CN213224193U - Anti-shifting casting mold - Google Patents

Anti-shifting casting mold Download PDFInfo

- Publication number

- CN213224193U CN213224193U CN202022184127.7U CN202022184127U CN213224193U CN 213224193 U CN213224193 U CN 213224193U CN 202022184127 U CN202022184127 U CN 202022184127U CN 213224193 U CN213224193 U CN 213224193U

- Authority

- CN

- China

- Prior art keywords

- casting mould

- hole

- branch

- top cap

- baffle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Casting Devices For Molds (AREA)

Abstract

The utility model discloses a casting mould of anti-migration, including the casting mould, the top lock of casting mould has the top cap, the equal rigid coupling in both ends of casting mould has branch, the screw thread has been attacked to the outer wall of branch, the through-hole has all been opened at the upper surface both ends of top cap, the top threaded connection of branch has the drum, the top of drum is moved the welding and is had the baffle, baffle and top cap closely laminate. This prevent casting mould of skew, install branch through the both ends at casting mould, make the top cap insert it through the through-hole that sets up on it in, make top cap and casting mould laminate mutually, effectually avoid producing the skew when top cap and casting mould are connected, and the inside that inserts the through-hole with the drum links to each other with the top thread of branch, and drive the baffle and remove, effectual convenience is in closely laminating the top cap on casting mould, increase the stability of its during operation, moreover, the operation is simple, it is also convenient to dismantle.

Description

Technical Field

The utility model relates to a prevent casting mould technical field of skew specifically is a prevent casting mould of skew.

Background

The casting mould is characterized in that in order to obtain the structural shape of a part, other easily-formed materials are made into the structural shape of the part in advance, then the mould is placed in a sand mould, so that a cavity with the same structural size as the part is formed in the sand mould, then a fluid liquid is poured into the cavity, the liquid can be cooled and solidified to form the part with the same shape and structure as the mould, when the existing casting mould is used, the existing casting mould cannot meet the problem that the existing casting mould is deviated when a top cover is buckled on the casting mould, the shape of the cast mould is distorted, the using effect of the casting mould is influenced, meanwhile, the fixing effect of the top cover and the casting mould after connection is poor, the operation is laborious, and the using efficiency.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide a prevent casting mould of skew to solve the problem that proposes among the above-mentioned background art.

In order to achieve the above object, the utility model provides a following technical scheme: the utility model provides a casting mould of anti-migration, includes the casting mould, the top lock of casting mould has the top cap, the equal rigid coupling in both ends of casting mould has branch, the screw thread has been attacked to the outer wall of branch, the through-hole has all been opened at the upper surface both ends of top cap, branch runs through the through-hole, the top threaded connection of branch has the drum, the welding is moved on the top of drum has the baffle, the baffle closely laminates with the top cap, the top rigid coupling of baffle has the crank.

Preferably, the diameter of the top end of the through hole is larger than that of the bottom end of the through hole, the diameter of the bottom end of the through hole is larger than that of the supporting rod, and the diameter of the top end of the through hole is larger than that of the cylinder.

Preferably, the outer wall of the supporting rod is respectively sleeved with a circular ring and a compression spring, and the circular ring is abutted against the top cover.

Preferably, handles are fixedly connected to the front side and the rear side of the top end of the top cover.

Compared with the prior art, the beneficial effects of the utility model are that: this prevent casting mould of skew, install branch through the both ends at casting mould, make the top cap insert it through the through-hole of seting up on it in, make top cap and casting mould laminate mutually, effectually avoid producing the skew when top cap and casting mould are connected, and the inside of inserting the through-hole with the drum links to each other with the top thread of branch, and drive the baffle and remove, effectual convenience is in closely laminating the top cap on casting mould, increase its stability when working, and easy operation, it is also convenient to dismantle, great enhancement casting mould's availability factor, thereby satisfy user's user demand.

Drawings

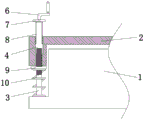

FIG. 1 is a schematic structural view of the present invention;

fig. 2 is a schematic view of the connection structure between the casting mold and the top cover in fig. 1 according to the present invention.

In the figure: 1. casting mould, 2, top cover, 3, support rod, 4, through hole, 5, handle, 6, crank, 7, baffle, 8, cylinder, 9, ring, 10 and compression spring.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

Referring to fig. 1-2, the present invention provides a technical solution: a casting mould for preventing deviation comprises a casting mould 1, a top cover 2 is buckled above the casting mould 1, handles 5 are fixedly connected to the front side and the rear side of the top end of the top cover 2, the handles 5 are used for driving the top cover 2 to move, supporting rods 3 are fixedly connected to the two ends of the casting mould 1, threads are tapped on the outer walls of the supporting rods 3, the supporting rods 3 are used for being in threaded connection with a cylinder 8, through holes 4 are formed in the two ends of the upper surface of the top cover 2, the supporting rods 3 penetrate through the through holes 4, the cylinder 8 is in threaded connection with the upper portions of the supporting rods 3, a baffle 7 is welded on the top of the cylinder 8, the baffle 7 is used for connecting a crank 6 and the cylinder 8, the baffle 7 is tightly attached to the top cover 2, a crank 6 is fixedly connected to the top end of the baffle 7, a circular ring 9 and a compression spring 10 are respectively sleeved on the outer wall of the supporting rods, the ring 9 is used for supporting the top cover 2;

the diameter of the top end of the through hole 4 is larger than that of the bottom end of the through hole 4, the diameter of the bottom end of the through hole 4 is larger than that of the supporting rod 3, and the diameter of the top end of the through hole 4 is larger than that of the cylinder 8.

In the embodiment, when the casting mold is used, firstly, the top cover 2 with the through hole 4 is buckled on the casting mold 1, the support rod 3 on the casting mold 1 is inserted into the through hole 4, the casting mold 1 and the top cover 2 are effectively and conveniently connected together, the deviation during connection can be avoided, then, the cylinder 8 is inserted into the through hole 4 of the top cover 2, the crank 6 is rotated to drive the cylinder 8 to rotate on the support rod 3 through the baffle 7, the top cover 2 is tightly attached to the top end of the casting mold 1, the stability of the casting mold 1 when the top cover 2 is connected with the top cover 2 is increased, then, molten iron is added into the casting mold 1 through the top cover 2, a workpiece is effectively and conveniently cast, after casting, the cylinder 8 is screwed down from the support rod 3 by rotating the crank 6 for the second time, the top cover 2 is conveniently detached from the casting mold 1, and the use effect of the casting mold 1 is increased, meanwhile, the bottom end of the outer wall of the supporting rod 3 is sleeved with a compression spring 10 and a circular ring 9 and used for supporting the top cover 2 and increasing the service efficiency of the casting mold 1.

In the description of the present invention, it is to be understood that the terms "coaxial", "bottom", "one end", "top", "middle", "other end", "upper", "one side", "top", "inner", "front", "center", "both ends", and the like, indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplicity of description, and do not indicate or imply that the device or element referred to must have a particular orientation, be constructed and operated in a particular orientation, and therefore, should not be construed as limiting the present invention.

In the present invention, unless otherwise expressly stated or limited, the terms "mounted," "disposed," "connected," "fixed," "screwed" and the like are to be construed broadly, e.g., as meaning fixedly connected, detachably connected, or integrally formed; can be mechanically or electrically connected; they may be directly connected or indirectly connected through an intermediate medium, and may be connected through the inside of two elements or in an interaction relationship between two elements, unless otherwise specifically defined, and the specific meaning of the above terms in the present invention will be understood by those skilled in the art according to specific situations.

Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, the scope of which is defined in the appended claims and their equivalents.

Claims (4)

1. The utility model provides a casting mould of anti-migration, includes casting mould (1), the top lock of casting mould (1) has top cap (2), its characterized in that: the equal rigid coupling in both ends of casting mould (1) has branch (3), the screw thread has been attacked to the outer wall of branch (3), through-hole (4) have all been opened at the upper surface both ends of top cap (2), through-hole (4) are run through in branch (3), the top threaded connection of branch (3) has drum (8), the top of drum (8) is moved the welding and is had baffle (7), baffle (7) closely laminate with top cap (2), the top rigid coupling of baffle (7) has crank (6).

2. The anti-shifting casting mold of claim 1, wherein: the diameter of the top end of the through hole (4) is larger than the diameter of the bottom end of the through hole (4), the diameter of the bottom end of the through hole (4) is larger than the diameter of the supporting rod (3), and the diameter of the top end of the through hole (4) is larger than the diameter of the cylinder (8).

3. The anti-shifting casting mold of claim 1, wherein: the outer wall of the supporting rod (3) is respectively sleeved with a circular ring (9) and a compression spring (10), and the circular ring (9) is abutted against the top cover (2) and is connected with the top cover.

4. The anti-shifting casting mold of claim 1, wherein: handles (5) are fixedly connected to the front side and the rear side of the top end of the top cover (2).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022184127.7U CN213224193U (en) | 2020-09-29 | 2020-09-29 | Anti-shifting casting mold |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022184127.7U CN213224193U (en) | 2020-09-29 | 2020-09-29 | Anti-shifting casting mold |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN213224193U true CN213224193U (en) | 2021-05-18 |

Family

ID=75877237

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202022184127.7U Active CN213224193U (en) | 2020-09-29 | 2020-09-29 | Anti-shifting casting mold |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN213224193U (en) |

-

2020

- 2020-09-29 CN CN202022184127.7U patent/CN213224193U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN211440464U (en) | Precast concrete column cap pouring mold | |

| CN213224193U (en) | Anti-shifting casting mold | |

| CN212310832U (en) | Manual casting trolley on casting production line | |

| CN214023353U (en) | Casting mould is used in removable foundry goods processing of mold core | |

| CN211588496U (en) | Cooling device for aluminum casting | |

| CN209867269U (en) | Diesel engine aluminum alloy water outlet pipe sprue cup with slag trap | |

| CN210359195U (en) | Die-casting die for long handle sleeve | |

| CN209077743U (en) | A kind of ring flange centrifugal forming device | |

| CN210208539U (en) | Multi-station casting device | |

| CN208068222U (en) | A kind of adjustable electric power tool suspension plate | |

| CN213288570U (en) | Novel casting mould | |

| CN210334263U (en) | Pipe welding die of stainless steel high-frequency pipe welding machine | |

| CN213028020U (en) | Detachable intercom aluminum alloy casting | |

| CN212760991U (en) | Can reduce gating system of sand hole | |

| CN214246615U (en) | Novel mould that aluminium mould unwrapping wire construction used | |

| CN209792549U (en) | Processing clamp for processing and grinding gland of metal arc convex surface device | |

| CN214576267U (en) | Aluminum alloy concrete baffle | |

| CN221870198U (en) | Casting box for sand mould casting | |

| CN213929920U (en) | High-performance durable ceramic tube | |

| CN209849817U (en) | Novel casting mould | |

| CN218591759U (en) | Casting sand box | |

| CN205464856U (en) | Graphite sweat soldering mould | |

| CN213002484U (en) | Aluminum alloy casting mould | |

| CN219465258U (en) | Mobile phone battery cover plate welding device | |

| CN217029508U (en) | High-wear-resistance high-toughness iron alloy connecting piece casting |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |