the disadvantages that the bolt connection is often subjected to various loads and the mutual coupling effect among various loads (such as static load, vibration load, high-temperature load and the like) under the working state, and the effect of the external loads causes no small challenge to the reliability of the connection. Among various external loads, the action of vibration load is one of the important factors causing the loosening of the bolt, and the action of multi-axial vibration load is common in the phenomenon of bolt connection in the running mechanical equipment. Thus, it may pose no small challenge to the safe operation of the device. In order to research the reliability of the bolt connection, a great deal of research is carried out, but most of the research currently stays in static analysis and test, and a small part of the research stops on the influence of unidirectional vibration load on the reliability of the bolt connection.

SUMMERY OF THE UTILITY MODEL

To the problem, the utility model provides a multiaxis vibration load causes bolt looseness testing arrangement for the influence of the bolt connection to its not hard up condition is acted on alone or simultaneously in the vibration load of research equidirectional not, has important meaning and value to the reliability scheduling problem of studying bolted connection.

In order to achieve the above object, the utility model adopts the following technical scheme: a multi-axis vibration load bolt loosening testing device comprises a base, an experiment table, a testing connecting plate, a support a and a support b, wherein the experiment table, the testing connecting plate, the support a and the support b are mounted on the base; the support a and the support b are in a shape of ' reverse ' L ', the guide rail a is vertical to the base and is arranged on the support a, and the guide rail b is horizontal to the base and is arranged on the support b;

the base is also provided with a first speed regulating motor and a second speed regulating motor, the shaft end of the first speed regulating motor is provided with a longitudinal crank slide block mechanism, and the shaft end of the second speed regulating motor is provided with a transverse crank slide block mechanism;

the longitudinal crank sliding block mechanism is composed of a driving disc a, a connecting rod a and a sliding block a, the driving disc a is connected with the shaft end of the first speed regulating motor, the connecting rod a is installed on the driving disc a, the other end of the connecting rod a is connected with the sliding block a, the sliding block a is connected with a track of the guide rail a, one end of a tension spring is connected with the sliding block a, and the other end of the tension spring is connected with a circular ring a at the loading end of the test connecting plate;

the transverse crank sliding block mechanism is composed of a driving disc b, a connecting rod b and a sliding block b, the driving disc b is connected with the shaft end of a second speed regulating motor, the connecting rod b is installed on the driving disc b, the other end of the connecting rod b is connected with the sliding block b, the sliding block b is connected with a track of a guide rail b, one end of a tension spring is connected with the sliding block b, and the other end of the tension spring is connected with a circular ring b of a loading end of the test connecting plate.

The utility model discloses the folk prescription that can carry out different bolt group is to or multi-direction vibration load send bolt looseness test experiment, has advantages such as simple structure, test method are simple, the parameter control mode is simple and convenient, experiment reliability height, has significant and reference value to the research in the aspect of the bolt group vibration fatigue failure and the bolt vibration locking that awaits measuring.

Drawings

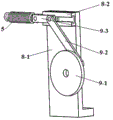

Fig. 1 is a schematic perspective view of the present invention;

FIG. 2 is a schematic view of the vertical installation structure of the middle slider of the present invention;

FIG. 3 is a schematic view of the horizontal installation structure of the middle slider of the present invention;

fig. 4 is a schematic perspective view of the middle test connection board 4 of the present invention.

In the figure: 1. a base; 2. a laboratory bench; 3. a bolt group to be tested; 4. the method comprises the following steps of testing a connecting plate, 4-1, a bearing end, 4-2, a loading end, 4-3, a ring a, 4-4 and a ring b; 5. a tension spring; 6. a longitudinal crank slider mechanism 6-1, a driving disc a, 6-2, a connecting rod a, 6-3 and a slider a; 7. longitudinal guide rail, 7-1, support a, 7-2, guide rail a; 8. a transverse guide rail 8-1, a support b8-2 and a guide rail b; 9. 9-1, 9-2, 9-3 and b; 10. the first speed regulating motor, 11, the second speed regulating motor.

Detailed Description

The invention will now be further described with reference to the accompanying drawings and examples. Referring to fig. 1 to 4, a test bench 2 with a through hole mounting plate is fixed on a base 1, the test bench 2 is connected with a bearing end 4-1 of a test connecting plate 4 through a bolt group 3 to be tested, the loading end 4-2 of the test connecting plate 4 is provided with two circular rings (namely, a circular ring a4-3 and a circular ring b4-4, as shown in fig. 4) which are respectively connected with a hook at one end of two tension springs 5, and a hook at the other end of each tension spring 5 is respectively connected with a slide block (namely, a slide block a6-3 and a slide block b 9-3) in two crank slide block mechanisms (namely, a longitudinal crank slide block machine 6 and a transverse crank slide block mechanism 9) (as shown in fig. 2 and 3).

Referring to fig. 1, the driving part mounting method: one end of a tension spring 5 is connected with a loading end 4-2 of the test connecting plate 4, the other end of the tension spring is connected with a sliding block a6-3 (or a sliding block b 9-3), a sliding block a6-3 (or a sliding block b 9-3) is mounted on a guide rail a7-2 (or a guide rail b 8-2) and can freely move along the length direction of the guide rail, the guide rail a7-2 (or the guide rail b 8-2) is fixed on the base 1 through a support a7-1 (or a support b 7-2), the other end of the sliding block a6-3 (or a sliding block b 9-3) is hinged with one end of a connecting rod a6-2 (or a connecting rod b 9-2), and the outer side of a driving disc a6-1 (or a driving disc b9-1) is hinged with the other end of the connecting rod a6-2 (.

The power part mounting method comprises the following steps: the first speed regulating motor 10 is fixed on the base 1 through bolts, and an output shaft of the first speed regulating motor 10 is connected with the driving disc a6-1 and rotates synchronously with the shaft. Similarly, the second adjustable-speed motor 11 is fixed on the base 1 through bolts and arranged in a reverse 'L' shape with the first adjustable-speed motor 10, and the output shaft thereof is connected with the driving disc b 9-1.

When the power supply is switched on, the driving disc a6-1 (or the driving disc b9-1) rotates along with the first speed regulating motor 10 (or the second speed regulating motor 11), and then the driving connecting rod a6-2 (or the connecting rod b 9-2) drives the sliding block a6-3 (or the sliding block b 9-3) to move along the guide rail a7-2 (or the guide rail b 8-2). Due to the action of the tension spring 5, a vibration load is applied to the loading end 4-2 of the test connecting plate 4 along the moving direction of the slide block a6-3 (or the slide block b 9-3), and is further transmitted to the bolt group 3 to be tested.

The rotation speed of the first speed regulating motor 10 or the second speed regulating motor 11 is changed, so that the vibration frequency of the loaded vibration load can be adjusted; by selecting the tension springs 5 having different elastic stiffness coefficients, the magnitude of the exciting force of the loaded vibration load can be adjusted.

The utility model discloses the test step is as follows:

1) placing the test connecting plate 4 on the experiment table 2, designing the layout of the bolt group 3 to be tested, connecting the test connecting plate with the experiment table 2 through the bolt group 3 to be tested, screwing the bolt group 3 to be tested, and controlling the pre-tightening force through a fixed-torque wrench;

2) according to the stroke of the sliding block a6-3 or the sliding block b9-3, considering the loading force required by the experiment, calculating the elastic stiffness coefficient of the required spring by Hooke's law, selecting a tension spring 5 corresponding to the elastic stiffness coefficient, and connecting the ring a4-3 or the ring b4-4 on the test connecting plate 4 with the corresponding sliding block a6-3 or the sliding block b 9-3;

3) selecting the loading direction and the loading frequency of the vibration load, respectively switching on the power supply of the first speed regulating motor 10 or the second speed regulating motor 11 (or simultaneously switching on the power supply of the first speed regulating motor 10 and the power supply of the second speed regulating motor 11), and adjusting the rotating speed to meet the loading frequency required by the experiment;

4) recording the initial position of the bolt group 3 to be tested, observing the condition of the bolt group 3 to be tested in real time, and respectively recording the loosening sequence and time of bolts in the bolt group 3 to be tested;

5) the installation layout of the bolt group 3 to be tested is changed, and a grouping experiment can be carried out by respectively or simultaneously adjusting experimental parameters such as the frequency of the first speed regulating motor 10 and the second speed regulating motor 11, the elastic coefficient of the tension spring 5, the vibration load direction of the test connecting plate 4 and the like, and the combination of at least two of the experimental conditions;

6) the experimental data obtained were summarized and analyzed to obtain experimental results.

Claims (1)

1. A multi-axis vibration load bolt loosening testing device comprises a base, an experiment table, a testing connecting plate, a support a and a support b, wherein the experiment table, the testing connecting plate, the support a and the support b are mounted on the base; the support a and the support b are in a shape of ' reverse ' L ', the guide rail a is vertical to the base and is arranged on the support a, and the guide rail b is horizontal to the base and is arranged on the support b;

the base is also provided with a first speed regulating motor and a second speed regulating motor, the shaft end of the first speed regulating motor is provided with a longitudinal crank slide block mechanism, and the shaft end of the second speed regulating motor is provided with a transverse crank slide block mechanism;

the longitudinal crank sliding block mechanism is composed of a driving disc a, a connecting rod a and a sliding block a, the driving disc a is connected with the shaft end of the first speed regulating motor, the connecting rod a is installed on the driving disc a, the other end of the connecting rod a is connected with the sliding block a, the sliding block a is connected with a track of the guide rail a, one end of a tension spring is connected with the sliding block a, and the other end of the tension spring is connected with a circular ring a at the loading end of the test connecting plate;

the transverse crank sliding block mechanism is composed of a driving disc b, a connecting rod b and a sliding block b, the driving disc b is connected with the shaft end of a second speed regulating motor, the connecting rod b is installed on the driving disc b, the other end of the connecting rod b is connected with the sliding block b, the sliding block b is connected with a track of a guide rail b, one end of a tension spring is connected with the sliding block b, and the other end of the tension spring is connected with a circular ring b of a loading end of the test connecting plate.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022938062.0U CN213422572U (en) | 2020-12-10 | 2020-12-10 | Multi-shaft vibration load bolt loosening testing device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022938062.0U CN213422572U (en) | 2020-12-10 | 2020-12-10 | Multi-shaft vibration load bolt loosening testing device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN213422572U true CN213422572U (en) | 2021-06-11 |

Family

ID=76252869

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202022938062.0U Withdrawn - After Issue CN213422572U (en) | 2020-12-10 | 2020-12-10 | Multi-shaft vibration load bolt loosening testing device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN213422572U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112284668A (en) * | 2020-12-10 | 2021-01-29 | 南昌航空大学 | Device and method for testing bolt loosening caused by multi-axis vibration load |

-

2020

- 2020-12-10 CN CN202022938062.0U patent/CN213422572U/en not_active Withdrawn - After Issue

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112284668A (en) * | 2020-12-10 | 2021-01-29 | 南昌航空大学 | Device and method for testing bolt loosening caused by multi-axis vibration load |

| CN112284668B (en) * | 2020-12-10 | 2024-07-02 | 南昌航空大学 | Multi-shaft vibration load induced bolt loosening testing device and method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112284668B (en) | Multi-shaft vibration load induced bolt loosening testing device and method | |

| CN100445713C (en) | Testing apparatus for high temperature, superconducting, magnetic suspension and dynamic performance and testing method with the same | |

| CN201266143Y (en) | Endurance test equipment for lifting jack | |

| CN204535985U (en) | Electrical spindle for machine tool reliability test bench centering adjusting device | |

| CN103344449B (en) | A kind of single-degree-of-freedom numerically-controlled machine charger and load test method | |

| CN111220375A (en) | Multifunctional rotor test bed with flexible excitation | |

| CN213422572U (en) | Multi-shaft vibration load bolt loosening testing device | |

| CN106017959B (en) | Lead screw guide rails reliability test bench based on electro-hydraulic loading | |

| CN111158262A (en) | Double-station load simulation tool device for steering engine | |

| CN111215648B (en) | Electric spindle reliability rapid experiment loading method and loading system | |

| CN106885746A (en) | A kind of wideband response, large stroke experimental provision for rubber fatigue performance test | |

| CN200975925Y (en) | Equipment for testing magnetic levitation dynamic performance of high-temperature superconduction block | |

| CN110618383A (en) | Servo motor test bench and test system | |

| CN204924677U (en) | Bull -dozer load test device | |

| CN109443762B (en) | Fault monitoring and life predicting test device for ball screw pair | |

| CN204988982U (en) | A electric friction wear testing machine for brush material | |

| CN204719208U (en) | Servo motor test bench | |

| CN107314905B (en) | Simulation actuator of automobile electronic braking system | |

| CN112903228A (en) | Magnetic force excitation bolt joint vibration failure experimental device and test method | |

| CN209961882U (en) | Special electric dynamometer of new energy automobile and control system | |

| CN217738652U (en) | Sliding bearing clearance fault simulation experiment device of reciprocating mechanism | |

| CN2741031Y (en) | Testing table of sutomatic gear of vehicle | |

| CN109406083B (en) | Suspension string hardware wind excitation vibration abrasion simulation test platform | |

| CN114705248B (en) | Test equipment of rotating unit | |

| CN106769034B (en) | Bearing accelerated life test bed |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| AV01 | Patent right actively abandoned |

Granted publication date: 20210611 Effective date of abandoning: 20240702 |

|

| AV01 | Patent right actively abandoned |

Granted publication date: 20210611 Effective date of abandoning: 20240702 |

|

| AV01 | Patent right actively abandoned | ||

| AV01 | Patent right actively abandoned |