CN210984466U - Cooling structure of non-encapsulated dry-type transformer - Google Patents

Cooling structure of non-encapsulated dry-type transformer Download PDFInfo

- Publication number

- CN210984466U CN210984466U CN201922339192.XU CN201922339192U CN210984466U CN 210984466 U CN210984466 U CN 210984466U CN 201922339192 U CN201922339192 U CN 201922339192U CN 210984466 U CN210984466 U CN 210984466U

- Authority

- CN

- China

- Prior art keywords

- cooling

- water

- insulating

- pipe

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Transformer Cooling (AREA)

Abstract

The utility model provides a non-cooling structure who encapsulates dry-type transformer, includes the transformer main part, be equipped with water cooling mechanism and air-cooled mechanism in the transformer main part, be equipped with on the footing in self vertically the bracing piece, the insulating cylinder is established on the bracing piece, be equipped with insulating fixed plate on the insulating cylinder, high-voltage coil winding is equipped with insulating fixed plate on the insulating cylinder, the bracing piece outside is equipped with the case of placing of built-in water cooling mechanism and air-cooled mechanism, cooling water tank with the water pump leads to pipe and connects, the water pump is connected the outlet pipe, the wet return with the cooling water tank top is connected, cooling water pipe passes through insulating fixed plate winding is in on the insulating cylinder, the cooling water pipe both ends respectively in the outlet pipe with the wet return is connected. The utility model discloses a high temperature resistant and insulating condenser tube absorbs inside heat, and the fan improves cooling efficiency in coordination simultaneously.

Description

Technical Field

The utility model relates to a transformer field especially relates to a dry-type transformer's cooling structure is sealed to non-.

Background

Dry-type transformers are widely used in local lighting, high-rise buildings, airports, wharf CNC machines and other places, and simply, dry-type transformers refer to transformers in which iron cores and windings are not immersed in insulating oil. The cooling method is classified into natural air cooling (AN) and forced air cooling (AF). During natural air cooling, the transformer can continuously operate for a long time under the rated capacity. When forced air cooling is carried out, the output capacity of the transformer can be improved by 50 percent. The device is suitable for intermittent overload operation or emergency accident overload operation; because the load loss and the impedance voltage amplification are large during overload and the device is in a non-economic operation state, the device is not required to be in continuous overload operation for a long time. The dry-type transformer is mainly divided into an open type, a closed type and a pouring type.

Non-encapsulated dry transformers, i.e. open dry transformers, typically employ a fan mounted at the bottom. After the cold air absorbs heat through the coil of the transformer, the heat is taken out of the transformer, and then the effects of heat dissipation, cooling and temperature reduction are achieved. But because the non-encapsulated state, the heat dissipation effect of the fan is low, and the transformer can not be cooled in certain environments.

SUMMERY OF THE UTILITY MODEL

The utility model aims at solving the defects of the prior art and providing a cooling structure of a non-encapsulated dry-type transformer.

A cooling structure of a non-encapsulated dry-type transformer is characterized by comprising a transformer main body, wherein a water cooling mechanism and an air cooling mechanism are arranged on the transformer main body, the transformer main body comprises a high-voltage coil, a footing, a supporting rod, an insulating cylinder and an insulating fixing plate, the supporting rod which is vertical to the footing is arranged on the footing, the insulating cylinder is arranged on the supporting rod, the insulating fixing plate is arranged on the insulating cylinder, the high-voltage coil is wound on the insulating cylinder provided with the insulating fixing plate, a placing box with a built-in water cooling mechanism and an air cooling mechanism is arranged on the outer side of the supporting rod, the water cooling mechanism comprises a cooling water tank, a water pump, a cooling water pipe, a water outlet pipe and a water return pipe, the cooling water tank is connected with the water pump through a water pipe, the water return pipe is connected with the top of the cooling water tank, and two ends of the cooling water pipe are respectively connected with the water outlet pipe and the water return pipe.

Preferably, air-cooling mechanism includes radiator fan, air inlet filter screen, air supply passageway, air outlet and dustproof filter screen, the air supply passageway with place the incasement side and connect, radiator fan establishes place the incasement, the air inlet filter screen is established place in the case outside tank wall, air supply passageway top is equipped with the air outlet, air outlet department is equipped with dustproof filter screen.

Preferably, the connection part of the water outlet pipe, the water return pipe and the cooling water pipe is arranged at the top of the placing box.

Preferably, a water level sensor is arranged in the cooling water tank.

Preferably, the cooling water pipe is folded and wound, equidistant grooves are formed in the inner sides of the insulating fixing plates, and the cooling water pipe penetrates through the grooves.

Preferably, the cooling water pipe is made of a material having high heat resistance and insulation properties.

The utility model has the advantages that:

the cooling water pipe is tightly attached to the insulating cylinder, so that heat generated by the internal low-voltage coil is effectively absorbed, the internal temperature of the insulating cylinder is reduced, and meanwhile, heat of the external high-voltage coil can be absorbed; the cooling fan supplies air from the inside of the insulating cylinder through the air outlet on the air supply channel, and cools down and dissipates heat in coordination with the cooling water pipe, and meanwhile, the air outlet is also arranged on two sides of the insulating cylinder, and the heat on the high-voltage coil is taken away by flowing air.

Drawings

The accompanying drawings are included to provide a further understanding of the invention, and are incorporated in and constitute a part of this specification, together with the description of embodiments of the invention, and are not intended to limit the invention. In the drawings:

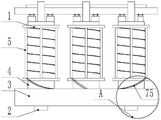

FIG. 1 is a schematic view of the overall structure of the present invention;

FIG. 2 is a schematic view of the external structure of the insulating cylinder;

FIG. 3 is a schematic bottom plan view of the transformer;

FIG. 4 is a schematic structural view of a ring A-water cooling mechanism;

labeled as: 1-high-voltage coil, 2-bottom foot, 3-support rod, 4-insulating cylinder, 5-insulating fixing plate, 6-air cooling mechanism, 7-water cooling mechanism, 8-placing box, 61-heat radiation fan, 62-air inlet filter screen, 63-air supply channel, 64-air outlet, 65-dustproof filter screen, 71-cooling water tank, 72-water pump, 73-water outlet pipe, 74-water return pipe, 75-cooling water pipe and 76-water level sensor.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments.

Referring to fig. 1 to 4, a cooling structure of a non-encapsulated dry type transformer includes a transformer body. Be equipped with water-cooling mechanism 7 and air cooling mechanism 6 in the transformer main part, the transformer main part includes high-voltage coil 1, footing 2, bracing piece 3, insulating cylinder 4 and insulating fixed plate 5. Be equipped with on footing 2 in self vertically bracing piece 3, insulating cylinder 4 is established on bracing piece 3, is equipped with insulating fixed plate 5 on the insulating cylinder 4, and high voltage coil 1 twines on insulating cylinder 4 that is equipped with insulating fixed plate 5, and the bracing piece 3 outside is equipped with built-in water cooling mechanism 7 and air cooling mechanism 6 place the case 8. The water cooling mechanism 7 comprises a cooling water tank 71, a water pump 72, a cooling water pipe 75, a water outlet pipe 73 and a water return pipe 74, the cooling water tank 71 is connected with the water pump 72 through a water pipe, the water pump 72 is connected with the water outlet pipe 73, the water return pipe 74 is connected with the top of the cooling water tank 71, the cooling water pipe 75 is wound on the insulating cylinder 4 through an insulating fixing plate 5, and two ends of the cooling water pipe 75 are respectively connected with the water outlet pipe 73 and the water return pipe 74. A water level sensor 76 is provided in the cooling water tank 71.

Air-cooled mechanism 6 includes radiator fan 61, air inlet filter screen 62, air supply channel 63, air outlet 64 and dustproof filter screen 65, and air supply channel 63 with place the 8 inboard connections of case, radiator fan 61 is established and is being placed the incasement 8, and air inlet filter screen 62 is established and is being placed 8 outside tank walls in, and air supply channel 63 top is equipped with air outlet 64, and air outlet 64 department is equipped with dustproof filter screen 65.

After the installation of the equipment is completed, the water pump 72 sends the coolant in the coolant tank 71 to the coolant pipe 73. When the cooling liquid passes through the cooling water pipe 73, the insulating cylinder 4 is in contact with the cooling water pipe 73, and the cooling liquid sucks heat from the insulating cylinder 4. The heat dissipation fan 61 is turned on by power supply, and absorbs air from the outside through the air intake filter 62, and the heat dissipation air is blown out from the air outlet 64 through the air supply passage 63. The blown wind brings air flow from inside and around the insulating tube 4, so that the temperature of the transformer and the surroundings is lowered.

Although the present invention has been described in detail with reference to the foregoing embodiments, it will be apparent to those skilled in the art that modifications may be made to the embodiments described in the foregoing embodiments, or equivalents may be substituted for elements thereof. Any modification, equivalent replacement, or improvement made within the spirit and principle of the present invention should be included in the protection scope of the present invention.

Claims (6)

1. A cooling structure of a non-encapsulated dry-type transformer is characterized by comprising a transformer main body, wherein a water cooling mechanism and an air cooling mechanism are arranged on the transformer main body, the transformer main body comprises a high-voltage coil, a footing, a supporting rod, an insulating cylinder and an insulating fixing plate, the supporting rod which is vertical to the footing is arranged on the footing, the insulating cylinder is arranged on the supporting rod, the insulating fixing plate is arranged on the insulating cylinder, the high-voltage coil is wound on the insulating cylinder provided with the insulating fixing plate, a placing box with a built-in water cooling mechanism and an air cooling mechanism is arranged on the outer side of the supporting rod, the water cooling mechanism comprises a cooling water tank, a water pump, a cooling water pipe, a water outlet pipe and a water return pipe, the cooling water tank is connected with the water pump through a water pipe, the, the cooling water pipe is wound on the insulating cylinder through the insulating fixing plate, and two ends of the cooling water pipe are respectively connected with the water outlet pipe and the water return pipe.

2. The cooling structure of a non-encapsulated dry-type transformer as claimed in claim 1, wherein the air cooling mechanism comprises a heat dissipating fan, an air inlet screen, an air supply channel, an air outlet and a dust screen, the air supply channel is connected to the inner side of the housing, the heat dissipating fan is disposed in the housing, the air inlet screen is disposed in the outer wall of the housing, the air outlet is disposed at the top of the air supply channel, and the dust screen is disposed at the air outlet.

3. The cooling structure of a non-encapsulated dry-type transformer as claimed in claim 1, wherein the connection of said outlet pipe and said return pipe to said cooling water pipe is provided at the top of said placing tank.

4. The cooling structure of a non-encapsulated dry-type transformer as claimed in claim 1, wherein a water level sensor is provided in said cooling water tank.

5. The cooling structure of a non-encapsulated dry-type transformer as set forth in claim 1, wherein said cooling water pipes are folded and wound, and grooves are formed at equal intervals inside said insulation fixing plate, said cooling water pipes passing through said grooves.

6. The cooling structure of a non-encapsulated dry-type transformer as claimed in claim 1, wherein the cooling water pipe is made of an insulating and heat-resistant material.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922339192.XU CN210984466U (en) | 2019-12-23 | 2019-12-23 | Cooling structure of non-encapsulated dry-type transformer |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922339192.XU CN210984466U (en) | 2019-12-23 | 2019-12-23 | Cooling structure of non-encapsulated dry-type transformer |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210984466U true CN210984466U (en) | 2020-07-10 |

Family

ID=71439027

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201922339192.XU Active CN210984466U (en) | 2019-12-23 | 2019-12-23 | Cooling structure of non-encapsulated dry-type transformer |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210984466U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112071674A (en) * | 2020-09-14 | 2020-12-11 | 国网河南省电力公司温县供电公司 | Multi-level voltage change-over switch device |

-

2019

- 2019-12-23 CN CN201922339192.XU patent/CN210984466U/en active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112071674A (en) * | 2020-09-14 | 2020-12-11 | 国网河南省电力公司温县供电公司 | Multi-level voltage change-over switch device |

| CN112071674B (en) * | 2020-09-14 | 2022-07-26 | 国网河南省电力公司温县供电公司 | Multi-stage voltage conversion switch device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111627654B (en) | Transformer box structure with circulation cooling function | |

| CN209103897U (en) | A kind of high-efficient heat-dissipating transformer applied to thermal power plant | |

| CN112509786B (en) | Explosion-proof and sun-proof transformer convenient to dissipate heat | |

| CN107658101A (en) | A kind of height warm area differentiation power transformer cooling device | |

| CN219677015U (en) | Efficient heat dissipation oil immersed transformer | |

| CN210984466U (en) | Cooling structure of non-encapsulated dry-type transformer | |

| CN111029103A (en) | Transformer with circulating liquid cooling function | |

| CN212990869U (en) | Fireproof and explosion-proof dry-type transformer structure | |

| CN211208183U (en) | Cooling device for dry-type transformer | |

| CN219457302U (en) | Dry-type transformer with multiple cooling circulation structure | |

| CN117316583A (en) | Oil immersed transformer with explosion-proof protection architecture | |

| CN213277721U (en) | High heat dissipation type epoxy dry-type transformer | |

| CN215496309U (en) | Oil-immersed transformer convenient to cool | |

| CN212782987U (en) | High-efficient heat dissipation type dry-type transformer core assembly | |

| CN213752222U (en) | Explosion-proof anti-solarization transformer convenient to dissipate heat | |

| CN213211919U (en) | Epoxy dry-type transformer convenient to equipment | |

| CN210349523U (en) | Water-cooled heat radiation structure of transformer | |

| CN209461249U (en) | A kind of power distribution network transformer cooling device | |

| CN208806113U (en) | A kind of new dry-type transformer | |

| CN219936812U (en) | Dry-type transformer with cooling circulation structure | |

| CN210805445U (en) | Dry-type voltage transformer | |

| CN220491704U (en) | Dry-type transformer heat sink | |

| CN216698043U (en) | Distribution transformer that cooling effect is good | |

| CN212411792U (en) | Novel three-phase transformer | |

| CN212342416U (en) | Dry-type transformer capable of realizing heat dissipation and cooling of coil |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |