CN210863955U - PCBA testing arrangement who facilitates use - Google Patents

PCBA testing arrangement who facilitates use Download PDFInfo

- Publication number

- CN210863955U CN210863955U CN201921469634.6U CN201921469634U CN210863955U CN 210863955 U CN210863955 U CN 210863955U CN 201921469634 U CN201921469634 U CN 201921469634U CN 210863955 U CN210863955 U CN 210863955U

- Authority

- CN

- China

- Prior art keywords

- pcba

- mounting plate

- testing

- plate

- box

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Testing Electric Properties And Detecting Electric Faults (AREA)

Abstract

The utility model discloses a PCBA testing device convenient to use, which comprises a testing box, wherein a first mounting plate is vertically fixed at one end of the top of the testing box, an air valve is arranged at the outer side of the first mounting plate, a second mounting plate is vertically arranged at the other end of the top of the testing box, a carrying plate is horizontally arranged between the top end of the second mounting plate and the top end of the first mounting plate, a cylinder corresponding to the air valve is arranged in the middle of the carrying plate, and the bottom end of the cylinder is fixedly connected with a pressing plate through a positioning head, the utility model discloses a PCBA testing device convenient to use, the pressing plate is driven to move up and down through the cylinder, time and labor are saved, different PCBA plates can be detected by replacing second adjusting blocks with different groove specifications, the PCBA plates are placed in a clamping groove, the longitudinal position can be adjusted by using the cooperation of the first adjusting block and the first U-shaped chute, and the transverse position can be adjusted by, make things convenient for testing arrangement to detect the PCBA board of different model specifications.

Description

Technical Field

The utility model relates to a testing arrangement, in particular to PCBA testing arrangement who facilitates use belongs to electronic circuit board check out test set technical field.

Background

The PCBA is the assembly of the printed circuit board, namely the empty board of the PCB is processed by SMT surface mounting technology and then processed by the whole process of DIP dual in-line package technology plug-in, namely the PCB which is welded and assembled with electronic components. In order to ensure the quality of the PCBA board, the PCBA board is generally tested using a PCBA testing device.

Current PCBA test equipment needs the staff to push down the PCBA board through rotatory handle then drive the clamp plate, and this kind of utilize mechanical type to move a frock of handle completely, and not only the availability factor is low, and the long time of use also can cause the frock fit-up gap not hard up moreover, influences the precision to PCBA board type number specification is different, makes the adjustment of PCBA board position inconvenient. Therefore, the PCBA testing device convenient to use is provided by improving the PCBA testing device.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide a PCBA testing arrangement who facilitates use to solve traditional PCBA test equipment that proposes in the above-mentioned background art and need the staff to push down the PCBA board through rotatory handle then drive the clamp plate, this kind of utilize mechanical type completely moves a frock of handle, not only the availability factor is low, and the live time is long also can cause the frock fit-up gap not hard up moreover, influence the precision, and PCBA board type number specification is not simultaneous, make PCBA board position adjustment inconvenient problem.

In order to achieve the above object, the utility model provides a following technical scheme: a PCBA testing device convenient to use comprises a testing box, wherein a first mounting plate is vertically fixed at one end of the top of the testing box, an air valve is arranged on the outer side of the first mounting plate, a second mounting plate is vertically arranged at the other end of the top of the testing box, a carrying plate is horizontally arranged between the top end of the second mounting plate and the top end of the first mounting plate, an air cylinder corresponding to the air valve is arranged in the middle of the carrying plate, the bottom end of the air cylinder is fixedly connected with a pressing plate through a positioning head, an universal meter is fixedly connected with the top of the outer side of the second mounting plate, a display electrically connected with the testing box is fixed at the bottom of the outer side of the second mounting plate, a first U-shaped chute is longitudinally arranged in the middle of the top of the testing box, a first adjusting block is slidably connected in the first U-shaped chute, a second U-shaped chute is transversely, the bottom of the second adjusting block is fixedly connected with a rectangular sliding block corresponding to the second U-shaped sliding groove, and a clamping groove is formed in the middle of the top of the second adjusting block.

As a preferred technical scheme of the utility model, the symmetry is provided with the guide arm with clamp plate both ends swing joint between year thing board bottom both ends and the test box.

As an optimal technical scheme of the utility model, rectangle slider and second regulating block are the integrated into one piece structure.

As an optimized technical scheme of the utility model, set up jaggedly in the middle of the draw-in groove one end.

As an optimal technical scheme of the utility model, electric connection between universal meter and the test box.

As an optimal technical scheme of the utility model, touch button is installed to test box one side.

Compared with the prior art, the beneficial effects of the utility model are that: the utility model relates to a PCBA testing arrangement who facilitates use has and utilizes the cylinder to drive the clamp plate, and work efficiency is high, can not cause the frock fit-up gap not hard up to PCBA board model specification is different, and the convenient advantage of its position control, in specific use, compare with traditional PCBA testing arrangement, the utility model discloses a cylinder drives the clamp plate and reciprocates, labour saving and time saving, the second regulating block of changing different draw-in groove specifications alright carry out the detection of different PCBA boards, the PCBA board is placed in the draw-in groove, the cooperation of utilizing first regulating block and first U type spout can carry out the regulation of longitudinal position, utilizes the cooperation of second regulating block and second U type spout can carry out the regulation of lateral position, makes things convenient for testing arrangement to detect the PCBA board of different model specifications, easy operation, excellent in use effect.

Drawings

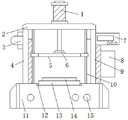

FIG. 1 is a schematic view of the overall structure of the present invention;

fig. 2 is a schematic structural diagram of a first adjusting block of the present invention;

fig. 3 is a schematic structural view of a second adjusting block of the present invention;

in the figure: 1. a cylinder; 2. a loading plate; 3. an air valve; 4. a first mounting plate; 5. pressing a plate; 6. positioning the head; 7. a universal meter; 8. a display; 9. a second mounting plate; 10. a guide bar; 11. a test box; 12. a first U-shaped chute; 13. a first regulating block; 14. a second regulating block; 15. a touch button; 16. a second U-shaped chute; 17. a card slot; 18. a rectangular slider; 19. and (4) a notch.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

Referring to fig. 1-3, the utility model provides a PCBA testing device convenient to use, which comprises a testing box 11, a first mounting plate 4 is vertically fixed at one end of the top of the testing box 11, an air valve 3 is arranged at the outer side of the first mounting plate 4, a second mounting plate 9 is vertically arranged at the other end of the top of the testing box 11, a carrying plate 2 is horizontally arranged between the top end of the second mounting plate 9 and the top end of the first mounting plate 4, an air cylinder 1 corresponding to the air valve 3 is arranged in the middle of the carrying plate 2, the bottom end of the air cylinder 1 is fixedly connected with a pressing plate 5 through a positioning head 6, a universal meter 7 is fixedly connected at the top of the outer side of the second mounting plate 9, a display 8 electrically connected with the testing box 11 is fixed at the bottom of the outer side of the second mounting plate 9, a first U-shaped chute 12 is longitudinally arranged at the middle of the top of the testing, the top of the first adjusting block 13 is transversely provided with a second U-shaped sliding groove 16, the top of the second U-shaped sliding groove 16 is connected with a second adjusting block 14, the bottom of the second adjusting block 14 is fixedly connected with a rectangular sliding block 18 corresponding to the second U-shaped sliding groove 16, and the middle of the top of the second adjusting block 14 is provided with a clamping groove 17.

Preferably, guide rods 10 movably connected with two ends of the pressing plate 5 are symmetrically arranged between two ends of the bottom of the object carrying plate 2 and the test box 11, so that the pressing plate 5 can stably move.

Preferably, the rectangular sliding block 18 and the second adjusting block 14 are of an integrally formed structure, so that the second adjusting block 14 can drive the PCBA board to adjust the transverse position.

Preferably, a notch 19 is formed in the middle of one end of the clamping groove 17, so that the PCBA after detection can be conveniently taken out from the inside of the clamping groove 17.

Preferably, the multimeter 7 is electrically connected with the test box 11, so that the equipment is simple and easy to assemble.

Preferably, a touch button 15 is installed on one side of the test box 11, so that the operation is convenient.

When specifically using, the utility model relates to a PCBA testing arrangement who facilitates use, it drives clamp plate 5 to have the utilization cylinder 1, high work efficiency, can not cause the frock fit-up gap not hard up, and PCBA board model specification is not different, the convenient advantage of its position adjustment, it reciprocates to drive clamp plate 5 through cylinder 1, time saving and labor saving, change the second regulating block 14 of different draw-in groove 17 specifications alright in order to carry out the detection of different PCBA boards, the PCBA board is placed in draw-in groove 17, utilize the cooperation of first regulating block 13 and first U type spout 12 can carry out the regulation of longitudinal position, utilize the cooperation of second regulating block 14 and second U type spout 16 to carry out the regulation of transverse position, make things convenient for testing arrangement to detect the PCBA board of different model specifications, just take out the PCBA board from breach 19 prescriptions, and simple to operate, good use effect, be worth extensively promoting.

In the description of the present invention, it should be understood that the indicated orientation or positional relationship is based on the orientation or positional relationship shown in the drawings, and is only for convenience of description and simplification of description, and does not indicate or imply that the indicated device or element must have a particular orientation, be constructed and operated in a particular orientation, and thus should not be construed as limiting the present invention.

In the present invention, unless otherwise explicitly specified or limited, for example, it may be fixedly connected, detachably connected, or integrated; can be mechanically or electrically connected; they may be directly connected or indirectly connected through an intermediate medium, and may be connected through the inside of two elements or in an interaction relationship between two elements, unless otherwise specifically defined, and the specific meaning of the above terms in the present invention will be understood by those skilled in the art according to specific situations.

Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, the scope of which is defined in the appended claims and their equivalents.

Claims (6)

1. The PCBA testing device convenient to use comprises a testing box (11) and is characterized in that a first mounting plate (4) is vertically fixed at one end of the top of the testing box (11), an air valve (3) is arranged on the outer side of the first mounting plate (4), a second mounting plate (9) is vertically arranged at the other end of the top of the testing box (11), a carrying plate (2) is horizontally arranged between the top end of the second mounting plate (9) and the top end of the first mounting plate (4), an air cylinder (1) corresponding to the air valve (3) is installed in the middle of the carrying plate (2), a pressing plate (5) is fixedly connected to the bottom end of the air cylinder (1) through a positioning head (6), a universal meter (7) is fixedly connected to the top of the outer side of the second mounting plate (9), and a display (8) electrically connected with the testing box (11) is fixed to the bottom, vertically seted up first U type spout (12) in the middle of test box (11) top, sliding connection has first regulating block (13) in first U type spout (12), second U type spout (16) have transversely been seted up at first regulating block (13) top, second U type spout (16) top links to each other with second regulating block (14), rectangle slider (18) that second regulating block (14) bottom fixedly connected with corresponds with second U type spout (16), draw-in groove (17) have been seted up in the middle of second regulating block (14) top.

2. A PCBA testing device for convenient use according to claim 1, wherein: guide rods (10) movably connected with the two ends of the pressing plate (5) are symmetrically arranged between the two ends of the bottom of the object carrying plate (2) and the test box (11).

3. A PCBA testing device for convenient use according to claim 1, wherein: the rectangular sliding block (18) and the second adjusting block (14) are of an integrally formed structure.

4. A PCBA testing device for convenient use according to claim 1, wherein: a notch (19) is formed in the middle of one end of the clamping groove (17).

5. A PCBA testing device for convenient use according to claim 1, wherein: and the multimeter (7) is electrically connected with the test box (11).

6. A PCBA testing device for convenient use according to claim 1, wherein: and a touch button (15) is arranged on one side of the test box (11).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921469634.6U CN210863955U (en) | 2019-09-05 | 2019-09-05 | PCBA testing arrangement who facilitates use |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921469634.6U CN210863955U (en) | 2019-09-05 | 2019-09-05 | PCBA testing arrangement who facilitates use |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210863955U true CN210863955U (en) | 2020-06-26 |

Family

ID=71301862

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921469634.6U Active CN210863955U (en) | 2019-09-05 | 2019-09-05 | PCBA testing arrangement who facilitates use |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210863955U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112577874A (en) * | 2020-11-11 | 2021-03-30 | 中汽研汽车检验中心(天津)有限公司 | General air conditioner filter test panel device |

| CN114083722A (en) * | 2021-11-19 | 2022-02-25 | 广州众山精密科技有限公司 | Quick die change debugging mechanism |

-

2019

- 2019-09-05 CN CN201921469634.6U patent/CN210863955U/en active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112577874A (en) * | 2020-11-11 | 2021-03-30 | 中汽研汽车检验中心(天津)有限公司 | General air conditioner filter test panel device |

| CN114083722A (en) * | 2021-11-19 | 2022-02-25 | 广州众山精密科技有限公司 | Quick die change debugging mechanism |

| CN114083722B (en) * | 2021-11-19 | 2023-11-03 | 广州众山精密科技有限公司 | Quick die change debugging mechanism |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN210863955U (en) | PCBA testing arrangement who facilitates use | |

| CN105044401A (en) | Test seat of passive microwave radio frequency transformer | |

| CN103673857A (en) | Novel testing device for testing projection height of workpiece | |

| CN103412212A (en) | PCB performance detection jig with positioning function | |

| CN206450762U (en) | Inductance measurement device and inductance coil automatic tin soldering, testing integrated machine | |

| CN109225929B (en) | Inductor performance automatic tester | |

| CN208140845U (en) | A kind of continuity test mechanism of harness | |

| CN211878159U (en) | Tray compatible with metering terminal and electric energy meter | |

| CN203759196U (en) | ICT test fixture with probe use number recording | |

| CN209592173U (en) | Battery core pretreatment unit | |

| CN203396909U (en) | PCB performance detection jig having locating stroke limiting function | |

| CN218767208U (en) | PCBA board test fixture | |

| CN103412173A (en) | Mobile phone PCB voltage testing jig | |

| CN203687862U (en) | Novel detection device used for detecting protrusion height of work piece | |

| CN210863956U (en) | PCBA testing arrangement | |

| CN204925171U (en) | Passive microwave radio frequency transformer's test seat | |

| CN210360028U (en) | Clamping tool for production and processing of switching power supply | |

| CN208954822U (en) | Capacitor aging mechanism | |

| CN103412252A (en) | PCB performance detection jig with positioning and stroke-limiting functions | |

| CN211318661U (en) | PCBA test system convenient to fix | |

| CN203405525U (en) | Automatic test system for PCB plates | |

| CN221100959U (en) | PCBA board multifunctional efficient test fixture | |

| CN208231104U (en) | A kind of printed circuit board laser drill panel turnover device | |

| CN207840513U (en) | A kind of sensor soft board apparatus for welding and positioning | |

| CN209201398U (en) | A kind of efficient anti-bias alignment device of pcb board |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |