CN212609294U - Tilting-type hydraulic elevator convenient to it is rotatory - Google Patents

Tilting-type hydraulic elevator convenient to it is rotatory Download PDFInfo

- Publication number

- CN212609294U CN212609294U CN201922261280.2U CN201922261280U CN212609294U CN 212609294 U CN212609294 U CN 212609294U CN 201922261280 U CN201922261280 U CN 201922261280U CN 212609294 U CN212609294 U CN 212609294U

- Authority

- CN

- China

- Prior art keywords

- fixedly connected

- connecting rod

- rotatably connected

- base

- top end

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000005540 biological transmission Effects 0.000 claims description 32

- 238000000034 method Methods 0.000 abstract description 5

- 230000000694 effects Effects 0.000 abstract description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 abstract 2

- 229910052742 iron Inorganic materials 0.000 abstract 1

- 230000000576 supplementary effect Effects 0.000 description 2

- 230000001174 ascending effect Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000010720 hydraulic oil Substances 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Landscapes

- Types And Forms Of Lifts (AREA)

Abstract

The utility model discloses a tilting-type hydraulic lift convenient to it is rotatory, the on-line screen storage device comprises a base, the top fixedly connected with pivot frame of base, the inside intermediate position station of pivot frame moves and is connected with the axis of rotation, the first drive wheel of fixedly connected with of axis of rotation. The utility model discloses in, the motor drives the second drive wheel and rotates, and then make the chain drive first drive wheel and axis of rotation at pivot frame internal rotation through leading to the groove, and then drive the bearing dish and accomplish the rotation positioning, at this in-process, the auxiliary wheel plays the effect of supplementary rotation and support, thereby it is more stable when rotating with the bearing dish to make the rotation seat, when the bearing dish that slopes needs carries out the position modulation, promote the bearing dish tilt up through the second pneumatic cylinder that starts on the second drive pole, can accomplish the regulation of bearing dish angle, therefore, the electric iron is very convenient, the second pneumatic cylinder sets up the inboard at head rod and second connecting rod simultaneously, be convenient for save equipment's usage space.

Description

Technical Field

The utility model relates to a hydraulic lift technical field especially relates to a tilting-type hydraulic lift convenient to it is rotatory.

Background

The hydraulic lift realizes the lifting function mainly through the pressure transmission of hydraulic oil, and the shear fork mechanical structure of the hydraulic lift enables the lift to have higher stability, a wide operation platform and higher bearing capacity, so that the high-altitude operation range is larger, the hydraulic lift is suitable for simultaneous operation of multiple persons, the high-altitude operation efficiency is higher, and the safety is more guaranteed;

at present, most of the existing hydraulic elevators do not have the functions of rotating and inclining to adjust the positions, and the elevators are very chicken-costed when some objects with irregular surfaces are transported or workers need to adjust the positions at high positions.

SUMMERY OF THE UTILITY MODEL

The utility model aims at solving the defects existing in the prior art and providing a tilting hydraulic elevator convenient to rotate.

In order to achieve the above purpose, the utility model adopts the following technical scheme: a tilting type hydraulic elevator convenient to rotate comprises a base, wherein a rotating shaft frame is fixedly connected to the top end of the base, a rotating shaft is fixedly connected to the middle position inside the rotating shaft frame in a standing mode, a first transmission wheel is fixedly connected to the rotating shaft, a through groove is formed in one side of the outer surface of the rotating shaft frame corresponding to the position of the first transmission wheel, a motor cover is fixedly connected to the position, close to the through groove, of the top of the base, the motor cover is fixedly connected with the rotating shaft frame, a motor is fixedly connected to the inner bottom wall of the motor cover, a second transmission wheel is fixedly connected to the output shaft of the motor, a chain is meshed with the second transmission wheel and the first transmission wheel together, a rotating seat is fixedly connected to the top end of the rotating shaft, a first connecting rod is rotatably connected to the top end of the rotating seat, and a second connecting rod is, and the second connecting rod is rotatably connected with the first connecting rod, the bottom of the second connecting rod is rotatably connected with a first pulley, a sliding groove is formed in the position, corresponding to the first pulley, of the top of the rotating seat, a sliding connection is embedded between the first pulley and the sliding groove, the top of the first connecting rod is rotatably connected with a bearing disc, a first transmission rod is fixedly connected to the position, close to the rotating seat, of the inner side of the first connecting rod, two first hydraulic cylinders are rotatably connected to the top of the rotating seat, the piston ends of the two first hydraulic cylinders are rotatably connected with the first transmission rod, a second transmission rod is fixedly connected to the position, close to the bearing disc, of the inner side of the first connecting rod, the top of the second transmission rod is rotatably connected with two second hydraulic cylinders, and the piston ends of the two second hydraulic cylinders are rotatably connected with the bearing disc.

As a further description of the above technical solution:

the top end of the rotating shaft frame is embedded and rotatably connected with six auxiliary wheels.

As a further description of the above technical solution:

the bottom end of the base is fixedly connected with four universal wheels.

As a further description of the above technical solution:

the base is fixedly connected with four hydraulic support legs.

As a further description of the above technical solution:

the bottom end of the bearing plate is fixedly connected with a limiting block.

As a further description of the above technical solution:

the top of second connecting rod rotates and is connected with the second pulley, and imbeds sliding connection between second pulley and the stopper.

The utility model discloses following beneficial effect has:

the tilting hydraulic elevator convenient to rotate moves a base together with equipment to a position where a worker needs to work through a universal wheel, then fixes the base at a required position through a hydraulic support leg to prevent the base from moving, then pushes a first transmission rod to ascend through a first hydraulic cylinder on a rotating seat, so that first connecting rods on two sides of the first transmission rod ascend simultaneously, meanwhile, second pulleys on the top ends of the first connecting rods slide inwards in a limiting block, in the process, the second connecting rods ascend simultaneously, meanwhile, first pulleys on the bottom of the second connecting rods move towards the middle position of the rotating seat in a sliding groove, so that the bearing disc drives the worker or an object to move upwards, if the bearing disc needs to be rotated, a motor in a motor cover drives a second transmission wheel to rotate, and further, a chain drives the first transmission wheel and a rotating shaft to rotate in a rotating shaft frame through a through groove, and then drive the bearing disc and accomplish the rotation positioning, at this in-process, the auxiliary wheel plays the effect of supplementary rotation and support, thereby make and rotate seat and bearing disc more stable when rotating, when the bearing disc that needs the slope carries out position control, promote the bearing disc tilt up through starting the second pneumatic cylinder on the second transfer line, can accomplish the regulation of bearing disc angle, and is very convenient, and the second pneumatic cylinder setting is in the inboard of head rod and second connecting rod simultaneously, is convenient for save the usage space of equipment.

Drawings

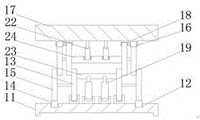

Fig. 1 is a schematic view of the overall structure of the present invention;

FIG. 2 is a schematic side view of the present invention;

fig. 3 is a top view of the rotating shaft frame of the present invention.

Illustration of the drawings: 1. a base; 2. a spindle bracket; 3. a rotating shaft; 4. a first drive pulley; 5. a through groove; 6. a chain; 7. a motor cover; 8. a motor; 9. a second transmission wheel; 10. an auxiliary wheel; 11. a rotating seat; 12. a chute; 13. a first connecting rod; 14. a first pulley; 15. a second connecting rod; 16. a second pulley; 17. a load-bearing plate; 18. a limiting block; 19. a first hydraulic cylinder; 20. a hydraulic support leg; 21. a universal wheel; 22. a second hydraulic cylinder; 23. a first drive lever; 24. and a second transmission rod.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

In the description of the present invention, it should be noted that the terms "center", "upper", "lower", "left", "right", "vertical", "horizontal", "inner", "outer", and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplification of description, but do not indicate or imply that the device or element referred to must have a specific orientation, be constructed and operated in a specific orientation, and thus, should not be construed as limiting the present invention; the terms "first," "second," and "third" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance, and furthermore, unless otherwise explicitly stated or limited, the terms "mounted," "connected," and "connected" are to be construed broadly and may be, for example, fixedly connected, detachably connected, or integrally connected; can be mechanically or electrically connected; they may be connected directly or indirectly through intervening media, or they may be interconnected between two elements. The specific meaning of the above terms in the present invention can be understood in specific cases to those skilled in the art.

Referring to fig. 1-3, the present invention provides an embodiment: a tilting type hydraulic elevator convenient to rotate comprises a base 1, a rotating shaft frame 2 is fixedly connected to the top end of the base 1, a rotating shaft 3 is fixedly connected to the middle position inside the rotating shaft frame 2 in a standing mode, a first driving wheel 4 is fixedly connected to the rotating shaft 3, a through groove 5 is formed in one side of the outer surface of the rotating shaft frame 2 corresponding to the position of the first driving wheel 4, a motor cover 7 is fixedly connected to the position, close to the through groove 5, of the top of the base 1, the motor cover 7 is fixedly connected with the rotating shaft frame 2, a motor 8 is fixedly connected to the inner bottom wall of the motor cover 7, a second driving wheel 9 is fixedly connected to an output shaft of the motor 8, the second driving wheel 9 and the first driving wheel 4 are jointly meshed and connected with a chain 6, a rotating seat 11 is fixedly connected to the top end of the rotating seat 11, a first connecting rod 13 is rotatably connected to the top end of, the second connecting rod 15 is rotatably connected with the first connecting rod 13, the bottom end of the second connecting rod 15 is rotatably connected with a first pulley 14, the top end of the rotating seat 11 is provided with a chute 12 corresponding to the position of the first pulley 14, and the first pulley 14 is embedded and slidably connected with the chute 12, the top end of the first connecting rod 13 is rotatably connected with a bearing disc 17, the inner side of the first connecting rod 13 close to the rotating seat 11 is fixedly connected with a first transmission rod 23, the top end of the rotating seat 11 is rotatably connected with two first hydraulic cylinders 19, and the piston ends of the two first hydraulic cylinders 19 are rotatably connected with the first transmission rod 23, the inner side of the first connecting rod 13 close to the bearing disc 17 is fixedly connected with a second transmission rod 24, the top of the second transmission rod 24 is rotatably connected with two second hydraulic cylinders 22, and the piston ends of the two second hydraulic cylinders 22 are rotatably connected with the bearing disc 17.

Six auxiliary wheels 10 are embedded and rotatably connected to the top end of the rotating shaft frame 2, and the auxiliary wheels 10 play a role in auxiliary rotation and support, so that the rotating seat 11 and the bearing disc 17 are more stable in rotation; the bottom end of the base 1 is fixedly connected with four universal wheels 21, so that the base 1 and the whole equipment can be conveniently moved to a position where a worker needs to work together through the universal wheels 21; the base 1 is fixedly connected with four hydraulic support legs 20 to prevent the base 1 from deviating; the bottom end of the bearing disc 17 is fixedly connected with a limiting block 18 which plays a limiting role in limiting the sliding of the second pulley 16; the top end of the second connecting rod 15 is rotatably connected with a second pulley 16, and the second pulley 16 and the limiting block 18 are connected in a sliding manner, so that the first connecting rod 13 can be conveniently lifted.

The working principle is as follows: when a tilting hydraulic elevator convenient to rotate is used, the base 1 and the whole equipment are moved together to a position where a worker needs to work through the universal wheel 21, then the base 1 is fixed at a required position through the hydraulic support legs 20 to prevent the base 1 from moving, then the first transmission rod 23 is pushed to ascend through the first hydraulic cylinder 19 on the rotating base 11, so that the first connecting rods 13 on the two sides of the first transmission rod 23 ascend simultaneously, meanwhile, the second pulleys 16 on the top ends of the first connecting rods 13 slide inwards in the limiting blocks 18, in the process, the second connecting rods 15 ascend simultaneously, meanwhile, the first pulleys 14 on the bottom of the second connecting rods 15 move towards the middle position of the rotating base 11 in the sliding grooves 12, thereby completing the ascending of the bearing disc 17 driving the worker or an object, and if the motor 8 in the motor cover 7 of the bearing disc 17 needs to rotate to drive the second transmission wheel 9, and then make chain 6 drive first drive wheel 4 and axis of rotation 3 at 2 internal rotations of pivot frame through leading to groove 5, and then drive bearing disc 17 and accomplish the rotation positioning, at this in-process, auxiliary wheel 10 plays the supplementary effect of rotating and supporting, thereby it is more stable when rotating with bearing disc 17 to make the seat 11 and the bearing disc 17 of rotating, when needs slope bearing disc 17 carries out the position control, promote bearing disc 17 and upwards incline through starting second pneumatic cylinder 22 on the second transfer line 24, can accomplish the regulation of bearing disc 17 angle, therefore, the device is convenient to use, simultaneously second pneumatic cylinder 22 sets up the inboard at head rod 13 and second connecting rod 15, be convenient for save the usage space of equipment, certain practicality has.

Finally, it should be noted that: although the present invention has been described in detail with reference to the foregoing embodiments, it will be apparent to those skilled in the art that modifications and variations can be made in the embodiments or in part of the technical features of the embodiments without departing from the spirit and the principles of the present invention.

Claims (6)

1. A tilting-type hydraulic elevator convenient to rotate, includes base (1), its characterized in that: the top end of the base (1) is fixedly connected with a rotating shaft frame (2), the inner middle position of the rotating shaft frame (2) is in standing connection with a rotating shaft (3), a first transmission wheel (4) is fixedly connected with the rotating shaft (3), a through groove (5) is formed in one side of the outer surface of the rotating shaft frame (2) corresponding to the position of the first transmission wheel (4), a motor cover (7) is fixedly connected to the position, close to the through groove (5), of the top of the base (1), the motor cover (7) is fixedly connected with the rotating shaft frame (2), a motor (8) is fixedly connected to the inner bottom wall of the motor cover (7), a second transmission wheel (9) is fixedly connected with an output shaft of the motor (8), the second transmission wheel (9) is jointly meshed with the first transmission wheel (4) to be connected with a chain (6), and a rotating base (11) is fixedly connected with the top end of the, the top end of the rotating seat (11) is rotatably connected with a first connecting rod (13), one side, far away from the first connecting rod (13), of the top end of the rotating seat (11) is provided with a second connecting rod (15), the second connecting rod (15) is rotatably connected with the first connecting rod (13), the bottom end of the second connecting rod (15) is rotatably connected with a first pulley (14), the top end of the rotating seat (11) is provided with a sliding groove (12) corresponding to the position of the first pulley (14), the first pulley (14) is in embedded sliding connection with the sliding groove (12), the top end of the first connecting rod (13) is rotatably connected with a bearing disc (17), the position, close to the rotating seat (11), of the inner side of the first connecting rod (13) is fixedly connected with a first transmission rod (23), the top end of the rotating seat (11) is rotatably connected with two first hydraulic cylinders (19), and the piston ends of the two first hydraulic cylinders (19) are rotatably connected with the first transmission rod (23), the inner side of the first connecting rod (13) is fixedly connected with a second transmission rod (24) close to the bearing disc (17), the top of the second transmission rod (24) is rotatably connected with the two second hydraulic cylinders (22), and the piston ends of the two second hydraulic cylinders (22) are rotatably connected with the bearing disc (17).

2. A portable rotary, tiltable hydraulic lift according to claim 1, wherein: the top end of the rotating shaft frame (2) is embedded and rotatably connected with six auxiliary wheels (10).

3. A portable rotary, tiltable hydraulic lift according to claim 1, wherein: the bottom end of the base (1) is fixedly connected with four universal wheels (21).

4. A portable rotary, tiltable hydraulic lift according to claim 1, wherein: the base (1) is fixedly connected with four hydraulic support legs (20).

5. A portable rotary, tiltable hydraulic lift according to claim 1, wherein: the bottom end of the bearing disc (17) is fixedly connected with a limiting block (18).

6. A portable rotary, tiltable hydraulic lift according to claim 1, wherein: the top end of the second connecting rod (15) is rotatably connected with a second pulley (16), and the second pulley (16) is connected with a limiting block (18) in an embedded sliding mode.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922261280.2U CN212609294U (en) | 2019-12-17 | 2019-12-17 | Tilting-type hydraulic elevator convenient to it is rotatory |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922261280.2U CN212609294U (en) | 2019-12-17 | 2019-12-17 | Tilting-type hydraulic elevator convenient to it is rotatory |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN212609294U true CN212609294U (en) | 2021-02-26 |

Family

ID=74728943

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201922261280.2U Expired - Fee Related CN212609294U (en) | 2019-12-17 | 2019-12-17 | Tilting-type hydraulic elevator convenient to it is rotatory |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN212609294U (en) |

-

2019

- 2019-12-17 CN CN201922261280.2U patent/CN212609294U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN216426499U (en) | Based on multi-direction platform adjusting device of electric automatization | |

| CN212609294U (en) | Tilting-type hydraulic elevator convenient to it is rotatory | |

| CN215515434U (en) | Material frame conveying device in limited space | |

| CN214273057U (en) | Assembled building construction strutting arrangement | |

| CN211444875U (en) | Lifting mechanism for automatic lifting workbench | |

| CN212630256U (en) | Placer for electronic communication convenient to remove | |

| CN216463322U (en) | Tongs part machining device convenient to adjust | |

| CN213532480U (en) | Movable supporting platform for elevator maintenance | |

| CN209872174U (en) | Hoisting accessory is used in compressor unit maintenance | |

| CN210791545U (en) | Panel cutting equipment for construction | |

| CN212096251U (en) | Lifting and rotating machining workbench and assembly line | |

| CN210313320U (en) | Shear force formula lift platform convenient to remove | |

| CN218862146U (en) | Automatic discharging platform for building construction | |

| CN113371606A (en) | Double-lifting container crane and working method thereof | |

| CN219009820U (en) | Mechanical automatic lifting device | |

| CN218371527U (en) | Lifting platform capable of turning over from multiple sides | |

| CN217838267U (en) | Mobile loading equipment with hydraulic lifting function | |

| CN212334504U (en) | Conveyer is used in hoist manufacturing | |

| CN213445910U (en) | Weather-proof gantry crane | |

| CN214213695U (en) | Electric power installation and debugging device | |

| CN218492305U (en) | Construction equipment for bridge anti-collision wall | |

| CN215443198U (en) | A assembled platform of unloading safely for construction | |

| CN215886199U (en) | Movable lifting platform | |

| CN219031678U (en) | Movable lifting machine for lifting screw rod | |

| CN217924771U (en) | Building support frame for high-rise building |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20210226 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |