CN212676331U - Novel vertical pelleter of full-automatic lithium cell - Google Patents

Novel vertical pelleter of full-automatic lithium cell Download PDFInfo

- Publication number

- CN212676331U CN212676331U CN202021438401.2U CN202021438401U CN212676331U CN 212676331 U CN212676331 U CN 212676331U CN 202021438401 U CN202021438401 U CN 202021438401U CN 212676331 U CN212676331 U CN 212676331U

- Authority

- CN

- China

- Prior art keywords

- rubberizing

- welding

- plate

- full

- material receiving

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

Abstract

The utility model discloses a novel vertical pelleter of full-automatic lithium cell, the test platform comprises a support, wherein, be equipped with receiving agencies, welding mechanism, rubberizing mechanism on the frame, cut the mechanism, controller and pole piece reel, receiving agencies is including receiving the material backup pad, adjustable stock guide, receive material actuating mechanism and receiving the material link plate, welding mechanism includes welded connection frame, welding installation frame, first motor lead screw subassembly, the bonding tool component, cut component and utmost point ear flattening mechanism, the rubberizing structure includes rubberizing mounting frame, second motor lead screw subassembly, the pay-off cylinder, the pay-off briquetting, a plurality of rubberizing cylinders, rubberizing clamp plate, rubberizing fixed plate, reel and a plurality of guide roll are put to the adhesive tape, the utility model discloses the structure is succinct clear, and the dismouting and the maintenance of being convenient for, and the work of many film-making processes is accomplished to the accessible controller, and it is.

Description

Technical Field

The utility model belongs to the technical field of battery manufacture equipment technique and specifically relates to a novel vertical pelleter of full-automatic lithium cell is related to.

Background

The lithium ion battery is a new generation of green high-energy battery with excellent performance, and has become one of the key points of the development of high and new technologies. The lithium ion battery has the following characteristics: high voltage, high capacity, low consumption, no memory effect, no public hazard, small volume, small internal resistance, less self-discharge and more cycle times. Because of the above characteristics, the lithium ion battery is widely applied to various civil and military fields such as mobile phones, notebook computers, tablet computers and the like.

Flaking is an essential process in the production process of lithium ion batteries, and is also a key process which directly influences various performances of the batteries such as safety, capacity, consistency and the like. As lithium battery flaking equipment, full-automatic pelleter to its high efficiency, convenient characteristics are widely used in the flaking process, and current full-automatic pelleter can provide convenience to a certain extent, but because the dismouting and the maintenance of equipment are inconvenient but to the complexity of its structure, inevitable existence operation inconvenience scheduling problem.

SUMMERY OF THE UTILITY MODEL

The utility model discloses an it is not enough to overcome above-mentioned condition, aims at providing the technical scheme that can solve above-mentioned problem.

A novel vertical sheet making machine for a full-automatic lithium battery comprises a machine base, wherein a material receiving mechanism, a welding mechanism, a gluing mechanism, a cutting mechanism and a controller are arranged on the machine base;

the material receiving mechanism comprises a material receiving supporting plate, an adjustable material guide plate, a material receiving driving mechanism and a material receiving hanging plate, the material receiving supporting plate is rotatably connected to the machine base, one side of the material receiving supporting plate is connected with the adjustable material guide plate, and the material receiving hanging plate is slidably arranged on the adjustable material guide plate through a guide rail;

the welding mechanism comprises a welding connecting frame fixed on the machine base, a welding mounting frame and a first motor lead screw assembly are arranged on the welding connecting frame, the welding connecting frame is connected with the welding mounting frame through the first motor lead screw assembly, and a welding head component, a cutting component and a lug flattening mechanism are arranged on the welding mounting frame;

the rubberizing structure comprises a rubberizing mounting frame fixed on the base, a second motor screw rod assembly and a feeding cylinder are mounted on the rubberizing mounting frame, and a piston rod of the feeding cylinder is connected with a feeding press block; a plurality of rubberizing cylinders are fixed on the mounting frame, and rubberizing pressing plates are connected to piston rods of the rubberizing cylinders; the rubberizing mounting bracket is connected with a rubberizing fixed plate, and the rubberizing fixed plate is rotatably connected with a gummed paper unwinding disc and a plurality of guide rollers.

As a further aspect of the present invention: the pole lug flattening mechanism comprises a third motor lead screw assembly installed on the welding installation frame, a sliding block of the third motor lead screw assembly is connected with a bearing plate and a flattening cylinder, and a piston rod of the flattening cylinder is connected with a lower pressing block.

As a further aspect of the present invention: the machine base is rotatably connected with a pole piece unwinding disc.

As a further aspect of the present invention: the controller comprises a display screen, a control button and a controller mounting frame fixed on the base.

Compared with the prior art, the beneficial effects of the utility model are that: the reel is put to the pole piece receives and unreels behind welding mechanism's the pulling force, carries out utmost point ear welding when unreeling welding mechanism, and the welding back is pull by rubberizing mechanism and is carried out the rubberizing, is pull by cutting the mechanism again and cuts, collects the pole piece that cuts by receiving the material machine at last, accomplishes the film-making process of lithium cell, the utility model discloses the structure is succinct clear, and the dismouting and the maintenance of being convenient for, and the work of many film-making processes is accomplished to the accessible controller, and it is more convenient to operate.

Additional aspects and advantages of the invention will be set forth in part in the description which follows and, in part, will be obvious from the description, or may be learned by practice of the invention.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings needed to be used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only some embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to these drawings without inventive exercise.

Fig. 1 is a schematic structural diagram of the present invention.

Fig. 2 is an enlarged view of a portion of a structure shown in fig. 1.

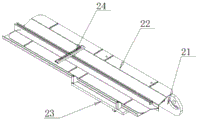

Fig. 3 is a schematic view of the material receiving mechanism of the present invention.

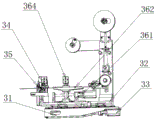

Fig. 4 is a schematic view of the welding mechanism of the present invention.

Fig. 5 is a schematic view of the middle rubberizing mechanism of the present invention.

In the figure: a machine base-1, a material receiving mechanism-2, a welding mechanism-3, a gluing mechanism-4, a cutting mechanism-5, a controller-6, a pole piece unwinding disc-7, a supporting seat-11, a roller-12, a material receiving supporting plate-21, an adjustable material guiding plate-22, a material receiving driving mechanism-23, a material receiving hanging plate-24, a welding connecting frame-31, a welding mounting frame-32, a first motor screw rod assembly-33, a welding head assembly-34, a cutting assembly-35, a gluing mounting frame-41, a second motor screw rod assembly-42, a feeding air cylinder-43, a feeding press block-44, a gluing air cylinder-45, a gluing press plate-46, a gluing fixing plate-47, a gummed paper unwinding disc-48, a guide roller-49 and a third motor screw rod assembly-361, a bearing plate-362, a flattening cylinder-363, a lower pressing block-364, a display screen-61, a control button-62 and a controller mounting rack-63.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely below, and it should be understood that the described embodiments are only some embodiments of the present invention, but not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

Referring to fig. 1-5, in an embodiment of the present invention, a novel vertical sheet making machine for a full-automatic lithium battery includes a base 1, and a receiving mechanism 2, a welding mechanism 3, a gluing mechanism 4, a cutting mechanism 5, and a controller 6 are installed on the base 1. The pole piece unwinding disc 7 is rotatably connected to the base, so that assembly of additionally arranging a feeding structure is omitted, and the structure is simpler. Specifically, the controller 6 includes a display 61, a control button 62, and a controller mounting bracket 63 fixed to the base 1. The reel is put to the pole piece receives and unreels behind welding mechanism's the pulling force, carries out utmost point ear welding when unreeling welding mechanism, and the welding back is pull by rubberizing mechanism and is carried out the rubberizing, is pull by cutting the mechanism again and cuts, collects the pole piece that cuts by receiving the material machine at last, accomplishes the film-making process of lithium cell, the utility model discloses the structure is succinct clear, and the dismouting and the maintenance of being convenient for, and the work of many film-making processes is accomplished to the accessible controller, and it is more convenient to operate.

Referring to fig. 3, the receiving mechanism includes a receiving support plate 21, an adjustable material guiding plate 22, a receiving driving mechanism 23 and a receiving hanging plate 24, the receiving support plate 21 is rotatably connected to the machine base 1, one side of the receiving support plate 21 is connected to the adjustable material guiding plate 22, the receiving hanging plate 24 is slidably disposed on the adjustable material guiding plate 22 through a guide rail, and the position of the receiving driving mechanism 23 is moved left and right to enable the pole piece to fall into an external receiving device (not shown) along the adjustable material guiding plate 22.

Referring to fig. 4, the welding mechanism includes a welding connection frame 31 fixed on the machine base, the welding connection frame 31 is provided with a welding installation frame 32 and a first motor lead screw assembly 33, the welding connection frame 32 is connected with the welding installation frame 32 through the first motor lead screw assembly 33, the welding installation frame 32 is provided with a welding head component 34, a cutting component 35 and a tab flattening mechanism, the tab flattening mechanism includes a third motor lead screw assembly 361 installed on the welding installation frame 32, a slide block of the third motor lead screw assembly 361 is connected with a bearing plate 362 and a flattening cylinder 363, a piston rod of the flattening cylinder 363 is connected with a lower pressing block 364, before the tab is sent to the welding head component 34, the pressure of the lower pressing block 364 acts on the bearing plate 362 of the tab flattening mechanism to flatten the tabs, and the welding head component 34 is used for welding and fixing the tabs and the pole pieces and performing cutting molding through the cutting component 35.

Specifically referring to fig. 5, the rubberizing structure includes a rubberizing mounting bracket 41 fixed on the base, a second motor screw rod assembly 42 and a feeding cylinder 43 are mounted on the rubberizing mounting bracket 41, and a feeding press block 44 is connected to a piston rod of the feeding cylinder 43; a plurality of rubberizing cylinders 45 are fixed on the rubberizing mounting frame 41, and a piston rod of each rubberizing cylinder 45 is connected with a rubberizing pressing plate 46; the rubberizing mounting frame 41 is connected with a rubberizing fixing plate 47, and the rubberizing fixing plate 47 is rotatably connected with a gummed paper releasing reel 48 and a plurality of guide rollers 49. The adhesive paper is placed on the adhesive paper placing reel 48 and is pressed tightly on the sliding block of the second motor screw assembly 42 by the feeding pressing block 44, the second motor screw assembly 42 drives the adhesive paper to be under the adhesive pasting pressing plate 46, and the adhesive pasting air cylinder 46 drives the adhesive pasting pressing plate 46 to paste the adhesive paper to the pole piece.

Further, the base bottom is connected with a plurality of supporting seats and a plurality of gyro wheels, and the gyro wheel is convenient for remove pelleter, and the supporting seat only need support the base, and is more stable during the use.

It is obvious to a person skilled in the art that the invention is not restricted to details of the above-described exemplary embodiments, but that it can be implemented in other specific forms without departing from the spirit or essential characteristics of the invention. The present embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein.

Claims (5)

1. A novel vertical pelleter of full-automatic lithium cell, including the bed plate, characterized by that, the bed plate is fitted with the receiving agencies, welding mechanism, rubberizing mechanism, cuts organization and control device;

the material receiving mechanism comprises a material receiving supporting plate, an adjustable material guide plate, a material receiving driving mechanism and a material receiving hanging plate, the material receiving supporting plate is rotatably connected to the machine base, one side of the material receiving supporting plate is connected with the adjustable material guide plate, and the material receiving hanging plate is slidably arranged on the adjustable material guide plate through a guide rail;

the welding mechanism comprises a welding connecting frame fixed on the machine base, a welding mounting frame and a first motor lead screw assembly are arranged on the welding connecting frame, the welding connecting frame is connected with the welding mounting frame through the first motor lead screw assembly, and a welding head component, a cutting component and a lug flattening mechanism are arranged on the welding mounting frame;

the rubberizing structure comprises a rubberizing mounting frame fixed on the base, a second motor screw rod assembly and a feeding cylinder are mounted on the rubberizing mounting frame, and a piston rod of the feeding cylinder is connected with a feeding press block; a plurality of rubberizing cylinders are fixed on the mounting frame, and rubberizing pressing plates are connected to piston rods of the rubberizing cylinders; the rubberizing mounting bracket is connected with a rubberizing fixed plate, and the rubberizing fixed plate is rotatably connected with a gummed paper unwinding disc and a plurality of guide rollers.

2. The novel vertical pelleter of full-automatic lithium cell of claim 1, characterized in that, utmost point ear flattening mechanism is including installing the third motor lead screw subassembly on the welding installation frame, is connected with bearing plate and flattening cylinder on the slider of third motor lead screw subassembly, is connected with down the briquetting on flattening cylinder's the piston rod.

3. The novel vertical pelleter of full-automatic lithium cell of claim 1, wherein a pole piece unwinding disc is rotatably connected to the machine base.

4. The novel vertical pelleter of full-automatic lithium cell of claim 1, wherein a plurality of supporting seats and a plurality of rollers are connected to the base bottom.

5. The novel vertical pelleter of full-automatic lithium battery as claimed in any one of claims 1-4, wherein the controller comprises a display screen, a control button, and a controller mounting bracket fixed to the stand.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021438401.2U CN212676331U (en) | 2020-07-21 | 2020-07-21 | Novel vertical pelleter of full-automatic lithium cell |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021438401.2U CN212676331U (en) | 2020-07-21 | 2020-07-21 | Novel vertical pelleter of full-automatic lithium cell |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN212676331U true CN212676331U (en) | 2021-03-09 |

Family

ID=74816504

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021438401.2U Active CN212676331U (en) | 2020-07-21 | 2020-07-21 | Novel vertical pelleter of full-automatic lithium cell |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN212676331U (en) |

-

2020

- 2020-07-21 CN CN202021438401.2U patent/CN212676331U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202930485U (en) | Full-automatic battery cell winding device with short circuit detection function | |

| CN202038745U (en) | Automatic diaphragm cutting and coiling equipment | |

| CN203839464U (en) | Hot-pressing and shaping machine for lithium ion battery | |

| CN101867045A (en) | Method for preparing positive plate of nickel hydrogen battery | |

| CN207459100U (en) | A kind of battery cover board rubberizing apparatus for shaping | |

| CN208208909U (en) | Electricity core winding machine | |

| CN212676331U (en) | Novel vertical pelleter of full-automatic lithium cell | |

| CN107403963B (en) | Pole piece driving and deviation rectifying device for cylindrical lithium battery sheet-making and winding all-in-one machine | |

| CN209056559U (en) | A kind of battery film sticking apparatus | |

| CN113964386A (en) | Novel vertical pelleter of full-automatic lithium cell | |

| CN201576711U (en) | Negative electrode sheet for lithium battery | |

| CN212366045U (en) | Lamination electricity core rubberizing device | |

| CN202996981U (en) | Polymer lithium battery adhesive tape stickup mechanism | |

| CN214378529U (en) | Winding device for lithium battery processing | |

| CN216288576U (en) | Battery diaphragm lamination centre gripping auxiliary device | |

| CN205882087U (en) | Tape device is tied up in square lithium cell subsides | |

| CN215745519U (en) | Pole piece rolling device for lithium battery production | |

| CN212676333U (en) | Rubberizing structure of novel pelleter of full-automatic lithium cell | |

| CN210231670U (en) | Automatic shaping and cutting device for tabs | |

| CN209953542U (en) | Pole lug shaping mechanism for ultrasonic welding of lithium battery pole lug | |

| CN112038569A (en) | Horizontal laminating mechanism for lithium supplement | |

| CN201321175Y (en) | Pneumatic label pressing device for sticking and positioning labels on square lithium-ion and nickel-hydrogen batteries | |

| CN211295296U (en) | Pole piece unwinding device with mechanism of rectifying | |

| CN215869519U (en) | Gravity self-adaptation pole piece group rubber coating covers device | |

| CN215516098U (en) | A rubberizing device for welding of electricity core switching piece |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |