CN211521950U - System for reducing concentration of pollutants in steel comprehensive wastewater - Google Patents

System for reducing concentration of pollutants in steel comprehensive wastewater Download PDFInfo

- Publication number

- CN211521950U CN211521950U CN201922136500.9U CN201922136500U CN211521950U CN 211521950 U CN211521950 U CN 211521950U CN 201922136500 U CN201922136500 U CN 201922136500U CN 211521950 U CN211521950 U CN 211521950U

- Authority

- CN

- China

- Prior art keywords

- tank

- filter

- water

- water inlet

- pipeline

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002351 wastewater Substances 0.000 title claims abstract description 51

- 239000003344 environmental pollutant Substances 0.000 title claims abstract description 27

- 231100000719 pollutant Toxicity 0.000 title claims abstract description 27

- 229910000831 Steel Inorganic materials 0.000 title claims abstract description 21

- 239000010959 steel Substances 0.000 title claims abstract description 21

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 91

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims abstract description 44

- 229910052742 iron Inorganic materials 0.000 claims abstract description 22

- 238000004062 sedimentation Methods 0.000 claims abstract description 20

- 238000009300 dissolved air flotation Methods 0.000 claims abstract description 13

- 238000005273 aeration Methods 0.000 claims abstract description 12

- 230000001105 regulatory effect Effects 0.000 claims abstract description 10

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 claims abstract description 9

- 230000003647 oxidation Effects 0.000 claims abstract description 9

- 238000007254 oxidation reaction Methods 0.000 claims abstract description 9

- 230000003197 catalytic effect Effects 0.000 claims abstract description 8

- 239000010802 sludge Substances 0.000 claims description 20

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 9

- 238000005276 aerator Methods 0.000 claims description 9

- 229910052799 carbon Inorganic materials 0.000 claims description 9

- 238000010438 heat treatment Methods 0.000 claims description 9

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 claims description 8

- UIIMBOGNXHQVGW-UHFFFAOYSA-M Sodium bicarbonate Chemical compound [Na+].OC([O-])=O UIIMBOGNXHQVGW-UHFFFAOYSA-M 0.000 claims description 8

- 238000006243 chemical reaction Methods 0.000 claims description 8

- 238000005188 flotation Methods 0.000 claims description 8

- 238000000926 separation method Methods 0.000 claims description 8

- 239000003814 drug Substances 0.000 claims description 7

- 239000000725 suspension Substances 0.000 claims description 7

- 235000008733 Citrus aurantifolia Nutrition 0.000 claims description 6

- 235000011941 Tilia x europaea Nutrition 0.000 claims description 6

- 229940079593 drug Drugs 0.000 claims description 6

- 239000011261 inert gas Substances 0.000 claims description 6

- 239000004571 lime Substances 0.000 claims description 6

- 239000003795 chemical substances by application Substances 0.000 claims description 5

- 239000007789 gas Substances 0.000 claims description 5

- 239000004576 sand Substances 0.000 claims description 5

- 239000013049 sediment Substances 0.000 claims description 5

- 239000002893 slag Substances 0.000 claims description 5

- 241000894006 Bacteria Species 0.000 claims description 4

- UXVMQQNJUSDDNG-UHFFFAOYSA-L Calcium chloride Chemical compound [Cl-].[Cl-].[Ca+2] UXVMQQNJUSDDNG-UHFFFAOYSA-L 0.000 claims description 4

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 claims description 4

- 239000001110 calcium chloride Substances 0.000 claims description 4

- 229910001628 calcium chloride Inorganic materials 0.000 claims description 4

- 230000005764 inhibitory process Effects 0.000 claims description 4

- 229910052698 phosphorus Inorganic materials 0.000 claims description 4

- 239000011574 phosphorus Substances 0.000 claims description 4

- 229910000030 sodium bicarbonate Inorganic materials 0.000 claims description 4

- 235000017557 sodium bicarbonate Nutrition 0.000 claims description 4

- 229910000029 sodium carbonate Inorganic materials 0.000 claims description 4

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 3

- 238000005485 electric heating Methods 0.000 claims description 3

- 229910052760 oxygen Inorganic materials 0.000 claims description 3

- 239000001301 oxygen Substances 0.000 claims description 3

- 238000011144 upstream manufacturing Methods 0.000 claims description 3

- 238000010612 desalination reaction Methods 0.000 abstract description 16

- 239000012528 membrane Substances 0.000 abstract description 11

- 239000003403 water pollutant Substances 0.000 abstract description 5

- 239000000126 substance Substances 0.000 abstract description 2

- 238000003911 water pollution Methods 0.000 abstract 1

- 238000000034 method Methods 0.000 description 11

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 10

- XKMRRTOUMJRJIA-UHFFFAOYSA-N ammonia nh3 Chemical compound N.N XKMRRTOUMJRJIA-UHFFFAOYSA-N 0.000 description 5

- 229910052757 nitrogen Inorganic materials 0.000 description 5

- KRHYYFGTRYWZRS-UHFFFAOYSA-M Fluoride anion Chemical compound [F-] KRHYYFGTRYWZRS-UHFFFAOYSA-M 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 229910002651 NO3 Inorganic materials 0.000 description 3

- NHNBFGGVMKEFGY-UHFFFAOYSA-N Nitrate Chemical compound [O-][N+]([O-])=O NHNBFGGVMKEFGY-UHFFFAOYSA-N 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 241001148470 aerobic bacillus Species 0.000 description 2

- 230000032683 aging Effects 0.000 description 2

- 239000012267 brine Substances 0.000 description 2

- 230000003750 conditioning effect Effects 0.000 description 2

- 238000001914 filtration Methods 0.000 description 2

- 239000010842 industrial wastewater Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000001556 precipitation Methods 0.000 description 2

- HPALAKNZSZLMCH-UHFFFAOYSA-M sodium;chloride;hydrate Chemical compound O.[Na+].[Cl-] HPALAKNZSZLMCH-UHFFFAOYSA-M 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- XFXPMWWXUTWYJX-UHFFFAOYSA-N Cyanide Chemical compound N#[C-] XFXPMWWXUTWYJX-UHFFFAOYSA-N 0.000 description 1

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 description 1

- VTLYFUHAOXGGBS-UHFFFAOYSA-N Fe3+ Chemical compound [Fe+3] VTLYFUHAOXGGBS-UHFFFAOYSA-N 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000006555 catalytic reaction Methods 0.000 description 1

- 238000005115 demineralization Methods 0.000 description 1

- 230000002328 demineralizing effect Effects 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229960004887 ferric hydroxide Drugs 0.000 description 1

- 238000005189 flocculation Methods 0.000 description 1

- 230000016615 flocculation Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- IEECXTSVVFWGSE-UHFFFAOYSA-M iron(3+);oxygen(2-);hydroxide Chemical compound [OH-].[O-2].[Fe+3] IEECXTSVVFWGSE-UHFFFAOYSA-M 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 238000009285 membrane fouling Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 238000004065 wastewater treatment Methods 0.000 description 1

Images

Landscapes

- Physical Water Treatments (AREA)

- Purification Treatments By Anaerobic Or Anaerobic And Aerobic Bacteria Or Animals (AREA)

Abstract

本实用新型涉及一种降低钢铁综合废水污染物浓度的系统,包括通过废水管道依次连接的调节池、高密度沉淀池、曝气生物滤池、反硝化生物滤池、高效溶气气浮池、滤池及臭氧催化氧化池;本实用新型能够彻底将废水中的污染物转化为非污染物质,达到降低污染物浓度的目的,满足《钢铁工业水污染物排放标准GB13456‑2012》表3中对水污染物特别排放限值的要求,并且完全满足双膜法除盐回用进水水质指标,以提高除盐回用设施的使用寿命。

The utility model relates to a system for reducing the pollutant concentration of iron and steel comprehensive wastewater, comprising a regulating tank, a high-density sedimentation tank, a biological aeration filter, a denitrification biological filter, a high-efficiency dissolved air flotation tank, a filter tank and a A pool and an ozone catalytic oxidation pool; the utility model can completely convert the pollutants in the waste water into non-pollutant substances, achieve the purpose of reducing the concentration of pollutants, and meet the requirements for water pollution in Table 3 of the "Iron and Steel Industry Water Pollutant Discharge Standard GB13456-2012" The requirements of the special discharge limit of pollutants, and fully meet the water quality indicators of the double-membrane desalination and reuse in order to improve the service life of the desalination and reuse facilities.

Description

技术领域technical field

本实用新型涉及工业废水处理技术领域,尤其涉及一种降低钢铁综合废水污染物浓度的系统。The utility model relates to the technical field of industrial wastewater treatment, in particular to a system for reducing the pollutant concentration of iron and steel comprehensive wastewater.

背景技术Background technique

钢铁企业是用水大户,产生大量生产废水,废水中SS、COD、氨氮、总氮、氟化物、氰化物等指标易超标,无法直接排放。对工业废水采用除盐回用是行业发展趋势,但该方法并没有将污染物去除,而是将污染物转移到浓盐水中,浓盐水再次使用势必造成二次污染。另外,双膜法除盐对进水要求严格,进水水质好,可以大大提高除盐设备的使用寿命。因此最好在废水进入双膜法除盐系统前,先降低污染物浓度。Iron and steel enterprises are major water users, producing a large amount of production wastewater. The indicators of SS, COD, ammonia nitrogen, total nitrogen, fluoride, cyanide and other indicators in the wastewater are easy to exceed the standard and cannot be directly discharged. The use of desalination and reuse of industrial wastewater is the development trend of the industry, but this method does not remove pollutants, but transfers the pollutants to concentrated brine, and the reuse of concentrated brine will inevitably cause secondary pollution. In addition, the double-membrane method for desalination has strict requirements on the influent water, and the quality of the influent water is good, which can greatly improve the service life of the desalination equipment. Therefore, it is best to reduce the concentration of pollutants before the wastewater enters the double-membrane desalination system.

发明内容SUMMARY OF THE INVENTION

本实用新型提供了一种降低钢铁综合废水污染物浓度的系统,能够彻底将废水中的污染物转化为非污染物质,达到降低污染物浓度的目的,满足《钢铁工业水污染物排放标准GB13456-2012》表3中对水污染物特别排放限值的要求,并且完全满足双膜法除盐回用进水水质指标,以提高除盐回用设施的使用寿命。The utility model provides a system for reducing the concentration of pollutants in comprehensive iron and steel wastewater, which can completely convert the pollutants in the wastewater into non-pollutant substances, achieve the purpose of reducing the concentration of pollutants, and meet the requirements of the "Water Pollutant Discharge Standard for Iron and Steel Industry GB13456- 2012 "Table 3 of the special discharge limit requirements for water pollutants, and fully meet the double-membrane desalination and reuse influent water quality indicators to improve the service life of desalination and reuse facilities.

为了达到上述目的,本实用新型采用以下技术方案实现:In order to achieve the above object, the utility model adopts the following technical solutions to realize:

一种降低钢铁综合废水污染物浓度的系统,包括通过废水管道依次连接的调节池、高密度沉淀池、曝气生物滤池、反硝化生物滤池、高效溶气气浮池、滤池及臭氧催化氧化池;其中:A system for reducing the concentration of pollutants in iron and steel comprehensive wastewater, including a regulating tank, a high-density sedimentation tank, a biological aeration filter, a biological denitrification filter, a high-efficiency dissolved air flotation tank, a filter tank and an ozone catalysis tank connected in sequence through a wastewater pipeline oxidation pool; where:

所述调节池中设可提升式曝气器;A liftable aerator is arranged in the regulating tank;

所述高密度沉淀池设药物投加装置,高密度沉淀池设沉淀物排放口通过管道连接污泥处理系统;The high-density sedimentation tank is provided with a drug dosing device, and the high-density sedimentation tank is provided with a sediment discharge port connected to the sludge treatment system through a pipeline;

所述曝气生物滤池内设固定式曝气器,固定式曝气器通过管道连接空气悬浮风机;The aeration biological filter is provided with a fixed aerator, and the fixed aerator is connected to the air suspension fan through a pipeline;

所述反硝化生物滤池设惰性气体引入口及碳源投加装置;反硝化生物滤池的底部设进水口,上部设出水口,池体内设至少2层滤层,包括设于下层的好氧菌抑制层及设于上层的反硝化层;The denitrification biological filter is provided with an inert gas inlet and a carbon source dosing device; the denitrification biological filter is provided with a water inlet at the bottom and a water outlet at the upper part, and at least two layers of filter layers are arranged in the tank body, including a filter layer arranged in the lower layer. Oxygen bacteria inhibition layer and denitrification layer arranged on the upper layer;

所述高效溶气气浮池上游的废水管道上设管式反应器,管式反应器设除磷剂添加口及絮凝剂添加口;高效溶气气浮池内沿水流方向依次划分为进水区、布水区及分离区,进水区的进水口与管式反应器的出水口相连,进水区设气浮装置;布水区的顶部设刮渣机,布水区的下部设波纹斜板,底部设排泥口;分离区的底部设刮泥机及自动排泥阀;刮渣机通过排渣槽连接污泥处理系统,刮泥机通过排泥管道连接污泥处理系统,排泥管道上设自动排泥阀。The waste water pipeline upstream of the high-efficiency dissolved air flotation tank is provided with a tubular reactor, and the tubular reactor is provided with a phosphorus removal agent addition port and a flocculant addition port; the high-efficiency dissolved air flotation tank is divided into water inlet area, In the water distribution area and separation area, the water inlet of the water inlet area is connected with the water outlet of the tubular reactor, and the air flotation device is installed in the water inlet area; the top of the water distribution area is equipped with a slag scraper, and the lower part of the water distribution area is equipped with a corrugated inclined plate , the bottom is provided with a mud discharge port; the bottom of the separation zone is provided with a mud scraper and an automatic mud discharge valve; There is an automatic mud valve on it.

所述调节池中还设有加热装置,加热装置为电加热装置或蒸汽加热装置。A heating device is also provided in the conditioning tank, and the heating device is an electric heating device or a steam heating device.

所述高密度沉淀池中的药物投加装置为石灰投加装置、氯化钙投加装置、碳酸钠投加装置、碳酸氢钠投加装置、PAC投加装置、PAM投加装置中的一种或多种。The drug dosing device in the high-density sedimentation tank is one of lime dosing device, calcium chloride dosing device, sodium carbonate dosing device, sodium bicarbonate dosing device, PAC dosing device and PAM dosing device. one or more.

所述空气悬浮风机采用变频控制。The air suspension fan adopts frequency conversion control.

所述气浮装置由溶气罐、循环泵及释放器组成,溶气罐上设空气入口、循环水入口及溶气水出口,循环水入口与进水区上的循环水出口通过循环水管道相连,循环水管道上设循环泵,溶气水出口与进水区内的释放器相连。The air flotation device is composed of a dissolved air tank, a circulating pump and a releaser. The dissolved air tank is provided with an air inlet, a circulating water inlet and a dissolved air water outlet. The circulating water inlet and the circulating water outlet on the water inlet area pass through the circulating water pipeline. The circulating water pipeline is provided with a circulating pump, and the dissolved air water outlet is connected with the releaser in the water inlet area.

所述滤池为砂滤池或V型滤池。The filter tank is a sand filter tank or a V-type filter tank.

所述滤池下游的废水管道上设反冲洗水出口,通过反冲洗水管道分别连接曝气生物滤池、反硝化生物滤池及滤池的反冲洗水入口;曝气生物滤池、反硝化生物滤池及滤池分别设反洗排水口,通过反洗排水管道连接调节池。A backwash water outlet is set on the waste water pipeline downstream of the filter tank, and the backwash water inlet of the aeration biological filter tank, the denitrification biological filter tank and the filter tank are respectively connected through the backwash water pipeline; The biological filter tank and the filter tank are respectively provided with a backwash drain outlet, which is connected to the adjustment tank through a backwash drain pipe.

与现有技术相比,本实用新型的有益效果是:Compared with the prior art, the beneficial effects of the present utility model are:

1)工艺及系统设置合理,能够适应钢铁综合废水水质,可同时去除废水中的SS、COD、氨氮、总氮、氟化物、硬度、浊度、色度、总铁、油等污染物。1) The process and system settings are reasonable, which can adapt to the comprehensive iron and steel wastewater quality, and can simultaneously remove SS, COD, ammonia nitrogen, total nitrogen, fluoride, hardness, turbidity, chroma, total iron, oil and other pollutants in the wastewater.

2)经处理后的废水可以达到《钢铁工业水污染物排放标准GB13456-2012》表3中对水污染物特别排放限值指标要求,并可作为双膜法除盐的预处理工序;2) The treated wastewater can meet the requirements of the special discharge limit index of water pollutants in Table 3 of "Water Pollutant Discharge Standard for Iron and Steel Industry GB13456-2012", and can be used as a pretreatment process for double-membrane desalination;

3)废水中污染物的去除率均大幅度提高,其中氨氮去除率可达95%以上,COD去除率可达90%以上,总氮去除率可达90%以上。3) The removal rate of pollutants in wastewater is greatly improved, among which the removal rate of ammonia nitrogen can reach more than 95%, the removal rate of COD can reach more than 90%, and the removal rate of total nitrogen can reach more than 90%.

附图说明Description of drawings

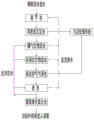

图1是本实用新型所述一种降低钢铁综合废水污染物浓度的系统的结构示意图。FIG. 1 is a schematic structural diagram of a system for reducing the concentration of pollutants in comprehensive iron and steel wastewater according to the present invention.

具体实施方式Detailed ways

下面结合附图对本实用新型的具体实施方式作进一步说明:The specific embodiments of the present utility model will be further described below in conjunction with the accompanying drawings:

如图1所示,本实用新型所述一种降低钢铁综合废水污染物浓度的系统,包括通过废水管道依次连接的调节池、高密度沉淀池、曝气生物滤池、反硝化生物滤池、高效溶气气浮池、滤池及臭氧催化氧化池;其中:As shown in Figure 1, a system for reducing the pollutant concentration of comprehensive iron and steel wastewater according to the present utility model comprises a regulating tank, a high-density sedimentation tank, a biological aerated filter tank, a biological denitrification filter tank, High-efficiency dissolved air flotation tank, filter tank and ozone catalytic oxidation tank; of which:

所述调节池中设可提升式曝气器;A liftable aerator is arranged in the regulating tank;

所述高密度沉淀池设药物投加装置,高密度沉淀池设沉淀物排放口通过管道连接污泥处理系统;The high-density sedimentation tank is provided with a drug dosing device, and the high-density sedimentation tank is provided with a sediment discharge port connected to the sludge treatment system through a pipeline;

所述曝气生物滤池内设固定式曝气器,固定式曝气器通过管道连接空气悬浮风机;The aeration biological filter is provided with a fixed aerator, and the fixed aerator is connected to the air suspension fan through a pipeline;

所述反硝化生物滤池设惰性气体引入口及碳源投加装置;反硝化生物滤池的底部设进水口,上部设出水口,池体内设至少2层滤层,包括设于下层的好氧菌抑制层及设于上层的反硝化层;The denitrification biological filter is provided with an inert gas inlet and a carbon source dosing device; the denitrification biological filter is provided with a water inlet at the bottom and a water outlet at the upper part, and at least two layers of filter layers are arranged in the tank body, including a filter layer arranged in the lower layer. Oxygen bacteria inhibition layer and denitrification layer arranged on the upper layer;

所述高效溶气气浮池上游的废水管道上设管式反应器,管式反应器设除磷剂添加口及絮凝剂添加口;高效溶气气浮池内沿水流方向依次划分为进水区、布水区及分离区,进水区的进水口与管式反应器的出水口相连,进水区设气浮装置;布水区的顶部设刮渣机,布水区的下部设波纹斜板,底部设排泥口;分离区的底部设刮泥机及自动排泥阀;刮渣机通过排渣槽连接污泥处理系统,刮泥机通过排泥管道连接污泥处理系统,排泥管道上设自动排泥阀。The waste water pipeline upstream of the high-efficiency dissolved air flotation tank is provided with a tubular reactor, and the tubular reactor is provided with a phosphorus removal agent addition port and a flocculant addition port; the high-efficiency dissolved air flotation tank is divided into water inlet area, In the water distribution area and separation area, the water inlet of the water inlet area is connected with the water outlet of the tubular reactor, and the air flotation device is installed in the water inlet area; the top of the water distribution area is equipped with a slag scraper, and the lower part of the water distribution area is equipped with a corrugated inclined plate , the bottom is provided with a mud discharge port; the bottom of the separation zone is provided with a mud scraper and an automatic mud discharge valve; There is an automatic mud valve on it.

所述调节池中还设有加热装置,加热装置为电加热装置或蒸汽加热装置。A heating device is also provided in the conditioning tank, and the heating device is an electric heating device or a steam heating device.

所述高密度沉淀池中的药物投加装置为石灰投加装置、氯化钙投加装置、碳酸钠投加装置、碳酸氢钠投加装置、PAC投加装置、PAM投加装置中的一种或多种。The drug dosing device in the high-density sedimentation tank is one of lime dosing device, calcium chloride dosing device, sodium carbonate dosing device, sodium bicarbonate dosing device, PAC dosing device and PAM dosing device. one or more.

所述空气悬浮风机采用变频控制。The air suspension fan adopts frequency conversion control.

所述气浮装置由溶气罐、循环泵及释放器组成,溶气罐上设空气入口、循环水入口及溶气水出口,循环水入口与进水区上的循环水出口通过循环水管道相连,循环水管道上设循环泵,溶气水出口与进水区内的释放器相连。The air flotation device is composed of a dissolved air tank, a circulating pump and a releaser. The dissolved air tank is provided with an air inlet, a circulating water inlet and a dissolved air water outlet. The circulating water inlet and the circulating water outlet on the water inlet area pass through the circulating water pipeline. A circulating pump is installed on the circulating water pipeline, and the dissolved gas water outlet is connected with the releaser in the water inlet area.

所述滤池为砂滤池或V型滤池。The filter tank is a sand filter tank or a V-type filter tank.

所述滤池下游的废水管道上设反冲洗水出口,通过反冲洗水管道分别连接曝气生物滤池、反硝化生物滤池及滤池的反冲洗水入口;曝气生物滤池、反硝化生物滤池及滤池分别设反洗排水口,通过反洗排水管道连接调节池。A backwash water outlet is set on the waste water pipeline downstream of the filter tank, and the backwash water inlet of the aeration biological filter tank, the denitrification biological filter tank and the filter tank are respectively connected through the backwash water pipeline; The biological filter tank and the filter tank are respectively provided with a backwash drain outlet, which is connected to the adjustment tank through a backwash drain pipe.

本实用新型所述一种降低钢铁综合废水污染物浓度的系统的工艺过程如下:The technological process of the system for reducing the pollutant concentration of iron and steel comprehensive wastewater according to the present invention is as follows:

1)钢铁综合废水首先进入调节池,调节池用于调节水量、均衡水质、防止污泥沉淀;通过曝气向废水中充氧,将废水中的二价铁氧化为三价铁,以便在后续高密度沉淀池中通过投加石灰形成氢氧化铁沉淀而去除总铁,满足废水除盐回用要求;在调节池中根据需要对废水进行加热,避免由于水温过低影响后续的生化处理效果和双膜除盐产水率;1) The comprehensive iron and steel wastewater first enters the regulating tank, which is used to adjust the water volume, balance the water quality, and prevent sludge precipitation; oxygenate the wastewater through aeration, and oxidize the ferrous iron in the wastewater to ferric iron, so that it can be used in the follow-up. In the high-density sedimentation tank, the total iron is removed by adding lime to form ferric hydroxide precipitation to meet the requirements of wastewater desalination and reuse; in the regulating tank, the wastewater is heated as needed to avoid the effect of subsequent biochemical treatment due to low water temperature. Double-membrane desalination water production rate;

2)调节池出水进入高密度沉淀池;在高密度沉淀池中,需根据废水水质情况投加药物,包括投加石灰去除硬度,以满足废水除盐回用要求;投加石灰和氯化钙去除氟化物,满足出水氟化物达标要求;投加碳酸钠或碳酸氢钠补充碱度,满足氨化反应需要的碱度,以及后续氨氮去除时的碱度要求;投加PAC、PAM形成絮体,以去除SS;高密度沉淀池产生的污泥进入污泥处理系统进行处理;2) The effluent from the adjustment tank enters the high-density sedimentation tank; in the high-density sedimentation tank, it is necessary to add drugs according to the water quality of the wastewater, including adding lime to remove hardness to meet the requirements of wastewater desalination and reuse; adding lime and calcium chloride Remove fluoride to meet the standard requirements of fluoride in effluent; add sodium carbonate or sodium bicarbonate to supplement the alkalinity to meet the alkalinity required for the ammoniation reaction and the alkalinity requirements for subsequent ammonia nitrogen removal; add PAC and PAM to form flocs , to remove SS; the sludge produced by the high-density sedimentation tank enters the sludge treatment system for treatment;

3)高密度沉淀池出水进入曝气生物滤池;在曝气生物滤池中去除废水中的COD,并将氨氮转化为硝酸盐;3) The effluent from the high-density sedimentation tank enters the biological aerated filter; the COD in the wastewater is removed in the biological aerated filter, and ammonia nitrogen is converted into nitrate;

4)曝气生物滤池出水进入反硝化生物滤池;反硝化生物滤池采用上出水方式,废水先经过好氧菌抑制层降低DO,再经过反硝化层;废水经过反硝化层时,以外加碳源为电子供体发生反硝化反应,将硝酸盐转化为氮气排出;加入惰性气体的作用是使滤料膨胀,生物产生的老化污泥顺水流流出;4) The effluent from the aerated biological filter enters the denitrification biological filter; the denitrification biological filter adopts the upper effluent method, and the wastewater first passes through the aerobic bacteria inhibition layer to reduce DO, and then passes through the denitrification layer; when the wastewater passes through the denitrification layer, the other The carbon source is an electron donor to undergo denitrification reaction, and the nitrate is converted into nitrogen and discharged; the function of adding an inert gas is to expand the filter material, and the biologically-generated aging sludge flows out along the water flow;

5)反硝化生物滤池出水进入高效溶气气浮池;废水首先进入管式反应器,在管式反应器中加入除磷剂和絮凝剂,使废水中的杂质形成可分离的絮凝物;废水进入进水区后,絮凝物与溶气水中释放的直径为30~50um的气泡接触,形成低密度的“气浮体”,同时去除废水中的油和悬浮物,絮凝物在布水区聚结为浮渣,通过刮渣机刮至收渣槽后,自流排入污泥处理系统;上升速度较慢的絮体与水向下流动通过波纹斜板进一步聚结,低密度的絮体上浮到水面,高密度的絮体沉淀到底部,在布水区沉积的砂子通过排砂口排出;进水区沉淀的泥沙及分离区底部沉淀的污泥由刮泥机刮至排泥端,通过自动排泥阀定期、定量排入污泥处理系统;5) The effluent of the denitrification biological filter enters the high-efficiency dissolved air flotation tank; the waste water first enters the tubular reactor, and the phosphorus removal agent and flocculant are added to the tubular reactor to make the impurities in the waste water form separable flocs; waste water After entering the water inlet area, the flocs come into contact with the air bubbles with a diameter of 30-50um released from the dissolved gas water to form a low-density "air flotation body", while removing oil and suspended solids in the wastewater, and the flocs coalesce in the water distribution area. It is scum, which is scraped to the slag collection tank by the slag scraper, and then discharged into the sludge treatment system; the flocs with a slower rising speed and water flow downward through the corrugated inclined plate to further coalesce, and the low-density flocs float up to the sludge. On the water surface, the high-density flocs settle to the bottom, and the sand deposited in the water distribution area is discharged through the sand discharge port; the sediment deposited in the water inlet area and the sludge deposited at the bottom of the separation area are scraped by the scraper to the sludge discharge end, and passed through the discharge port. The automatic sludge discharge valve is regularly and quantitatively discharged into the sludge treatment system;

6)高效溶气气浮池出水进入滤池,去除悬浮物,降低浊度;6) The effluent from the high-efficiency dissolved air flotation tank enters the filter tank to remove suspended solids and reduce turbidity;

7)滤池出水进入臭氧催化氧化池,废水中的部分COD在高密度沉淀池和曝气生物滤中得到降解,剩余部分在臭氧催化氧化池去除;通过臭氧催化氧化池保证废水中的COD和BOD达标,系统出水COD≤30mg/L。7) The effluent from the filter tank enters the ozone catalytic oxidation tank, part of the COD in the wastewater is degraded in the high-density sedimentation tank and aerated biological filtration, and the remaining part is removed in the ozone catalytic oxidation tank; The BOD reaches the standard, and the COD of the system effluent is less than or equal to 30mg/L.

本实用新型作为双膜法除盐工艺的预处理工艺,系统出水进入双膜法除盐系统,此时省略步骤5)或将反硝化生物滤池出水通过超越管道直接送入后续处理装置。The utility model is used as the pretreatment process of the double-membrane desalination process, and the effluent of the system enters the double-membrane desalination system, and step 5) is omitted at this time, or the effluent of the denitrification biological filter is directly sent to the subsequent treatment device through the surpassing pipeline.

曝气生物滤池采用空气悬浮风机曝气,根据出水DO情况进行变频控制,节约耗电量。The aeration biological filter adopts air suspension fan aeration, and performs frequency conversion control according to the effluent DO situation, saving power consumption.

所述反硝化生物滤池采用惰性气体驱除DO,提高反硝化效果;采用外加碳源进行反硝化反应。将抑制细菌生长的滤料布置在下层,投加的碳源不会因为好氧菌的生长而被消耗,节约碳源约三分之一。采用上出水方式,废水经过反硝化层,以外加碳源为电子供体发生反硝化反应,将硝酸盐转化为氮气排出。同时由于惰性气体的进入,使滤料膨胀,生物产生的老化污泥顺水流流出,降低滤料堵塞概率,延长反洗周期。如果系统出水进入双膜法除盐系统,则可取消反硝化生物滤池这一过程或通过超越管道进行超越设置。The denitrification biological filter adopts an inert gas to drive out DO to improve the denitrification effect; and an external carbon source is used to carry out the denitrification reaction. The filter material that inhibits the growth of bacteria is arranged in the lower layer, and the added carbon source will not be consumed due to the growth of aerobic bacteria, saving about one third of the carbon source. Using the upper effluent method, the wastewater passes through the denitrification layer, and the carbon source is used as the electron donor to undergo a denitrification reaction, and the nitrate is converted into nitrogen and discharged. At the same time, due to the entry of inert gas, the filter material expands, and the biologically-generated aging sludge flows out along the water flow, reducing the probability of filter material blockage and prolonging the backwash cycle. If the effluent of the system enters the double-membrane desalination system, the process of denitrification biological filter can be canceled or the setting can be overridden by overtaking the pipeline.

高效溶气气浮池用于去除反硝化过程产生的难以沉降的生物污泥,降低后续过滤压力;去除废水中的油,保护后续双膜法除盐系统,防止油造成膜的污堵。由于生物污泥中含有气泡,难以沉淀,来水首先进入管式反应器,在管式反应器中加入絮凝药剂以形成可分离的絮凝物,与部分溶气水混合后,使得絮体聚结、密实。进水区沉淀的泥沙和分离区底部沉淀的污泥由刮泥机刮至排泥端,通过自动排泥阀定期、定量排入污泥系统,不影响设备的正常运行。The high-efficiency dissolved air flotation tank is used to remove the difficult-to-settlement biological sludge produced by the denitrification process, and reduce the subsequent filtration pressure; remove the oil in the wastewater, protect the subsequent double-membrane desalination system, and prevent the oil from causing membrane fouling. Since the biological sludge contains air bubbles, it is difficult to settle. The incoming water first enters the tubular reactor, and the flocculation agent is added to the tubular reactor to form separable flocs. After mixing with part of the dissolved gas water, the flocs are coalesced. , dense. The sediment deposited in the water inlet area and the sludge deposited at the bottom of the separation area are scraped by the scraper to the sludge discharge end, and discharged into the sludge system regularly and quantitatively through the automatic sludge discharge valve, which does not affect the normal operation of the equipment.

气浮装置采用空气为气源,在溶气罐内与循环泵加压的出水混合,形成溶气水,通过释放器释放到进水室。可同时去除废水中的油和悬浮物,保护后续双膜法除盐进水水质,延长滤池反洗周期。The air flotation device uses air as the air source, which is mixed with the water pressurized by the circulating pump in the dissolved air tank to form dissolved air water, which is released to the water inlet chamber through the releaser. It can remove oil and suspended solids in wastewater at the same time, protect the water quality of the subsequent double-membrane demineralization, and prolong the filter backwash cycle.

所述臭氧催化氧化池起到降低出水COD、色度等作用。废水中的部分COD在高密度沉淀池和曝气生物滤池中得到降解,剩余部分在臭氧催化氧化池去除;为了使反硝化达到更高的去除效果,防止投加碳源过量或没有完全被生物所利用,通过臭氧催化氧化池能够起到保证出水COD和BOD不超标的作用。The ozone catalytic oxidation tank plays the role of reducing the COD and chromaticity of the effluent. Part of the COD in the wastewater is degraded in the high-density sedimentation tank and aerated biological filter, and the remaining part is removed in the ozone catalytic oxidation tank; in order to achieve a higher removal effect by denitrification, prevent excessive or incomplete addition of carbon sources. Biological utilization, through the ozone catalytic oxidation tank can play a role in ensuring that the effluent COD and BOD does not exceed the standard.

以上所述,仅为本实用新型较佳的具体实施方式,但本实用新型的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本实用新型揭露的技术范围内,根据本实用新型的技术方案及其实用新型构思加以等同替换或改变,都应涵盖在本实用新型的保护范围之内。The above description is only a preferred embodiment of the present invention, but the protection scope of the present invention is not limited to this. Equivalent replacement or modification of the new technical solution and its utility model concept shall be included within the protection scope of the present utility model.

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922136500.9U CN211521950U (en) | 2019-12-03 | 2019-12-03 | System for reducing concentration of pollutants in steel comprehensive wastewater |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922136500.9U CN211521950U (en) | 2019-12-03 | 2019-12-03 | System for reducing concentration of pollutants in steel comprehensive wastewater |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN211521950U true CN211521950U (en) | 2020-09-18 |

Family

ID=72444524

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201922136500.9U Active CN211521950U (en) | 2019-12-03 | 2019-12-03 | System for reducing concentration of pollutants in steel comprehensive wastewater |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN211521950U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110818205A (en) * | 2019-12-03 | 2020-02-21 | 鞍钢集团工程技术有限公司 | System and process for reducing concentration of pollutants in steel comprehensive wastewater |

-

2019

- 2019-12-03 CN CN201922136500.9U patent/CN211521950U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110818205A (en) * | 2019-12-03 | 2020-02-21 | 鞍钢集团工程技术有限公司 | System and process for reducing concentration of pollutants in steel comprehensive wastewater |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN207933226U (en) | A kind of industrial wastewater treatment system | |

| CN101074141B (en) | Low-concentration organic wastewater regeneration and reuse process | |

| CN110818205A (en) | System and process for reducing concentration of pollutants in steel comprehensive wastewater | |

| WO2009124426A1 (en) | A method for treating pharmaceutical mixed wastewater in chemical industry park | |

| CN108147625B (en) | Pretreatment method and pretreatment system for pharmaceutical chemical high-concentration wastewater | |

| CN110902962A (en) | A waste water system for treating melamine adhesive film paper | |

| CN111762965A (en) | A method for advanced treatment and recycling of petrochemical wastewater | |

| CN111392984A (en) | Advanced treatment system and method for supplementing water by using urban reclaimed water as circulating water of power plant | |

| CN116813143A (en) | Production process wastewater treatment system and application thereof | |

| CN111825269A (en) | Industrial wastewater advanced treatment system | |

| CN108275780A (en) | The nitrogenous petrochemical wastewater processing unit of novel height and the method for parameter adjustment | |

| CN101863592A (en) | A kind of leachate treatment method of urban small domestic waste landfill | |

| CN106746223A (en) | Aerobic collaboration processing cutting liquid waste plant and the method for coagulation anaerobic hydrolysis | |

| CN211521950U (en) | System for reducing concentration of pollutants in steel comprehensive wastewater | |

| CN110342634A (en) | The micro- oxygen sludge bed process of membrane aeration biomembrane and its wastewater treatment method | |

| CN206328290U (en) | The aerobic collaboration processing cutting liquid waste plant of coagulation anaerobic hydrolysis | |

| CN212102493U (en) | An advanced treatment system for urban reclaimed water as circulating water supplement in power plants | |

| CN110183066B (en) | Blue algae deep dehydration wastewater treatment system and process | |

| CN219709306U (en) | Simultaneously is applicable to hot electrogalvanizing cold rolling acid-base wastewater treatment and recycling system | |

| CN220335004U (en) | Lithium iron phosphate production wastewater treatment system | |

| CN207537309U (en) | IGCC plant coal gasification and sulfur-bearing composite waste treatment for reuse Zero discharging system | |

| CN110498574A (en) | A kind of refractory biodegradable organic wastewater treatment equipment and treatment method | |

| CN201250159Y (en) | Complete equipment used for treating dyeing light pollution waste water for reuse | |

| CN212174734U (en) | Chemical synthesis type pharmaceutical wastewater treatment system for pollutants difficult to degrade | |

| CN110510824B (en) | A sewage treatment equipment and sewage treatment method based on coagulation enhanced membrane biological reaction tank |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |