CN212528593U - Plastic toy injection molding mold - Google Patents

Plastic toy injection molding mold Download PDFInfo

- Publication number

- CN212528593U CN212528593U CN202020703495.5U CN202020703495U CN212528593U CN 212528593 U CN212528593 U CN 212528593U CN 202020703495 U CN202020703495 U CN 202020703495U CN 212528593 U CN212528593 U CN 212528593U

- Authority

- CN

- China

- Prior art keywords

- fixed mounting

- fixedly mounted

- injection molding

- lead screw

- plastics

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Abstract

The utility model relates to an injection molding machine technical field just discloses a plastics toy injection moulding mould, including a supporting bench, the equal fixed mounting in both ends on brace table upper portion has first lead screw, two the equal threaded connection in middle part of first lead screw has first motor, and the equal fixed mounting in left end of two first lead screws has the movable plate, the top fixed mounting of first motor has the fixer, the equal fixed mounting in both sides at brace table middle part has the support frame. This plastics toy injection moulding mould reaches injection moulding effectually through being provided with movable plate, second lead screw and hydraulic stem etc. and the movable plate can drive injection moulding mould and carry out lateral shifting, and the lead screw drives the ware of moulding plastics and is longitudinal movement, and the hydraulic stem then drives the ware of moulding plastics and be elevating movement at last, and a plurality of structure cooperations are used, can carry out the operation of moulding plastics to the toy mould of multiple size and size, and it is stable to utilize the lead screw to remove, can guarantee the precision of moulding plastics.

Description

Technical Field

The utility model relates to an injection molding machine technical field specifically is a plastics toy injection moulding mould.

Background

Injection molding, which is a method for obtaining a molded product by stirring a completely molten plastic material through a screw at a certain temperature, injecting the completely molten plastic material into a mold cavity by high pressure, and cooling and solidifying the completely molten plastic material, is suitable for batch production of parts with complex shapes, is one of important processing methods, mainly comprises 6 stages of mold closing, glue injection, pressure maintaining, cooling, mold opening and product taking out, the processes are repeated, so that the products can be produced in batches periodically, the molding of thermosetting plastic and rubber also comprises the same process, but the temperature of a charging barrel is lower than that of thermoplastic plastic, the injection pressure is higher, the mold is heated, the material needs to be solidified or vulcanized in the mold after the injection of the material, and then the mold is removed when the material is hot, and the injection molding technology is also applied to a large scale by people along with the increasing maturity of the technology, wherein the injection molding technology is very important equipment in the manufacturing industry.

The existing plastic toy injection molding equipment still has problems when in use: the injection molding mode is very single, the injection molding operation of a small number of molds can be solved and completed, the molds with different heights and sizes are difficult to operate and easy to cause problems, and the working efficiency and the product quality are greatly reduced.

SUMMERY OF THE UTILITY MODEL

Not enough to prior art, the utility model provides a plastics toy injection moulding mould possesses the effectual and good advantage of follow-up processing of moulding plastics, has solved the problem that the above-mentioned technical background proposed.

The utility model provides a following technical scheme: the utility model provides a plastics toy injection moulding mould, includes a supporting bench, the equal fixed mounting in both ends on brace table upper portion has first lead screw, two the equal threaded connection in middle part of first lead screw has first motor, and the equal fixed mounting in left end of two first lead screws has the movable plate, the top fixed mounting of first motor has the fixer, the equal fixed mounting in both sides at brace table middle part has the support frame, the right side fixed mounting of support frame upper end has the second lead screw, the middle part threaded connection of second lead screw has the shifter, the middle part activity joint of shifter has the ware of moulding plastics, the top fixed mounting of the ware of moulding plastics has the pipe of moulding plastics, the left side fixed mounting of second lead screw has the second motor, the upper end fixed mounting who moulds plastics the pipe has the drive piece, the left end fixed mounting of drive piece has the hydraulic stem.

The air conditioner is characterized in that a treatment chamber is fixedly mounted at the top of the left end of the support table, a clamping plate is movably clamped at the right side of the treatment chamber, a turnover plate is fixedly mounted at the top of the treatment chamber, and an air conditioner is fixedly mounted in the middle of the back of the treatment chamber.

Carefully, the fixer is including the fixing base, the inside joint of fixing base has a joint section of thick bamboo, and the top of fixing base has seted up the card pinhole, the bottom fixed mounting of fixing base is at the top of movable plate.

And carefully selecting fifteen holders, wherein the holders are distributed on the top of the moving plate in a three-by-five manner, and the sum of the transverse lengths of the five holders is smaller than the length value of the second screw rod.

Carefully, three bending grooves are formed in the side face of the fixing seat, three clamping blocks are fixedly mounted at the lower end of the clamping cylinder, the clamping pin holes sequentially penetrate through the protruding blocks of the fixing seat and the clamping blocks of the clamping cylinder, and threaded grooves are formed in the clamping cylinder.

Preferably, the bottom area value of the processing chamber is greater than the bottom area value of the moving plate.

Compared with the prior art, the utility model discloses possess following beneficial effect:

1. this plastics toy injection moulding mould reaches injection moulding effectually through being provided with movable plate, second lead screw and hydraulic stem etc. and the movable plate can drive injection moulding mould and carry out lateral shifting, and the lead screw drives the ware of moulding plastics and is longitudinal movement, and the hydraulic stem then drives the ware of moulding plastics and be elevating movement at last, and a plurality of structure cooperations are used, can carry out the operation of moulding plastics to the toy mould of multiple size and size, and it is stable to utilize the lead screw to remove, can guarantee the precision of moulding plastics.

2. This plastics toy injection moulding mould reaches subsequent processing effectual through being provided with fixer, process chamber and air conditioner etc. adopts detachable fixer, has made things convenient for the dismantlement of mould to handle, when subsequent going wrong, also can in time maintain and change, is provided with process chamber and air conditioner then and has accelerated the cooling rate of mould, reduces the cooling latency, has improved work efficiency greatly.

Drawings

FIG. 1 is a schematic view of the whole structure of the present invention;

FIG. 2 is a schematic top view of the structure of the present invention;

FIG. 3 is a schematic diagram of the structure shifter and the position of the supporting frame of the present invention;

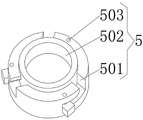

FIG. 4 is a schematic view of the structure fixing device of the present invention;

fig. 5 is a schematic view of the structure fixing base and the clamping cylinder of the present invention.

In the figure: 1. a support table; 2. a first lead screw; 3. a first motor; 4. moving the plate; 5. a holder; 501. a fixed seat; 502. a clamping cylinder; 503. a pin clamping hole; 6. a support frame; 7. a second lead screw; 8. a mover; 9. an injection molding machine; 10. injection molding a tube; 11. a second motor; 12. a hydraulic lever; 13. driving the sheet; 14. a processing chamber; 15. clamping a plate; 16. turning the folded plate; 17. an air conditioner.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work all belong to the protection scope of the present invention.

Referring to fig. 1-5, an injection molding mold for plastic toys comprises a supporting table 1, first screws 2 are fixedly mounted at both ends of the upper portion of the supporting table 1, a first motor 3 is connected to the middle portions of the two first screws 2 through threads, and the equal fixed mounting in left end of two first lead screws 2 has movable plate 4, the top fixed mounting of first motor 3 has fixer 5, the equal fixed mounting in both sides at brace table 1 middle part has support frame 6, the right side fixed mounting of support frame 6 upper end has second lead screw 7, the middle part threaded connection of second lead screw 7 has shifter 8, the middle part activity joint of shifter 8 has injection molding machine 9, the top fixed mounting of injection molding machine 9 has injection molding pipe 10, the left side fixed mounting of second lead screw 7 has second motor 11, the upper end fixed mounting of injection molding pipe 10 has drive piece 13, the left end fixed mounting of drive piece 13 has hydraulic stem 12.

Wherein, the top fixed mounting of the support table 1 left end has a processing chamber 14, the right side activity joint of processing chamber 14 has a cardboard 15, and the top fixed mounting of processing chamber 14 has a board 16 that turns over, the middle part fixed mounting at the processing chamber 14 back has an air conditioner 17, what air conditioner 17 adopted is camel industry air-cooler, through being provided with the board 16 that turns over and cardboard 15 entering of being convenient for injection mold, and subsequent cooling observation, be provided with processing chamber 14 simultaneously, the fashioned speed of plastics toy production has been accelerated greatly.

Wherein, fixer 5 is including fixing base 501, and fixing base 501's inside joint has a joint section of thick bamboo 502, and fixing base 501's top has seted up card pinhole 503, and fixing base 501's bottom fixed mounting adopts the mode of rotatory joint to fix the mould at the top of movable plate 4, can effectual realization mould installation and dismantlement, has made things convenient for subsequent maintenance greatly to handle, has reduced the trouble of handling.

The number of the fixing devices 5 is fifteen, the fixing devices 5 are distributed on the top of the moving plate 4 in a three-by-five mode, the sum of the transverse lengths of the five fixing devices 5 is smaller than the length value of the second screw rod 7, the fixing devices 5 arrive at the bottom of the injection molding device 9 by means of the aid of the moving plate 4, the injection molding device 9 can conduct three-dimensional injection molding operation under the aid of the second screw rod 7 and the hydraulic rod 12, the injection molding effect is good, and meanwhile the working efficiency is greatly improved.

Wherein, three bending groove has been seted up to fixing base 501's side, the lower extreme fixed mounting of a joint section of thick bamboo 502 has three fixture block, card pinhole 503 runs through fixing base 501's bulge and the fixture block of a joint section of thick bamboo 502 in proper order, the thread groove has been seted up to the inside of a joint section of thick bamboo 502, with the rotatory joint of a joint section of thick bamboo 502 in bending groove department, can guarantee the relatively fixed of a joint section of thick bamboo 502 position, place the stable installation that a joint section of thick bamboo 502 just can be realized to the joint round pin in card pinhole 503 afterwards, guarantee the stability of structure, make the accurate effective of work of injection molding machine.

Wherein, the bottom area value of process chamber 14 is greater than the bottom area value of movable plate 4, and the mould that is moulded plastics is often the temperature higher, and unable direct dismantlement is handled, through removing it to process chamber 14 and cool down the operation, can accelerate the shaping speed of plastics toy, has shortened subsequent wait to dismantle time greatly, has improved work efficiency.

The working principle is as follows: during the use, with plastic mold threaded connection in a joint section of thick bamboo 502, be later on with the rotatory joint of a joint section of thick bamboo 502 on fixing base 501, utilize the bayonet lock to realize the stability of the two, start first motor 3 afterwards, utilize two first lead screws 2 to drive movable plate 4 and shift to the ware of moulding plastics 9 lower extreme, second motor 11 starts this moment, control second lead screw 7 and drive the removal ware 8 and remove about doing, hydraulic stem 12 can also reciprocate in the cooperation, cooperation work through a plurality of structures, make injection mold injection molding effectual, the completion is moulded plastics, remove movable plate 4 to the treatment chamber 14 in, start air conditioner 17 work, accelerate the shaping of plastic toy, dismantle the toy after the completion cooling and get off and carry out processing on next step can.

It is noted that, herein, relational terms such as first and second, and the like may be used solely to distinguish one entity or action from another entity or action without necessarily requiring or implying any actual such relationship or order between such entities or actions. Also, the terms "comprises," "comprising," or any other variation thereof, are intended to cover a non-exclusive inclusion, such that a process, method, article, or apparatus that comprises a list of elements does not include only those elements but may include other elements not expressly listed or inherent to such process, method, article, or apparatus. Also in the description of the present invention, it is to be understood that the terms "center", "longitudinal", "lateral", "length", "width", "thickness", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", "top", "bottom", "inner", "outer", "clockwise", "counterclockwise", and the like, indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and for simplicity of description, and do not indicate or imply that the equipment or element referred to must have a particular orientation, be constructed and operated in a particular orientation, and therefore, should not be construed as limiting the present invention. In addition, in the drawings of the present invention, the filling pattern is only for distinguishing the pattern layer, and is not limited to any other pattern.

Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, the scope of which is defined in the appended claims and their equivalents.

Claims (6)

1. The utility model provides a plastics toy injection moulding mould, includes brace table (1), its characterized in that: the injection molding machine is characterized in that first screw rods (2) are fixedly mounted at two ends of the upper portion of the supporting table (1), a first motor (3) is connected to the middle portions of the two first screw rods (2) in a threaded manner, a movable plate (4) is fixedly mounted at the left ends of the two first screw rods (2), a fixer (5) is fixedly mounted at the top of the first motor (3), supporting frames (6) are fixedly mounted at two sides of the middle portion of the supporting table (1), a second screw rod (7) is fixedly mounted at the right side of the upper end of each supporting frame (6), a shifter (8) is connected to the middle portion of each second screw rod (7) in a threaded manner, an injection molding device (9) is movably clamped in the middle portion of each shifter (8), an injection molding pipe (10) is fixedly mounted at the top of each injection molding device (9), a second motor (11) is fixedly mounted at the left side of each second screw rod (7, and a hydraulic rod (12) is fixedly installed at the left end of the driving sheet (13).

2. The plastic toy injection mold of claim 1, wherein: the top fixed mounting of brace table (1) left end has treatment chamber (14), the right side activity joint of treatment chamber (14) has cardboard (15), and the top fixed mounting of treatment chamber (14) has turnover board (16), the middle part fixed mounting at the treatment chamber (14) back has air conditioner (17).

3. The plastic toy injection mold of claim 1, wherein: the fixing device (5) comprises a fixing seat (501), a clamping cylinder (502) is clamped inside the fixing seat (501), a clamping pin hole (503) is formed in the top of the fixing seat (501), and the bottom of the fixing seat (501) is fixedly installed at the top of the movable plate (4).

4. The plastic toy injection mold of claim 1, wherein: the number of the fixing devices (5) is fifteen, the fixing devices (5) are distributed on the top of the moving plate (4) in a three-by-five mode, and the sum of the transverse lengths of the five fixing devices (5) is smaller than the length value of the second screw rod (7).

5. A plastic toy injection mold as claimed in claim 3, wherein: three bending grooves are formed in the side face of the fixing seat (501), three clamping blocks are fixedly mounted at the lower end of the clamping cylinder (502), the clamping pin holes (503) sequentially penetrate through the protruding blocks of the fixing seat (501) and the clamping blocks of the clamping cylinder (502), and a threaded groove is formed in the clamping cylinder (502).

6. A plastic toy injection mold as claimed in claim 2, wherein: the bottom area value of the processing chamber (14) is larger than that of the moving plate (4).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202020703495.5U CN212528593U (en) | 2020-04-30 | 2020-04-30 | Plastic toy injection molding mold |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202020703495.5U CN212528593U (en) | 2020-04-30 | 2020-04-30 | Plastic toy injection molding mold |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN212528593U true CN212528593U (en) | 2021-02-12 |

Family

ID=74540199

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202020703495.5U Active CN212528593U (en) | 2020-04-30 | 2020-04-30 | Plastic toy injection molding mold |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN212528593U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115157543A (en) * | 2022-07-04 | 2022-10-11 | 无锡蒙力特科技有限公司 | Batch injection molding process for plastic objects |

-

2020

- 2020-04-30 CN CN202020703495.5U patent/CN212528593U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115157543A (en) * | 2022-07-04 | 2022-10-11 | 无锡蒙力特科技有限公司 | Batch injection molding process for plastic objects |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103918737A (en) | Novel patterned steamed bread molding machine | |

| CN212528593U (en) | Plastic toy injection molding mold | |

| CN211105275U (en) | Novel automobile injection mold with high demolding speed | |

| CN203776027U (en) | Novel patterned steamed bun forming machine | |

| CN210080694U (en) | Metal product injection mold capable of achieving rapid demolding | |

| CN212948706U (en) | Accurate goggles rubber and plastic demoulding structure for mould | |

| CN214324012U (en) | Injection mold capable of automatically cleaning injection molding opening | |

| CN209755933U (en) | high-precision nail bin injection mold | |

| CN210910962U (en) | Injection mold convenient for mold stripping | |

| CN103891811A (en) | Forming machine for pattern steamed buns | |

| CN213733067U (en) | Easy demoulding's mould | |

| CN215283054U (en) | Glass spare embedding injection mold | |

| CN219820508U (en) | Injection molding machine for plastic product processing | |

| CN215791496U (en) | III-shaped plastic tray mold with crossed inclined top demolding mechanism | |

| CN215434827U (en) | Automatic change plastic drum injection mold of drawing of patterns | |

| CN216506472U (en) | Mould is used in production of refrigerator control panel | |

| CN218053810U (en) | Air conditioner injection molding unloading mechanism of moulding plastics | |

| CN217196677U (en) | Integrative ejecting injection mold of drawing of patterns of convex hollow injection molding | |

| CN220826266U (en) | Forming die | |

| CN218342750U (en) | Injection molding device is used in production of car plastic parts | |

| CN217944118U (en) | Shell injection mold convenient to drawing of patterns | |

| CN218906139U (en) | Injection mold with stamping demolding structure | |

| CN216230584U (en) | Injection mold convenient to take off material | |

| CN213440909U (en) | Intelligent portable dust collector mold | |

| CN220261827U (en) | Multi-cavity laminated precise injection molding die structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |