Integrated charger capable of being rapidly disassembled and assembled

Technical Field

The utility model relates to a machine field charges, in particular to but quick integral type machine that charges of dismantling and installing charges.

Background

With the development of industrial technology, most of equipment used in modern industry is driven by electricity, the equipment driven by electricity is more environment-friendly than the traditional fuel equipment, the mobile equipment driven by electricity can maintain work after being charged, and the electric equipment used outdoors needs to be not charged by a charger;

the integrated charger is installed in outdoor power equipment, the existing integrated charger is fixed with a building, and the charger needs to be detached when the power equipment needs to be maintained, so that the operation is troublesome, and much labor is wasted.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to prior art not enough, an integral type machine that charges that can dismantle fast and install is provided, when the installation integral type machine that charges, in the fixed box is put to the machine that charges box, then insert the building block, in the foundation ditch of equipment propulsion ground, then twist and move the rotary rod, the rotary rod drives first bevel gear and second bevel gear, carousel this moment is followed second bevel gear synchronous revolution, inside the carousel drove the expansion plate through the guide arm and injects the mounting groove, the function that the convenient installation and dismantlement integral type machine that charges has been realized.

In order to solve the above problem, the utility model provides a following technical scheme: the utility model provides a can dismantle fast and integral type machine that charges of installation, includes the ground, the inboard of ground is provided with the foundation ditch, and one side of foundation ditch is provided with the mounting groove, the mounting box is installed to the inboard of foundation ditch, and four universal wheels are installed to the bottom of mounting box, and the top fixed mounting of mounting box has a fixed box, the machine box that charges is installed on the top of fixed box, and the inboard of fixed box is provided with the arc face slope, the building block is installed to one side of arc face slope, and the cross-section of fixed box is greater than the cross section of the machine box that charges.

Further, the carousel is installed to the inboard of mounting box, and the top fixed mounting of carousel has a second bevel gear, the axle bed is installed to one side of mounting box, and the inboard of axle bed installs the rotary rod, the one end fixed mounting of rotary rod has first bevel gear, first bevel gear and second bevel gear intermeshing, and one side of mounting box installs the expansion plate, and one side of mounting box is provided with the fluting that matches with the expansion plate, connects through the guide arm between carousel and the expansion plate, and the both ends of guide arm are articulated with carousel and expansion plate respectively.

Furthermore, the both sides of machine box that charges all are provided with the bearing handle, and one side of machine box that charges is provided with ventilates and punches a hole, the rain piece is installed to one side on machine box top that charges.

Further, the heat collecting plate is installed on the inner side of the charger box body, the coil pipe is embedded on the inner side of the heat collecting plate, the water pump and the water replenishing tank are installed at the bottom end of the charger box body, the input end of the water pump is connected with the water replenishing tank through a connecting pipe, one end of the coil pipe extends to the inside of the water replenishing tank, and the other end of the coil pipe is connected to the output end of the water pump.

Furthermore, a heat conducting plate is installed on one side of the heat collecting plate, fins are arranged on one side of the heat conducting plate, two heat radiators are fixedly installed on one side of each fin, and an opening matched with the heat conducting plate is formed in the top end of the charger box body.

Furthermore, an opening and closing door is installed on one side of the charger box body, an observation window is arranged in the middle of the opening and closing door, and a door handle is installed on one side of the opening and closing door.

Has the advantages that:

firstly, when the integrated charger is installed, a charger box body is placed in a fixed box, then building blocks are inserted, equipment is pushed into a foundation pit of a foundation, then a rotating rod is screwed, the rotating rod drives a first bevel gear and a second bevel gear, the rotating disc rotates synchronously along with the second bevel gear at the moment, and the rotating disc drives a telescopic plate to be inserted into an installation groove through a guide rod, so that the function of conveniently installing and detaching the integrated charger is realized;

secondly, the heat that the integral type machine of charging produced during operation waits is transmitted to the heat-conducting plate through the hydrologic cycle in the coil pipe on, the heat-conducting plate with the heat dispersion on the fin, the heat dissipation machine gives the fin and dispels the heat fast, and water-cooling heat dissipation has increased heat conduction efficiency for equipment heat dissipation.

Drawings

FIG. 1 is a front view of the present invention;

FIG. 2 is a schematic cross-sectional view of the present invention;

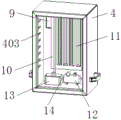

FIG. 3 is a schematic view of a charger case of the present invention;

FIG. 4 is a schematic view of the mounting box of the present invention;

FIG. 5 is a schematic sectional view of the charger case of the present invention;

fig. 6 is a schematic view of the foundation of the present invention.

Description of reference numerals:

1-foundation, 101-foundation pit, 102-installation groove, 2-installation box, 201-shaft seat, 202-rotating rod, 203-rotating disc, 204-first bevel gear, 205-second bevel gear, 206-guide rod, 207-expansion plate, 3-fixed box, 301-arc slope, 302-building block, 4-charger box body, 401-bearing handle, 402-rain blocking sheet, 403-ventilation punching hole, 5-opening and closing door, 501-observation window, 502-door handle, 6-universal wheel, 7-heat radiator, 8-fin, 9-heat conducting plate, 10-heat collecting plate, 11-coil pipe, 12-water pump, 13-water replenishing tank and 14-connecting pipe.

Detailed Description

In order to make the objects, technical solutions and advantages of the present invention more apparent, the present invention is described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are merely illustrative of the invention and are not intended to limit the invention.

In the description of the present invention, it is to be understood that the terms "longitudinal", "lateral", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", "top", "bottom", "inner", "outer", and the like, indicate orientations or positional relationships based on those shown in the drawings, are merely for convenience of description of the present invention, and do not indicate or imply that the referenced devices or elements must have a particular orientation, be constructed and operated in a particular orientation, and thus, are not to be construed as limiting the present invention.

Referring to fig. 1 to 6 show that can dismantle fast and integral type machine that charges of installation, including ground 1, the inboard of ground 1 is provided with foundation ditch 101, and one side of foundation ditch 101 is provided with mounting groove 102, mounting box 2 is installed to the inboard of foundation ditch 101, four universal wheels 6 are installed to the bottom of mounting box 2, and the top fixed mounting of mounting box 2 has fixed box 3, machine box 4 charges is installed on the top of fixed box 3, and the inboard of fixed box 3 is provided with cambered surface slope 301, building block 302 is installed to one side of cambered surface slope 301, the cross-section of fixed box 3 is greater than the cross section of machine box 4 charges, fixed box 3 and mounting box 2 fixed mounting are in the same place, machine box 4 charges puts fixed box 3 inboard, then there is building block 302 in one side of cambered surface slope 301 at fixed box 3.

The inner side of the mounting box 2 is provided with a rotary disc 203, the top end of the rotary disc 203 is fixedly provided with a second bevel gear 205, one side of the mounting box 2 is provided with a shaft seat 201, the inner side of the shaft seat 201 is provided with a rotary rod 202, one end of the rotary rod 202 is fixedly provided with a first bevel gear 204, the first bevel gear 204 and the second bevel gear 205 are mutually meshed, one side of the mounting box 2 is provided with a telescopic plate 207, one side of the mounting box 2 is provided with a slot matched with the telescopic plate 207, the rotary disc 203 and the telescopic plate 207 are connected through a guide rod 206, two ends of the guide rod 206 are respectively hinged with the rotary disc 203 and the telescopic plate 207, the device is pushed into a foundation pit 101 on the inner side of the foundation 1, then the rotary rod 202 is screwed, the rotary rod 202 drives the first bevel gear 204 and the second bevel gear 205, the rotary disc 203 rotates synchronously, the function of conveniently installing and disassembling the integrated charger is realized.

The both sides of machine box 4 all are provided with bearing handle 401, and one side of machine box 4 is provided with the hole 403 that punches a hole of ventilating, and the rain blocking piece 402 is installed to one side on machine box 4 top, and bearing handle 401 is with manual transport machine box 4 that charges.

The heat collecting plate 10 is installed on the inner side of the charger box body 4, the coil pipe 11 is embedded on the inner side of the heat collecting plate 10, the water pump 12 and the water replenishing tank 13 are installed at the bottom end of the charger box body 4, the input end of the water pump 12 is connected with the water replenishing tank 13 through the connecting pipe 14, one end of the coil pipe 11 extends to the inside of the water replenishing tank 13, the other end of the coil pipe 11 is connected to the output end of the water pump 12, and the water pump 12 pushes cooling liquid to circulate in the.

The heat-conducting plate 9 is installed to one side of heat collection plate 10, and one side of heat-conducting plate 9 all is provided with fin 8, and one side fixed mounting of fin 8 has two radiators 7, and the top of machine box 4 that charges is provided with and heat-conducting plate 9 assorted opening, and heat transfer in the coil pipe 11 gives heat-conducting plate 9, then fin 8 is given with the heat dispersion to heat-conducting plate 9, and the radiator 7 is quick gives the fin 8 heat dissipation, and the water-cooled speed is higher than forced air-cooled speed.

The door 5 that opens and shuts is installed to one side of machine box 4 that charges, and the centre of opening and shutting door 5 is provided with observation window 501, and door handle 502 is installed to one side of door 5 that opens and shuts, and the staff charges the condition of 4 insides through observation window 501, is convenient for real-time supervision.

The fixed box 3 and the mounting box 2 are fixedly mounted together, the charger box body 4 is placed on the inner side of the fixed box 3, then a building block 302 is inserted into one side of the fixed box 3 with an arc slope 301, the device is pushed into a foundation pit 101 on the inner side of a foundation 1, then a rotating rod 202 is screwed, the rotating rod 202 drives a first bevel gear 204 and a second bevel gear 205, a rotating disc 203 rotates synchronously with the second bevel gear 205 at the moment, the rotating disc drives an expansion plate 207 to be inserted into a mounting groove 102 through a guide rod 206, the function of conveniently mounting and dismounting the integrated charger is realized, a bearing handle 401 manually carries the charger box body 4, a water pump 12 pushes cooling liquid to circulate in a coil pipe 11, heat in the coil pipe 11 is transferred to a heat conducting plate 9, the heat conducting plate 9 disperses the heat to fins 8, the heat is quickly dissipated to the fins 8 by a heat dissipater 7, the water cooling rate is higher than the air, and real-time monitoring is facilitated.

The above description is only a preferred embodiment of the present invention, and is not intended to limit the technical scope of the present invention, so that any slight modifications, equivalent changes and modifications made by the technical spirit of the present invention to the above embodiments are all within the scope of the technical solution of the present invention.